Automatic enameled wire conveyor line based on visual inspection system

A visual inspection and enameled wire technology, applied in the direction of conveyor objects, packaging, packaging machines, etc., can solve the problems of affecting production efficiency, time-consuming and labor-consuming enameled wire packaging, etc., and achieve the effect of compact structure, easy promotion and use, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

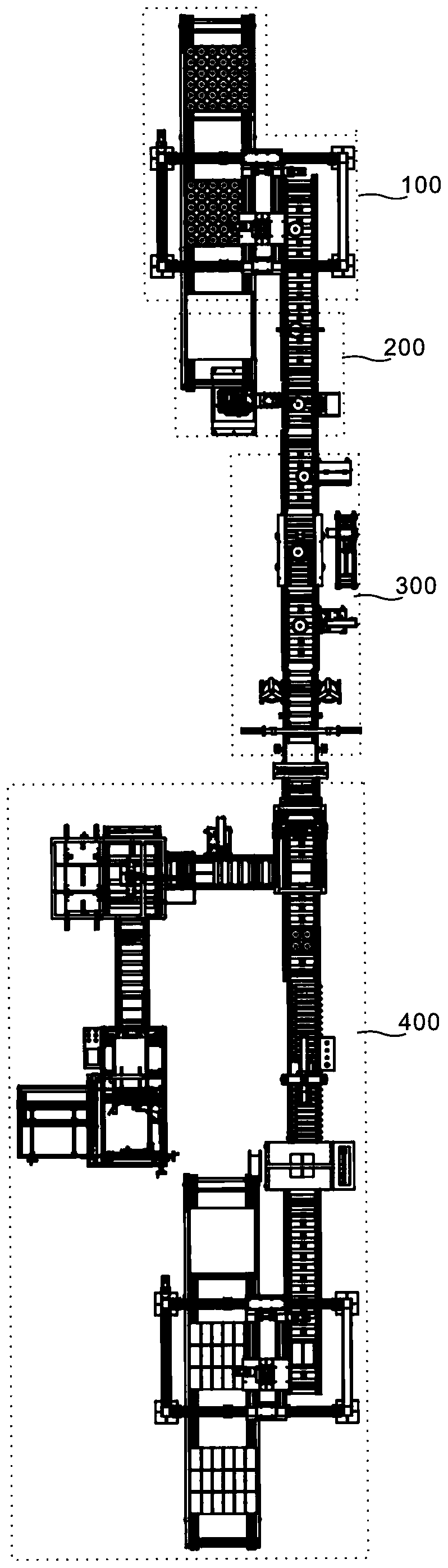

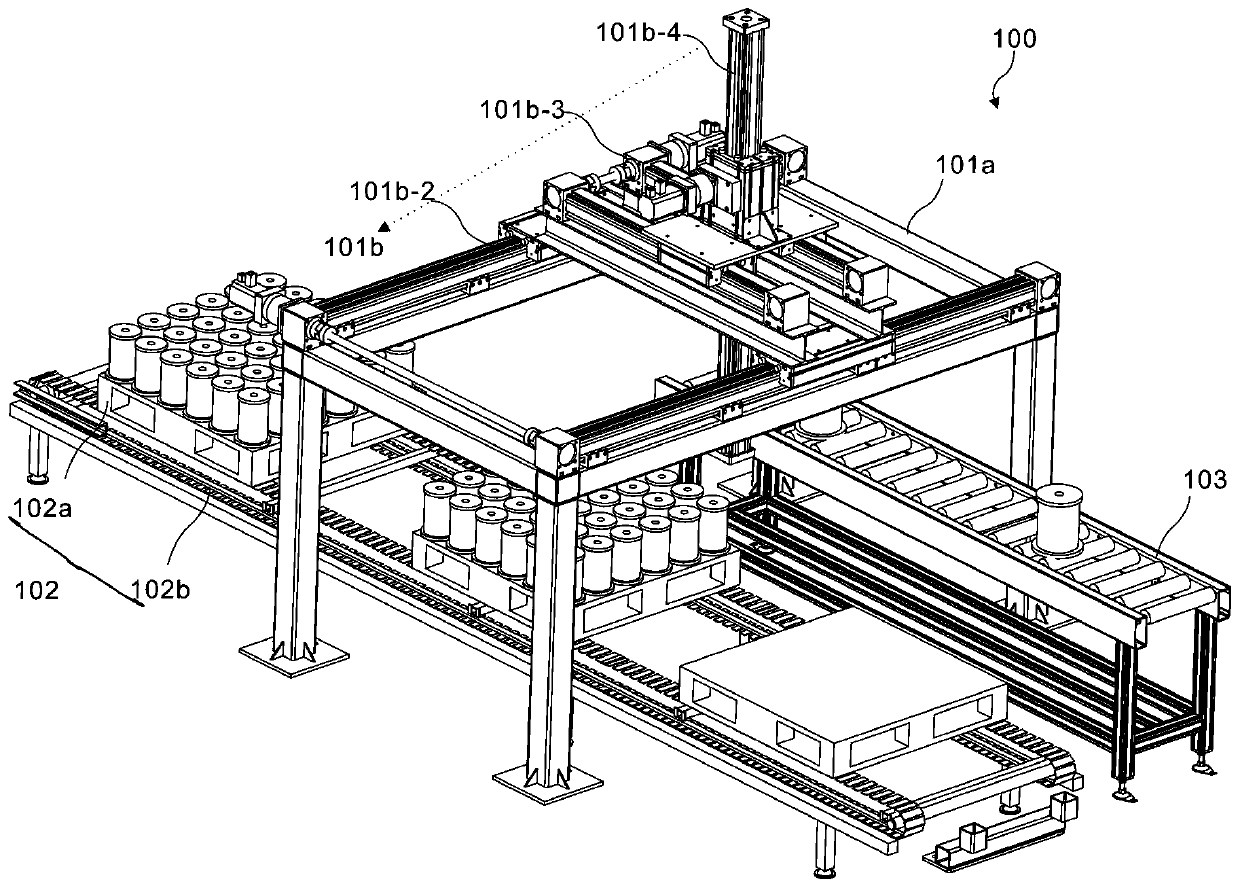

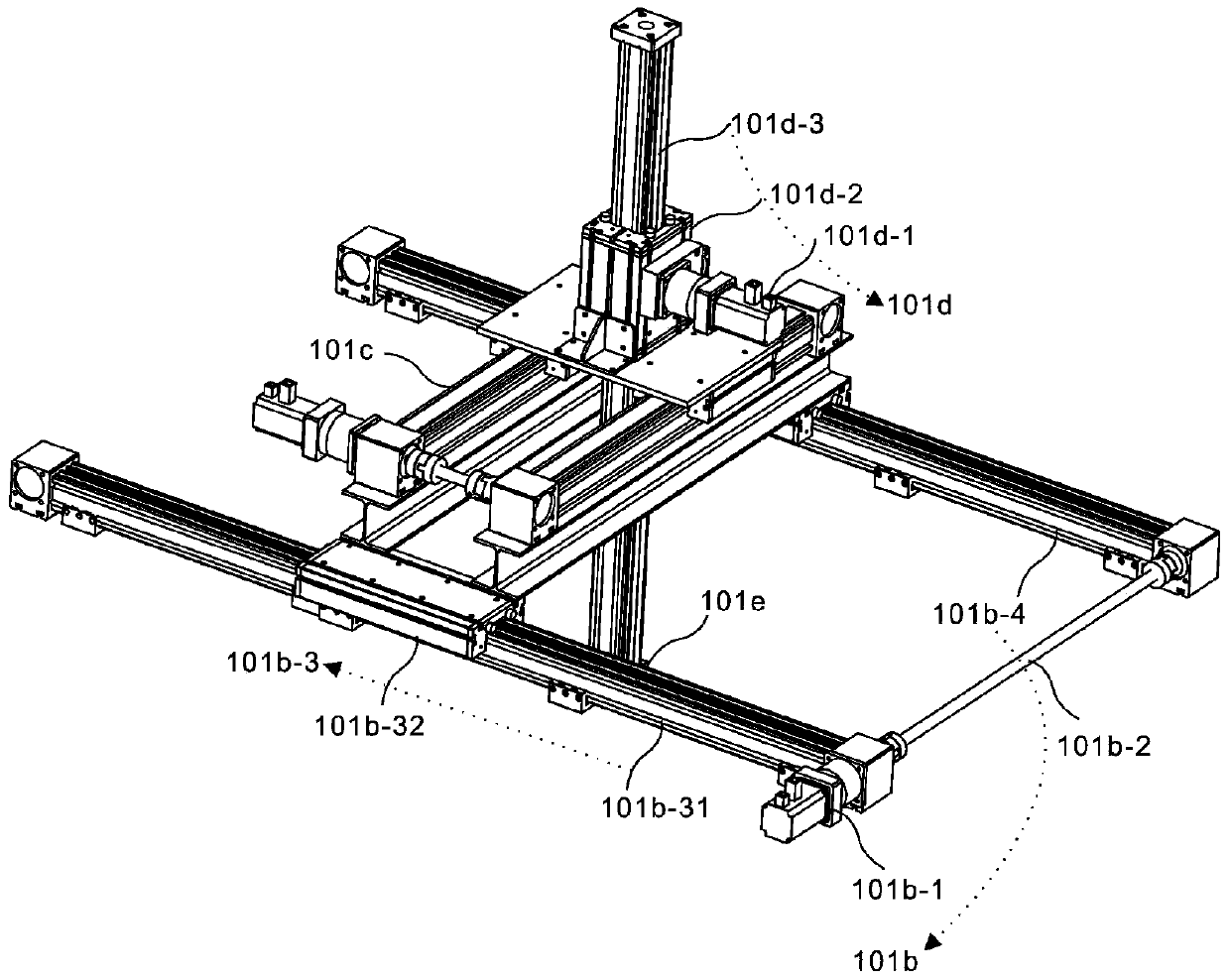

[0059] refer to figure 1 , provides a schematic diagram of the overall structure of an automated enameled wire conveying line based on a visual inspection system, such as figure 1 , an automated enameled wire conveying line based on a visual inspection system includes a handling unit 100, including a first handling assembly 101 and a first transfer assembly 102 and a first conveyor 103 arranged inside the first transfer assembly 101, the first transfer assembly 102 It is arranged on the first conveyor 103; the detection unit 200 includes a visual inspection assembly 203 arranged on the first conveyor 103, a quality inspection