Polygonal special-shaped eccentric grinding device and method

An eccentric grinding and special-shaped technology, which is applied in the field of grinding processing, can solve the problems of low grinding efficiency, and achieve the effects of stable operation, reduced friction, and convenient and efficient grinding work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present invention provides polygonal special-shaped eccentric grinding device and method thereof through improvement, and the technical scheme of the present invention is:

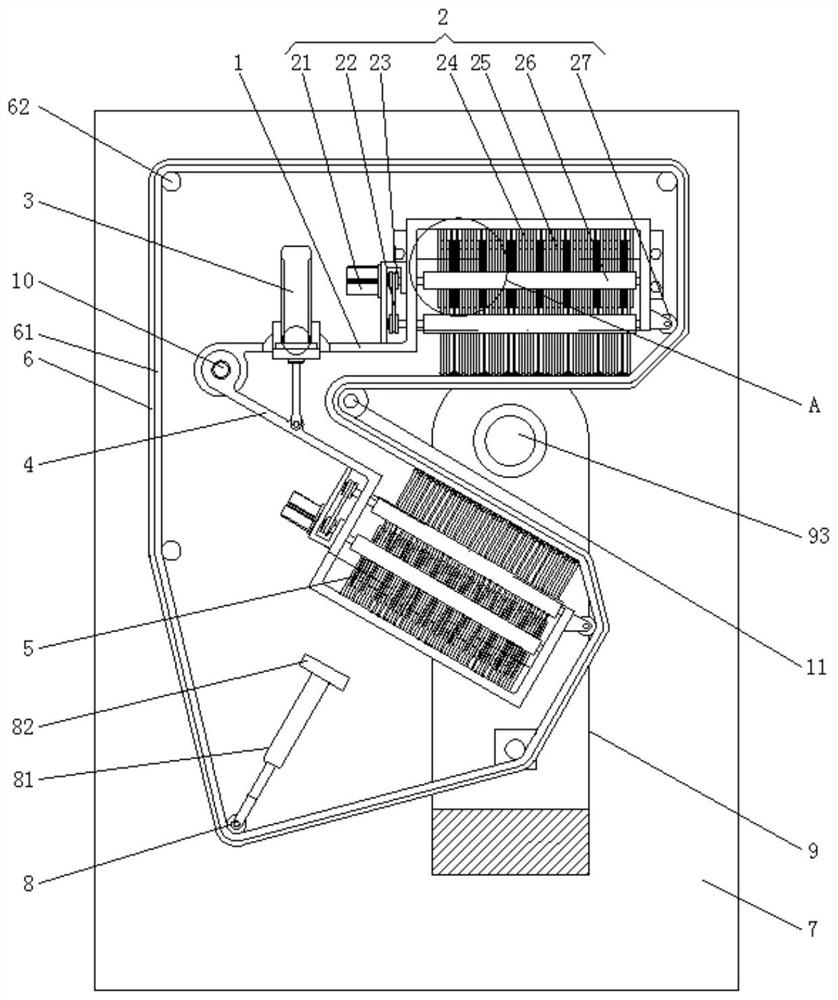

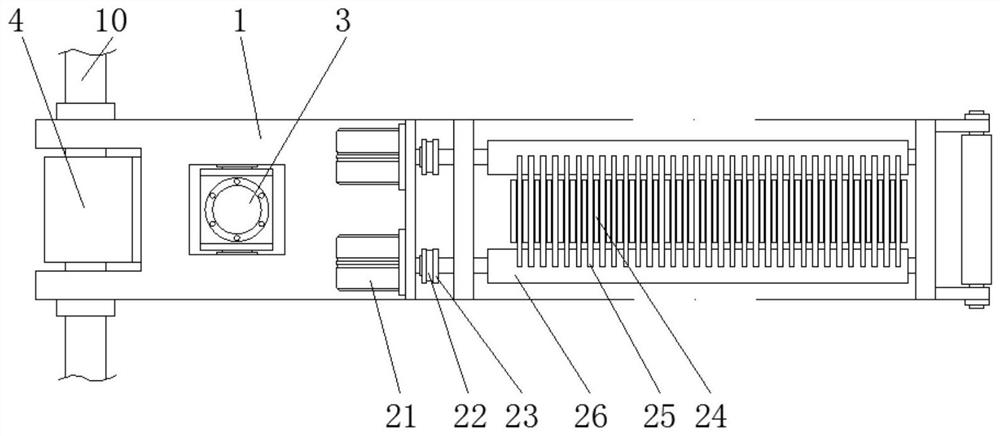

[0047] Such as Figure 1-Figure 8 As shown, the polygonal special-shaped eccentric grinding device includes a grinding belt 6, and one side of the grinding belt 6 is supported by the first pushing mechanism 2, the outer wall support roller 11 and the second pushing mechanism 5 to form a "V"-shaped structure. , and the first pushing mechanism 2 and the second pushing mechanism 5 are arranged on the fixed clamp frame 1 and the movable clamp frame 4 respectively, and one end of the fixed clamp frame 1 and the movable clamp frame 4 is hinged, and the fixed clamp frame 1 The first telescopic cylinder 3 is connected with the movable clamp frame 4, and the first telescopic cylinder 3 is a hydraulic cylinder;

