Patents

Literature

61results about How to "Realize visual inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

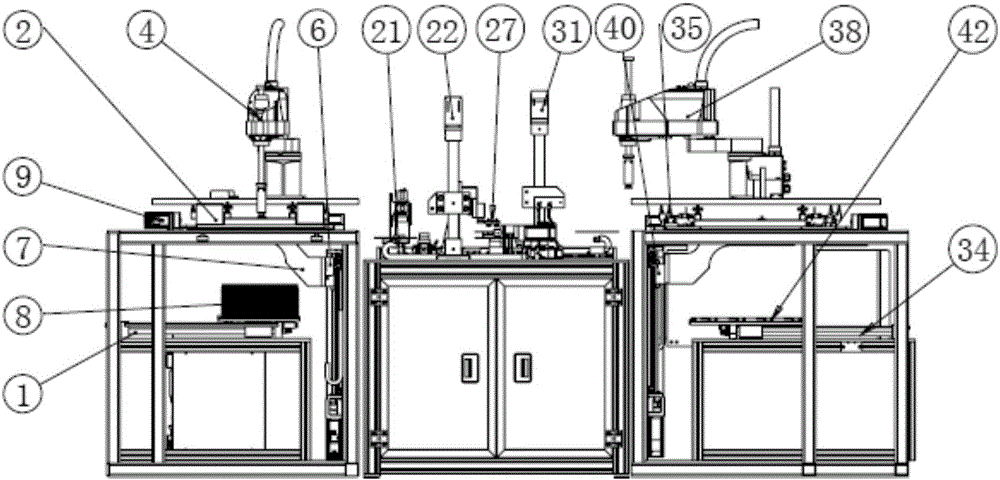

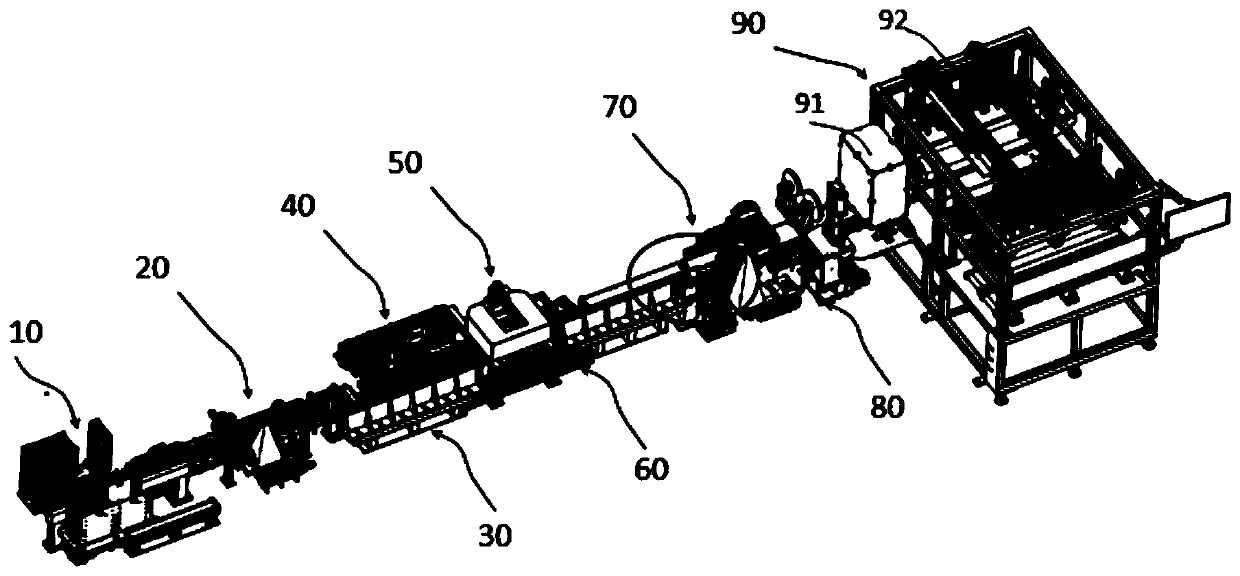

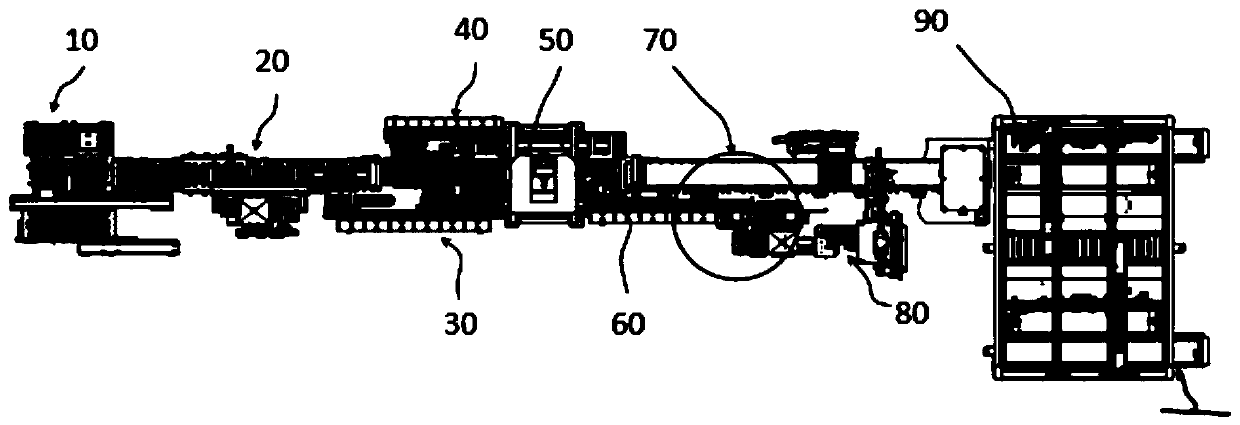

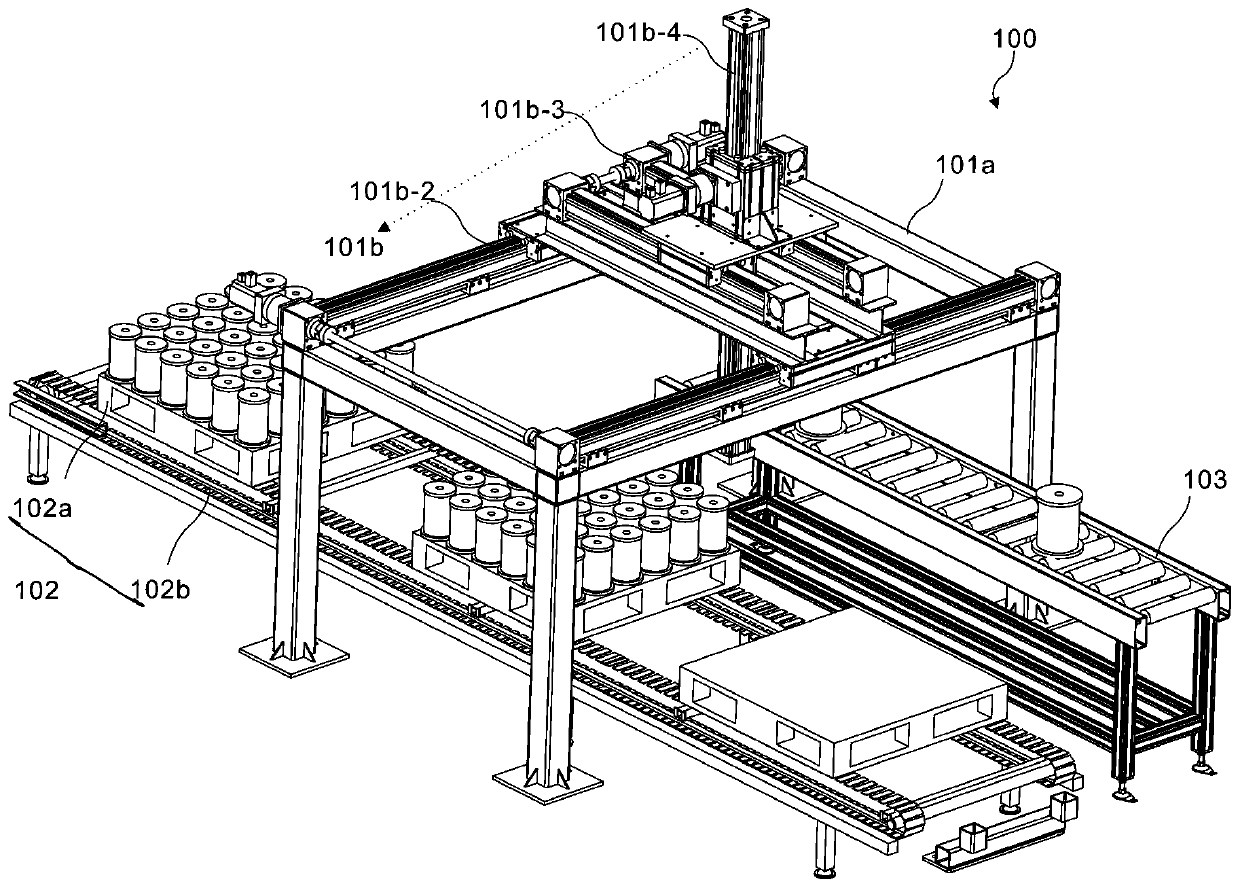

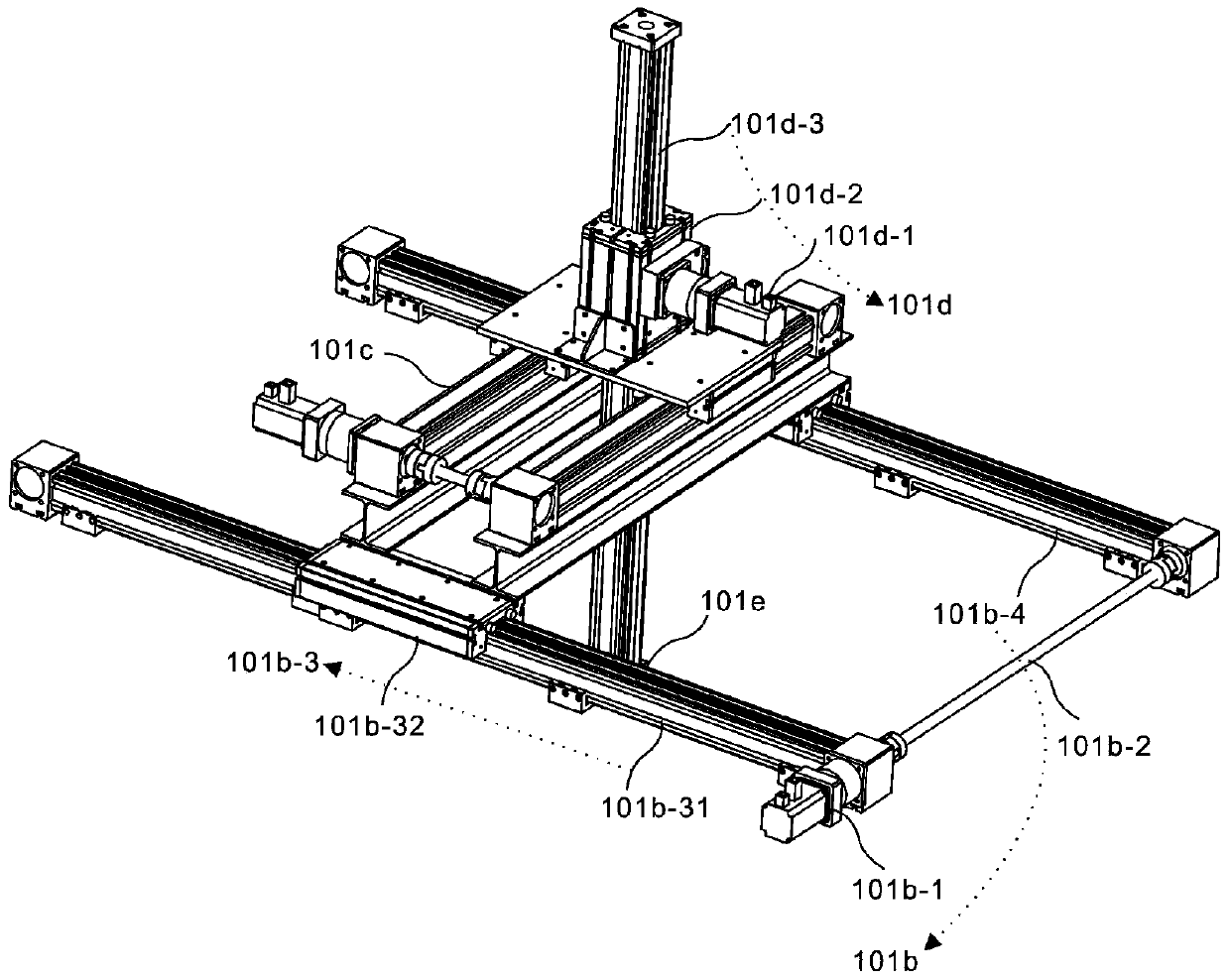

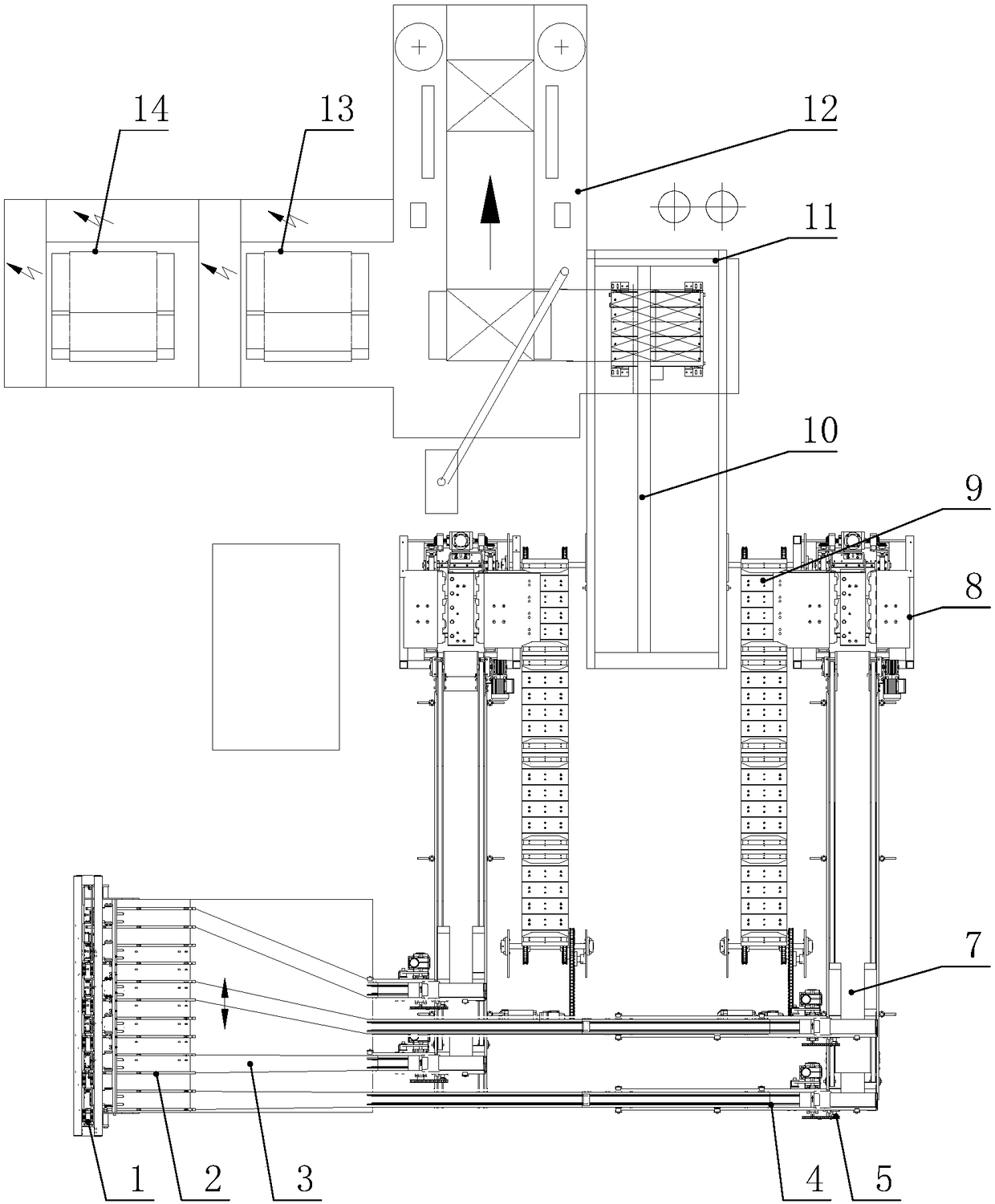

Full-automatic visual inspection system for screen defects

The invention relates to a full-automatic visual inspection system for screen defects. The system comprises a controller as well as an automatic feeding unit, an automatic inspection unit and an automatic classifying and discharging unit which are connected with the controller; the automatic feeding unit, the automatic inspection unit and the automatic classifying and discharging unit are sequentially arranged to form an automatic assembly line; the automatic feeding unit conveys to-be-inspected screens to the automatic inspection unit; the automatic inspection unit performs automatic defect inspection to determine whether the screens belong to non-defective products or defective products; and the automatic classifying and discharging unit acquires the inspected screens from the automatic inspection unit and performs classification and output according to inspection results. Compared with the prior art, the system has the advantages that the automation degree is high, the whole inspection process is simple to operate, the labor intensity of workers is reduced, the human capital is reduced, and the production efficiency is improved.

