Switch cabinet static contact assembly quality detection device and detection method

A detection device and static contact technology, applied in switching devices, measuring devices, optical devices, etc., can solve the problems of increasing the cost of batch testing, affecting the next use, and low reusability, and reducing batch testing. Cost, convenient detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

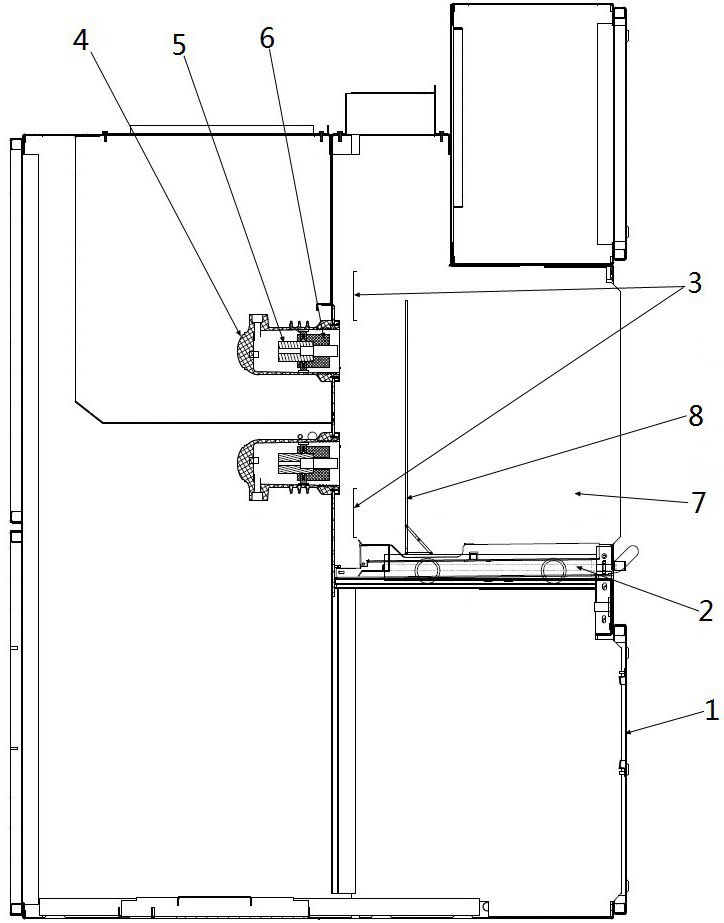

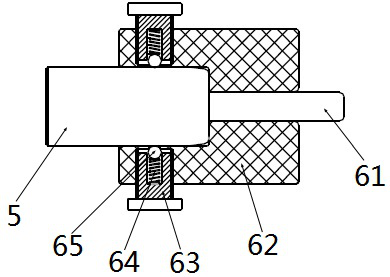

[0033] An embodiment of the assembly quality detection device for the static contact of the switchgear in the present invention is as follows: figure 1 As shown, the assembly quality detection device of the static contact of the switch cabinet (hereinafter referred to as the detection device) includes a chassis car 2 that is pushed into the circuit breaker chamber 7 in the switch cabinet 1 during use, and the contact box 4 is installed in the switch cabinet 1. A static contact 5 is installed in the box 4 , and the detection device also includes a visible light emitter 6 installed on the static contact 5 .

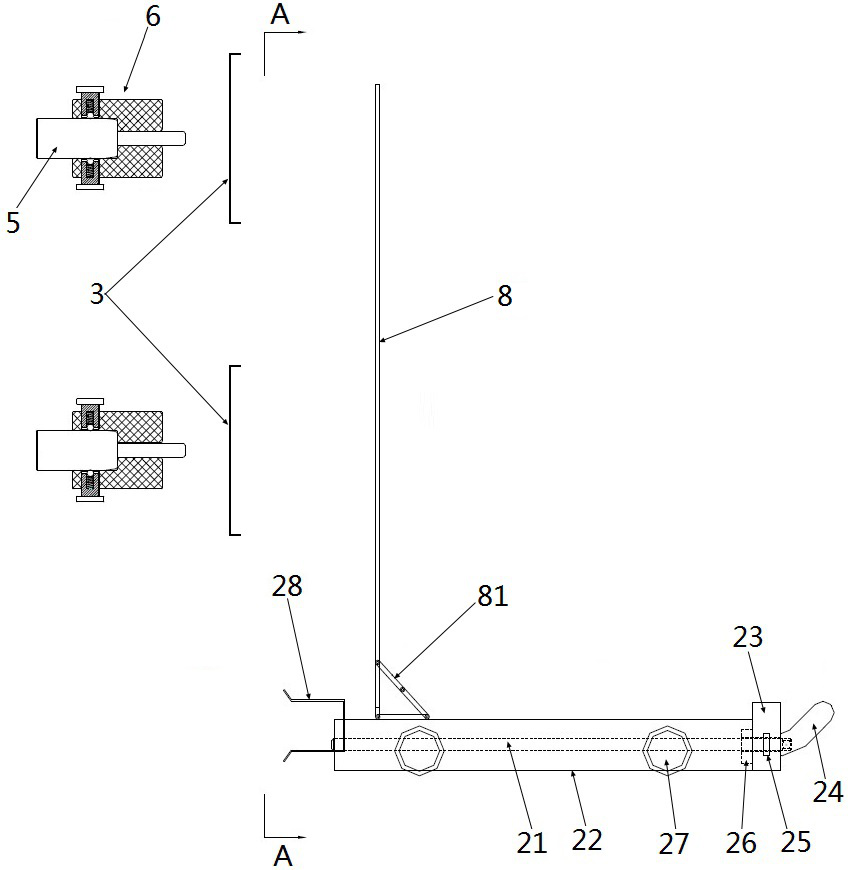

[0034] The chassis car 2 is used to simulate the chassis car of the circuit breaker handcart. The chassis car of the circuit breaker handcart belongs to the prior art. A simplified chassis car is provided in this embodiment, such as figure 2 As shown, the chassis vehicle 2 includes a base plate 22, four rollers 27 are installed on the base plate 22, and there are downward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com