assembly 202 located at one end of the first conveyor 103, and is arranged on the first conveyor 103; The packaging unit 300 is connected to the quality inspection component 202 ; and the packing unit 400 is arranged at one end of the pre-packaging unit 300 .

[0060] Specifically, the main structure of the present invention includes a handling unit 100,...

Embodiment 2

[0064] refer to Figure 4 , This embodiment is different from the first embodiment in that the detection unit 200 includes a sorting component 201, a quality inspection component 202, a visual inspection component 203 and a sorting box 204, and the sorting component 201, the quality inspection component 202 , the visual inspection component 203 and the sorting box 204 cooperate with each other to realize the process of barcode detection, quality detection and detection of unqualified enameled wires. Specifically, the detection unit 200 includes a sorting assembly 201, a quality inspection assembly 202, a visual inspection assembly 203, and a sorting box 204. At one end away from the first moving assembly 101, the visual inspection assembly 203 is arranged on the first conveyor 103, and the sorting box 204 is located on the side of the sorting assembly 201; wherein, the concave bracket 203a of the visual inspection assembly 203 is located on the first conveyor 103 On the mount...

Embodiment 3

[0068] refer to Figure 6 and Figure 7 , this embodiment is different from the above embodiments in that: the sorting assembly 201 includes a rotating part 201a and a clamping part 201b, through the mutual cooperation between the set rotating part 201a and the clamping part 201b, it is convenient to clamp the transfer material, so that the Lock automation production efficiency. Specifically, the sorting assembly 201 has the same structure as the second conveying assembly 203; wherein, the sorting assembly 201 includes a rotating part 201a and a clamping part 201b, and the clamping part 201b is arranged on the turning head 201a-1 of the rotating part 201a.

[0069] Further, the clamping part 201b includes a mounting block 201b-1 and a second air claw gripper 201b-2, and the second air gripper gripper 201b-2 is fixed on the mounting block 201b-1.

[0070]Further, the rotary member 201a includes a rotary head 201a-1, a first rocker arm 201a-2, a second rocker arm 201a-3, a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com