Owner:SHANGHAI WEISONG IND AUTOMATION

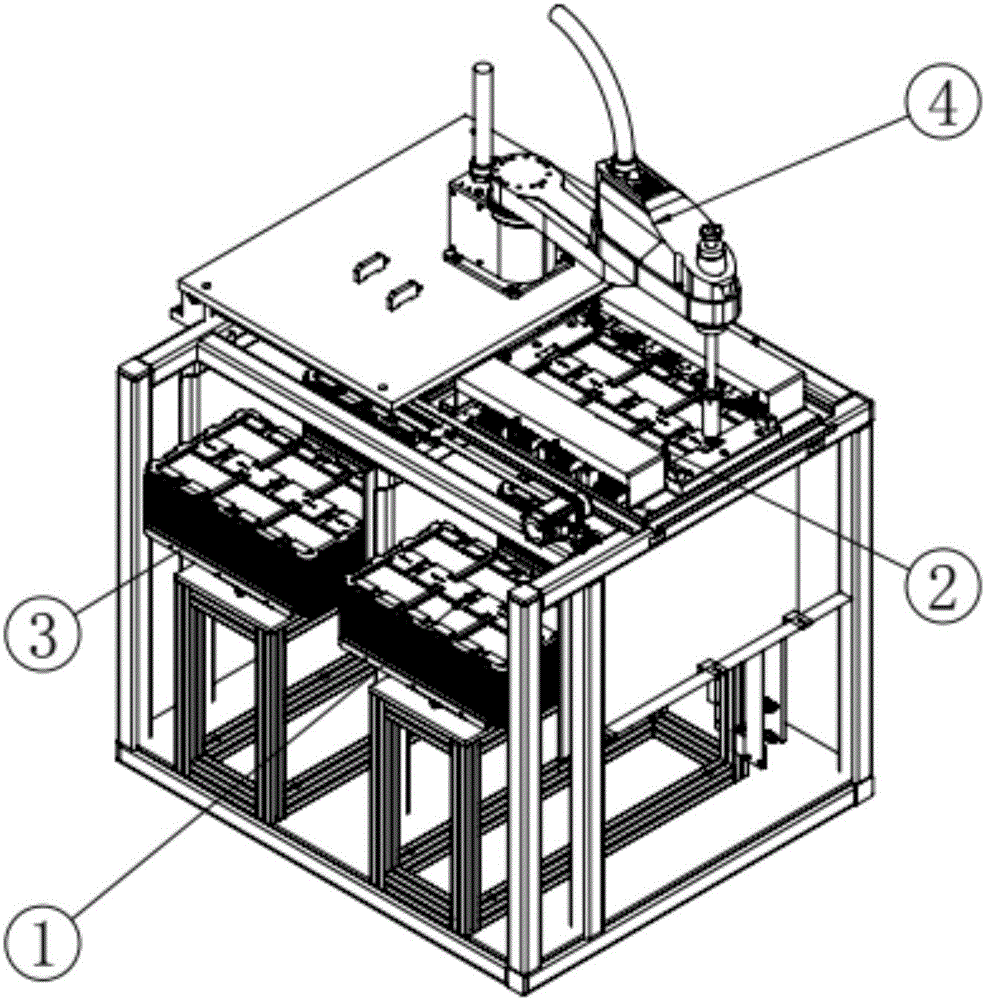

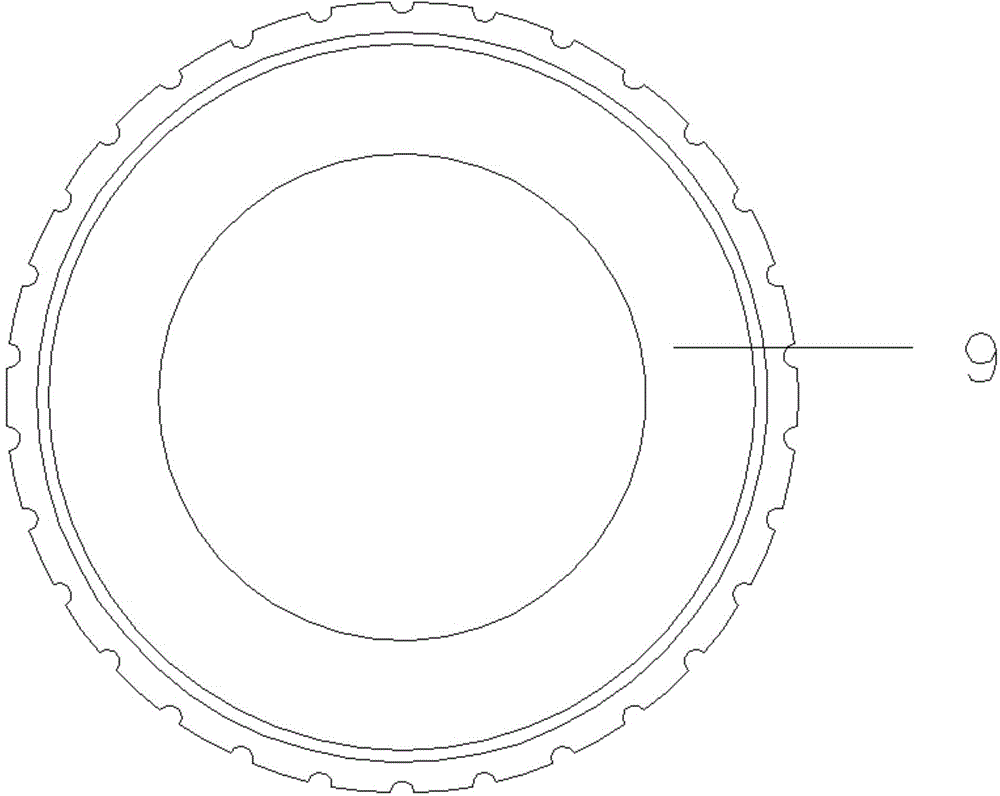

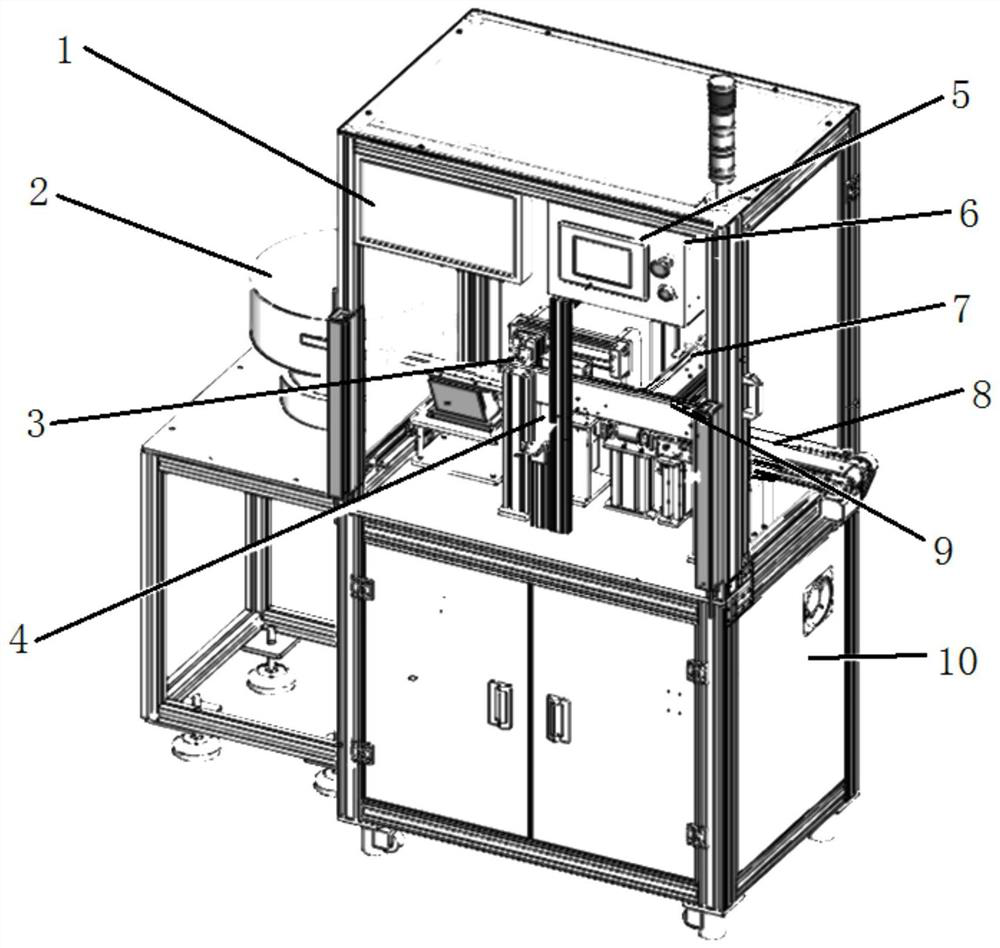

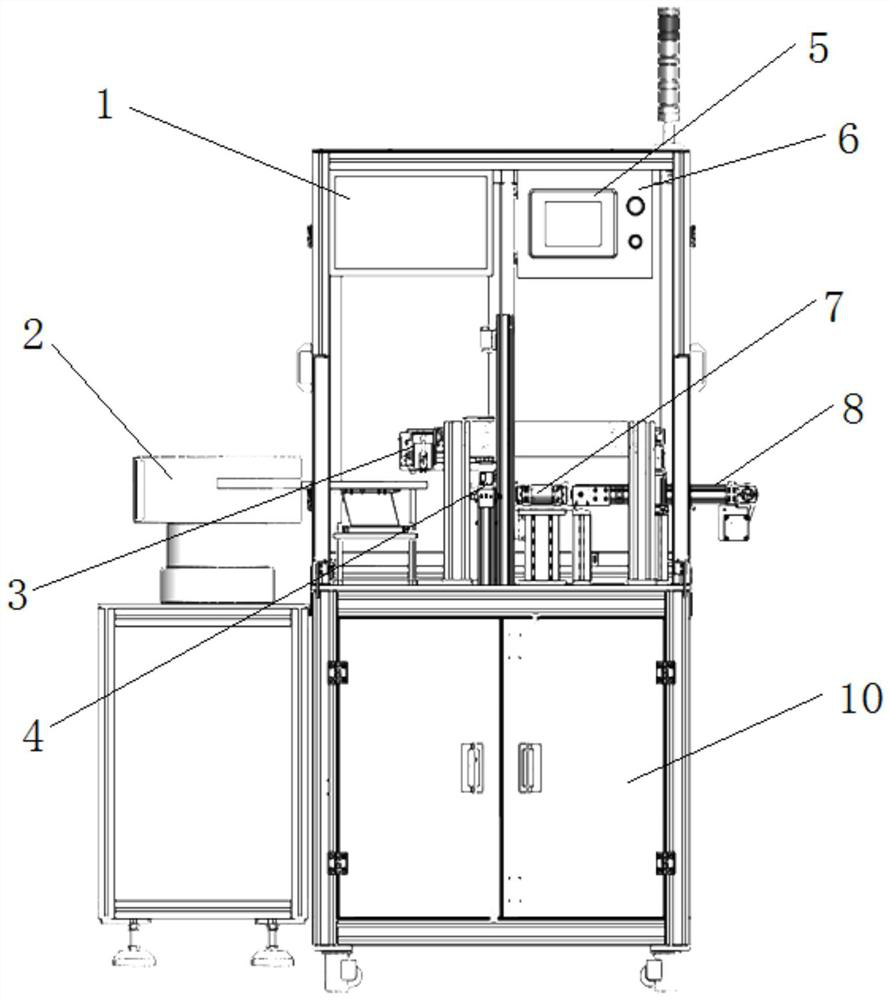

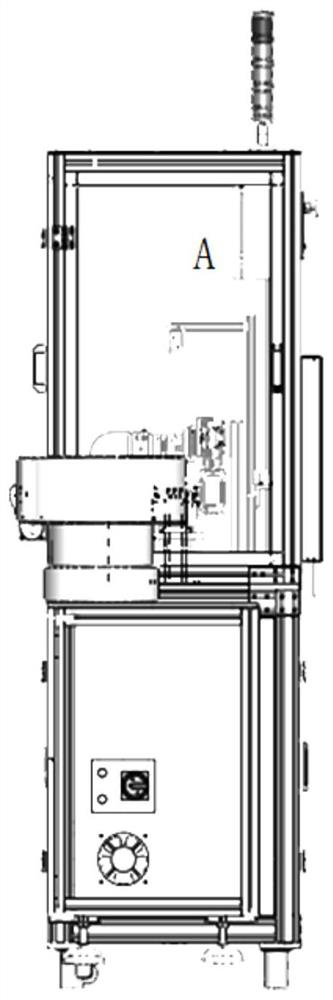

Quality testing system for friction discs

ActiveCN105784716AReduce false detection rateReduce manufacturing costOptically investigating flaws/contaminationMechanical thickness measurementsForeign matterDistance detection

The invention discloses a quality testing system for friction discs. The quality testing system consists of a first defect detection device, a second defect detection device, an internal tooth stick distance detection device, a thickness and flatness detection device, and a controlling and managing machine, wherein the first defect detection device, the second defect detection device, the internal tooth stick distance detection device and the thickness and flatness detection device are sequentially arranged, and the controlling and managing machine is used for controlling the whole testing system to work; a feeding manipulator is arranged at the front end of the first defect detection device; a discharging manipulator is arranged at the tail end of the thickness and flatness detection device; a moving and overturning manipulator which is used for completing the overturning operation of the friction discs in a moving process is arranged between the first defect detection device and the second defect detection device; moving manipulators are arranged between the second defect detection device and the internal tooth stick distance detection device, and between the internal tooth stick distance detection device and the thickness and flatness detection device. The detection of the friction plates on scratches, patches, foreign matters in grooves, broken blocks, grooving traces, center distances of internal tooth sticks, flatness and thickness can be completed at the same time; unmanned automated operation can be realized, a false detection rate generated due to the weariness of staff is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:SUZHOU JIUDIAN INTELLIGENT TECH CO LTD

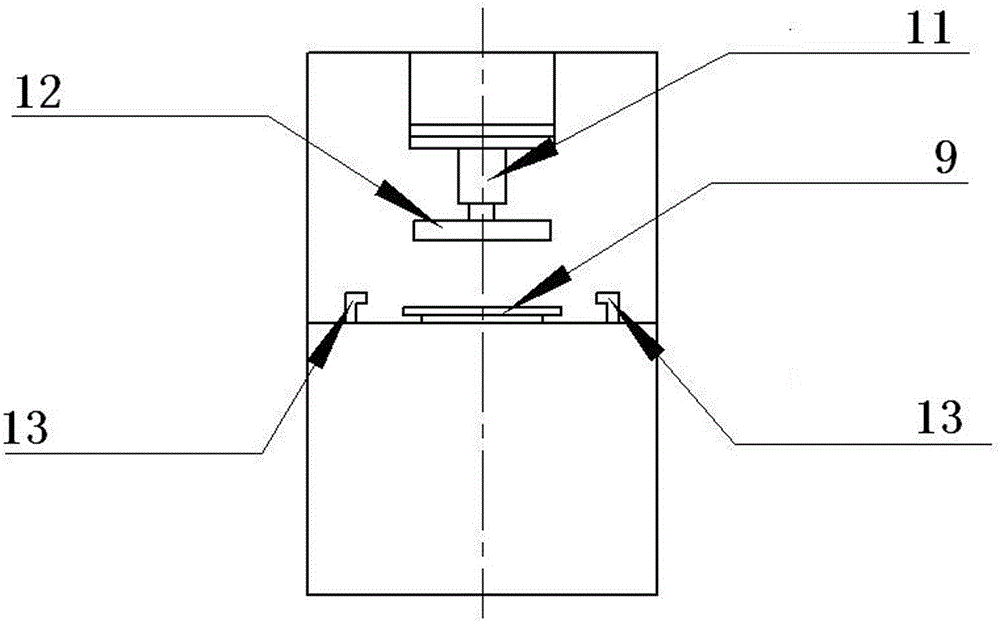

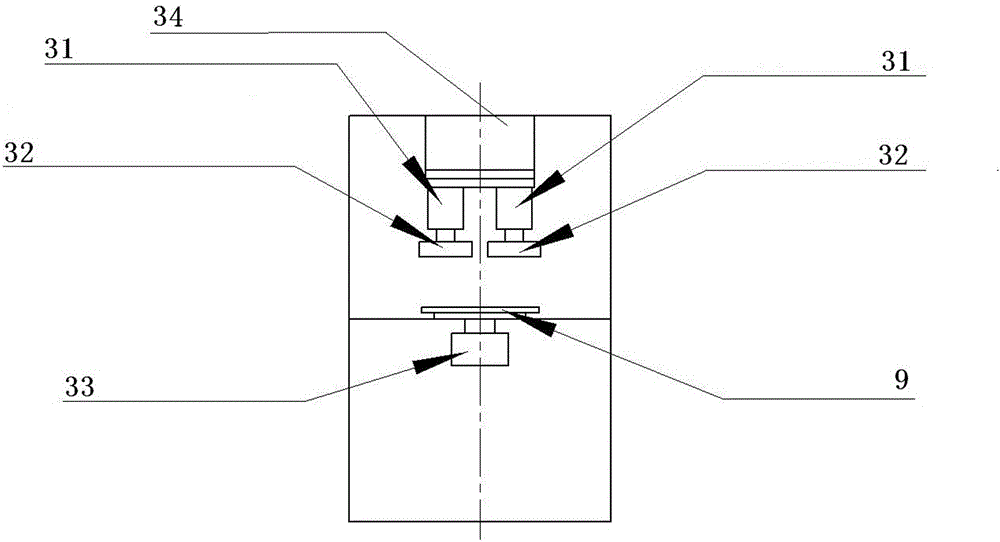

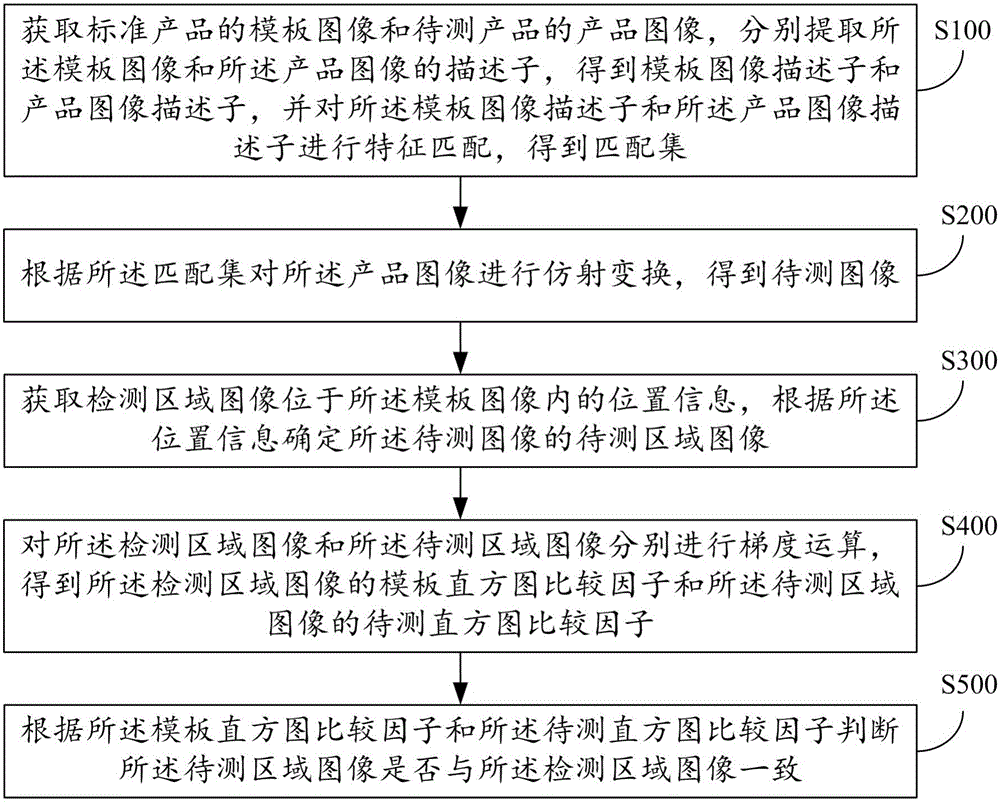

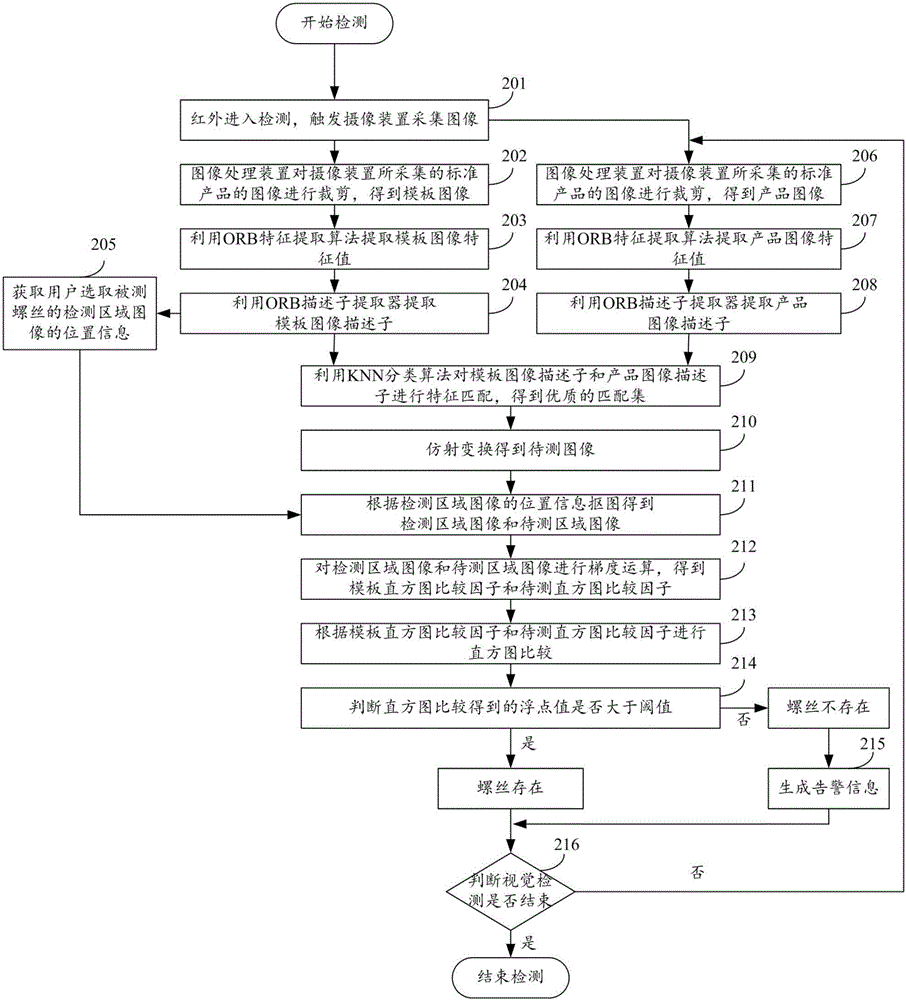

Object visual detection method and device

ActiveCN106056597ARealize visual inspectionImproved visual inspectionImage analysisVisual perceptionHistogram

The present invention relates to an object visual detection method and an object visual detection device. According to the method and the device, gradient operation is carried out on a detection region image in a template image and a to-be-detected region image in a to-be-detected image respectively, so that the template histogram comparison factor of the detection region image and the to-be-detected histogram comparison factor of the to-be-detected region image are obtained; histogram comparison is carried out on the template histogram comparison factor and the to-be-detected histogram comparison factor; and whether the to-be-detected region image is consistent with the detection region image can be judged, and visual detection and recognition of a product can be realized. Since direction judgment on whether the images are matched with each other according to the gray values of the to-be-detected region image and the detection region image is avoided, accurate visual detection and recognition of an object of which the color which is close to background color can be still realized; and since the sizes of the detection region image and the to-be-detected region image are smaller than the sizes of the original template image and the original to-be-detected image, the operation efficiency of the gradient operation is high, and the efficiency of visual detection is high.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

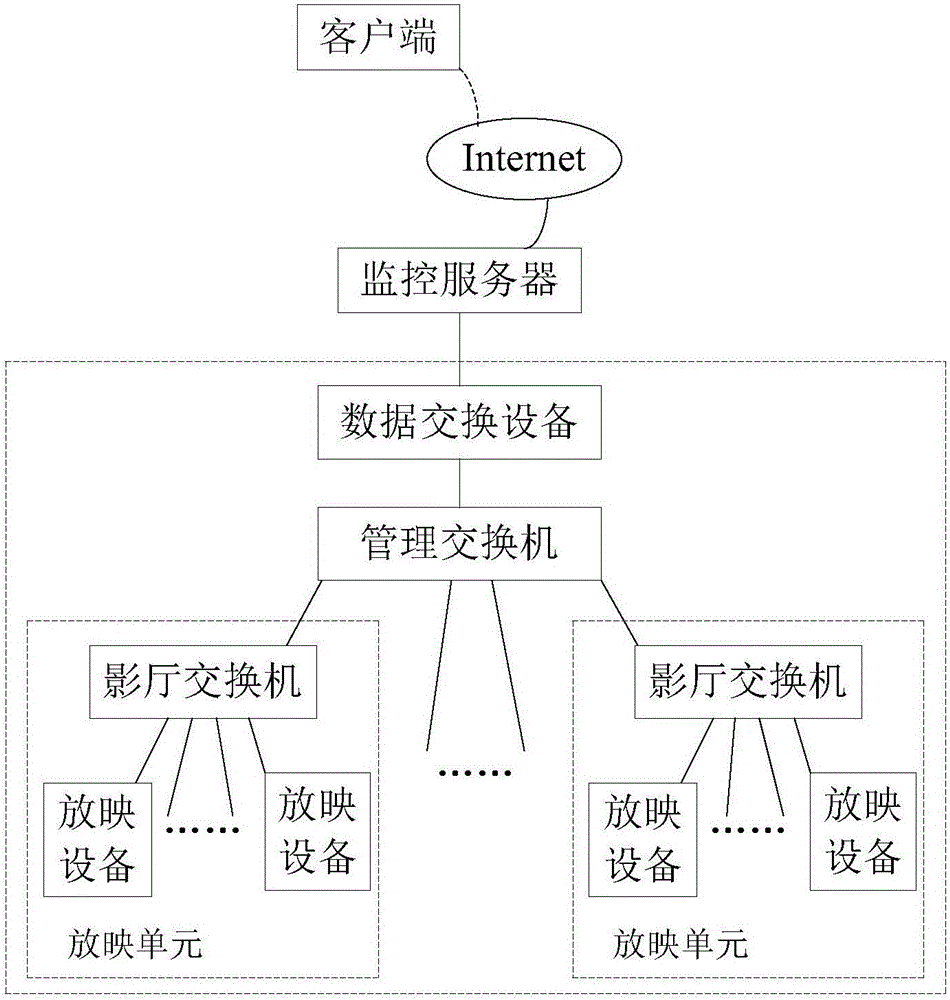

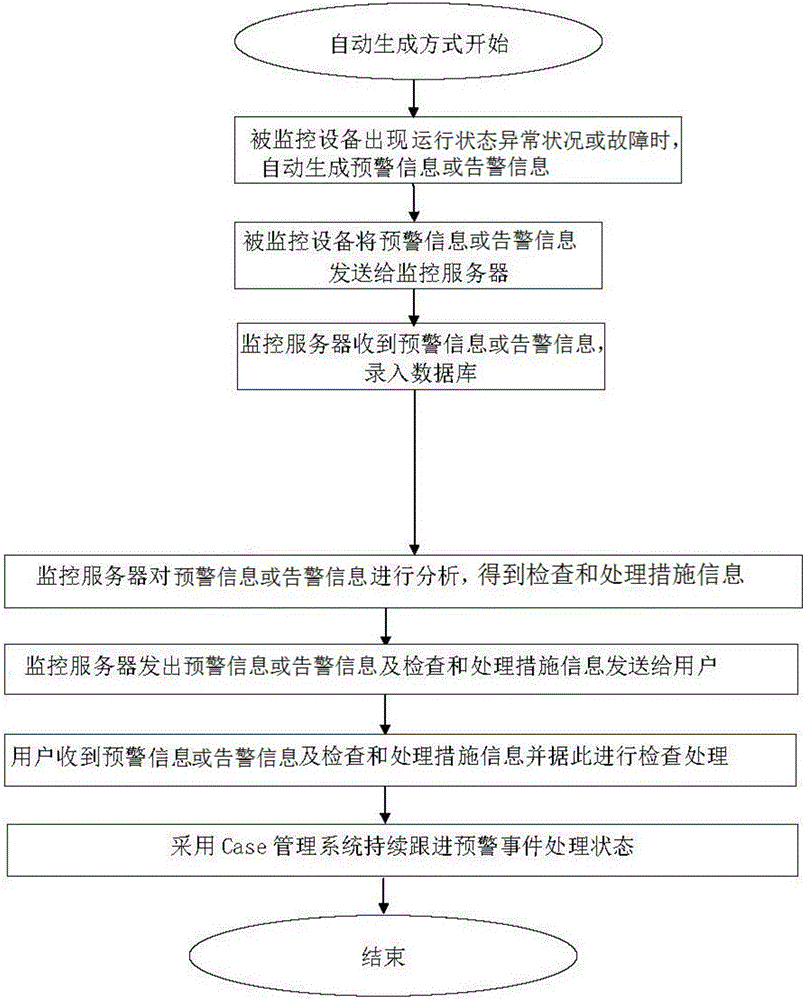

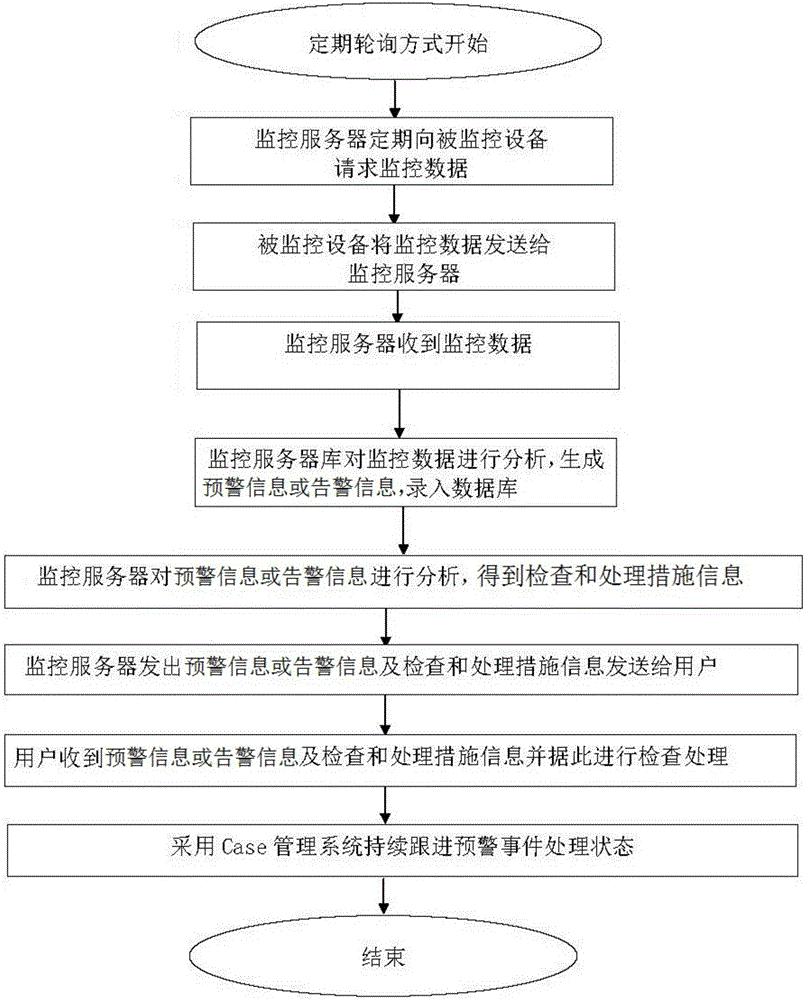

Digital movie theater device monitoring and maintenance system

ActiveCN105933411AImprove operational efficiencyImprove efficiencyData switching networksThe InternetBud

The invention relates to a digital movie theater device monitoring and maintenance system including a client, a monitoring server, a data exchange device, a management switch and a plurality of projection units. Each of the projection unit comprises an auditorium switch and a plurality of projection devices connected thereto. The auditorium switch is connected with the management switch. The client is connected with the monitoring server through the internet. The monitoring server, the data exchange device and the management switch are connected one by one. The system can monitor, maintain and process the work status of projection devices of a digital movie theater, solves the problem that digital projection device faults are difficult to find and process currently, can give early warning or warning in time, eliminates a problem in the bud, can quickly find the problem and deal with the problem when the problem happens, largely reduces the device fault time, and thus improves the operation efficiency and benefits.