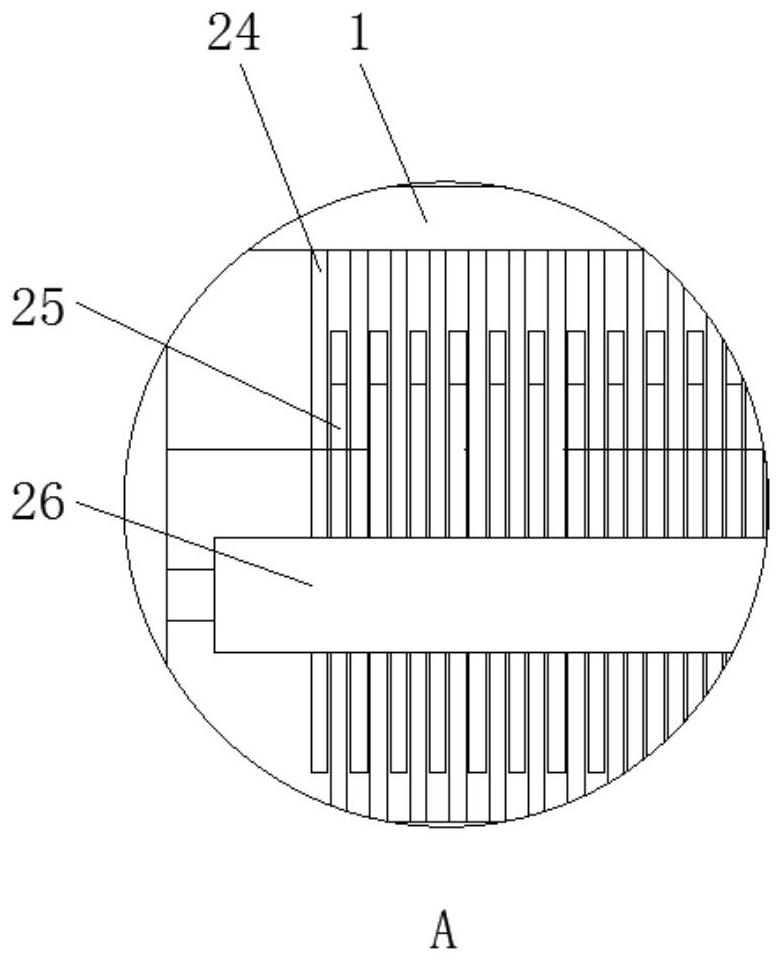

[0048]The first pushing mechanism 2 comprises several pushing strips 25 distributed equidist...

Embodiment 2

[0064] The invention also discloses a polygonal special-shaped eccentric grinding method, including the following steps:

[0065] S1: Place the workpiece between the three-jaw chuck 92 and the indenter 93, operate the three-jaw chuck 92 to clamp and position one end of the workpiece, and the second telescopic cylinder 94 stretches and pushes the lower indenter 93 to push the other end of the workpiece Keep the workpiece in the positioned state, so that the workpiece is clamped and positioned to the "V" shape structure on one side of the grinding belt 6;

[0066] S2: Control the contraction of the first telescopic cylinder 3, the first telescopic cylinder 3 pulls the movable clamp frame 4 upward with the support of the fixed clamp frame 1, because the fixed clamp frame 1 and the movable clamp frame 4 are hinged for rotation, so that the fixed clamp frame 1 and the movable clamp frame 4 are hinged. The movable clamping frame 4 can be rotated close, so that the first pushing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com