Single butt-joint boxing and sealing system and method for multiple brands of cigarettes

A multi-brand, cartoning and sealing machine technology, applied in the field of machinery, can solve the problems of high equipment cost, large equipment area, shutdown of the cartoning and sealing system, etc., to achieve centralized information collection and identification, reduce floor space, reduce Overall cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

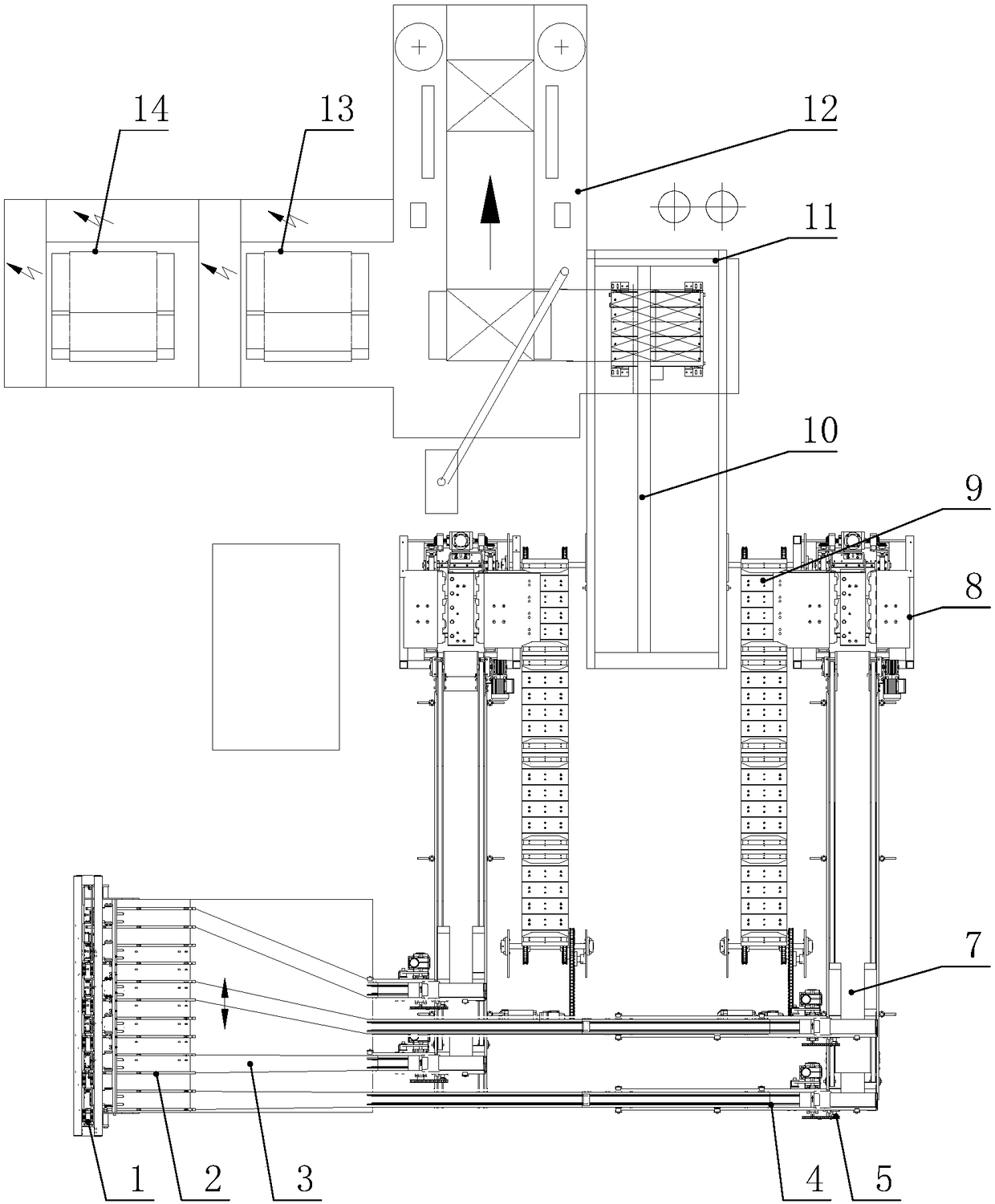

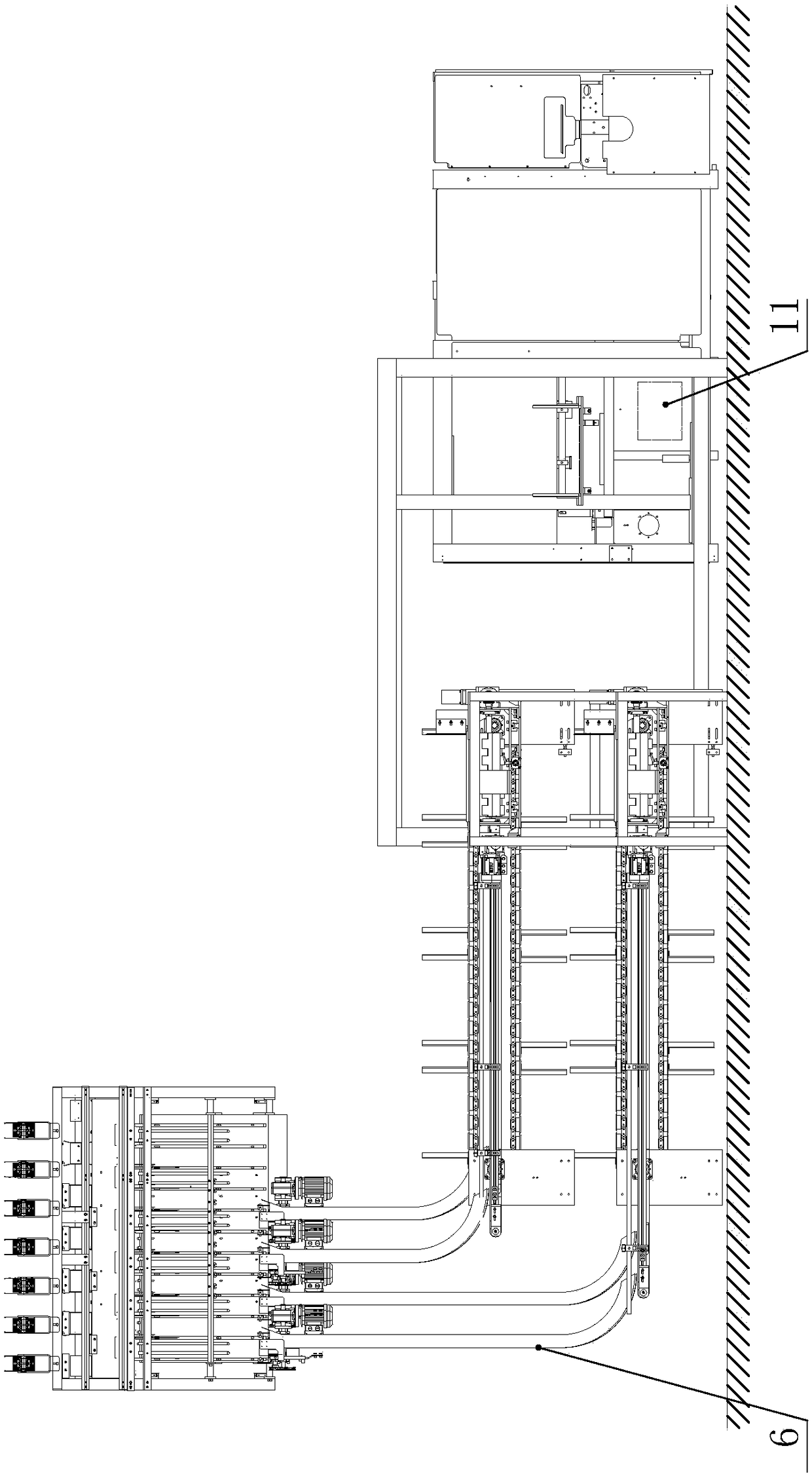

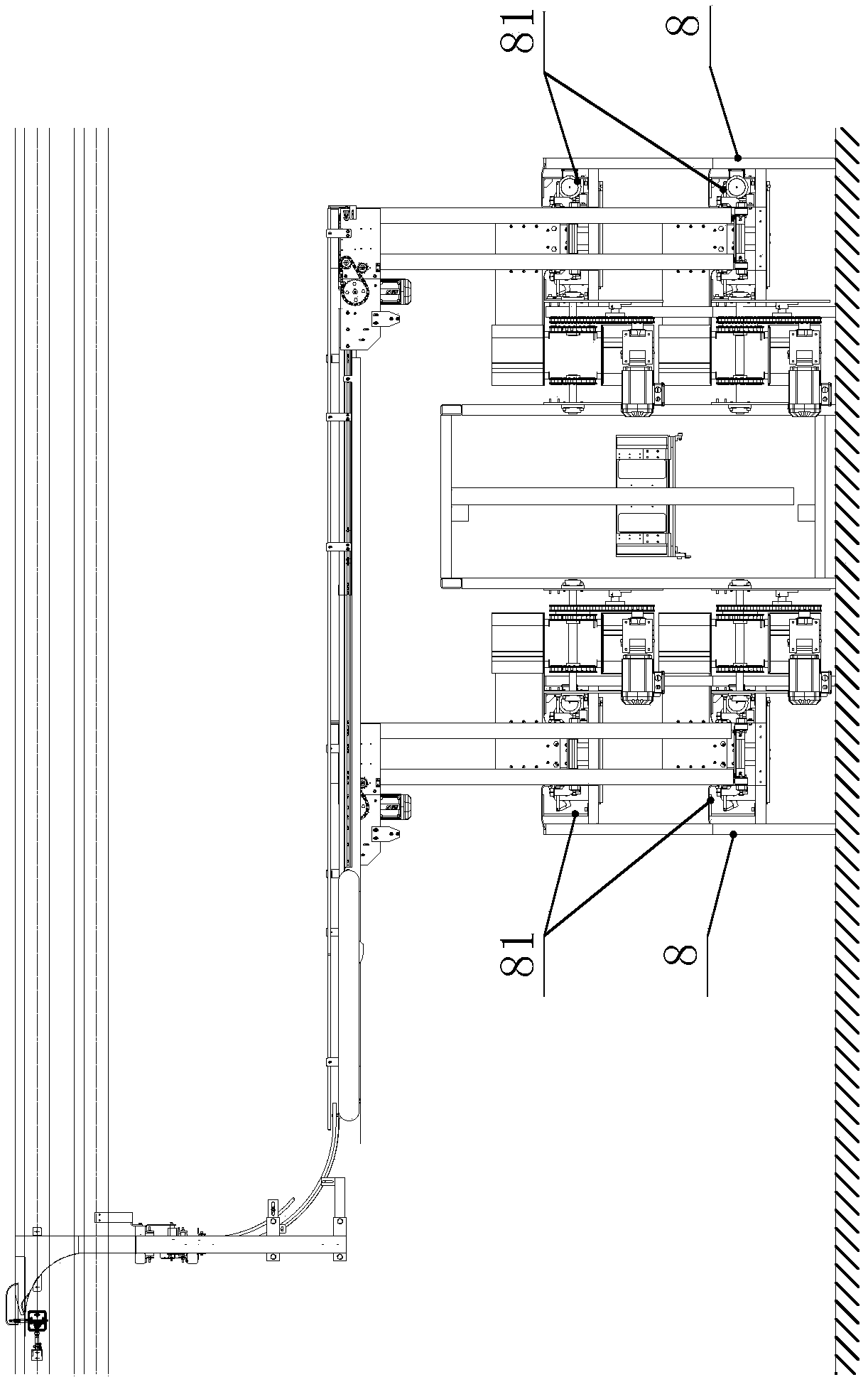

[0036] Such as Figure 1-Figure 3 As shown, a multi-brand carton single-butt packing and sealing system disclosed in this embodiment, after the cartons are produced by the wrapping unit, they are transported, stacked, etc. until they enter the cartoning and sealing machine 12 to complete the packaging, that is, multiple Packing unit, carton hoist, horizontal to vertical device, multi-channel chain plate conveyor 1, carton shunting channel selection mechanism 2, multi-channel sliding mechanism 3; single-lane horizontal conveyor 4, carton vertical and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com