Owner:世纪美映影院技术服务(北京)有限公司

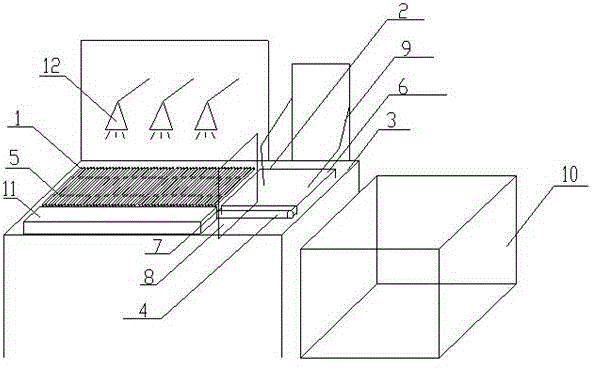

Light source arrangement method for RFID (radio frequency identification) tag automatic optical detection

InactiveCN106885810ADo visual inspectionAvoid defectsOptically investigating flaws/contaminationDisplay deviceEngineering

The invention relates to a light source arrangement method for RFID (radio frequency identification) tag automatic optical detection. The method comprises a machine frame, wherein the machine frame is provided with an unreeling roll, a reeling roll, a visual detection device, a plurality of delivery wheels, a display device and an ink-jet printer, wherein one end of an RFID tag tape formed by bonding a plurality of RFID tags to a release paper tape is wound on the unreeling roll, and the other end penetrates through the visual detection device sequentially via the delivery wheels and is wound on the reeling roll; the visual detection device comprises a first detection device and a second detection device which are arranged horizontally at an interval; the first detection device comprises a front camera, a first left reflected light source, a first right reflected light source and a first transmitted light source; the second detection device comprises a back camera, a second left reflected light source, a second right reflected light source and a second transmitted light source; and the front camera and back camera are respectively connected with the display device through signal wires. The method is advanced and scientific; and the detection combination of the front and back sets and the visual solution of reflected light-transmitted light composite mode are utilized to effectively detect various types of defects in various materials.

Owner:ARIZON RFID TECH YANGZHOU

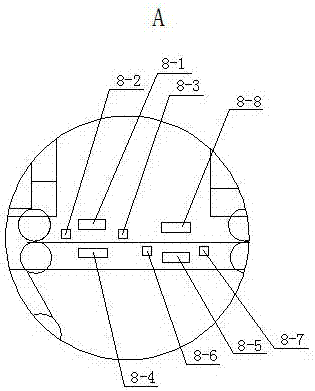

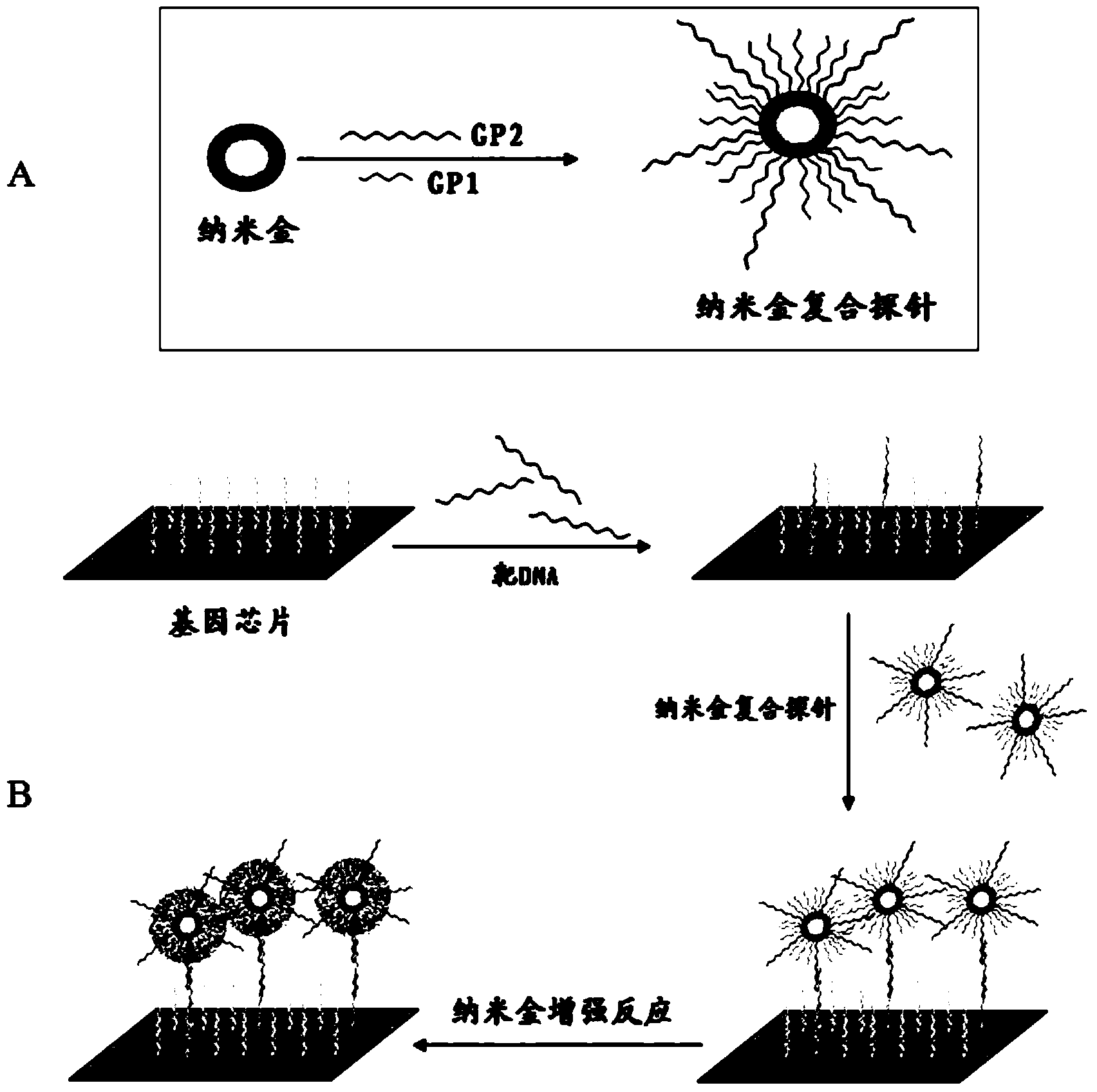

Gold deposition detection method for gene chip

ActiveCN103451313AHigh sensitivityEasy to detectMicrobiological testing/measurementBiological macromoleculeHydrogen peroxide

The invention provides a gold deposition detection method for a gene chip. The method is characterized by comprising the steps of carrying out sample application on an existing DNA sequence to a micro array to prepare the gene chip, previously decorating a biological macromolecule at the 5' end of nucleic acid to be detected, marking the other biological macromolecule matched with a decorative molecule on the nucleic acid to be detected on nanogold to establish a nanogold composite probe, then mixing the decorated nucleic acid to be detected, the marked nanogold composite probe and the gene chip, incubating, washing the unreacted nanogold composite proble and adding hydrogen peroxide gold to enhance reaction liquid observation. The gold deposition detection method for the gene chip has the advantages of being high in flexible, convenient to detect, simple to operate, short in consumed time, low in cost, visual in detection and low in relying degree on detecting and signal reading equipment.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

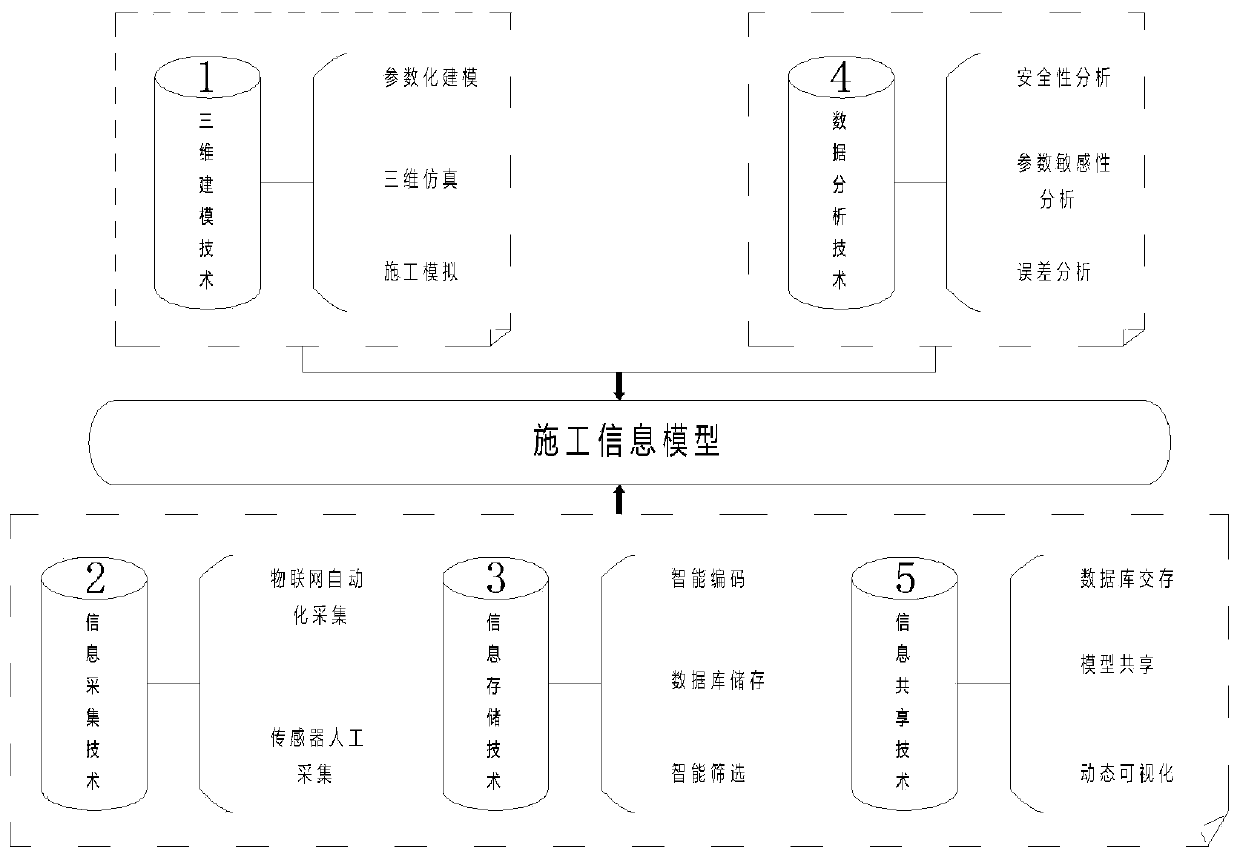

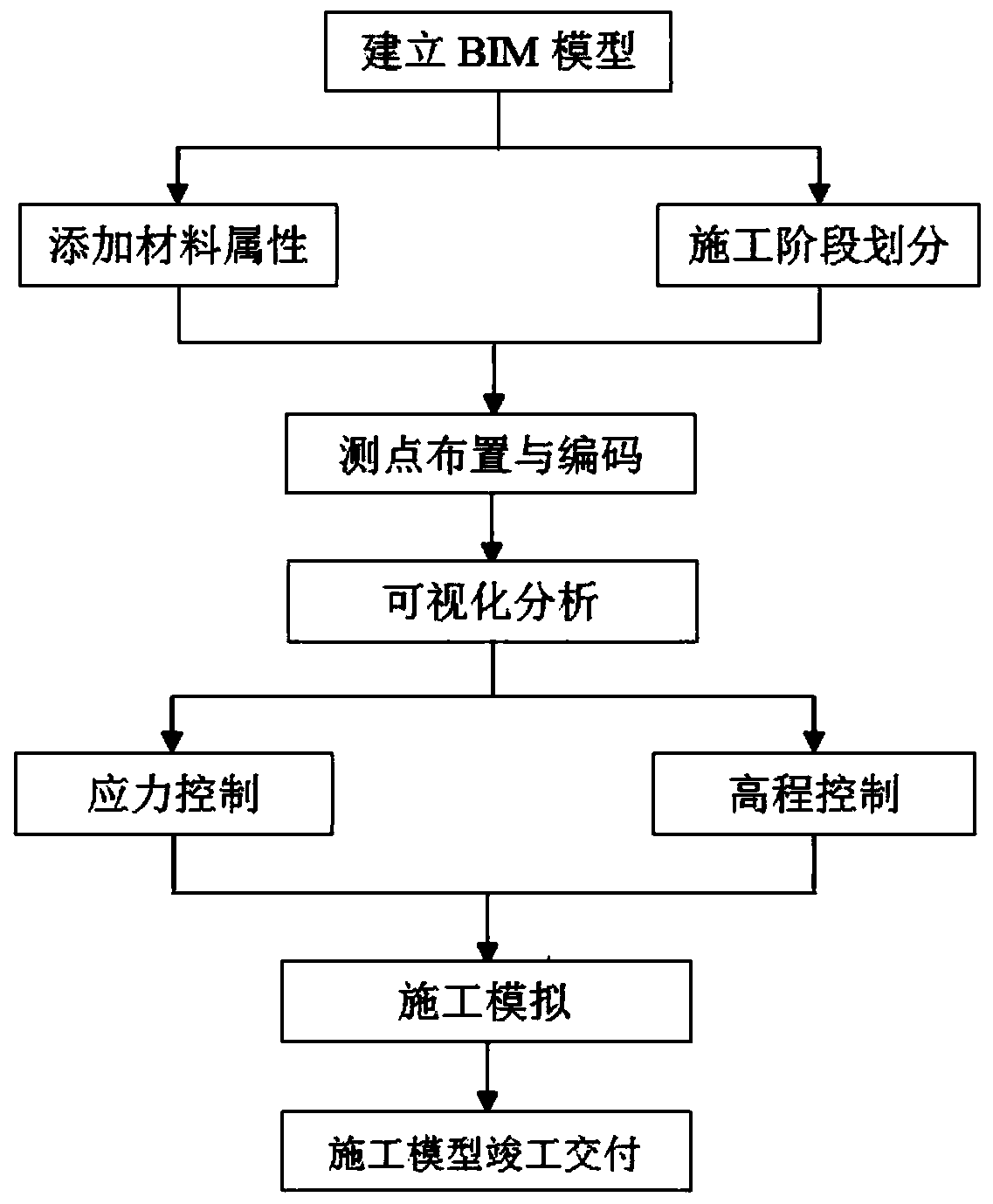

Continuous rigid frame bridge construction management control method based on BIM

ActiveCN110008591AReal-time inputImplement database storageGeometric CADDesign optimisation/simulationComplete dataConstruction management

The invention discloses a continuous rigid frame bridge construction management control method based on BIM, and belongs to the technical field of building construction. The method comprises the following steps: step 1, establishing a model; step 2, measuring point arrangement and coding; step 3, visual analysis; and step 4, construction simulation: carrying out whole-process construction simulation by utilizing the built continuous rigid frame bridge BIM model, visualizing disclosure, optimizing a construction scheme, and carrying out completion delivery on a full-information model. Accordingto the invention, real-time recording and database storage of Revit model information are realized; the integrity and the sharing of construction information are ensured, the efficiency of rigid frame bridge construction management control is improved, complete data support and visual check are provided for construction of the continuous rigid frame bridge, and the application of the BIM technology in the aspect of bridge construction monitoring is promoted.

Owner:CHINA MCC17 GRP

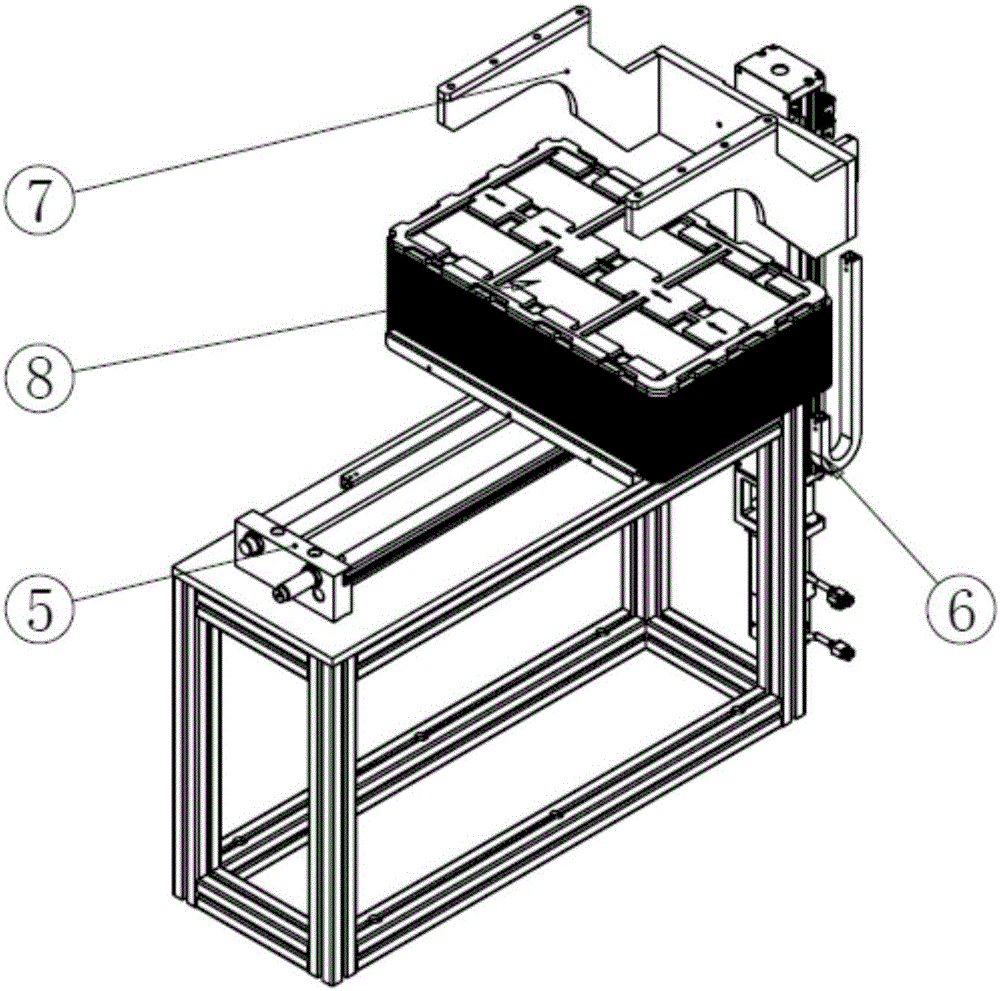

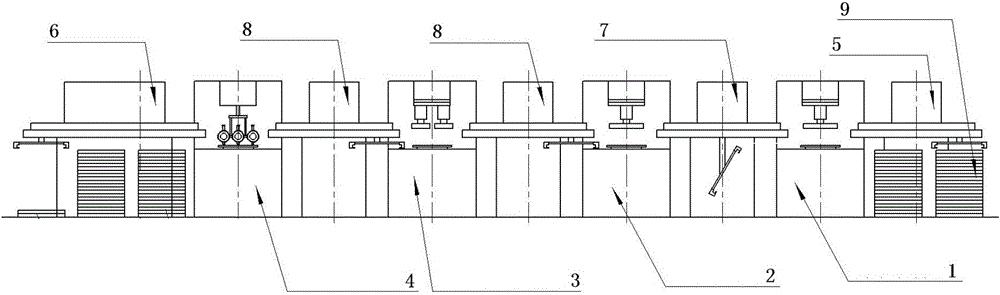

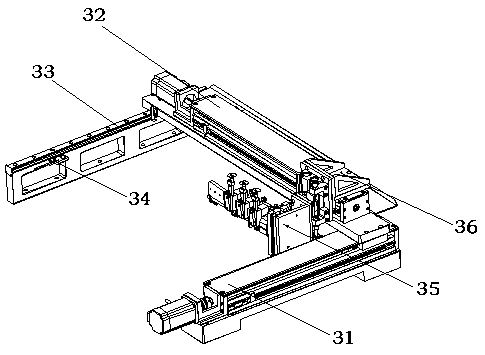

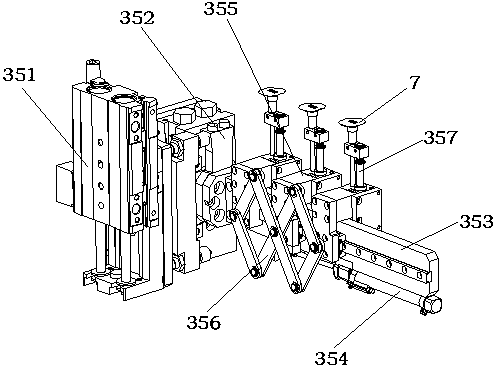

Imbricated battery string production equipment

PendingCN111146310ARealize visual inspectionRealization of hidden crack detectionFinal product manufactureSemiconductor/solid-state device manufacturingMechanical engineeringBattery cell

The invention relates to imbricated battery string production equipment. The equipment comprises a battery piece feeding device, a battery piece arranging device, a battery piece gluing device, an imbrication device, a bus bar laying device and a welding device. The battery piece feeding device feeds a battery piece to the conveying line; a battery piece detecting and replacing device replaces anunqualified battery piece on the conveying line with a qualified battery piece; a battery piece carrying device is used for carrying the qualified battery piece on the conveying line to the battery piece arranging device; the battery piece arranging device is used for arranging the battery piece; the battery piece carrying device is also used for carrying the structured battery piece to the battery piece gluing device; the battery piece gluing device is used for gluing the battery piece; the imbrication device performs the imbrication of the battery piece and then puts the battery piece back to the conveying line; the bus bar laying device is used for laying bus bars at the head and tail parts of the imbricated battery piece; and the welding device welds the battery piece into an imbricated battery string. According to the invention, automatic production of the imbricated battery string is realized, and the production efficiency is improved.

Owner:WUXI AUTOWELL TECH

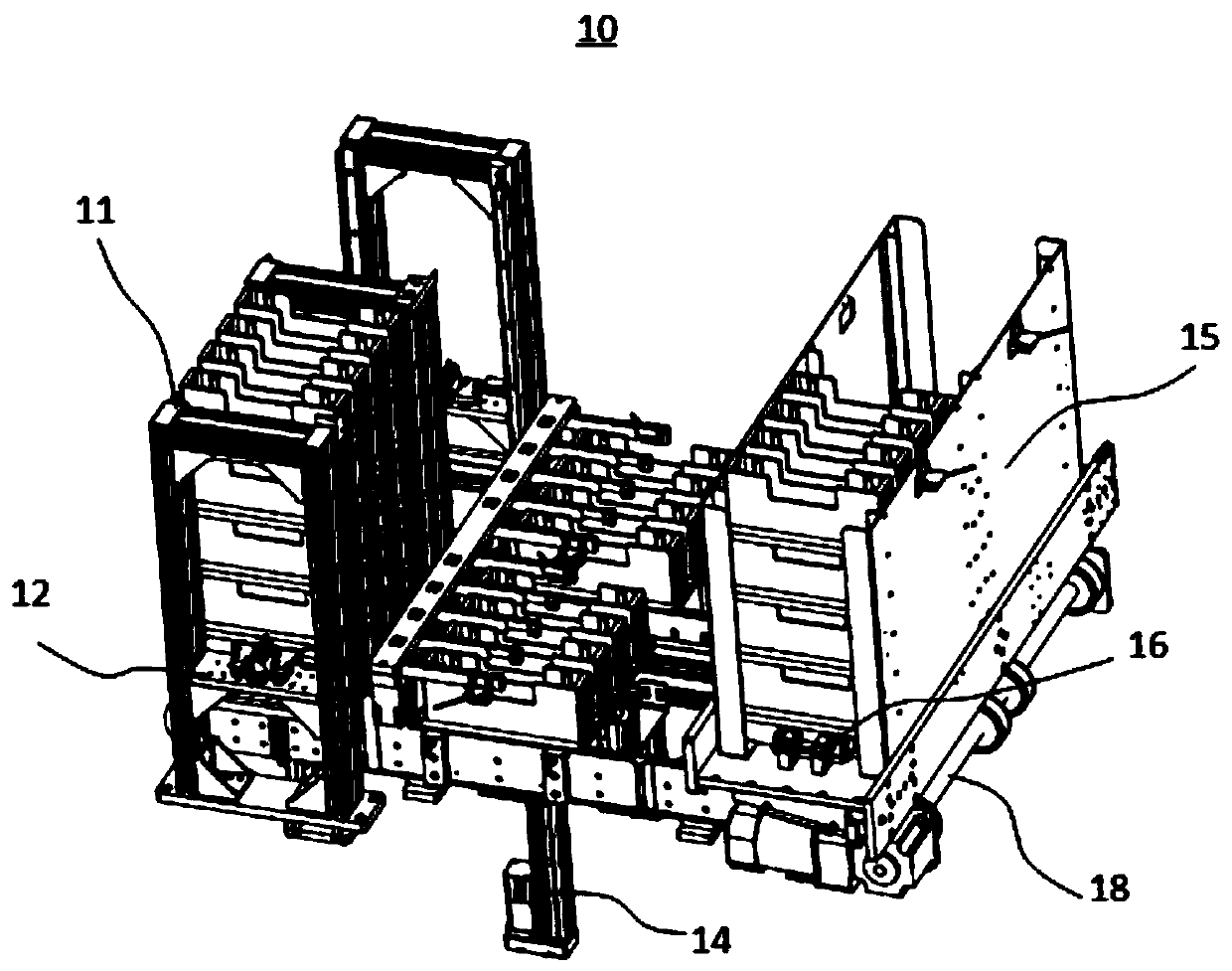

Method for detecting uneven thickness defect of exterior grid line of battery piece

ActiveCN107742283AImprove detection qualityRealize visual inspectionImage enhancementImage analysisArray data structureCurve fitting

The invention provides a method for detecting the uneven thickness defect of an exterior grid line of a battery piece. According to the method, the process is divided into three parts, the first partis that an image preprocessing unit acquires vertical discontinuous grid line information, the second part is that a curve fitting unit fits the average value of each line of the grid line, and the third part is that a grid line uneven thickness defect detection unit conducts judgment and detection by using the difference value of an image array and a fitted curve.

