A closed-loop control test method for converter subunits under full operating conditions

A technology of closed-loop control and test method, which is applied in the field of power electronics and can solve problems such as waste of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

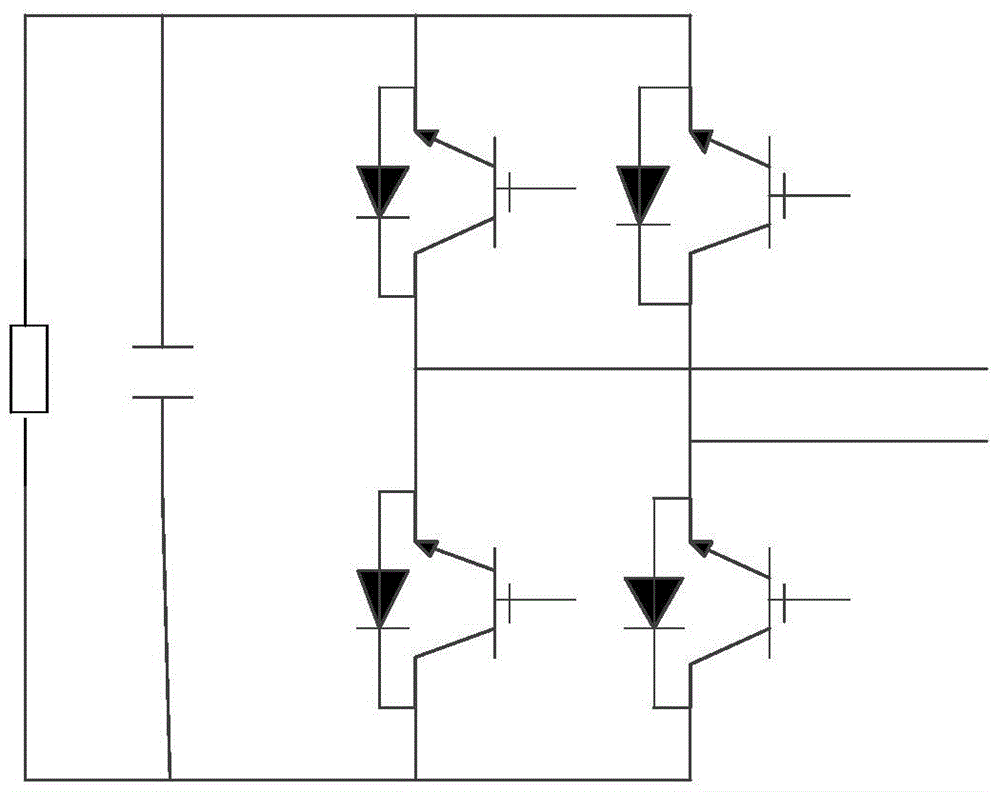

[0046] The chain-link converter is formed by cascading several identical converter subunits. Among them, the cascaded subunits adopt no differentiation configuration, and each converter subunit adopts H-bridge topology, followed by DC capacitors and Voltage grading resistors, the main wiring diagram of which is given by figure 1 shown. Each unit is equipped with an intelligent unit controller, whose functions include subunit data sampling, logic control and subunit level protection. In the chain topology, the working voltage of the power electronic devices in the converter subunit is effectively clamped at the voltage of the DC capacitor, which avoids the problem of series connection of power electronic devices. The voltage level greatly simplifies the high voltage converter design.

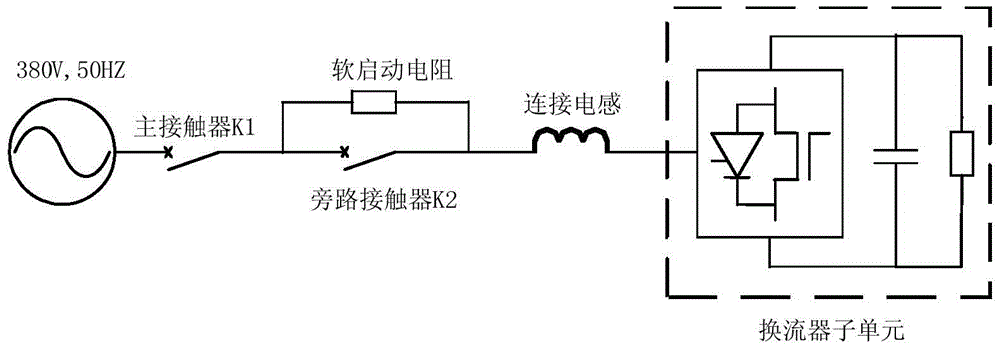

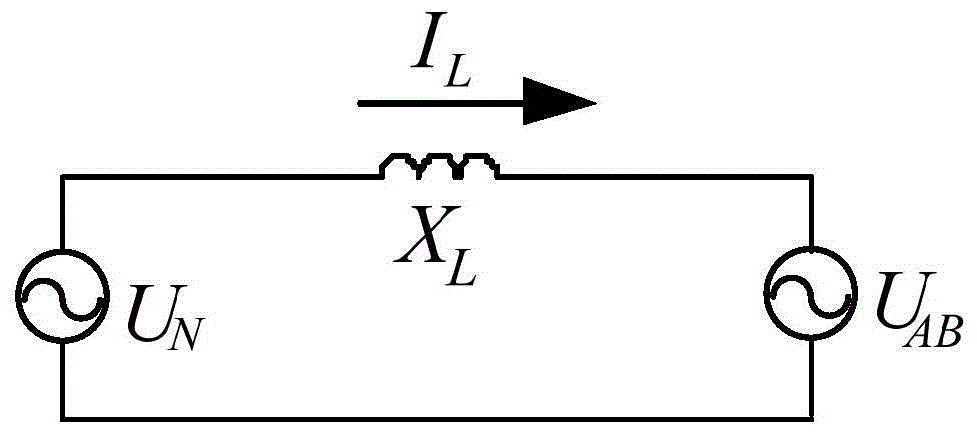

[0047] The present invention provides a closed-loop control test method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com