Precise dispensing information processing method and system

An information processing method and dispensing technology, applied in the field of information processing, can solve the problem of insufficient intelligent control of dispensing accuracy, and achieve the effect of improving dispensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

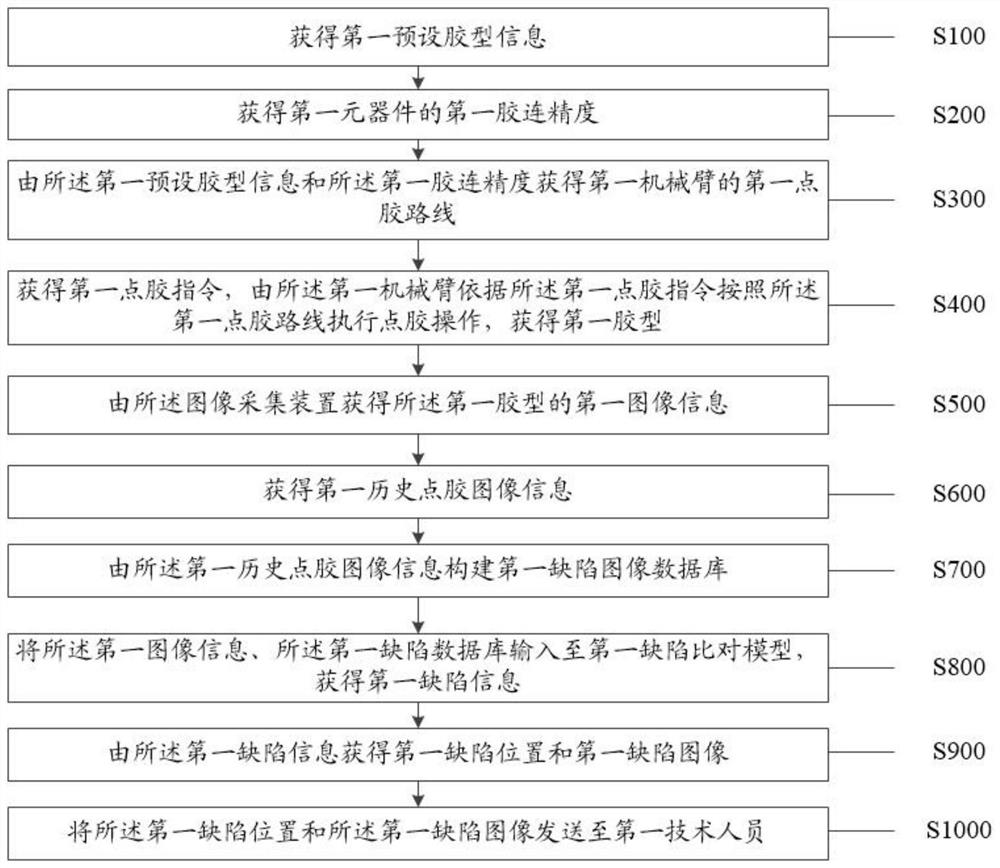

[0025] Such as figure 1 As shown, the embodiment of the present application provides an information processing method for precision dispensing, wherein the method is applied to a precision dispensing control system, and the first precision dispensing control system has a built-in image acquisition device, and the Methods include:

[0026] Step S100: obtaining the first preset glue type information;

[0027] Specifically, the precision dispensing machine is an automatic machine that controls the fluid, drips and coats the fluid on the surface of the product or inside the product. It can realize three-dimensional and four-dimensional path dispensing, precise positioning, and precise glue control. The glue dispenser is mainly used for accurate pointing, injecting, coating, and dripping of glue, paint and other liquids in the product process to the precise position of each product, and can be used to achieve dots, lines, circles or arcs. The first preset glue type information is...

Embodiment 2

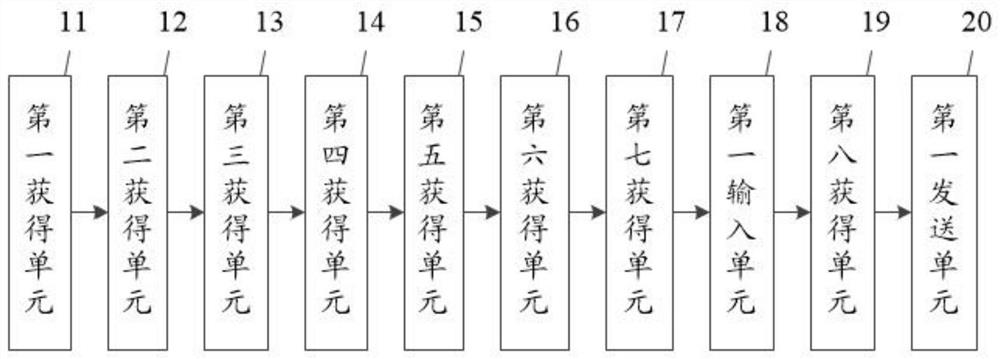

[0085] Based on the same inventive concept as the information processing method for precise dispensing in the foregoing embodiments, the present invention also provides an information processing system for precise dispensing, such as figure 2 As shown, the system includes:

[0086] A first obtaining unit 11, the first obtaining unit 11 is used to obtain the first preset glue type information;

[0087] A second obtaining unit 12, the second obtaining unit 12 is used to obtain the first glue connection accuracy of the first component;

[0088] A third obtaining unit 13, the third obtaining unit 13 is used to obtain the first dispensing route of the first mechanical arm from the first preset glue type information and the first glue connection accuracy;

[0089] A fourth obtaining unit 14, the fourth obtaining unit 14 is used to obtain a first dispensing instruction, and the first robotic arm executes a dispensing operation according to the first dispensing route according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com