Owner:HEBEI UNIV OF TECH +1

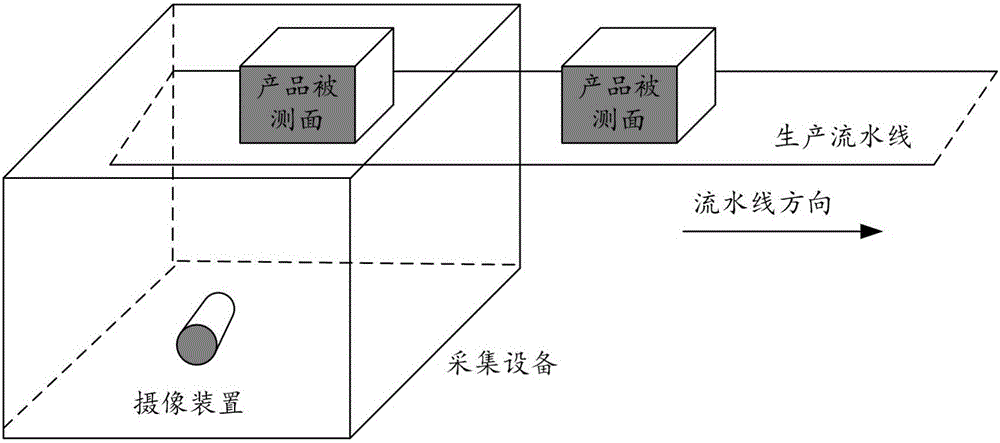

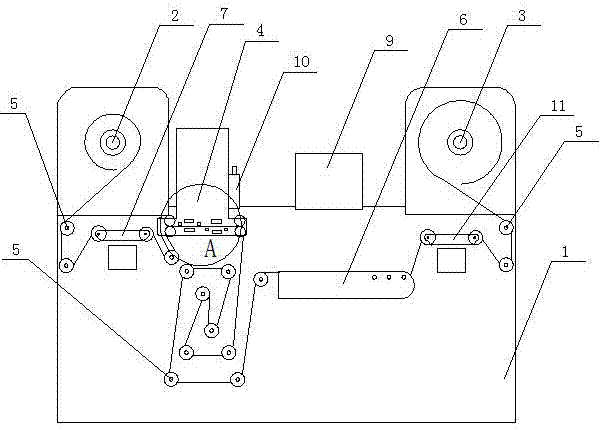

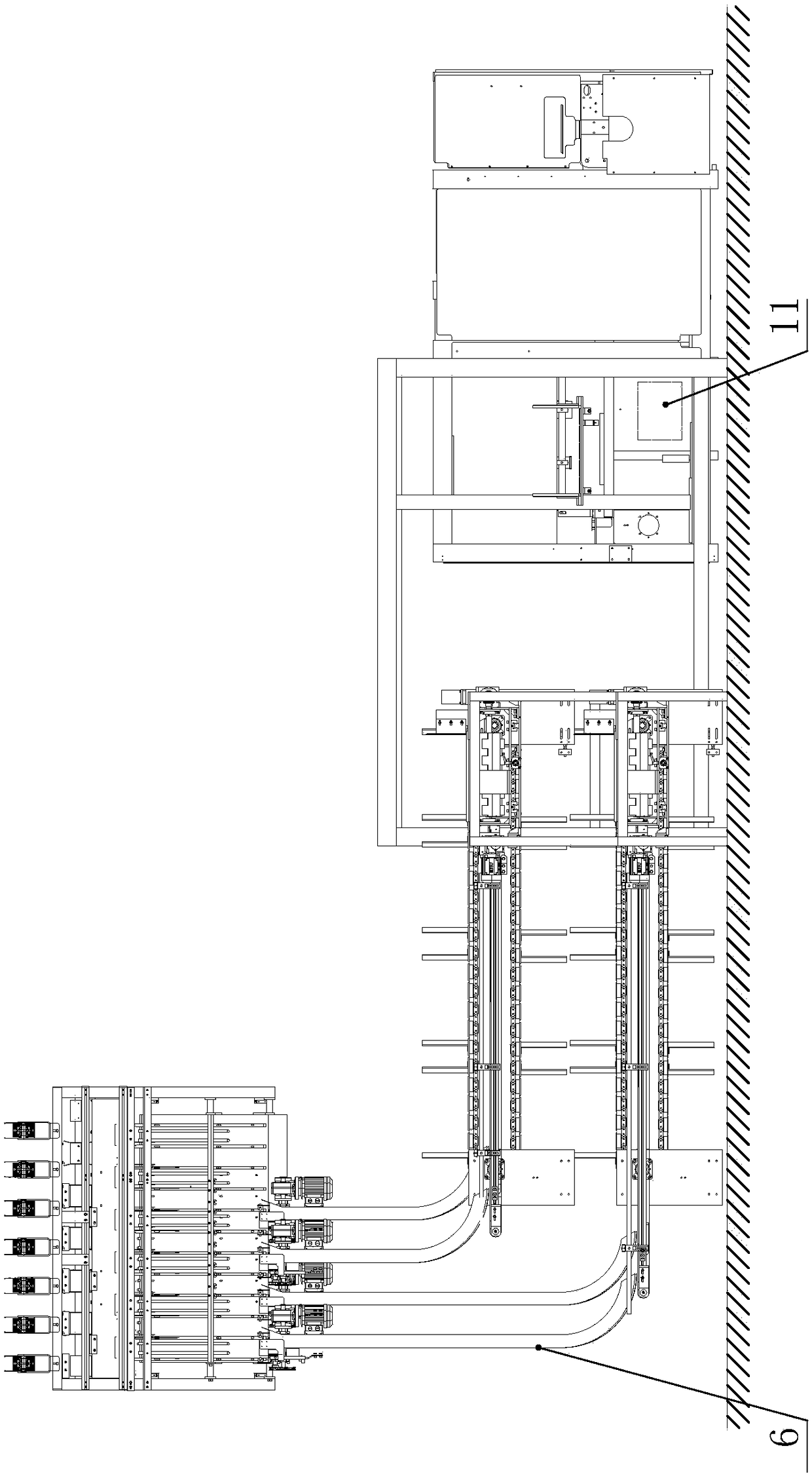

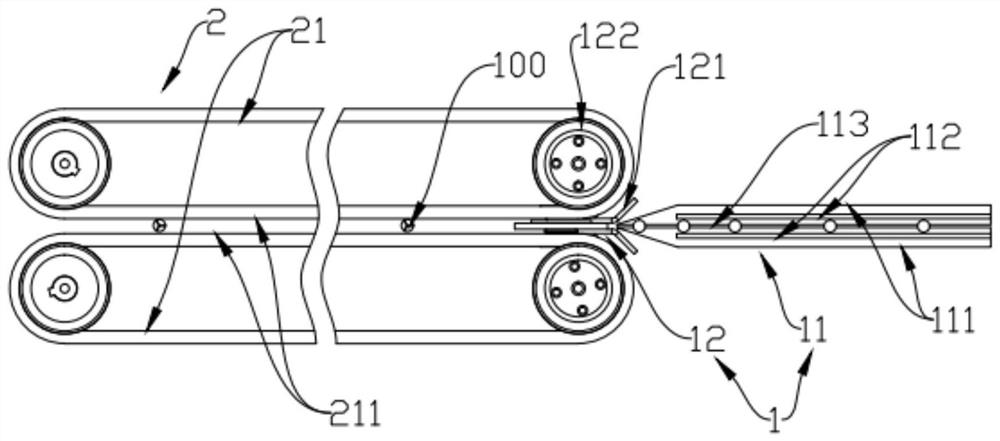

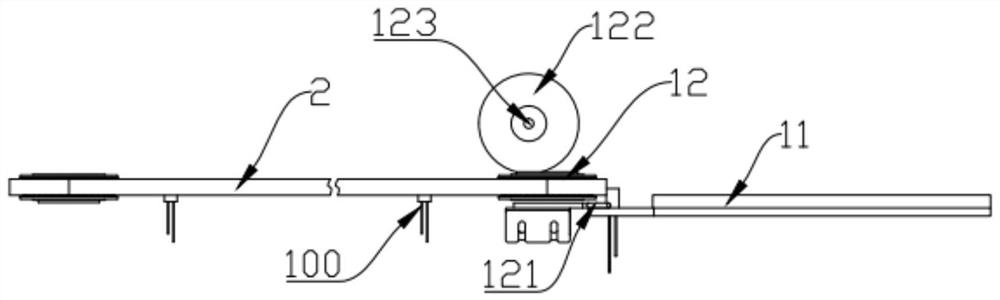

Automatic enameled wire conveyor line based on visual inspection system

ActiveCN110844591AImprove automationImprove the level of automated productionWrappingWrapper twisting/gatheringVisual inspectionChain conveyor

The invention discloses an automatic enameled wire conveyor line based on a visual inspection system. The automatic enameled wire conveyor line comprises a handling unit, an inspection unit, a prepackaging unit, and a packing unit; the handling unit comprises a first handling assembly, and a first transfer assembly and a first conveyor which are arranged on the inner side of the first handling assembly; the first transfer assembly is arranged on one side of the first conveyor; the inspection unit comprises a visual inspection assembly arranged on the first conveyor, and a quality inspection assembly located at one end of the first conveyor; the prepackaging unit is connected with the quality inspection assembly; the packing unit is arranged at one end of the prepackaging unit; and the first transfer assembly comprises a bearing platform and a chain conveyor, and the bearing platform is arranged on the chain conveyor. According to the automatic enameled wire conveyor line, through mutual cooperation of the arranged handling unit, the inspection unit, the prepackaging unit and the packing unit, full-automatic packaging of an enameled wire can be achieved; the production automation level of the enameled wire is improved, and the operating process saves time and labors; and the production efficiency of the enameled wire is improved greatly, and the production cost of the enameled wire is reduced.

Owner:DONGGUAN SUN CABLE EQUIP CO LTD

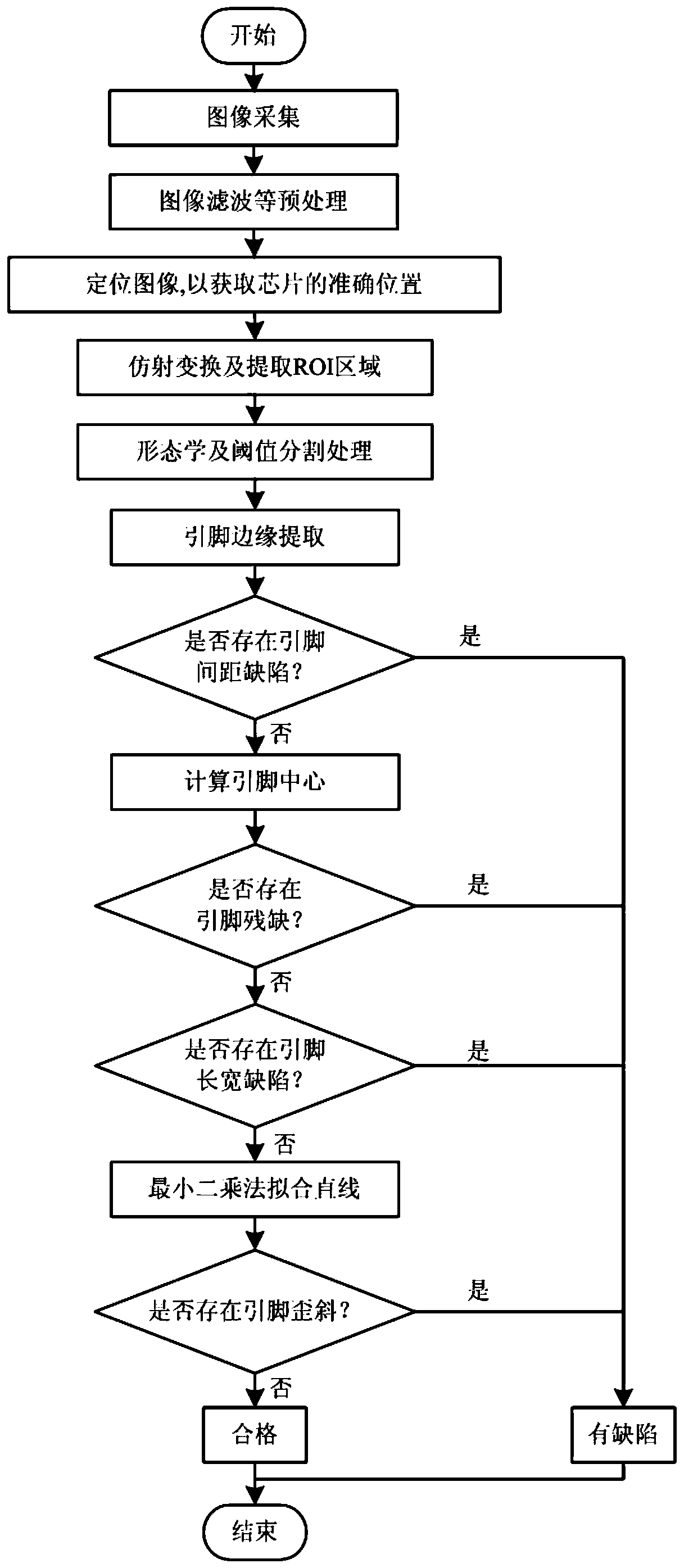

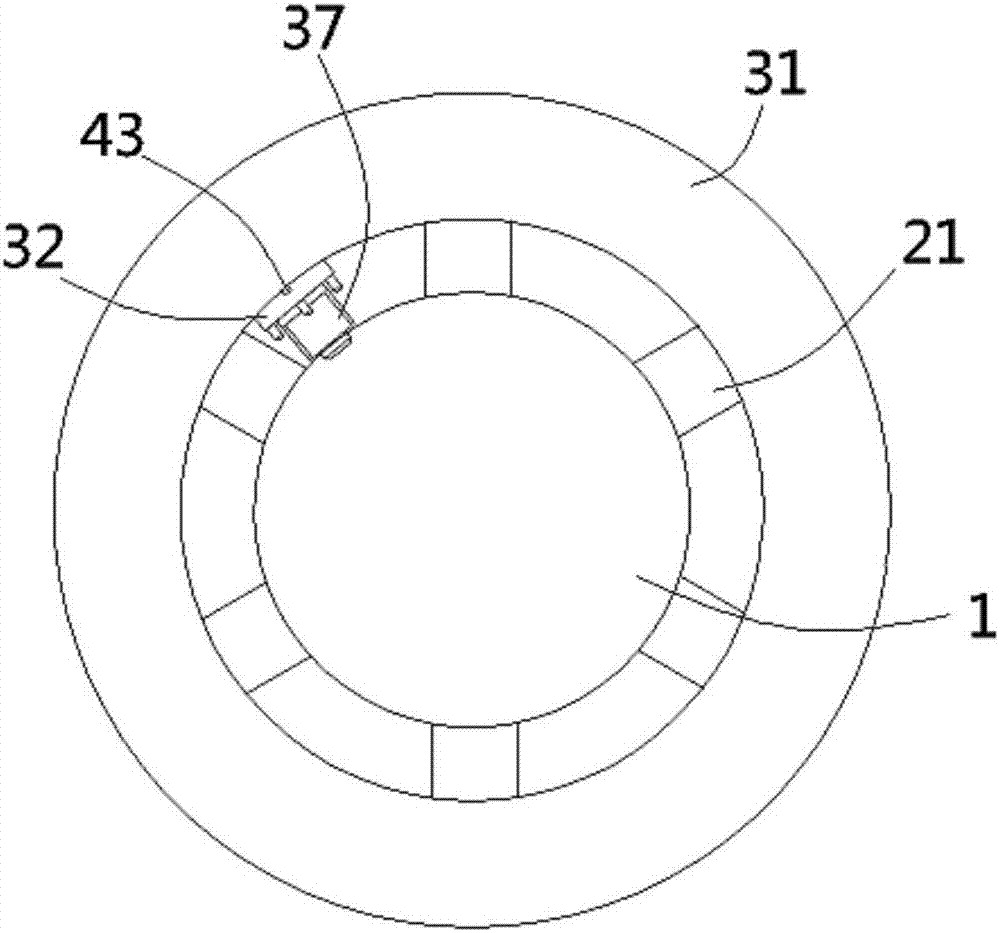

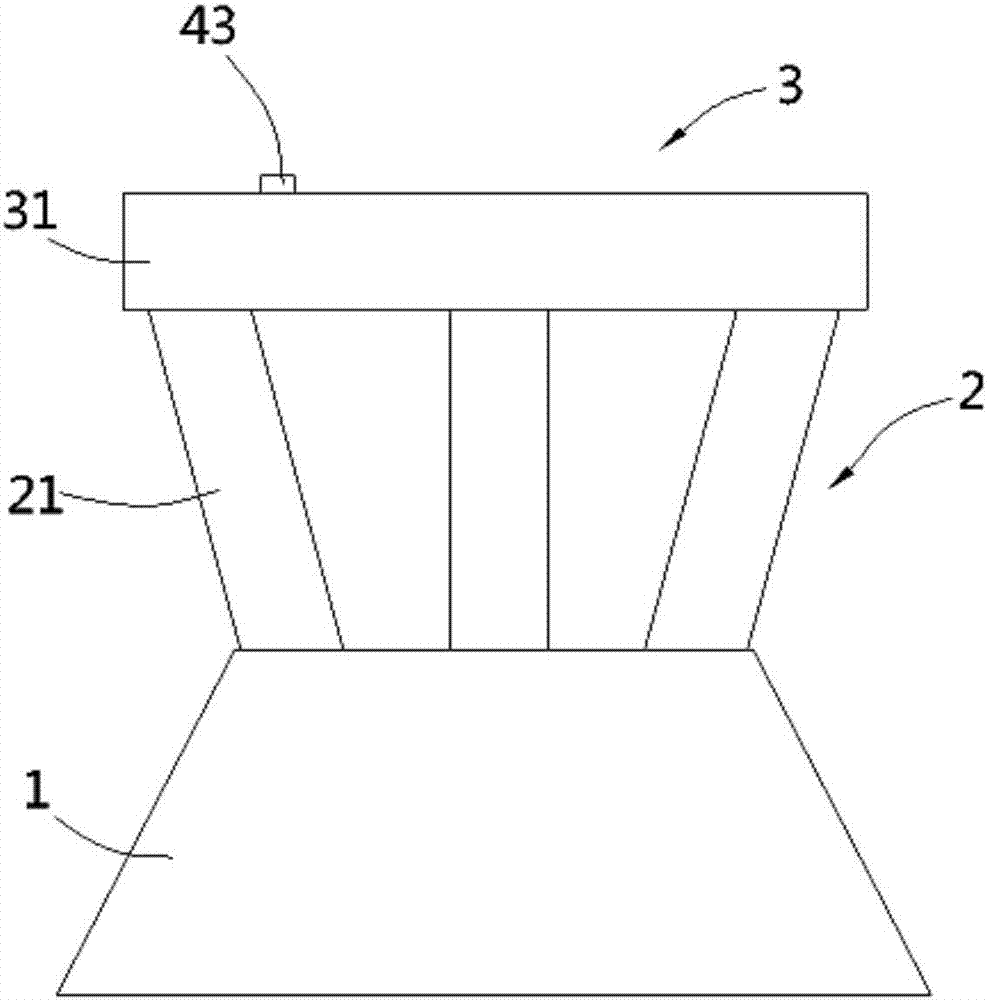

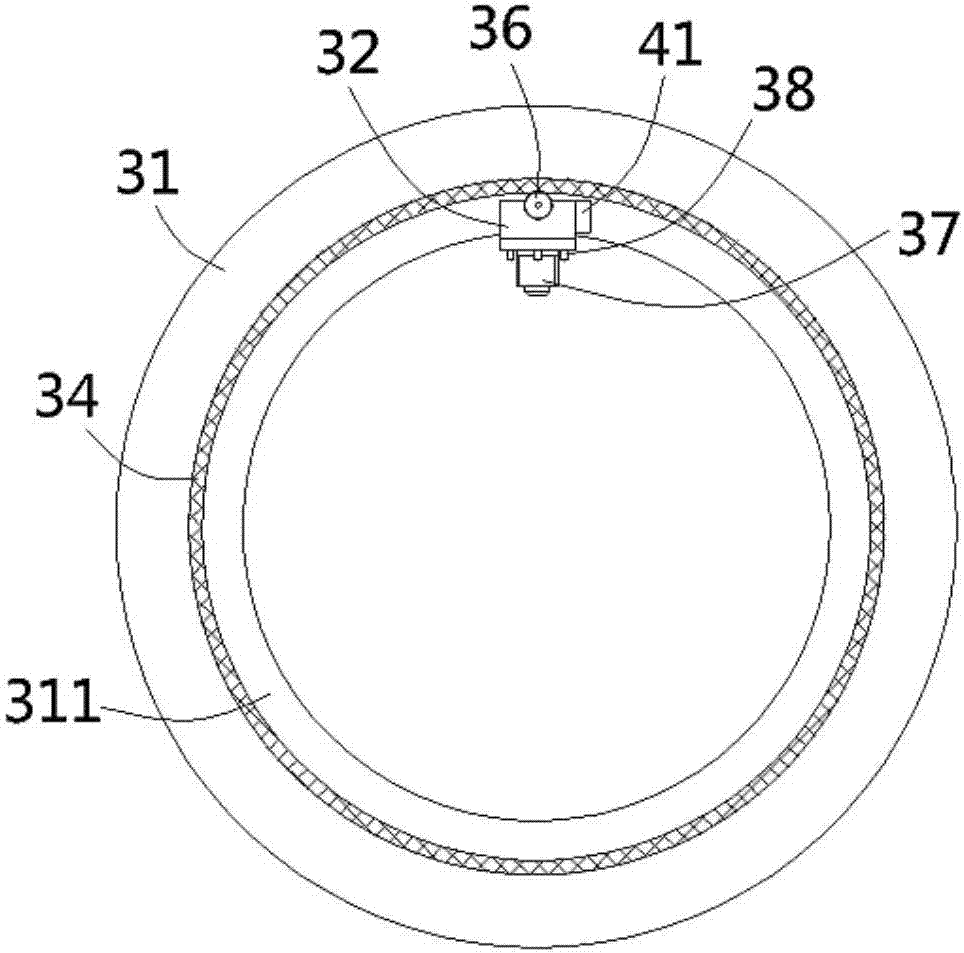

SMT chip defect detection system and method

InactiveCN110333238ARealize visual inspectionImprove detection efficiencyOptically investigating flaws/contaminationUsing optical meansImaging processingPersonal computer

The invention discloses a SMT chip defect detection system and method. The system comprises an annular LED light source, an image acquisition system, an image processing system and an industrial personal computer. The detection method comprises the following steps: the image acquisition system transmits an acquired image signal to the image processing system; the image processing system processesan original image, extracts a pin image, and measures the related data of the pin; the related data of the pin is compared with the standard value and judged; and the related data of the pin and the judgment result are visually displayed in a human-machine interaction way, and a detection result is output. The vision detection of the SMT chip is realized, the detection difficulty is reduced, the working condition of the detection worker is improved, and the detection efficiency and the detection quality of the SMT chip are improved.

