Flexible printed circuit board for welding imaging sensor

A flexible circuit board and image sensor technology, which is applied in the directions of printed circuits, printed circuits, and printed circuits where non-printed electrical components are connected, and can solve problems such as large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

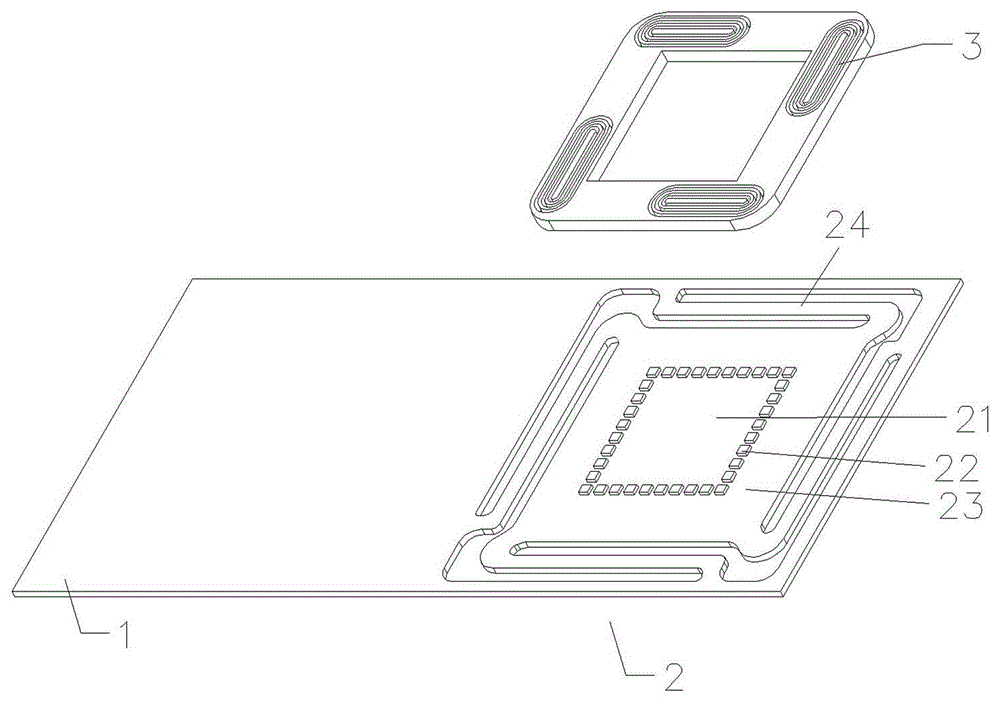

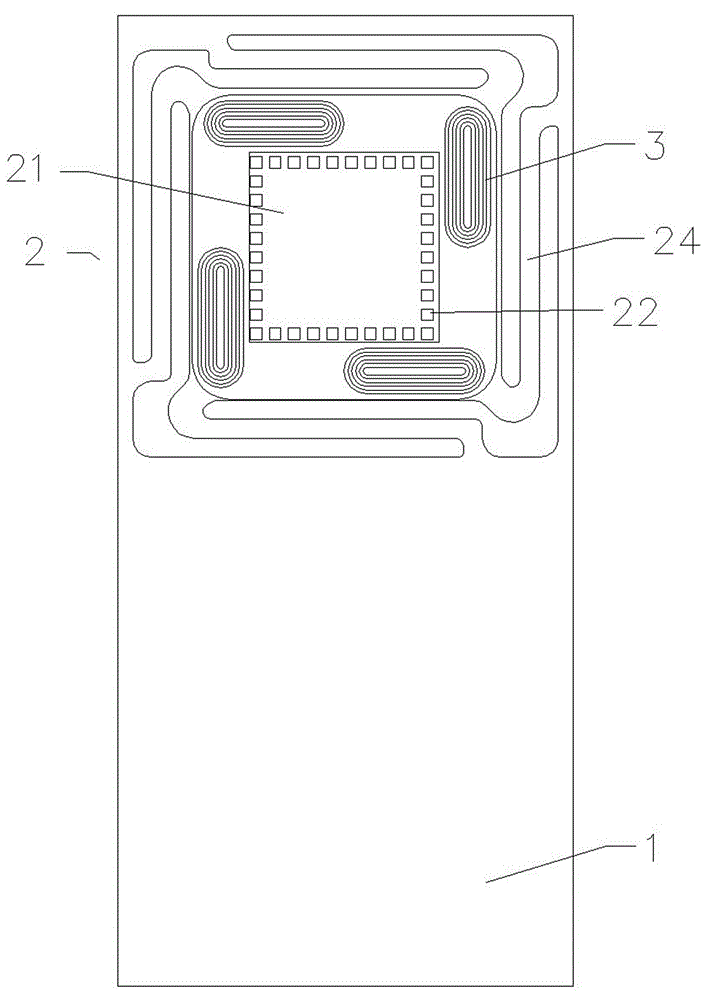

[0012] The structural principle of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0013] figure 1 , figure 2 The flexible circuit board for welding image sensor of the present invention is given, it is divided into two areas, one is figure 1 The first area 1 is located below, and the other is the second area 2 located above. The first area 1 is used to conduct the coil 3 in the second area 2 and communicate with the motherboard platform, and the second area 2 is used for soldering. An image sensor electrically connects the coil 3 to the first area 1 .

[0014] Wherein, the second area 2 has a central part 21 located at the center thereof, on which there are welding feet 22 for welding with the image sensor, and the surrounding of the central part 21 is called a frame part 23, and coils are evenly distributed on the frame part Group. The coil group includes at least two or more coils 3, the example given in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com