Imbricated battery string production equipment

A technology for production equipment and batteries, applied in the manufacture of circuits, electrical components, final products, etc., can solve problems such as low production efficiency, achieve the effects of improving production efficiency, improving production efficiency, and ensuring quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

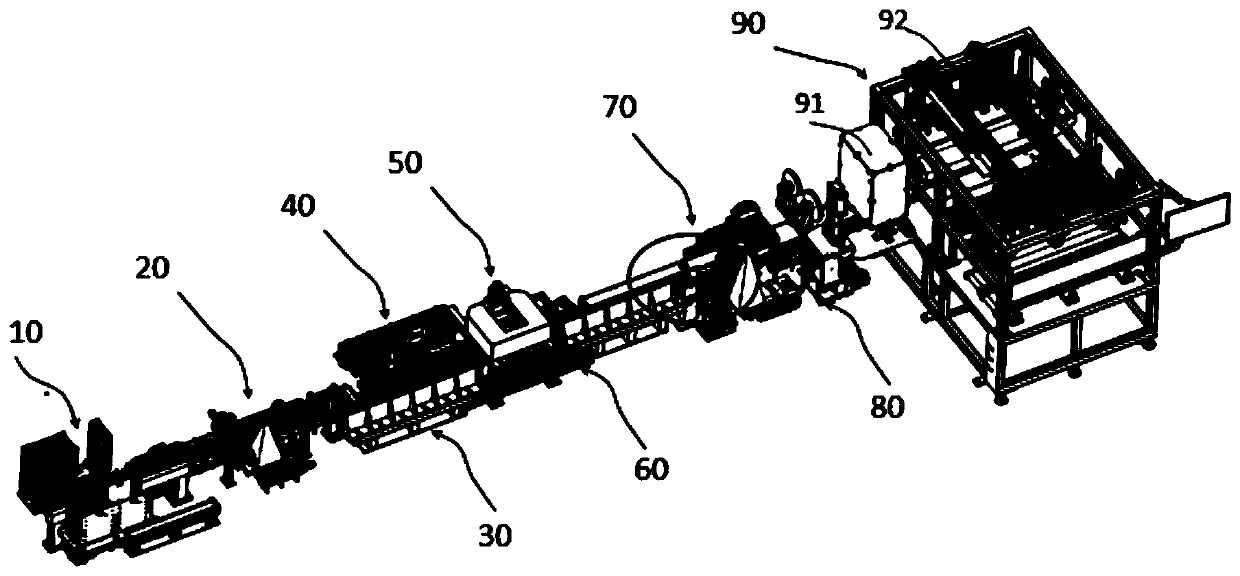

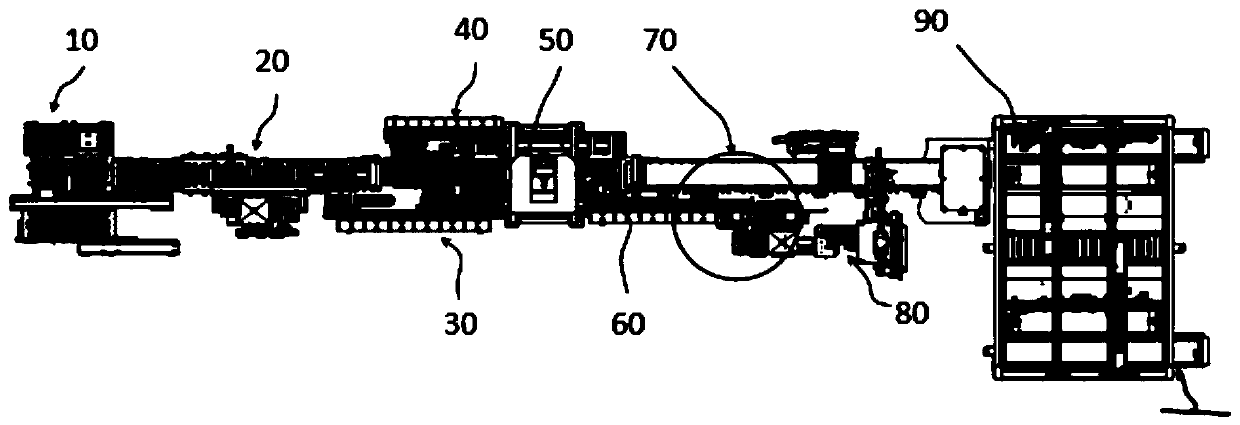

[0057] Such as Figure 1 to Figure 2 As shown, the shingled battery string production equipment provided by the present invention includes a battery sheet feeding device 10, a battery sheet regularizing device 40, a battery sheet gluing device 50, a shingle device 60, a bus bar laying device 70, and a welding device arranged along a conveyor line. 装置80。 Device 80.

