SMT chip defect detection system and method

A chip defect and detection method technology, which is applied in the direction of optical testing flaws/defects, measuring devices, instruments, etc., can solve problems such as high labor costs, poor quality inspection results, and operator mental fatigue, so as to reduce the difficulty of detection and improve detection. Efficiency and detection quality, effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

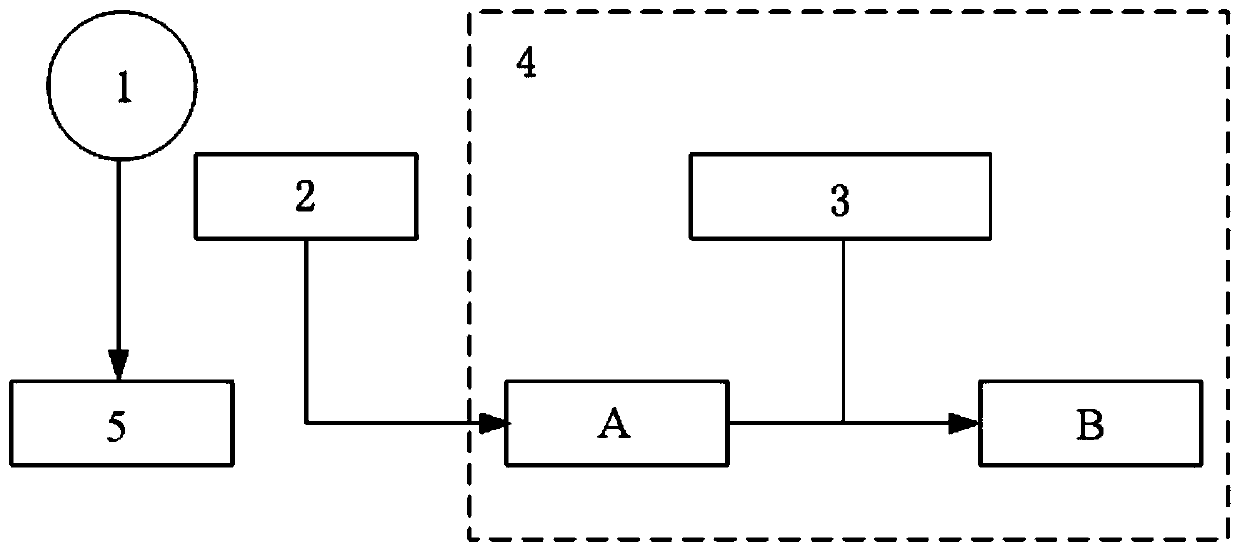

[0031] Such as figure 1 Shown, for a kind of SMT chip defect detection system provided by the present invention, it comprises:

[0032] A ring-shaped LED light source 1 for illuminating the SMT chip 5;

[0033] An imaging system 2, configured to acquire an image and transmit the acquired image signal A to an image processing system 3;

[0034] An image processing system 3, configured to process the image signal A acquired by the imaging system 2;

[0035] The industrial computer 4 is used to intuitively output the image signal A processed by the image processing system 3 in the form of human-computer interaction. The industrial computer 4 includes the port of the imaging system 2, the image processing system 3 and the human-computer interaction interface, wherein the human-computer interaction interface can execute manually written image processing codes to output the detection result B intuitively.

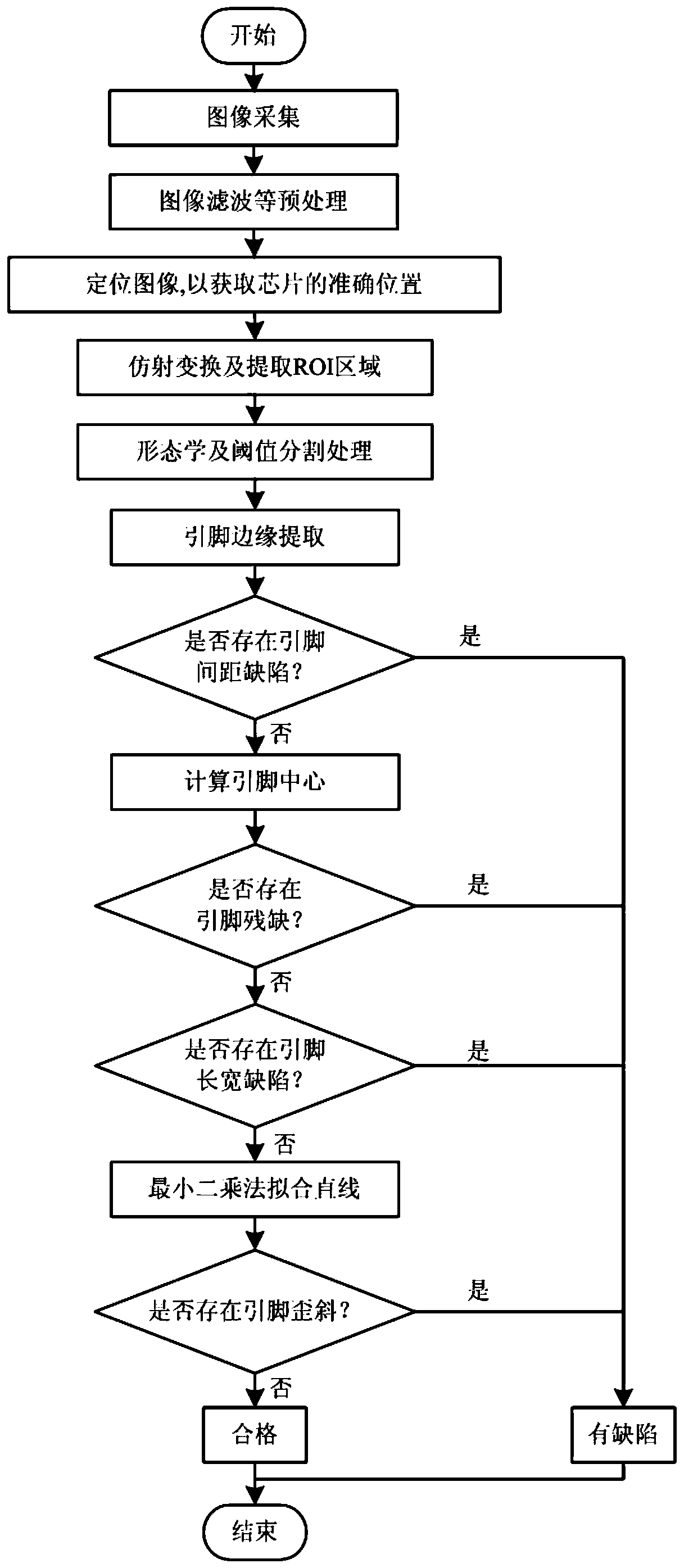

[0036] A kind of SMT chip defect detection method, such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com