Owner:DONGHUA UNIV

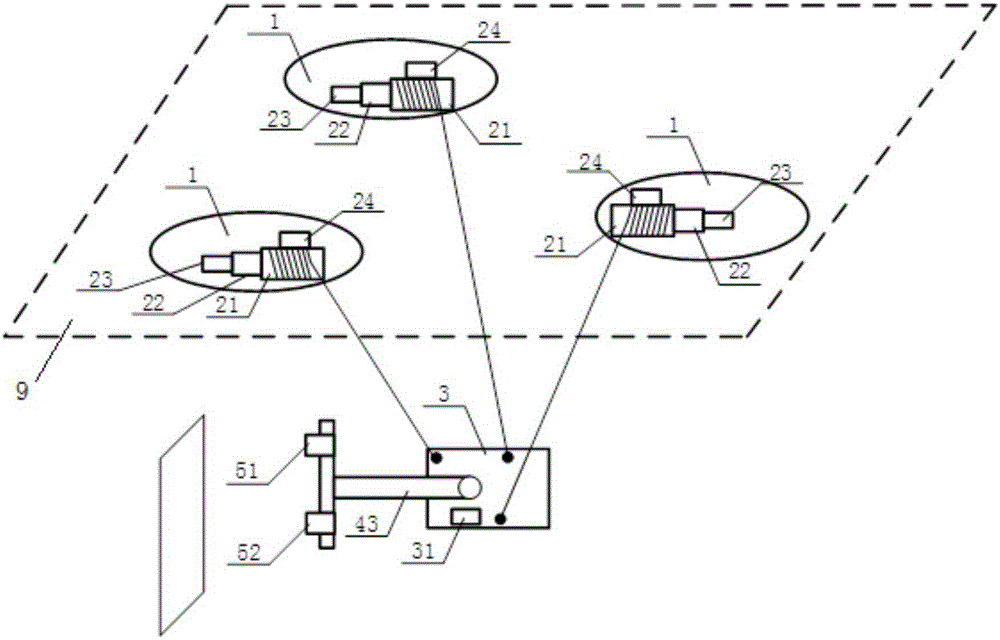

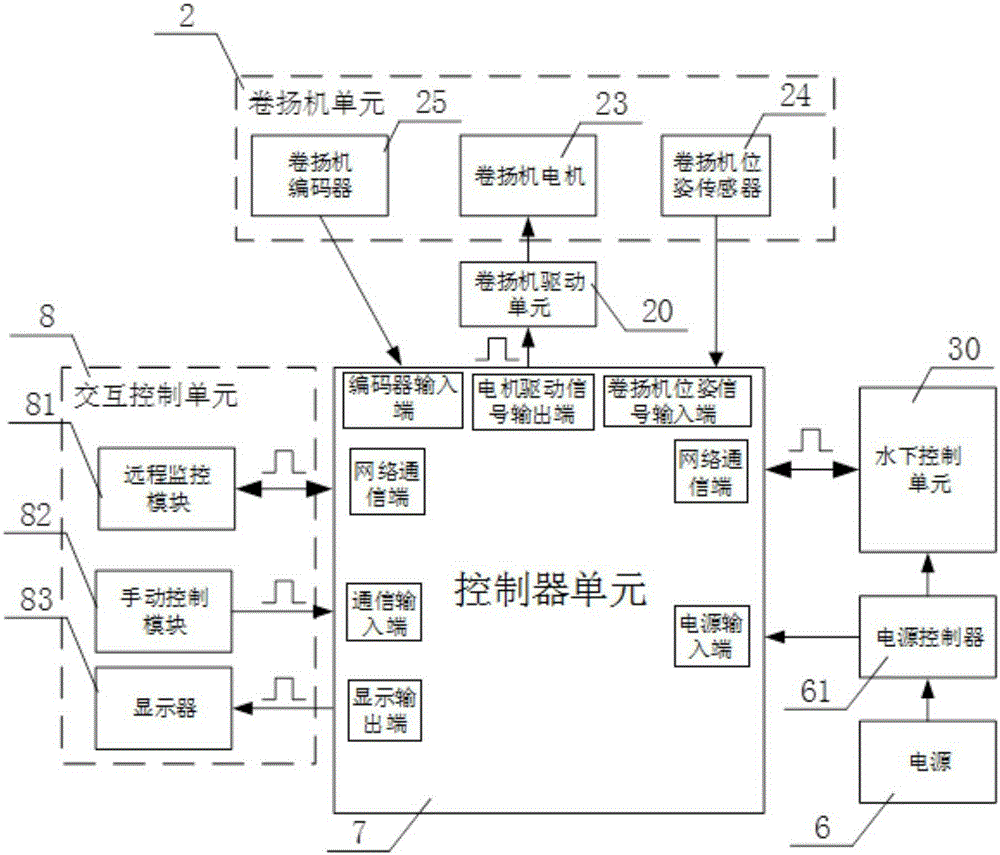

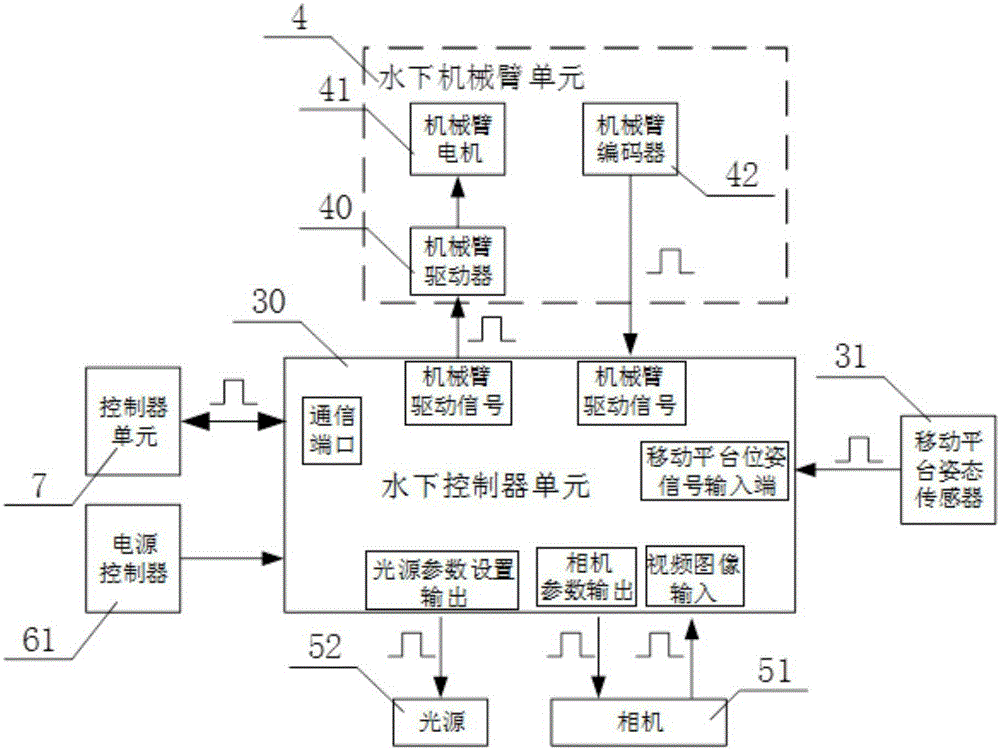

Rope-driven underwater detection robot

ActiveCN105197206AImplement mobile controlRealize visual inspectionUnderwater equipmentPropellerWinch

The invention relates to a rope-driven underwater detection robot, which can be used for visual detection on an underwater structure and comprises an above water platform, a winch unit, an underwater mobile platform, an underwater mechanical arm unit, a camera, a light source, a power supply, a controller unit and an interactive control unit, wherein a winch is connected with the mobile platform by a rope, and the rope is wound on the winch; the camera and the light source respectively sleeve one end of the underwater mechanical arm unit; an underwater control unit is fixed on the underwater mobile platform, and the underwater mechanical arm unit, the camera, the light source, a mobile platform attitude sensor and the controller unit are respectively connected with the underwater control unit. By means of rope driving, the mobile platform is controlled to do the actions of ascending and horizontal movement, and a mechanical arm adjusts the camera in a small scope; the condition that a propeller is adopted, so that a water body is more turbid and imaging detecting quality is reduced can be avoided, and thus a final detection effect can be improved, and the underwater imaging detecting sensitivity is improved.

Owner:苏州蛟视智能科技有限公司

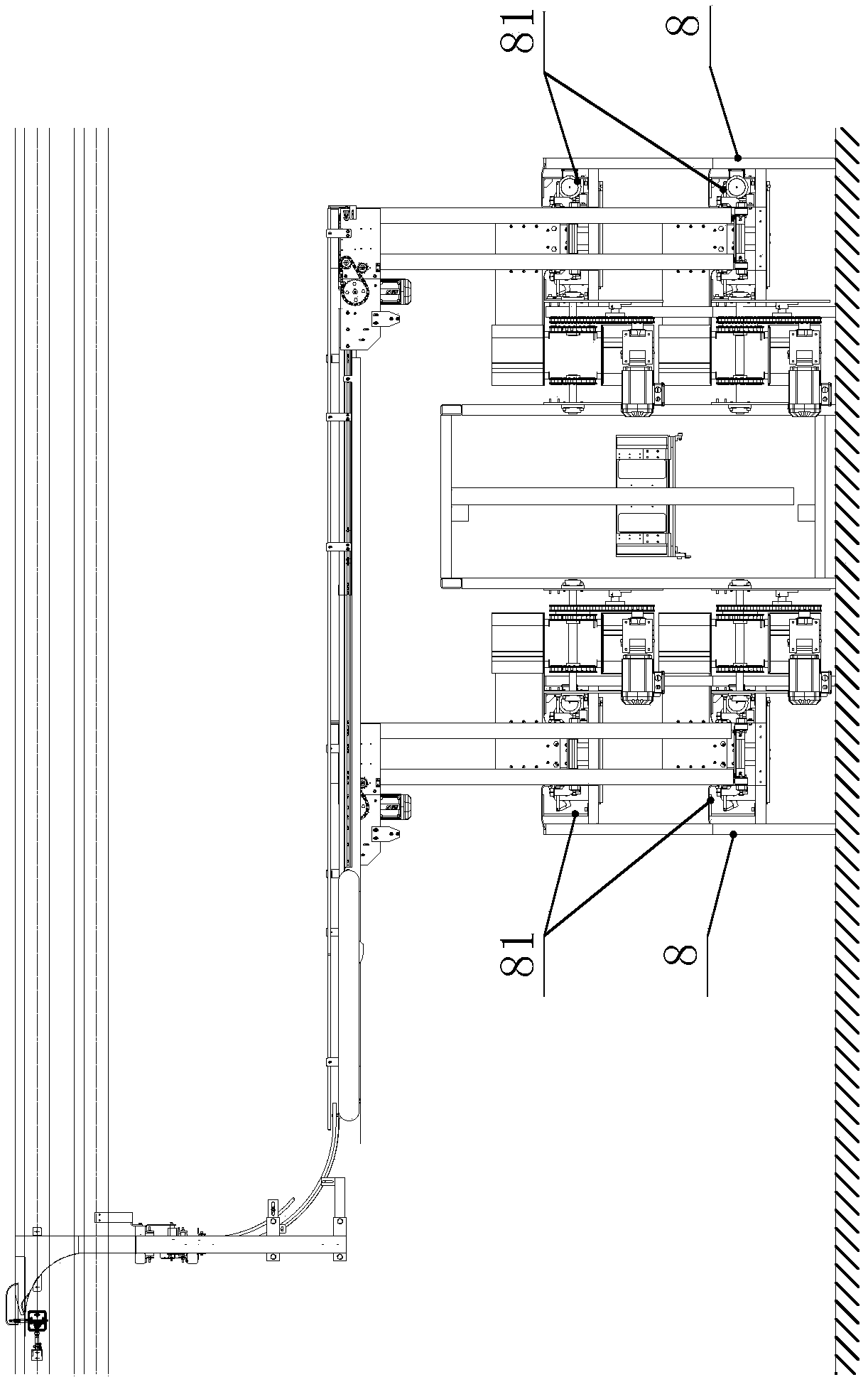

Single butt-joint boxing and sealing system and method for multiple brands of cigarettes

The invention discloses a single butt-joint boxing and sealing system and method for multiple brands of cigarettes. A cigarette lifting machine, a flat-to-vertical device and a multi-way chain plate conveyor are sequentially mounted behind multiple winding units. The multi-way chain plate conveyor is provided with a cigarette division and channel selection mechanism, and the cigarette division andchannel selection mechanism is connected with a multi-way sliding-down mechanism. Each sliding way of the multi-way sliding-down mechanism is connected with the front end of a single-way transverse conveyor. The rear end of the single-way transverse conveyor is connected with the front end of a single-way longitudinal conveyor. The rear end of the single-way longitudinal conveyor is connected toa cigarette stacking mechanism. The stacking mechanism is composed of multiple stacking devices. A cigarette stack transfer mechanism is arranged on the outer sides of the stacking devices. A cigarette stack temporary storage device is arranged between the cigarette stack transfer mechanism and the stacking mechanism. The cigarette stack transfer mechanism cooperates with a boxing and sealing machine so as to achieve final boxing of cigarettes. The function of packaging the multiple brands of cigarettes through the single boxing and sealing machine can be achieved, and the equipment efficiencyis greatly improved; and meanwhile the cigarette stack temporary storage device used when the system breaks down is arranged.

Owner:ETABONG QINGDAO TOBACCO MACHINERY

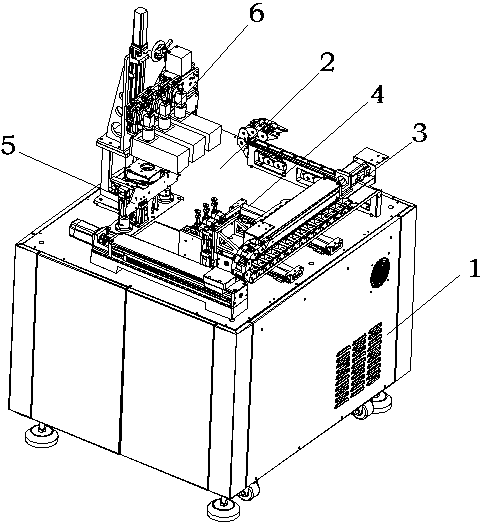

Electronic product LOGO detecting machine

ActiveCN109187562AAchieve absorptionRealize visual inspectionOptically investigating flaws/contaminationDistribution controlVisual inspection

The invention relates to an electronic product LOGO detecting machine, comprising a rack, a bottom plate, a gantry mechanism, a feeding mechanism, a positioning mechanism and a detecting mechanism, wherein a power distribution control box is arranged in the rack, the bottom plate is fixedly installed on an upper end of the rack, the feeding mechanism is fixedly installed on the upper end of the bottom plate, the gantry mechanism is arranged on a side edge of the feeding mechanism, the positioning mechanism is arranged on one side of the gantry mechanism away from the feeding mechanism, the detecting mechanism fixed on the bottom plate is correspondingly arranged above the positioning mechanism, and an overturning device is arranged on the gantry mechanism; the invention aims at providingthe electronic product LOGO detecting machine, the suction and overturning of a LOGO are achieved by adding the overturning device on the gantry mechanism, the visual inspection on the other surface of the LOGO is further achieved by the cooperation of the positioning mechanism and the detecting mechanism, and the problems that the traditional machine platform is difficult to achieve double-faceddetection and that the universality is low are solved.

Owner:王爱平

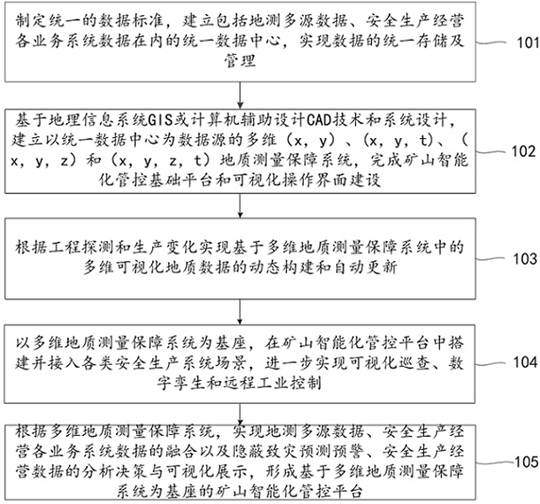

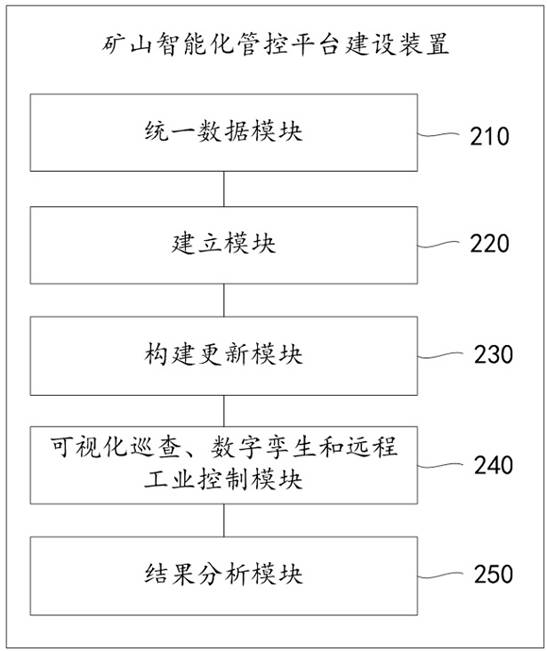

Mine intelligent management and control platform construction method based on geological survey guarantee system

ActiveCN114611180ARealize managementIntuitive implementation of daily managementGeometric CADData processing applicationsData centerGeological survey

Owner:BEIZHING LONGRUAN TEKNOLODZHIS INK

Precise dispensing information processing method and system

ActiveCN112950604ARealize visual inspectionImprove dispensing qualityLiquid surface applicatorsImage analysisInformation processingEngineering

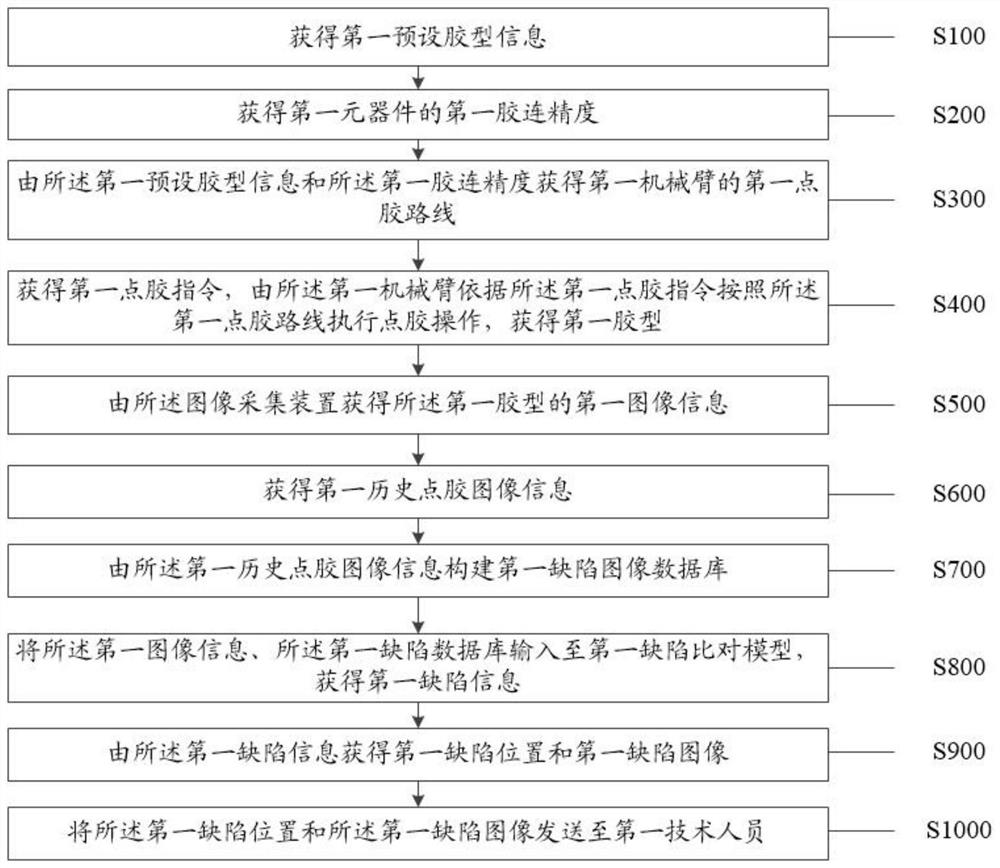

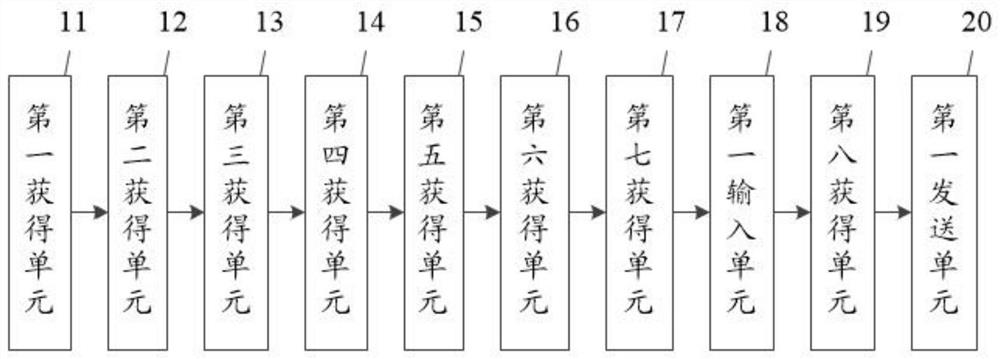

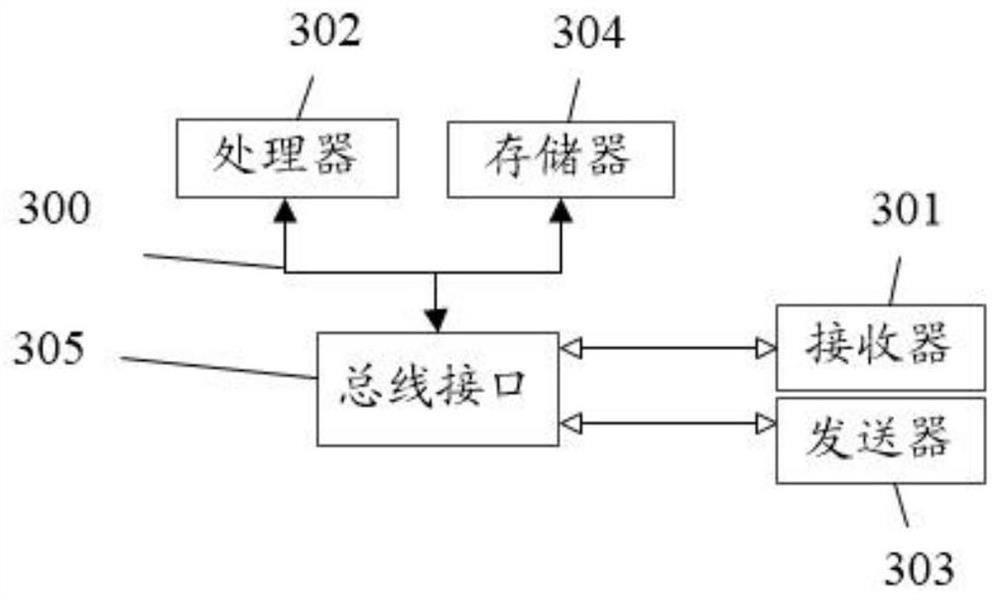

The invention discloses an information processing method and system for precise dispensing, and the method comprises the steps: obtaining first preset glue type information; obtaining the first glue connection precision of the first component; obtaining a first dispensing route of a first mechanical arm according to the first preset glue type information and the first glue connection precision; the first mechanical arm executing dispensing operation according to the first dispensing route, and a first glue type being obtained; obtaining first image information of the first glue type; constructing a first defect image database according to the historical dispensing image information; inputting the first image information and the first defect database into a first defect comparison model to obtain first defect information; and obtaining a first defect position and a first defect image according to the first defect information, and sending the first defect position and the first defect image to a first technician. The technical problems that in the prior art, the intelligent control degree of the dispensing precision is not enough, and defect analysis cannot be conducted in real time are solved.

