Full-automatic visual inspection system for screen defects

A visual inspection and automatic inspection technology, applied in sorting and other directions, can solve the problems that the accuracy and standard uniformity of inspection cannot be guaranteed, cannot meet the rapid production of enterprises in batches, and cannot measure the actual size of defects, etc., to save human capital, Compact, easy-to-set effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

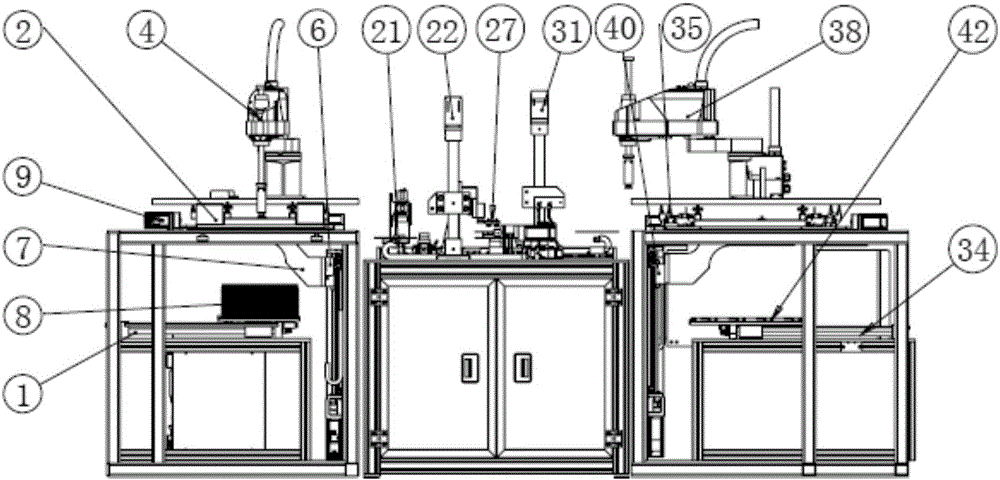

[0038] Such as figure 1 As shown, a fully automatic visual detection system for screen defects, the system includes a controller and an automatic feeding unit, an automatic detection unit and an automatic sorting and unloading unit connected to it, an automatic feeding unit, an automatic detection unit and an automatic sorting unit The unloading units are arranged in sequence to form an automatic assembly line; the automatic loading unit transports the screens to be tested to the automatic detection unit, and the automatic detection unit conducts automatic defect detection to determine whether the screen is a good or defective product, and the automatic classification and unloading unit obtains the detection from the automatic detection unit The completed screen is classified and output according to the detection results.

