Visual identification device for type of integrated circuit punching system and identification method and application

An integrated circuit and visual recognition technology, applied in sorting and other directions, can solve problems such as inability to detect product varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

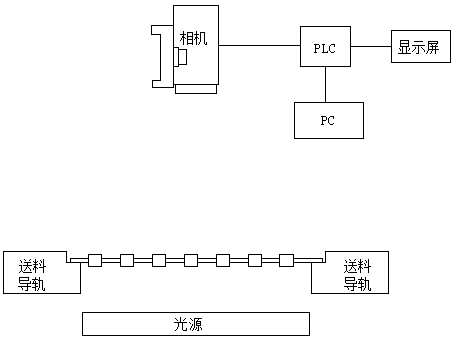

[0016] Embodiment 1: The visual recognition device of the kind of integrated circuit die-cutting system, it comprises feeding guide rail, is distributed with visual imaging system on the vertical direction between described feeding guide rail, described visual imaging system is connected with PC signal by PLC, PC and PC The display screen signal is connected, and the PLC is also signal-connected with a manipulator; the visual imaging system includes a light source positioned at the bottom of the feed guide rail and a camera above the feed guide rail, and the camera is connected with the PLC signal; the feed guide rail includes a horizontal interval distribution The left feeding guide rail and the right feeding guide rail are driven by a motor to move synchronously.

Embodiment 2

[0017] Embodiment 2: The difference from Embodiment 1 is that the left feeding guide rail and the right feeding guide rail are driven by a cylinder to move synchronously.

Embodiment 3

[0018] Embodiment 3: The difference from Embodiment 1 is that the left feeding guide rail and the right feeding guide rail are hydraulically driven to move synchronously.

[0019] The identification method of the visual identification device of the variety of integrated circuit punching system, which includes the following steps: (1) Judgment of abnormal position: the manipulator puts the correct lead frame on the feeding guide rail, and the visual imaging system detects the placement of the lead frame And feed back to PLC, PLC drives visual imaging system to take pictures, PC selects a search range of heterotopic hole, gives a positioning range to determine the position parameters of the heterotopic hole, saves the parameters to PLC after debugging to become template of heterotopic hole, manipulator Grab a new lead frame and put it on the feeding guide rail to compare the different position holes. If the similarity with the different position hole template is greater than or e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com