Owner:SHENZHEN XINLUYUAN ELECTRONICS EQUIP CO LTD

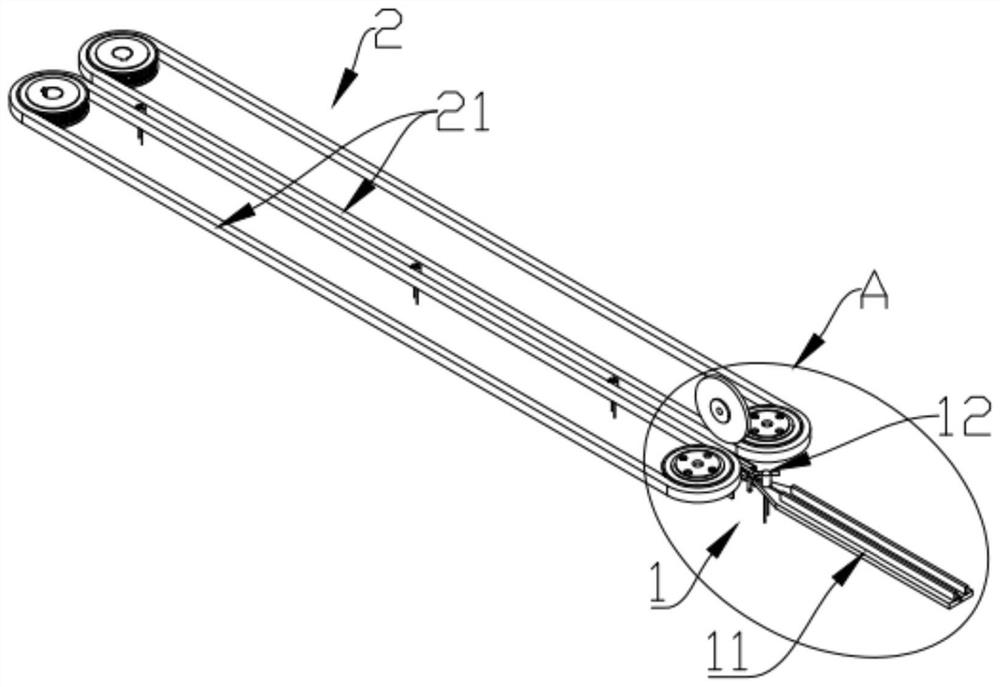

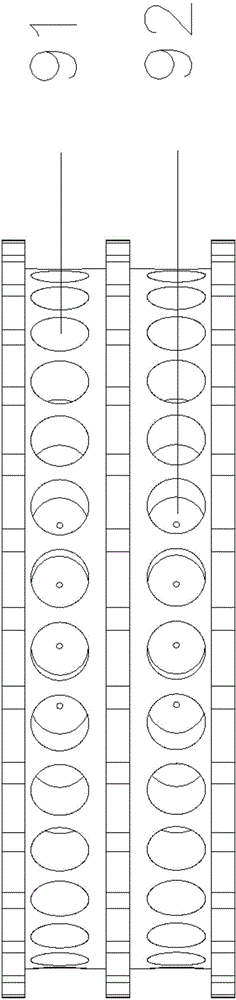

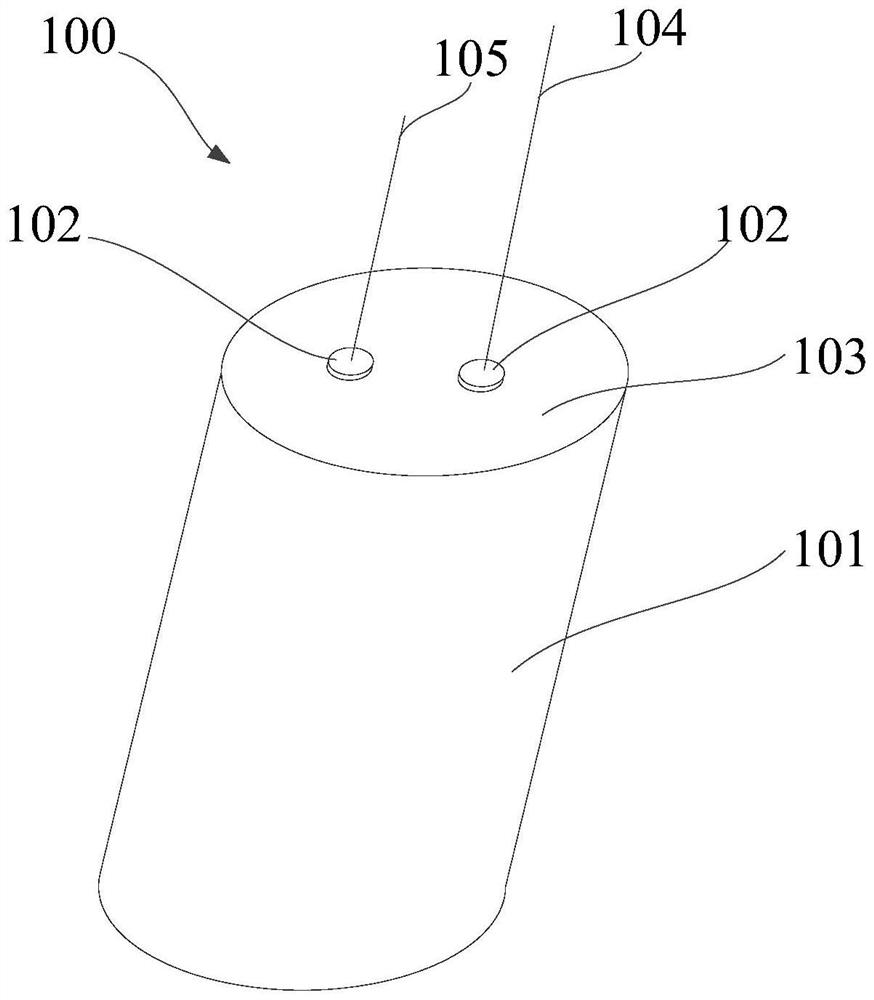

Arrangement device for capacitor with pins and detection equipment with arrangement device

The invention discloses an arrangement device for a capacitor with pins. The device comprises a feeding arrangement device and a detection clamping device. The detection clamping device comprises two clamping conveying belts which are oppositely arranged and synchronously move, the conveying surfaces of the two clamping conveying belts are oppositely arranged, and the distance between the two conveying surfaces adapts to a capacitor main body; the two conveying surfaces clamp the capacitor from two sides of the capacitor main body and convey the capacitor forwards; and the feeding arrangement device is arranged at the feeding end of the detection clamping device. According to the arrangement device for the capacitor with the pins, clamping and synchronous conveying of the capacitor are achieved through the detection clamping device, image extraction of all detection positions is completed in the clamping and forward conveying process of the capacitor, appearance detection is achieved, and in other words, at the moment when image extraction is conducted on the capacitor, the capacitor and the image extraction device are relatively static or fixed, the posture of the capacitor is controllable, the imaging position is controllable, the extracted image is reliable, and the appearance detection of the capacitor is accurate and reliable.

Owner:苏州科亿信息科技有限公司

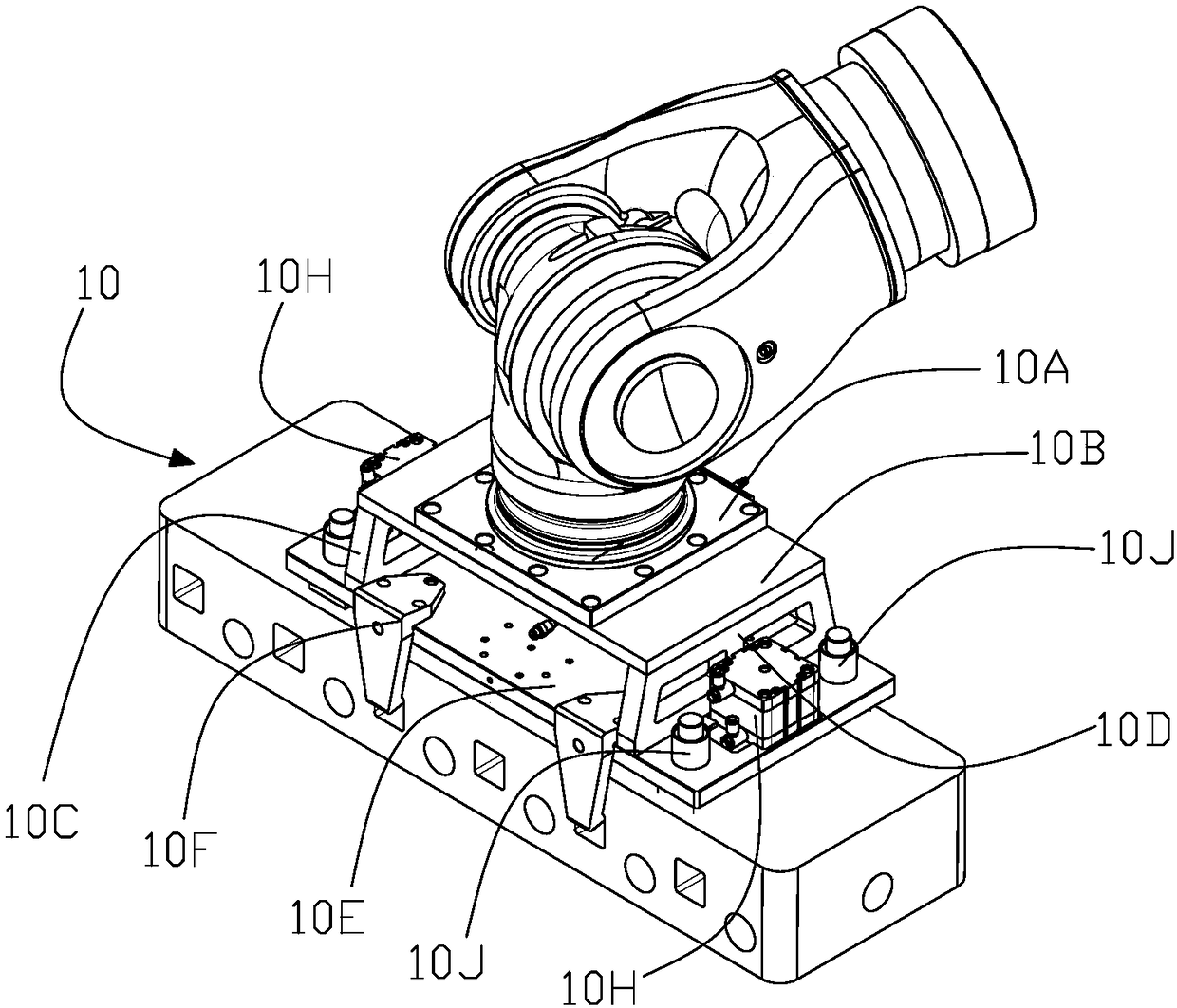

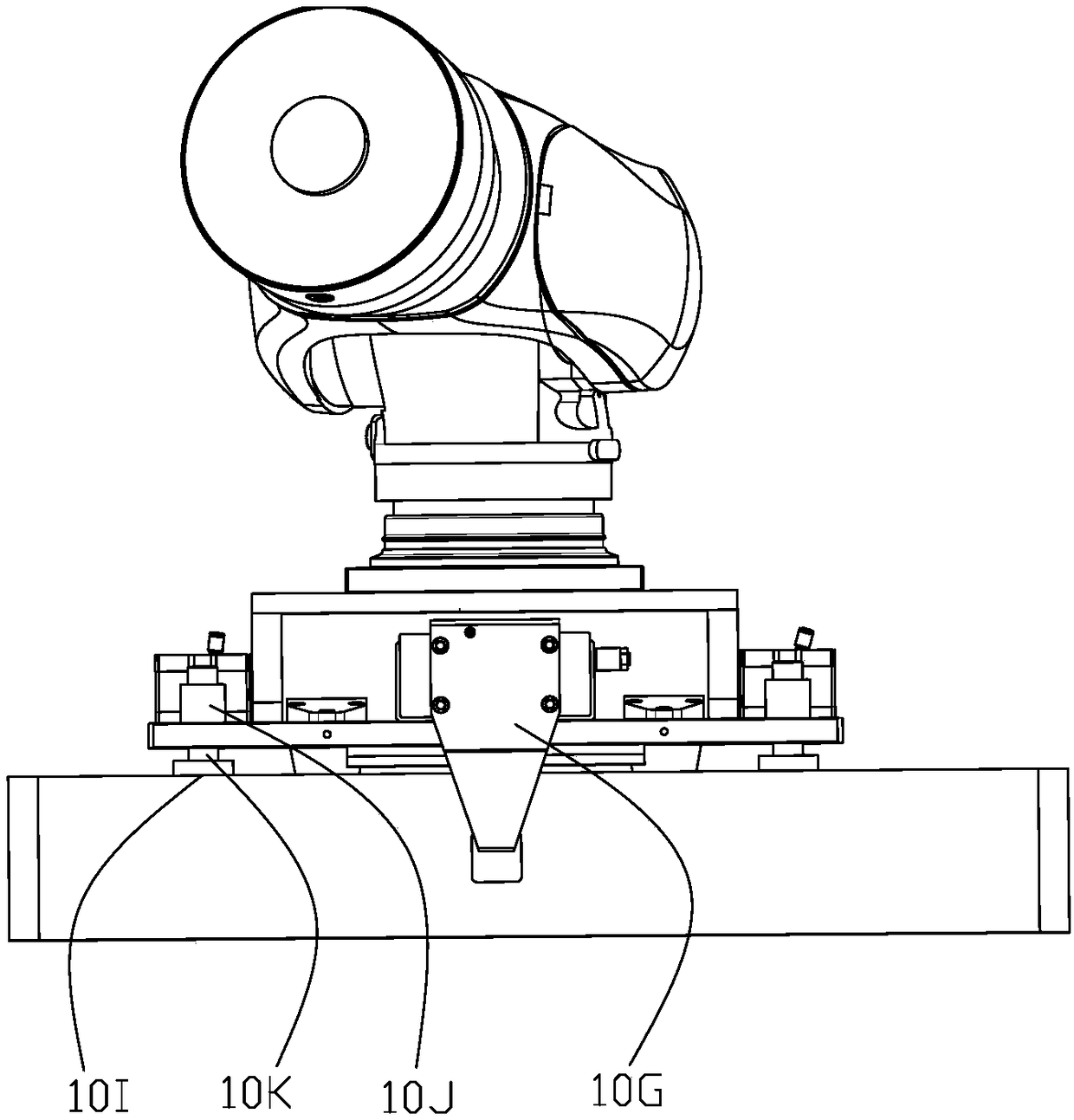

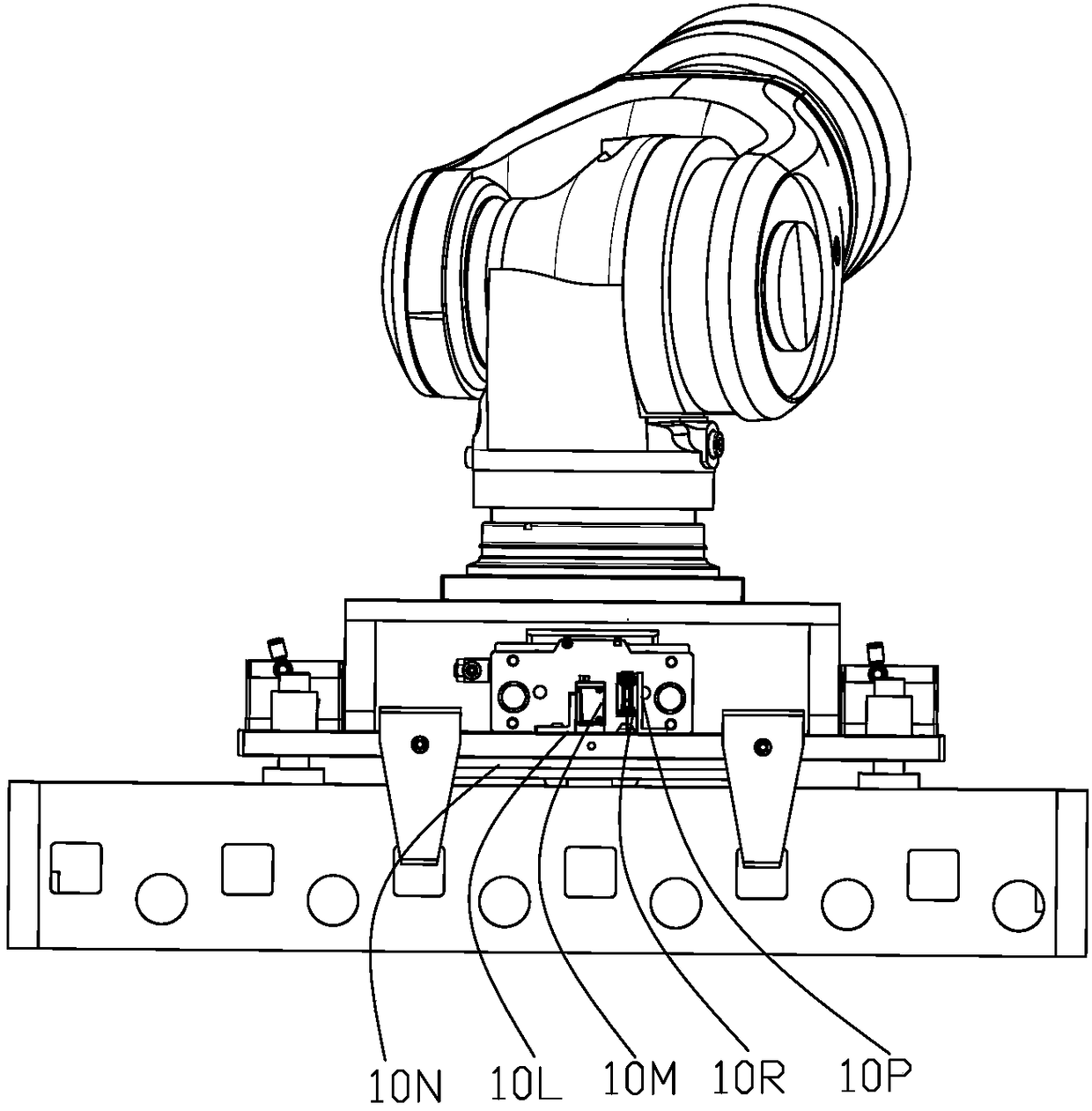

Vision-guided engine cylinder head unstacking and detecting robot

InactiveCN108544470ARealize visual inspectionSolve shakingProgramme-controlled manipulatorOptically investigating flaws/contaminationCylinder headEngineering

The invention relates to a vision-guided engine cylinder head unstacking and detecting robot which comprises a robot mounting flange mechanism, a clamping mechanism, a push-on mechanism, a vision positioning system and a signal detection system, wherein the signal detection system calculates the distance of the vision-guided engine cylinder head unstacked to the engine cylinder head, the visual positioning system finds the position of the to-be-carried engine cylinder head and detects the appearance, a joint robot drives the vision-guided engine cylinder head unstacked to a grapping position and guides the clamping mechanism to clamp the engine cylinder head and the push-on mechanism to push the engine cylinder head on so as to carry the engine cylinder head to an appointed position. The robot clamps the engine cylinder head firmly, overcomes the problem that the engine cylinder head shakes in the carrying process, and avoids manual operations and improves the work efficiency effectively.

Owner:无锡黎曼机器人科技有限公司

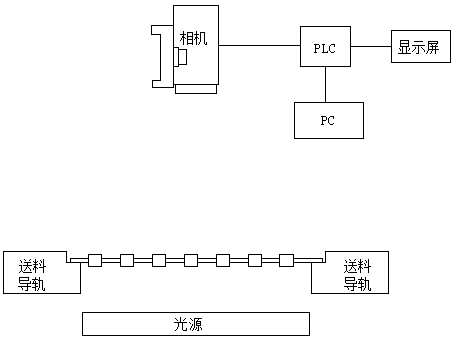

Visual identification device for type of integrated circuit punching system and identification method and application

InactiveCN109158325ARealize visual inspectionSortingProgrammable logic controllerControl engineering

The invention discloses a visual identification device for types of integrated circuit punching systems and an identification method and application. The visual identification device comprises conveying guide tracks, wherein a visual imaging system is distributed in a vertical direction between the conveying guide tracks; the visual imaging system is in signal connection with a display screen through a PLC (Programmable Logic Controller); the PLC is in signal connection with a manipulator. The visual identification device has the beneficial effects that through linkage of the visual imaging system and the PLC, displacement holes, lead frame sizes and pin numbers of lead frame products on the conveying guide tracks are detected, when the three parameters meet requirements, the result showsthat a lead frame is a type meeting requirements, the lead frame is fed to a next operation station by using the conveying guide tracks, if one parameter does not meet the requirements, the result shows that the lead frame is not a type meeting the requirements or the product self has defects, then the lead frame is placed into an unqualified product box, visual detection on varieties and appearances of lead frames is achieved, and lead frames of different types can be classified according to the method, thus being convenient and rapid.

Owner:TONGLING SANJIA YAMADA TECH

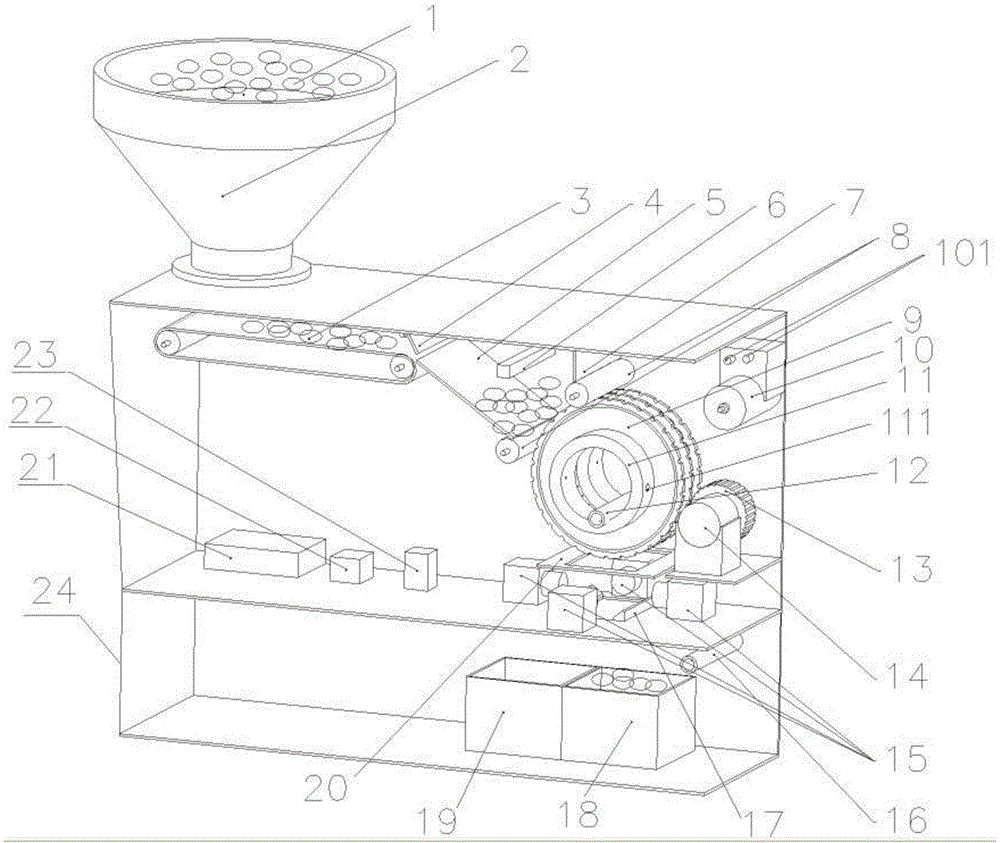

360-degree non-contact type automatic vision detector

PendingCN104655640AEasy to useImprove efficiencyOptically investigating flaws/contaminationLight sourceEngineering

The invention discloses a 360-degree non-contact type automatic vision detector. The 360-degree non-contact type automatic vision detector comprises a charge hopper, a box body, a conveying belt, a material gate, an industrial control machine, a PLC, a light source controller and a removing and air blowing pipe, wherein a baffle I is arranged behind the material gate; a horizontal level sensor is arranged on the baffle I; a baffle II is arranged behind the horizontal level sensor; a roller is arranged behind the baffle II and another roller is arranged at the tail end of the baffle I; a wheel disc is arranged below the right part of the roller; each wheel disc is provided with a bayonet which is internally provided with a small ventilation hole; a vacuum pump is arranged right above each wheel disc; the middle of each wheel disc is provided with a wheel disc shaft; the middle of each wheel disc shaft is provided with a spraying and air blowing pipe; a wheel disc driving wheel is arranged below the right part of each wheel disc; a wheel disc driving motor is arranged in front of the wheel disc driving wheel; a position sensor is arranged below each wheel disc driving wheel; a light source is arranged below each position sensor; industrial cameras are around the periphery of the light source. With the 360-degree non-contact type automatic vision detector, the vision detection efficiency for the material appearance can be improved, and 360-degree dead-angle-free ominibearing full-automatic vision detection is realized.