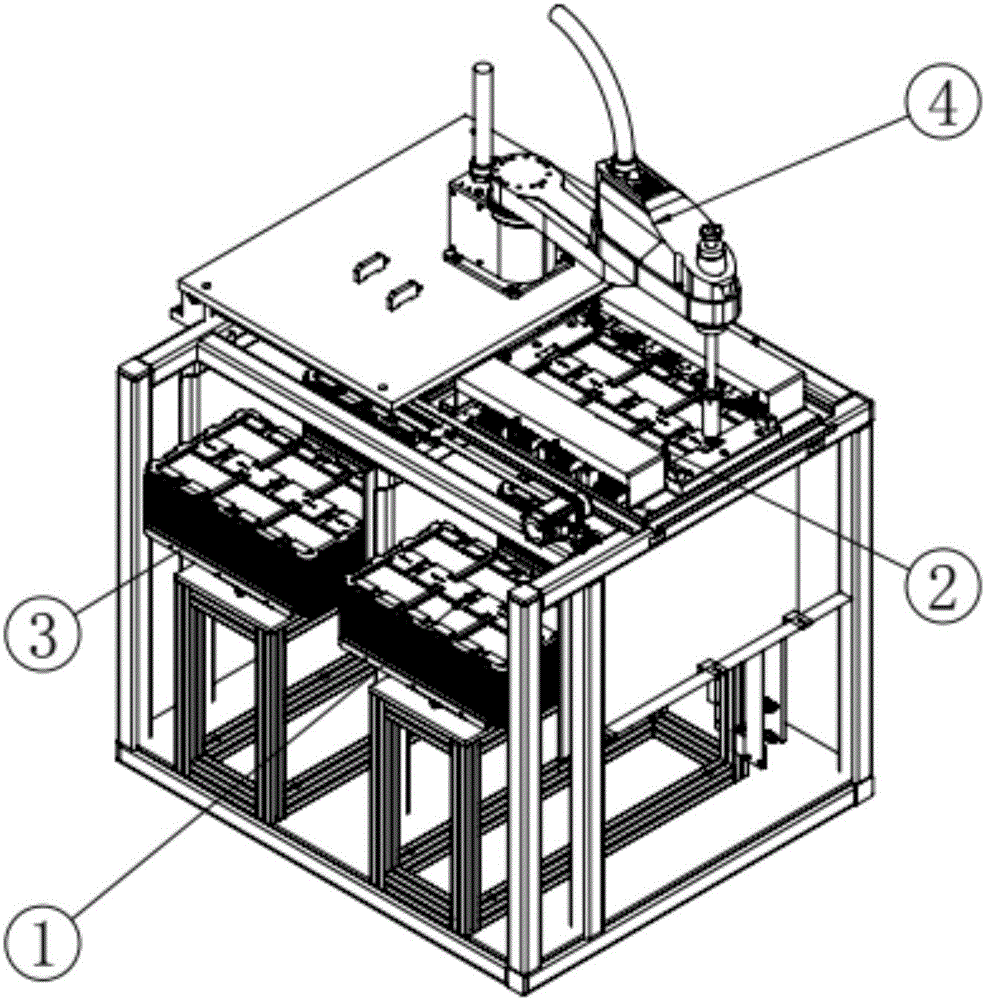

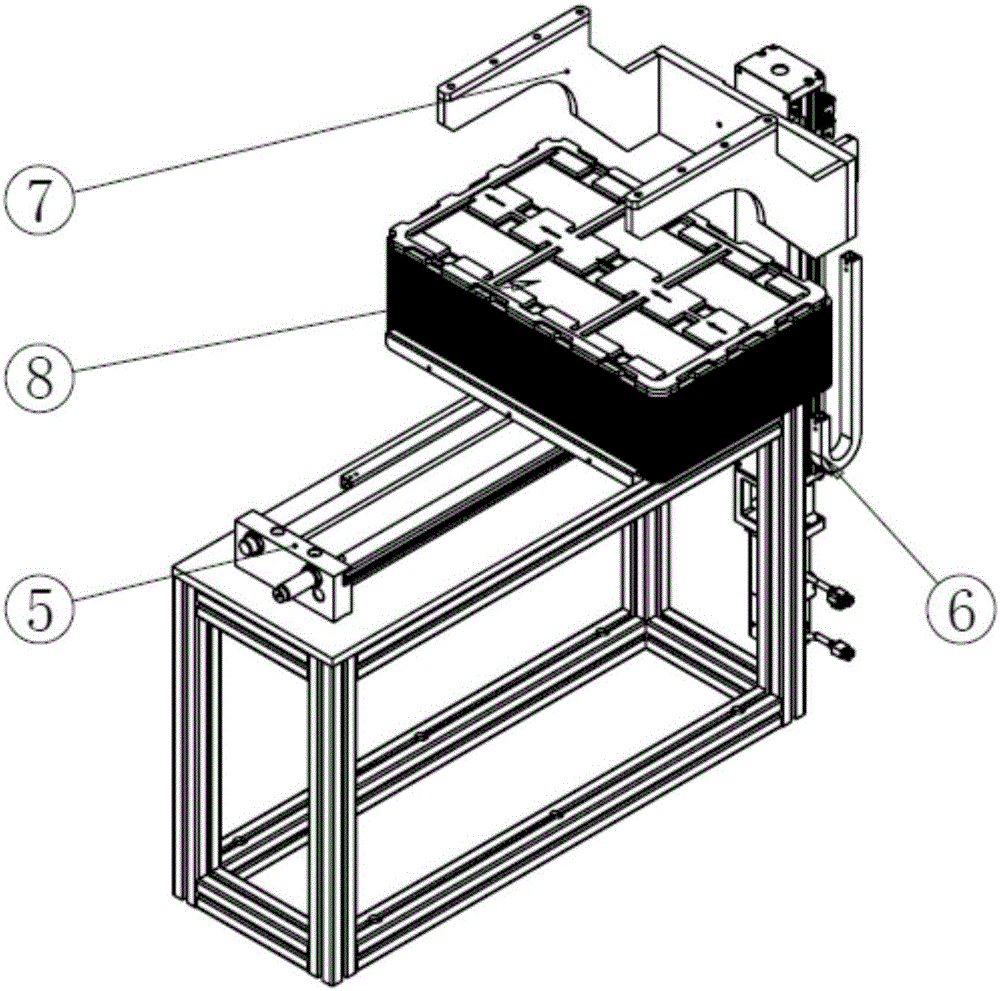

[0039] Such as figure 2 As shown, the automatic loading unit includes a Y-direction full pallet loading mechanism 1 connected to the controller, a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com