Perforating bullet height automatic measuring device

A technology of automatic measurement and perforating bullets, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of high cost of measurement, high cost, unsuitable for the industry, etc., and achieve good measurement stability and high accuracy , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described by a specific embodiment:

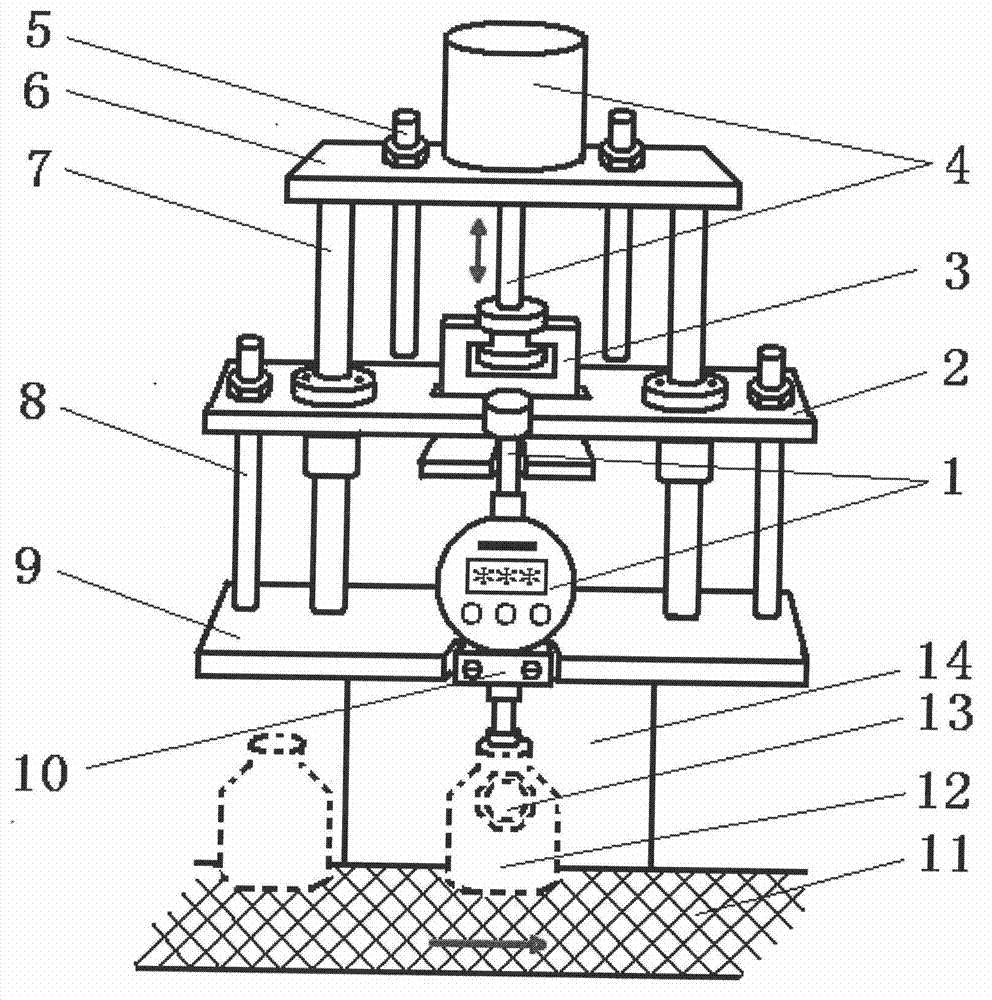

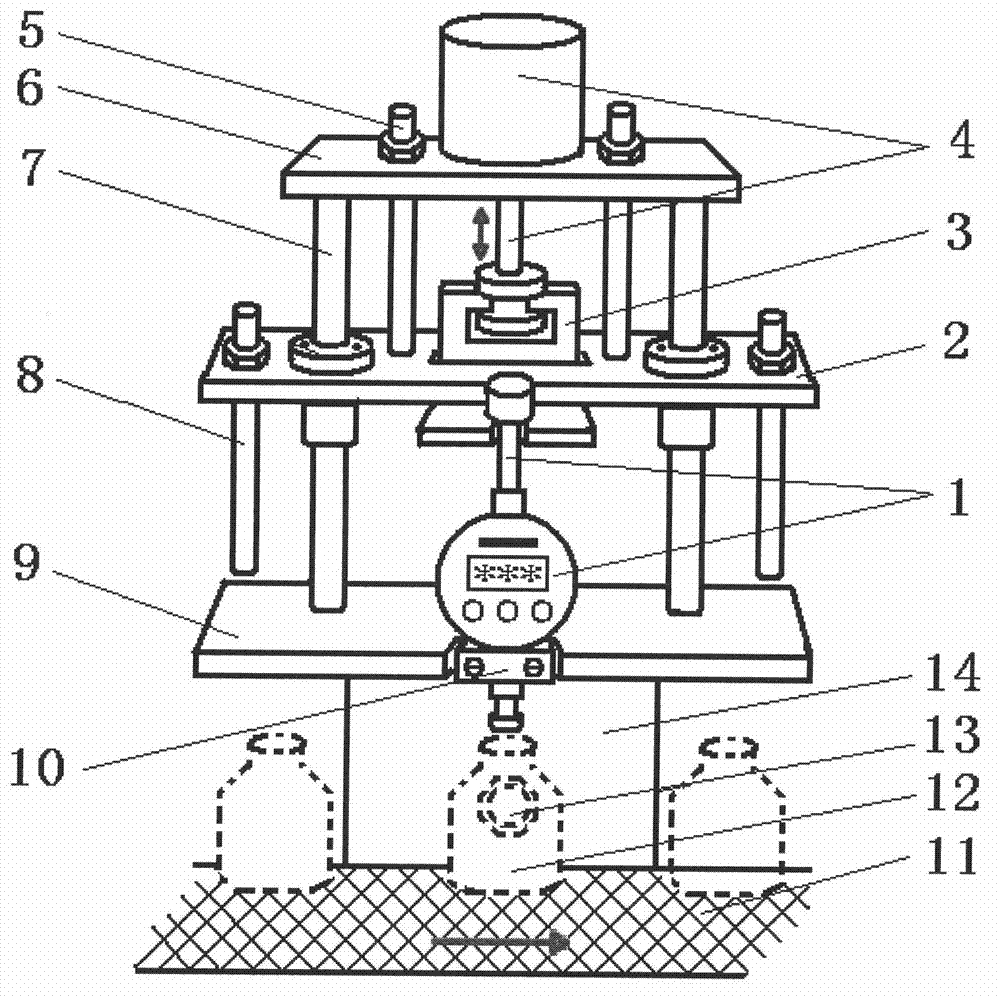

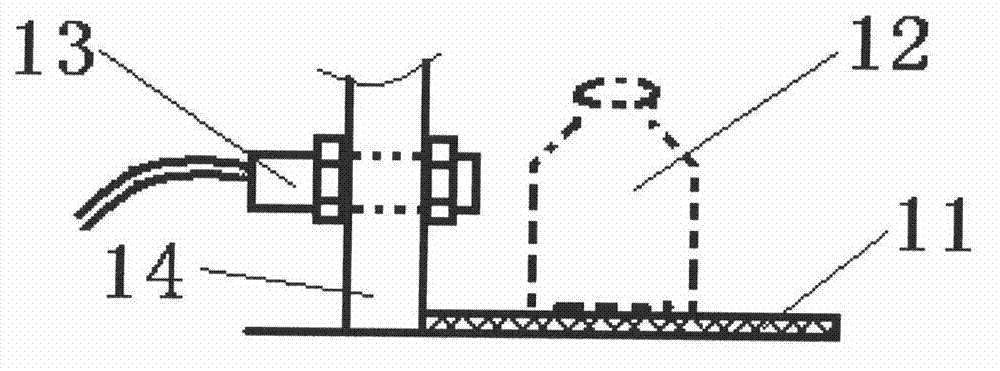

[0016] like figure 1 , figure 2 and image 3 As shown, an automatic measuring device for the height of perforating charges includes: a conveyor belt 11 for transporting perforating charges 12, a digital dial indicator 1, and a connecting frame 3. The connecting frame 3 adopts an L-shaped design, and the concave hole at the lower end The width of the slot is larger than the diameter of the measuring rod of digital dial gauge 1, and smaller than the diameter of the measuring cap of digital dial gauge 1, and pushes and pulls along the vertical direction (moving direction such as figure 1 Shown in the two-way arrow in) cylinder 4 and support, it is characterized in that:

[0017] Described support is made up of the bracket upper plate 6 of support positioning cylinder 4, the support lower plate 9 of support positioning digital dial indicator 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com