Light source arrangement method for RFID (radio frequency identification) tag automatic optical detection

An RFID label and automatic optical detection technology, which is applied in the field of RFID label detection, can solve the problems of imperfect detection items and the inability to detect the dirty detection of the inner bottom paper of INLAY, and achieve the effect of uniform image acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and description of the accompanying drawings.

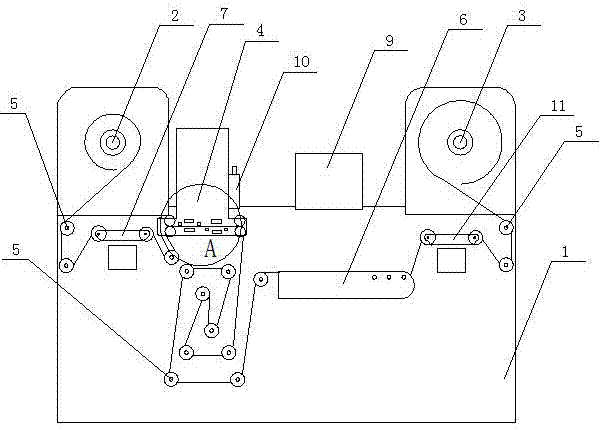

[0027] A light source configuration method for automatic optical detection of RFID tags, including a frame 1, on which a discharge reel 2, a rewinding reel 3, a visual detection device 4, several transmission wheels 5, a display 9, and a printer 10 are arranged. Wrap one end of the RFID label tape formed by a number of RFID tags on the release paper tape on the unwinding reel 2, and the other end passes through the visual inspection device 4 through several transmission wheels 5 and is wound on the rewinding reel 3; The detection device 8 includes a first detection device and a second detection device arranged horizontally at intervals.

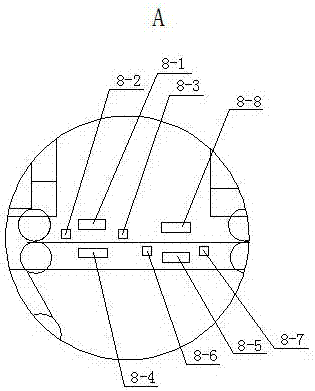

[0028] The first detection device comprises a front camera 8-1, a first left reflection light source 8-2, a first right reflection light source 8-3, a first transmission light source 8-4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com