Owner:天津中新华兴光电技术有限公司

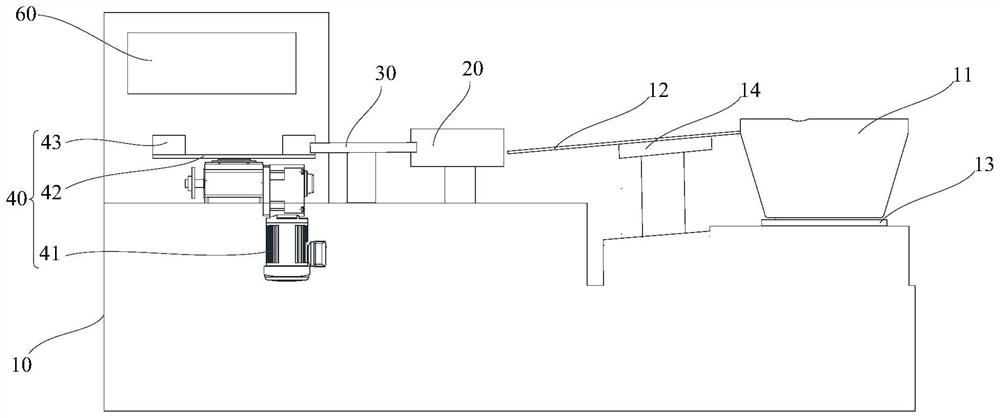

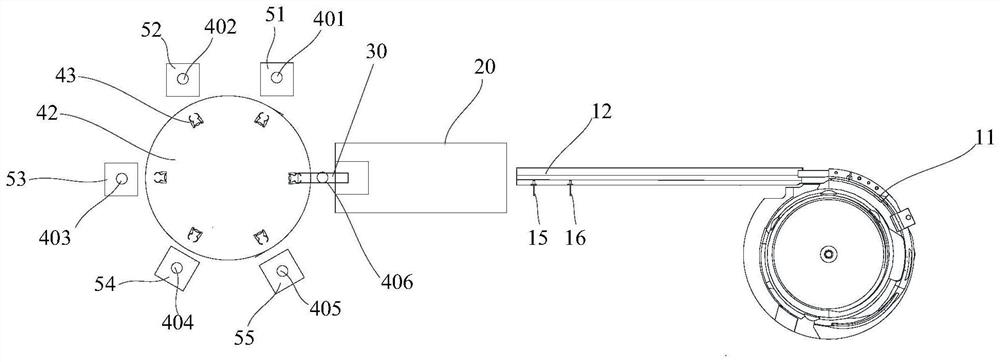

Capacitor appearance detection device and method based on artificial intelligence technology

PendingCN112083002AReduce difficultyGood resolutionOptically investigating flaws/contaminationSortingCapacitance meterArtificial neuronal network

The invention discloses a capacitor appearance detection device and method based on artificial intelligence technology. The lower part of a first combined frame is provided with an electric control box, and the upper surface of the electric control box is provided with a feeding module, a rotary table and a discharging module in sequence along the capacitor transfer direction; a feeding vibrationdisc is installed on the upper surface of a second combined frame, and a discharging port of the feeding vibration disc is located below the feeding end of the feeding module; an unqualified product discharging belt line feeding end and a qualified product discharging belt line feeding end are arranged below the discharging end of the discharging module; a vertical image collector is arranged above the rotary table, and a horizontal image collector is arranged in the horizontal direction; and a detection capacitor is placed on the rotary table through the feeding module, a high-definition image of the surface of the capacitor is transmitted to an upper computer through the image collector, whether defects exist or not is judged through the artificial neural network, sorting is conducted, and detection is completed. The automation level of the capacitance detection device is improved, and the detection precision is enhanced in combination with the artificial intelligence technology.

Owner:SUZHOU CASIA ALL PHASE INTELLIGENCE TECH CO LTD

Garbage environmental protection intelligent separation and nutrient soil conversion system

ActiveCN111169860AAvoid discomfortQuality improvementSolid waste disposalWaste collection and transferEnvironmental resource managementEnvironmental engineering

The invention provides a garbage environmental protection intelligent separation and nutrient soil conversion system. A recycling method of the garbage environmental protection intelligent separationand nutrient soil conversion system comprises the steps that a code is scanned to register on an intelligent garbage recycling system cabinet; a bound mobile phone number is input or a card is swipedfor user identification; an intelligent garbage recycling system identifies an user according to information of the mobile phone number or the card, and confirms that the user is an ordinary user, a recycler, a maintainer or a non-registered user; and when the user is judged to be the ordinary user, a first recycling button pops up on a touch panel, when the first recycling button is pressed, a material inlet port door of the intelligent garbage recycling system is opened, the user puts a garbage bag into a material inlet port, after internal weighing equipment detects that the garbage bag isput in, the material inlet port door is closed, and the intelligent garbage recycling system carries on recycling processing to garbage, and displays garbage information on the touch panel. Accordingto the garbage environmental protection intelligent separation and nutrient soil conversion system, the automation degree is high, the garbage recycling efficiency is high, and the effect is good.

Owner:XINCHANG BENYE AGRI MACHINERY CO LTD

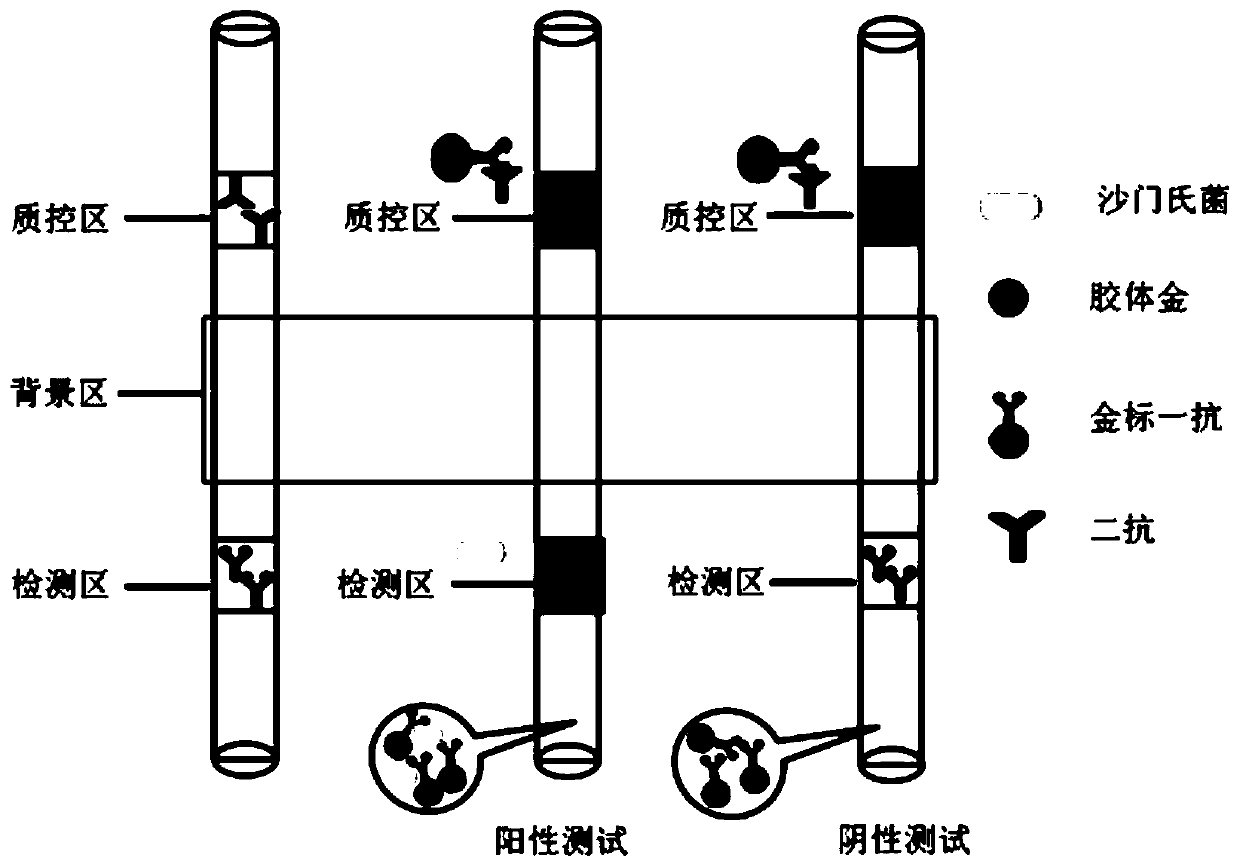

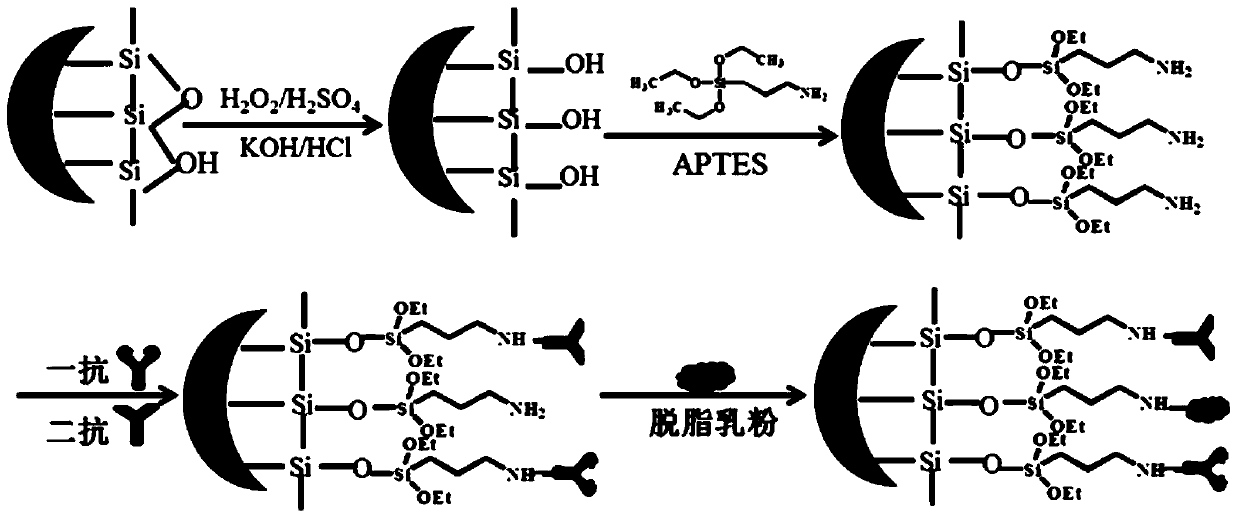

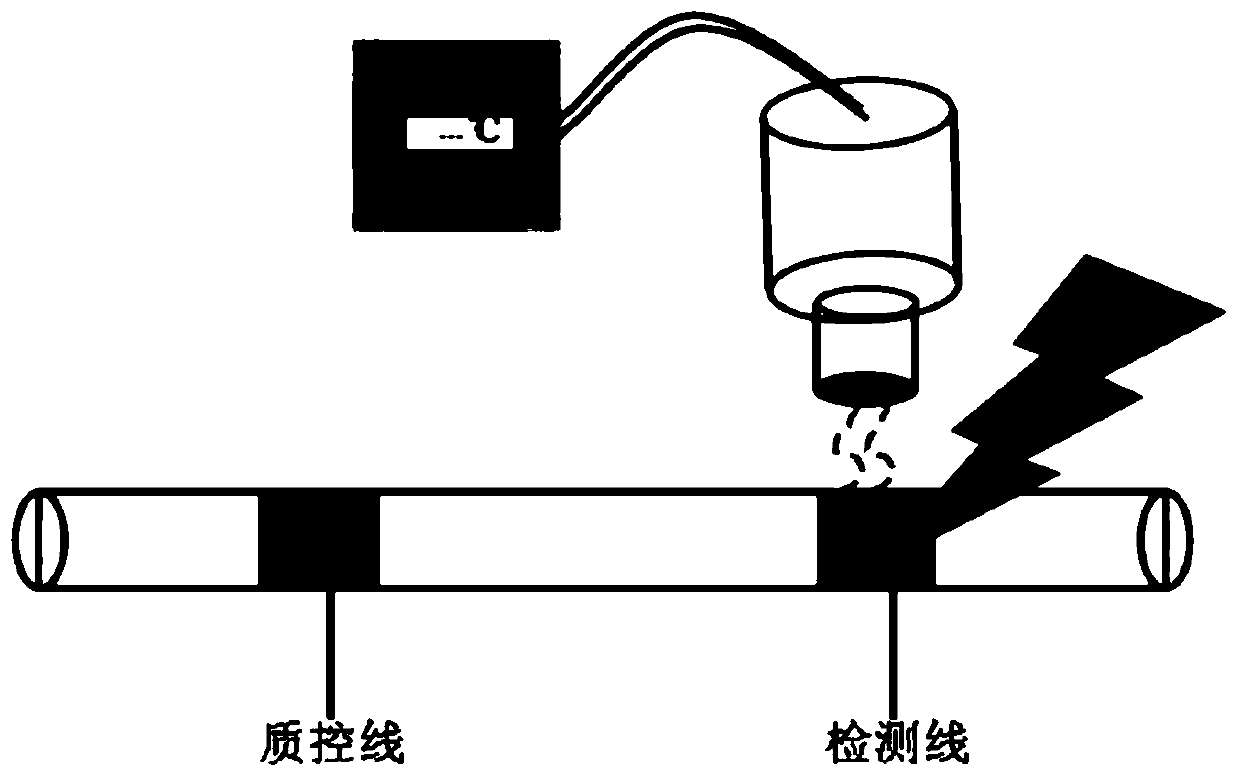

Immunochromatographic capillary based on colloidal gold photothermal effect and application thereof

ActiveCN110361532AExcellent light-to-heat conversion performanceRealize visual inspectionMaterial analysisAgainst vector-borne diseasesTemperature resistanceSalmonella immunization

The invention provides an immunochromatographic capillary based on the colloidal gold photothermal effect and application thereof. A glass capillary is used as a carrier, the colloidal gold is used asa tracer and a capillary immunochromatographic method for the detection of Salmonella based on the colloidal gold photothermal effect is developed according to the sandwich principle of double antibodies. According to the method, the glass is used as the solid phase carrier and has high temperature resistance and high ionic strength and is more stable and is not liable to break or influenced by the outside world and is cheap and easy to obtain. The colloidal gold is used as the tracer to construct the immunochromatographic capillary, and the visual detection of salmonella in the sample can bequickly realized. Meanwhile, the temperature change value is obtained by laser irradiation by using the excellent photothermal conversion performance of the colloidal gold, and the quantitative and sensitive detection of Salmonella is realized by using the immunochromatographic capillary so as to have good practical application value.

Owner:SHANDONG NORMAL UNIV

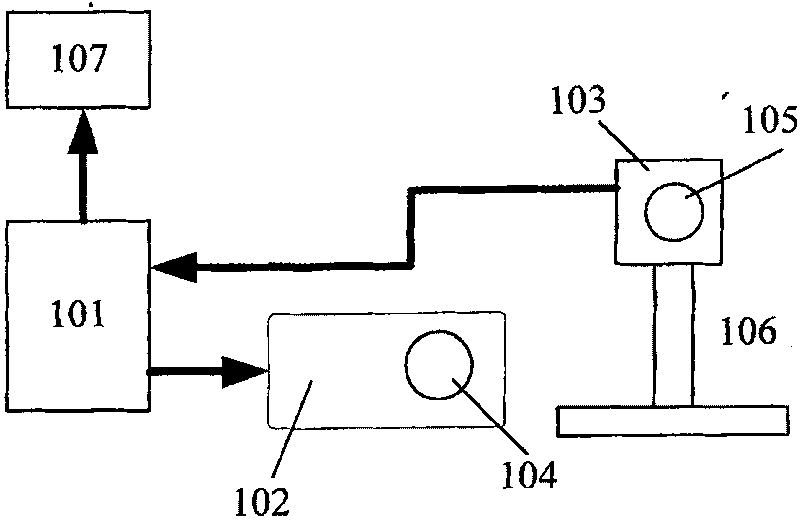

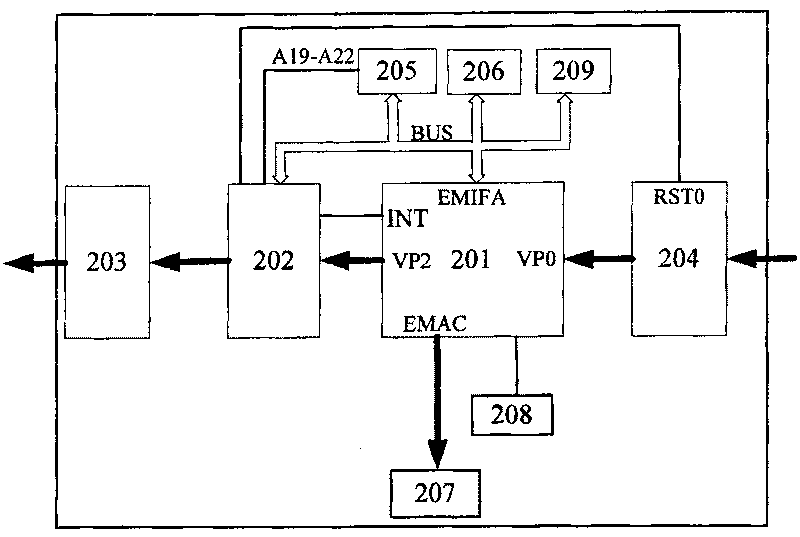

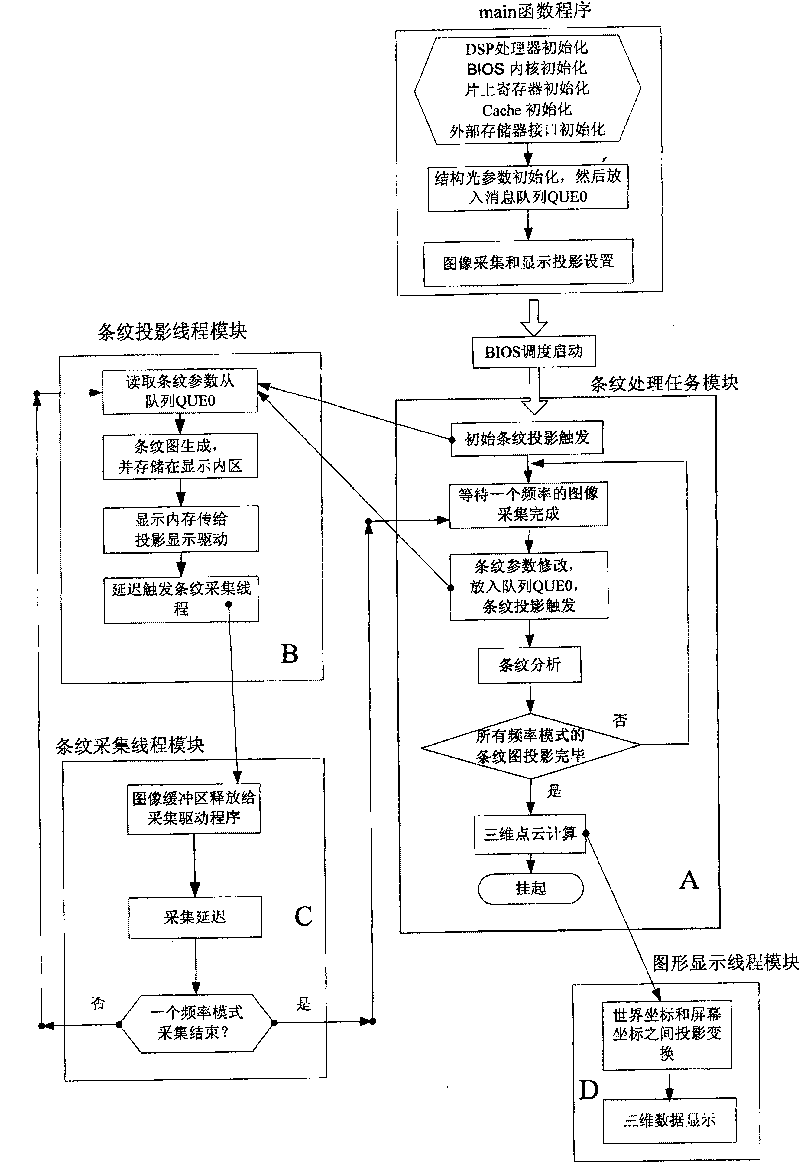

Built-in three-dimension digital imaging device and its method

InactiveCN101127923BFast multiresolutionRapid multi-resolution 3D digital imagingSteroscopic systems3D modellingDigital signal processingCMOS sensor

Owner:SHENZHEN UNIV

Device for detecting seal of plastic bottle

InactiveCN107255639ARealize multi-angle shootingRealize visual inspectionOptically investigating flaws/contaminationDrive motorEngineering

The invention discloses a device for detecting seal of a plastic bottle; the device comprises a skirt support portion at the lower end, a middle connection portion and a detection portion at the upper end; the detection portion comprises a circular top plate fixed to the upper end of a connection plate; a circular receiving groove is formed in the inner circular sidewall of the circular top plate, an L-shaped camera support is inserted into the circular receiving groove, the camera support includes a horizontal portion and a vertical portion, the horizontal portion is inserted into the circular receiving groove, the inner wall of the circular receiving groove is provided with a circular toothed ring, a driving motor is fixed to the horizontal portion, a spindle of the driving motor is sleeved with a gear, the gear meshes with the toothed ring, and an industrial camera and a lamp are fixed to the vertical portion; the camera support is abutted to a vertical limiting retainer, another limiting retainer is fixed to a piston rod of a limiting cylinder, and a sensor is arranged on the circular top plate above the camera support. The device herein is capable of taking multi-angle photos around a drink bottle, so that missing of inferior sealing of drink bottles is avoided.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Automatic equipment and method for capacitor appearance detection

PendingCN114739309ARealize visual inspectionLabor savingUsing optical meansFluid-tightness measurement using lightComputer hardwareCapacitance

The invention provides an automatic device and method for capacitor appearance detection, and relates to the field of capacitor production. The automatic equipment for capacitor appearance detection comprises a first feeding module, a correction module, a second feeding module, a rotary workbench, a first acquisition module, a second acquisition module, a third acquisition module, a first collection box, a second collection box and a control module. An image of a cover plate of a capacitor is collected through a first collection module, an image of a through hole of the cover plate is collected through a second collection module, an image of an aluminum shell of the capacitor is collected through a third collection module, and a control module judges whether the capacitor is qualified or not according to the images collected by the first collection module, the second collection module and the third collection module. The automatic detection of the capacitor appearance is realized, the labor is reduced, and the detection efficiency is improved.

Owner:ZHONGTIAN SUPERCAPACITOR TECH CO LTD +1

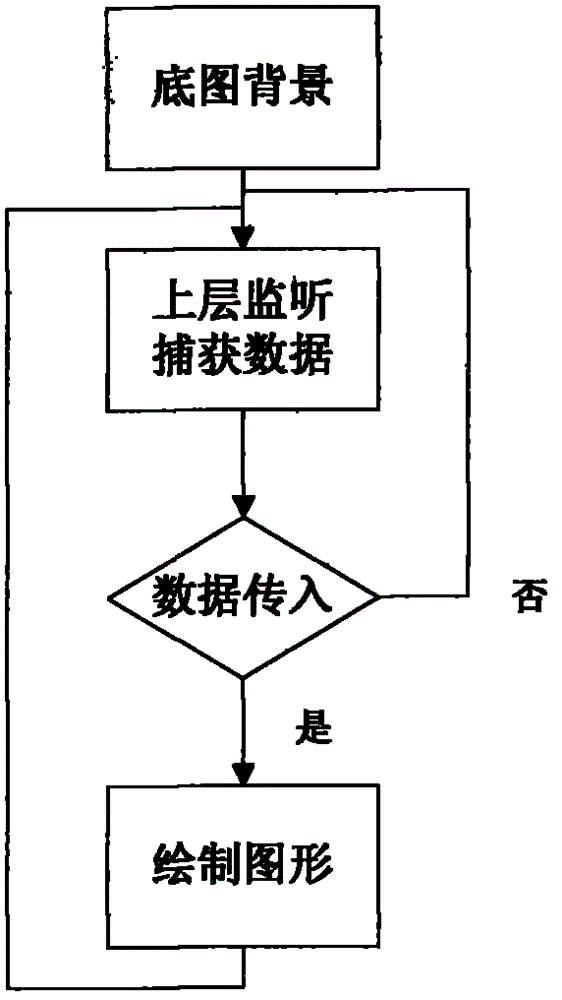

Display method for simulating motion of tidal volume respiration air box of anesthesia machine

The invention provides a display method for simulating motion of a tidal volume respiration air box of an anesthesia machine. The display method includes the steps that 1, canvas is used for drawing a background in an Android display interface system, and a simulation air box background base map is prepared; 2, the system receives and monitors data transmitted from the bottom layer of the anesthesia machine; 3, the data is compiled into a relevant array, and surfaceview is used for simulating a dynamic effect; 4, when a patient inhales, surfaceview is used for carrying out drawing starting from a left peak, and the length of a drawn graph is changed accordingly along with the change of the value of the inspiratory tidal volume; 5, when the patient exhales, surfaceview is used for carrying out drawing starting from a right peak, and the length of the drawn graph is correspondingly changed along with the change of the value of the exhaling tidal volume.

