MEMS thermal type wind speed sensor having on-chip self calibration function

A wind speed sensor, self-calibration technology, applied in the direction of instrumentation, speed/acceleration/shock measurement, speed/acceleration/shock measurement equipment testing/calibration, etc., can solve the problem of increasing the test cost of MEMS thermal wind speed sensor and limiting MEMS thermal wind speed sensor Problems such as application range and long duration can achieve the effect of reducing the cost of batch testing without affecting the measurement accuracy and short duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

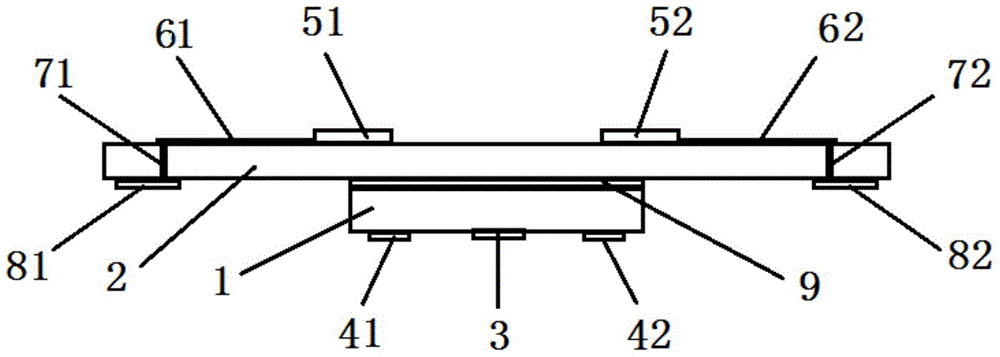

[0013] Such as figure 1 Shown is a MEMS thermal wind velocity sensor with an on-chip self-calibration function, including a sensor chip substrate 1 and a packaging material 2. The sensor chip substrate 1 is attached to the center of the lower surface of the packaging material 2 through a thermally conductive adhesive layer 9. A temperature generating element 3 is arranged at the center of the lower surface of the sensor chip substrate 1, and a first temperature measuring sensor 41 and a second temperature measuring sensor 42 are also arranged on the lower surface of the sensor chip substrate 1. The first temperature measuring sensor 41 and the second temperature measuring sensor The second temperature measuring sensor 42 is symmetrically distributed with respect to the temperature generating element 3; the upper surface of the packaging material 2 is provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com