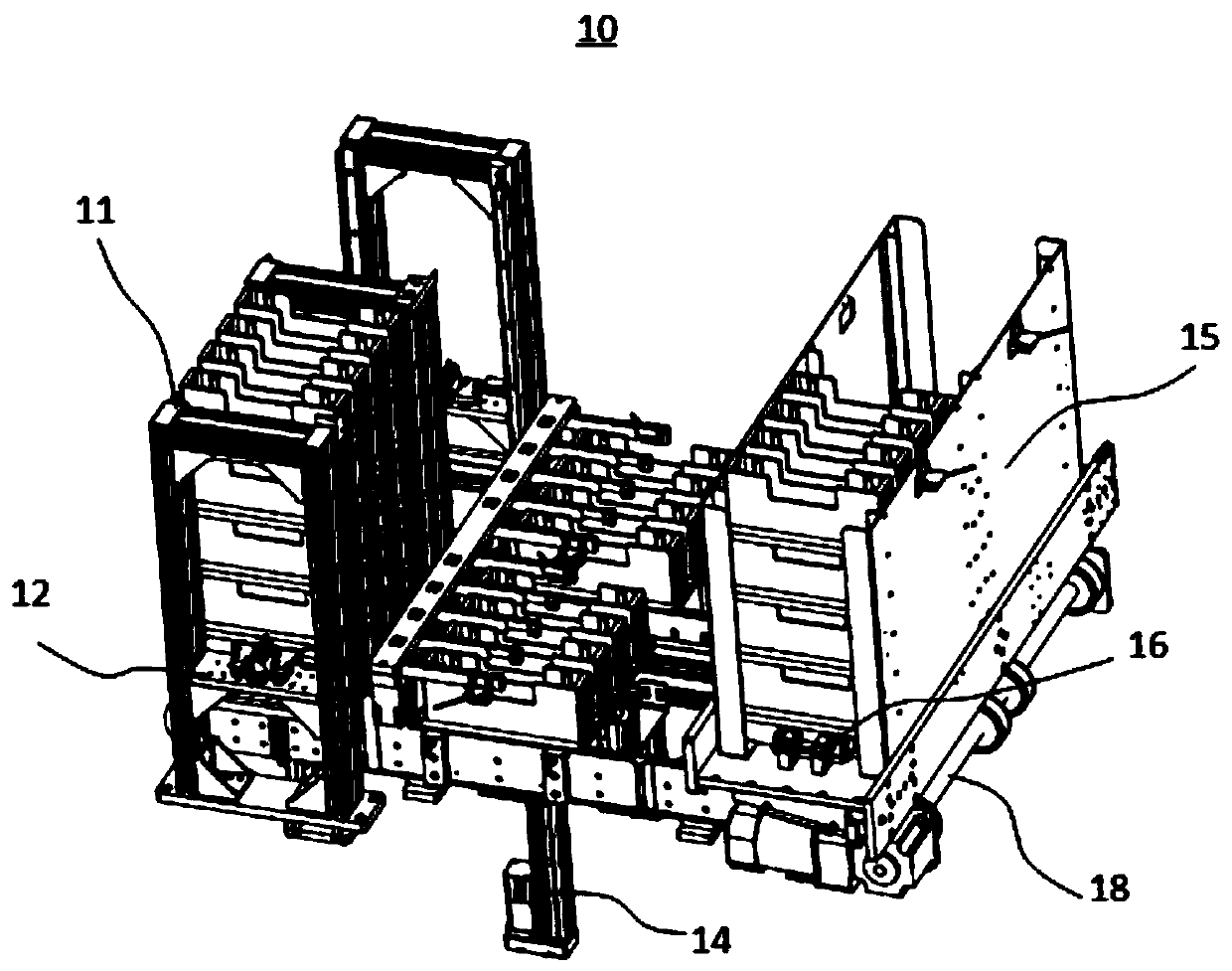

[0058] The battery chip loading device 10 is configured to load the battery chips onto the conveyor line. The cell sheet is transported toward the cell sheet regularizing device 40 by the transport line.

[0059] The cell regularization device 40 is configured to regularize the cell that is loaded onto the conveyor line.

[0060] The cell glue application device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com