Owner:BEIJING AEROSPACE CHANGFENG CO LTD

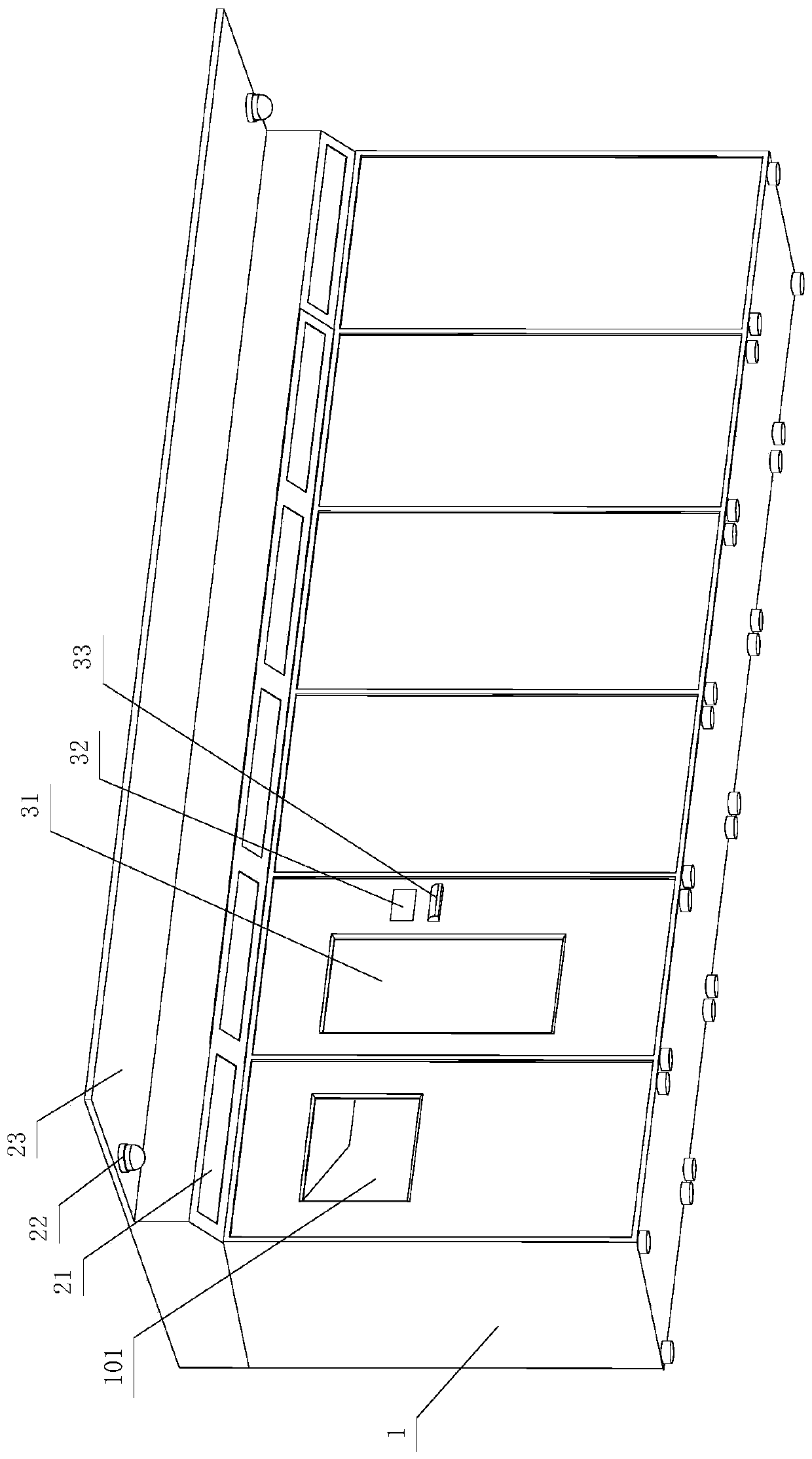

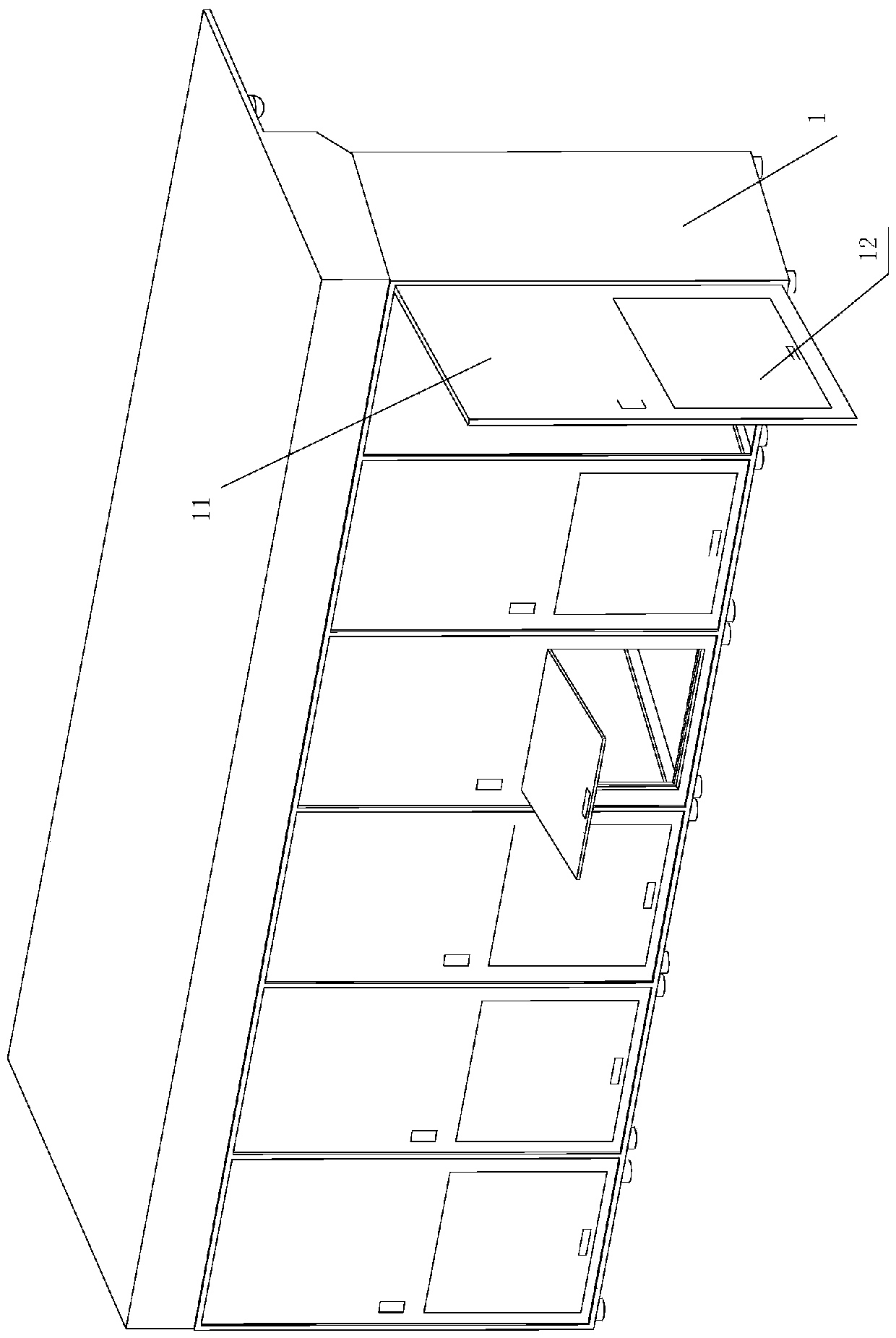

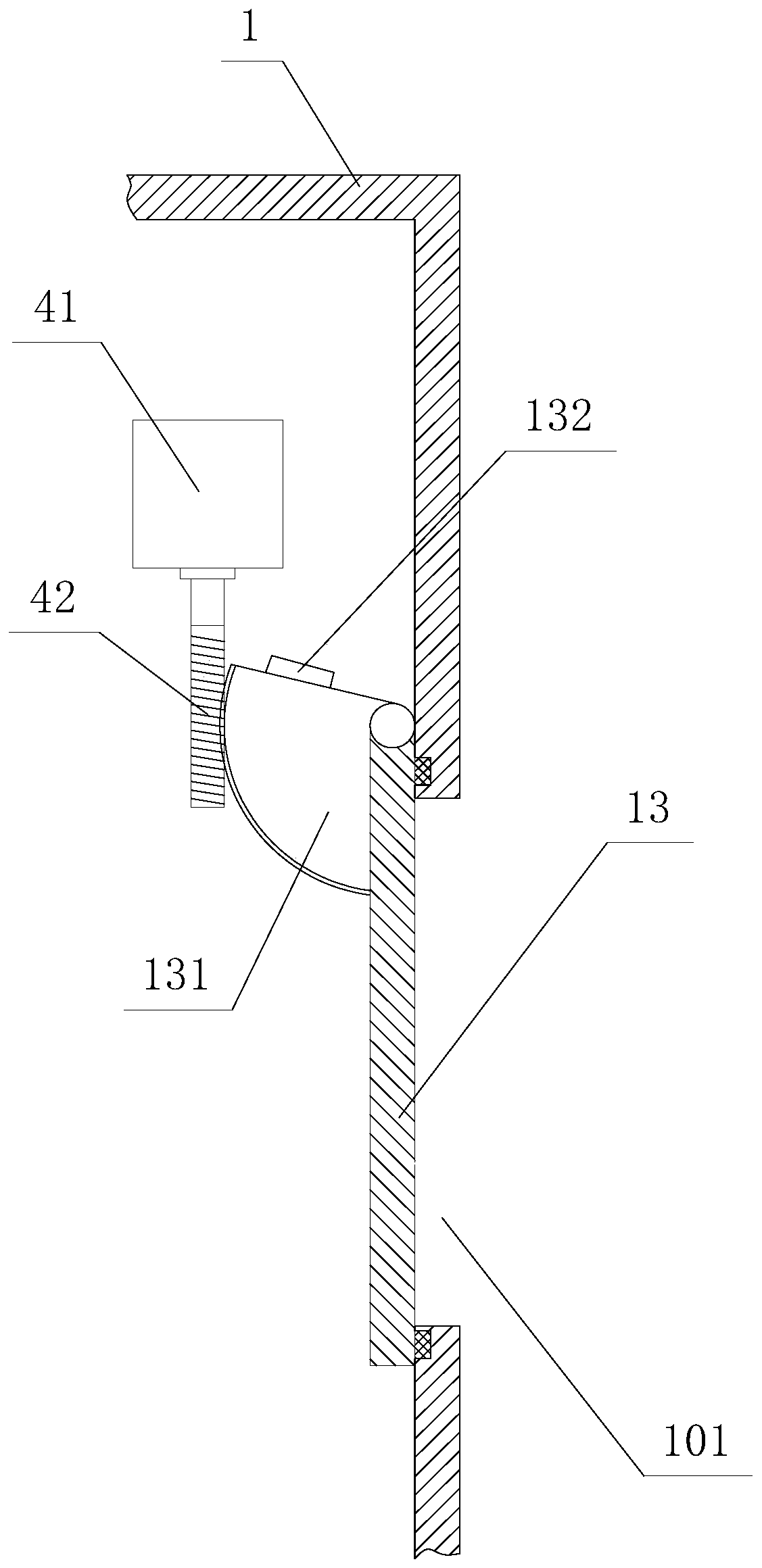

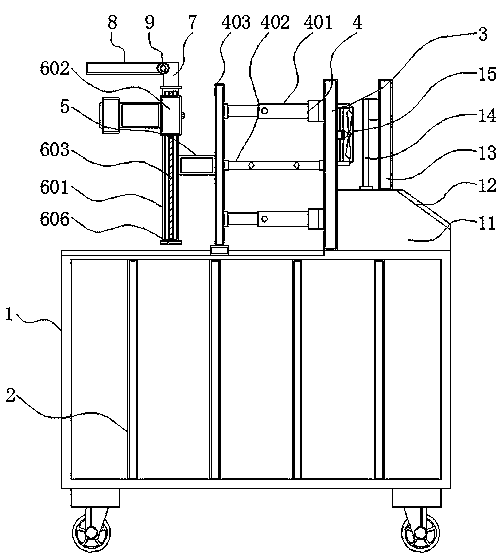

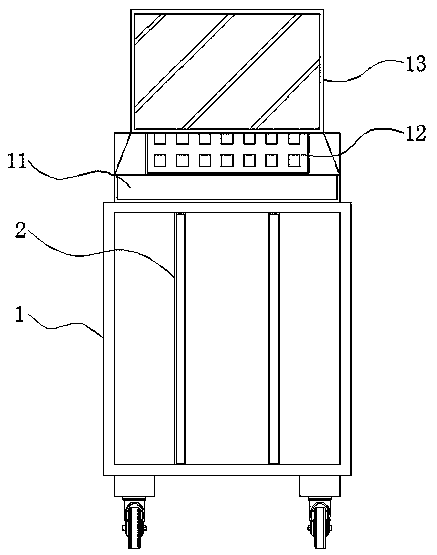

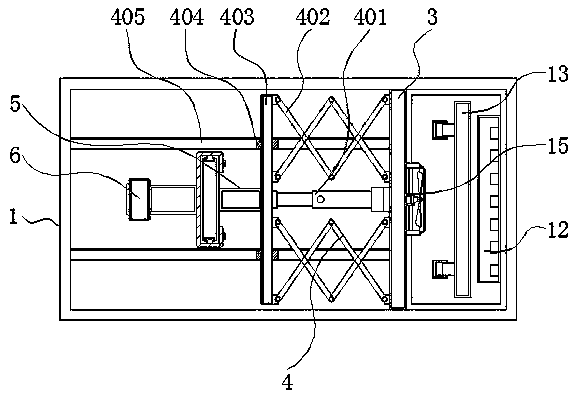

Visual inspection equipment with double-limiting structure

InactiveCN110907452AEasy to moveLimited telescoping rangeMaterial analysis by optical meansVisual inspectionStructural engineering

The invention discloses visual inspection equipment with a double-limiting structure, and relates to the technical field of visual inspection. The equipment comprises a machine body, an image acquisition mechanism, a light supplementing mechanism and a display screen. A reinforcing plate is fixed on the outer side of the machine body. A fixed plate is mounted on one side of the upper part of the machine body. A telescopic adjusting structure is mounted on one side of the fixed plate. A connecting rod is fixed to one side of the telescopic adjusting structure. The image acquisition mechanism ismounted on one side of the connecting rod. A connecting plate is arranged above the connecting rod. A light supplementing plate is mounted on one side of the connecting plate. A hinge is arranged between the light supplementing plate and the connecting plate. The light supplementing mechanism is mounted below the light supplementing plate. The equipment has the advantages that by arranging the telescopic adjusting structure, telescopic adjustment of the position of the image acquisition mechanism is facilitated, and by arranging the electric push rod, movement of the push plate is facilitated, so that adjustment of the position of the image acquisition mechanism is facilitated.

Owner:DONGGUAN UNIV OF TECH

Battery discharging mechanism

InactiveCN105692156ARealize visual inspectionReduce workloadConveyor partsElectrical batteryEngineering

A battery discharging mechanism comprises a conveying device and an arranging device. The conveying device comprises a conveying frame, a conveying belt is arranged on the conveying frame, a gear conveying belt is fixedly arranged on the front side of the conveying belt, a containing flat plate is arranged on the rear side of the conveying belt, and the conveying frame is provided with a supporting rod for supporting the containing flat plate. A clamping plate capable of descending and ascending is arranged between the containing flat plate and the gear conveying belt. The arranging device comprises a mechanical arm and a containing box. The mechanical arm is arranged on one side of the containing flat plate and picks up and transfers batteries on the containing flat plate, and the containing box is arranged at the tail end of the conveying belt. According to the battery discharging mechanism, the appearance of the discharged batteries can be detected only by one worker, the batteries can be contained as well, the workload of the worker is low, time and labor are saved, convenience and rapidness are achieved, and a very good using effect is achieved.

Owner:JIANGSU YONGCHANG NEW ENERGY TECH

Machine room equipment operation visual management system and method and storage medium

PendingCN113590417AConducive to macro-controlRealize visual inspectionRelational databasesHardware monitoringEngineeringManagement system

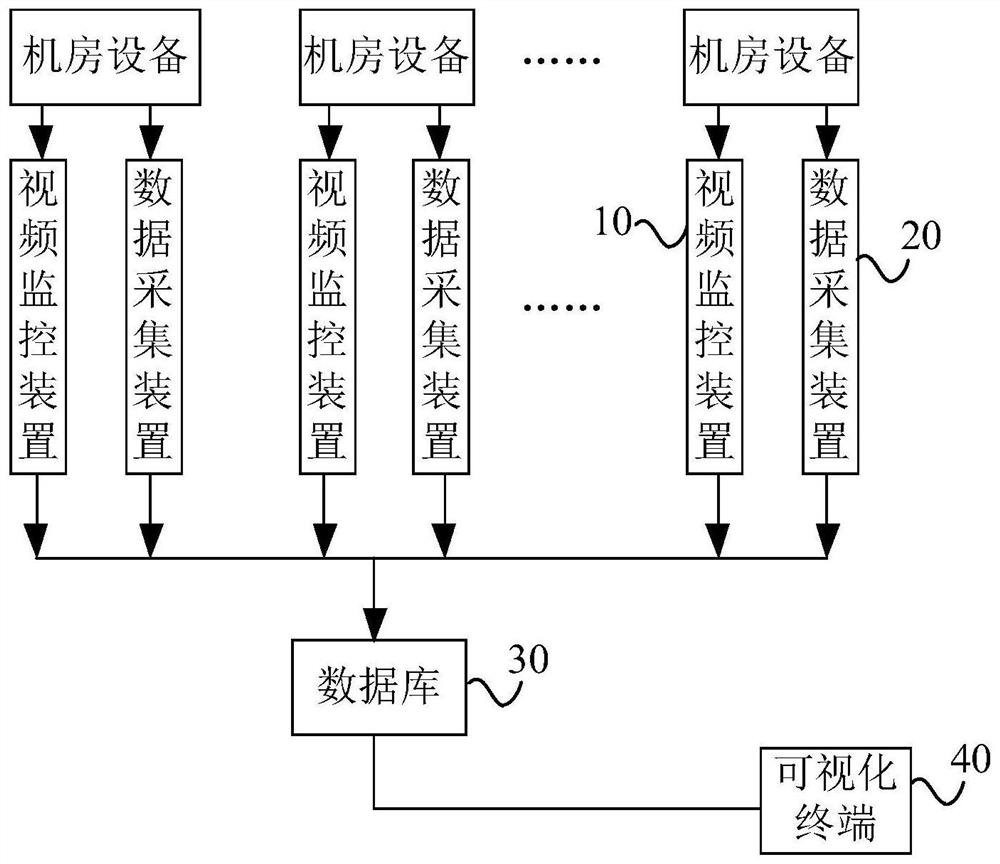

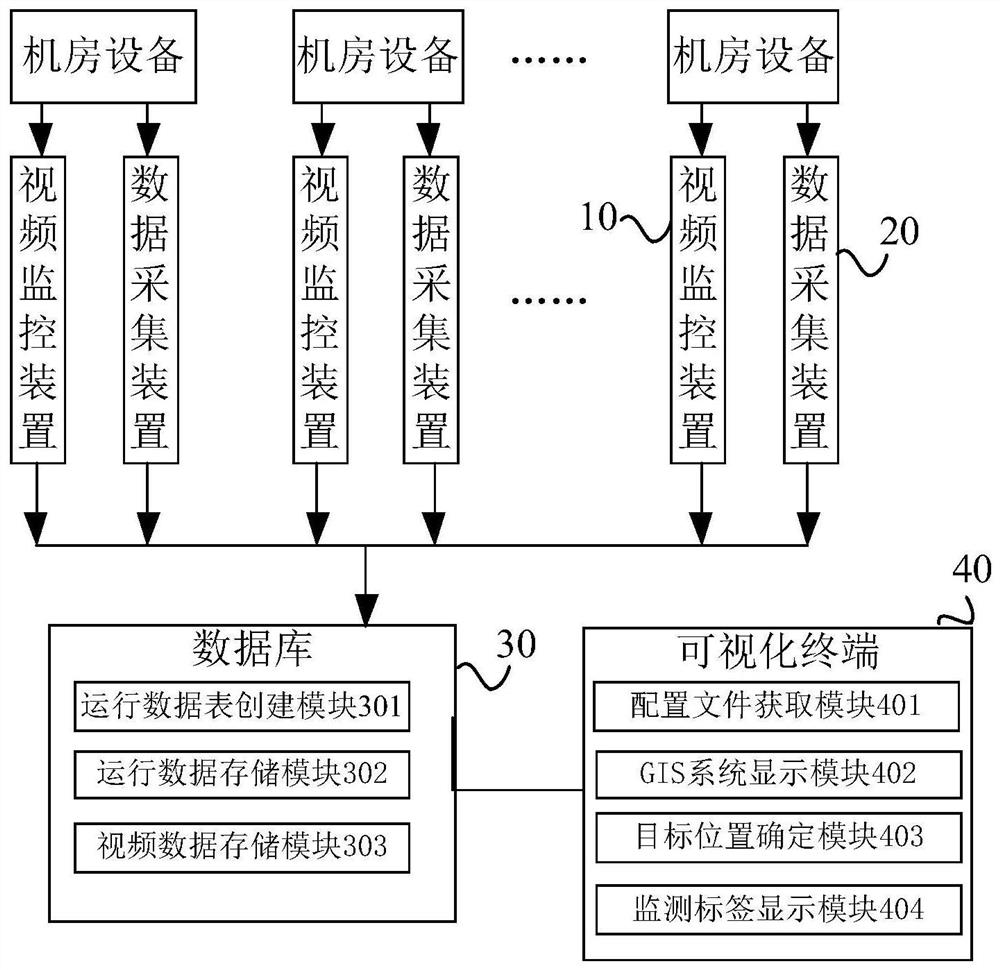

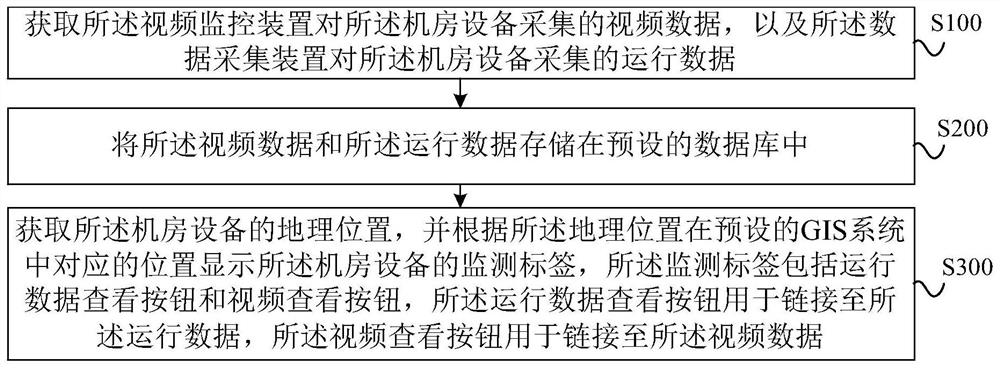

The embodiment of the invention discloses a machine room equipment operation visual management system and method and a storage medium, and in the machine room equipment operation visual management system, a video monitoring device is used for collecting video data of machine room equipment; a data acquisition device is used for acquiring operation data of machine room equipment; a database is used for storing video data and operation data; a visual terminal is used for acquiring the geographic position of the machine room equipment and displaying a monitoring label of the machine room equipment at a corresponding position in a preset GIS system according to the geographic position, and the monitoring label comprises an operation data viewing button and a video viewing button; and the operation environment in the machine room and the operation data of the equipment in the machine room can be monitored in real time through the video monitoring device and the data acquisition device, the operation environment and the operation data in the equipment in the machine room can be visually checked through the monitoring label in the GIS system, a dispatcher can also conveniently and visually know the position of the equipment in the machine room, and macroscopic regulation and control by regional dispatching personnel are facilitated.

Owner:GUANGDONG POWER GRID CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com