Vision-guided engine cylinder head unstacking and detecting robot

An engine cylinder head, vision-guided technology, applied in manipulators, program-controlled manipulators, optical testing flaws/defects, etc., can solve problems such as shaking of clamping cylinder heads, and achieve the effect of overcoming shaking and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

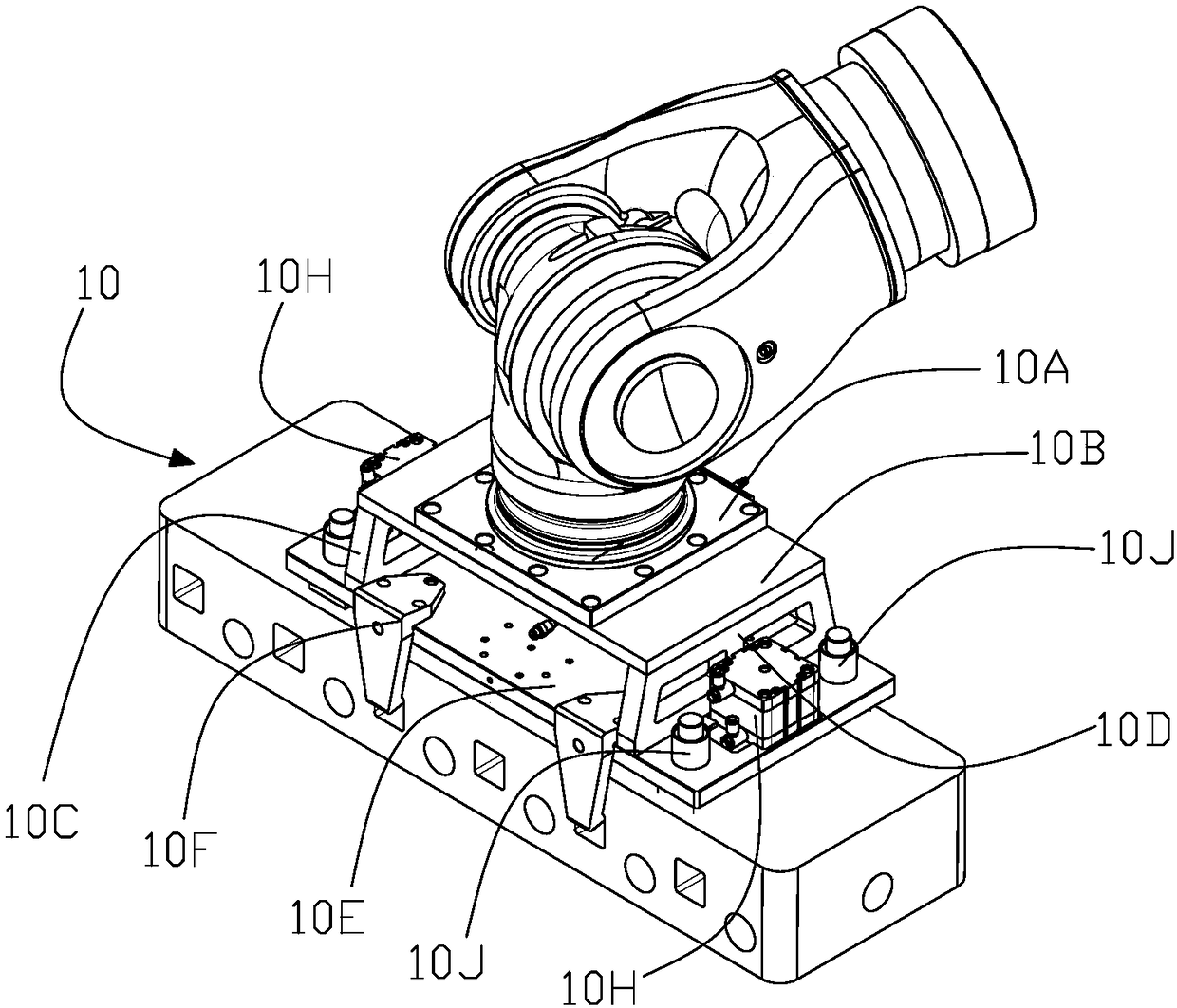

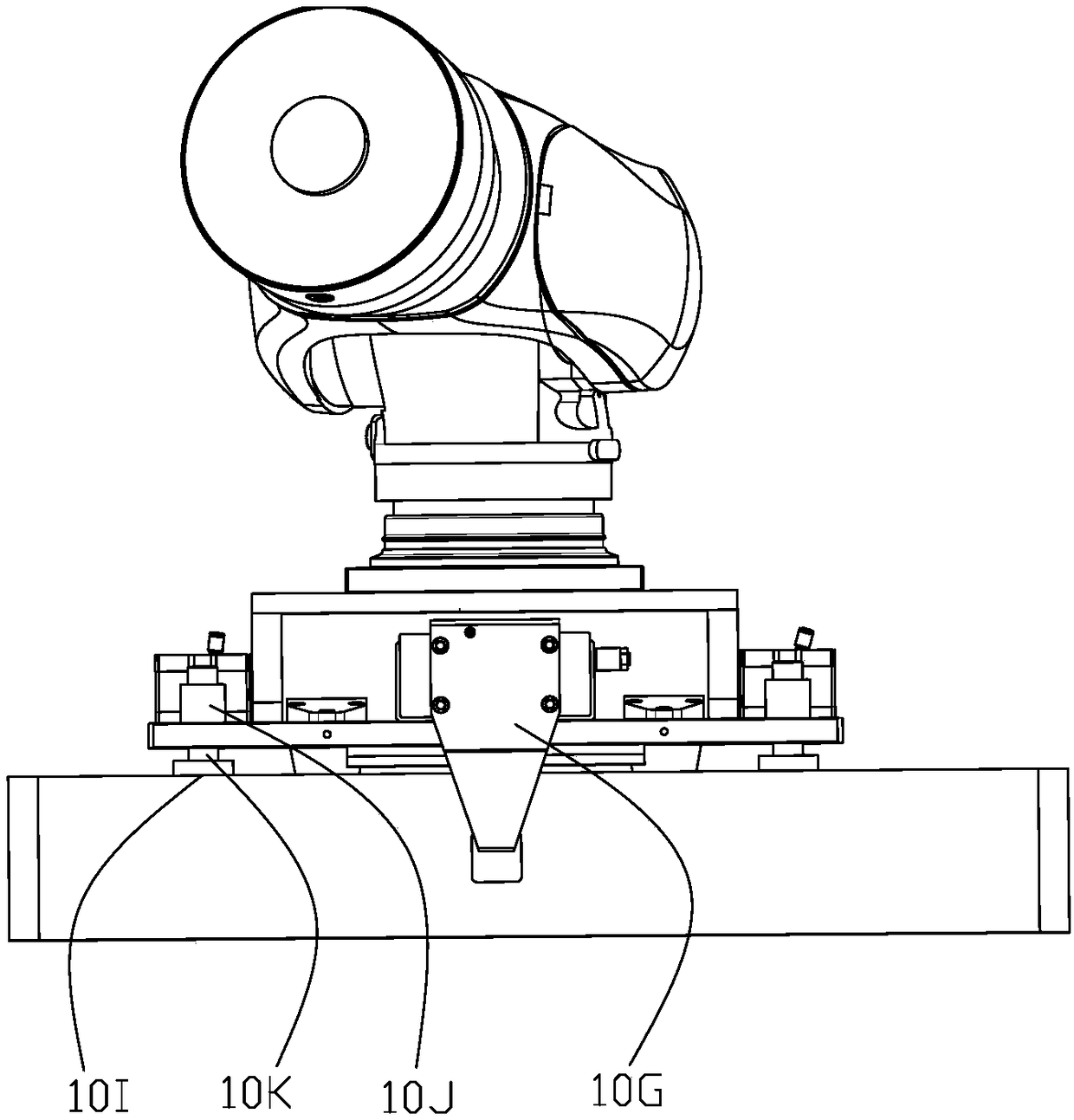

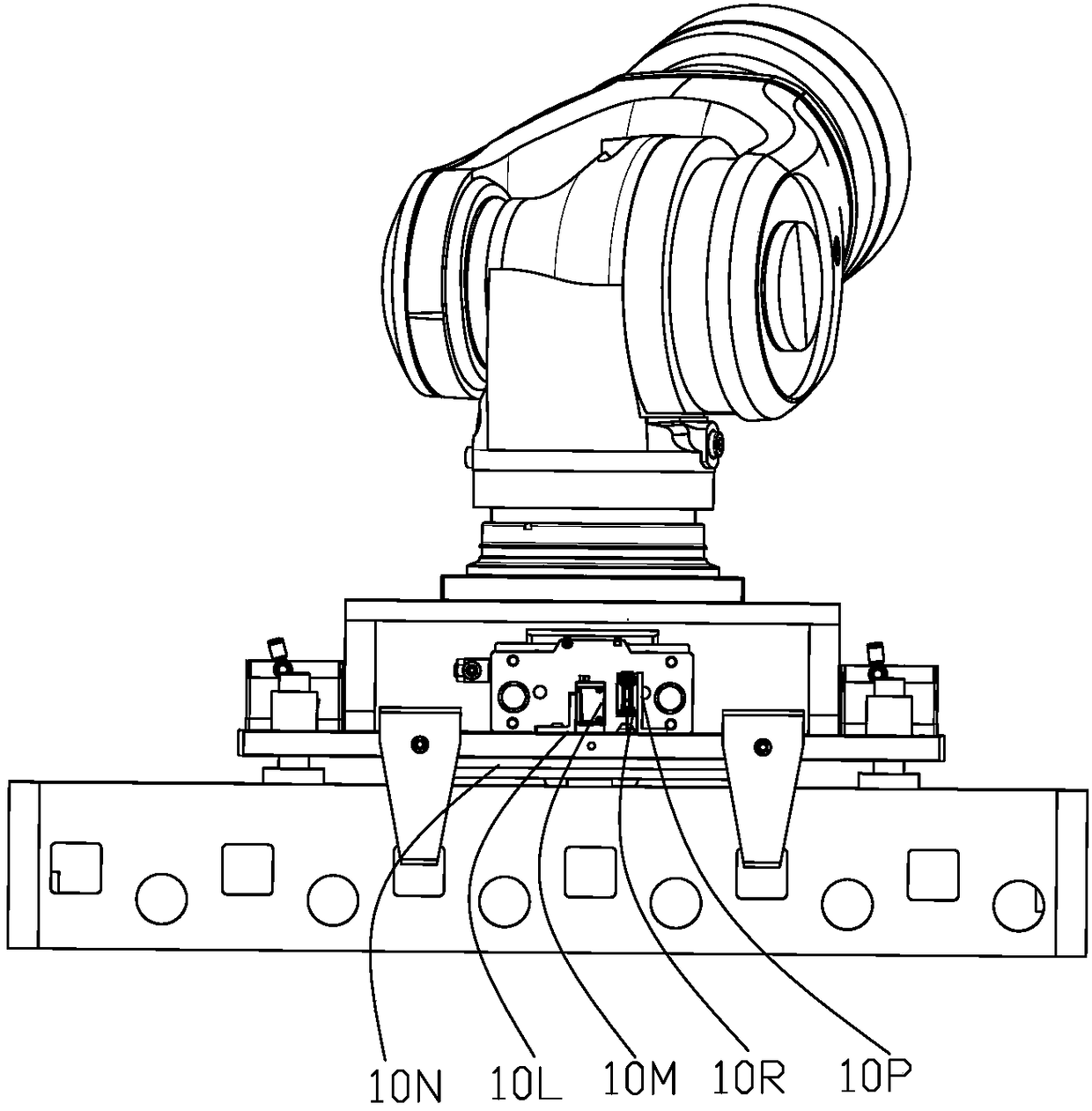

[0027] Please refer to figure 1 and figure 2 as well as image 3 As shown, this embodiment provides a vision-guided destacking engine cylinder head 10, which is installed at the end of the mechanical arm of the joint robot, including a robot mounting flange mechanism, a clamping mechanism, a pushing mechanism, a visual positioning system and a signal detection system , wherein the clamping mechanism is installed on the robot mounting flange mechanism, the pushing mechanism is arranged at both ends of the robot mounting flange mechanism, and the visual positioning system and signal detection system are located on the robot mounting flange mechanism. In the cavity of the flange mechanism, the signal detection system calculates the distance from the vision-guided engine cylinder head unstacking 10 to the engine cylinder head, and the vision positioning system finds out the position of the engine cylinder head to be transported and After inspecting the appearance, the joint rob...

Embodiment 2

[0037] Please refer to Figure 4 and Figure 5 As shown, this embodiment provides a detection robot, which includes the vision-guided engine cylinder head destacking described in Embodiment 1, and also includes a joint robot system, a visual detection and marking system 30, and a control system 40, wherein the section The robot system, the vision-guided engine cylinder head destacking 10 and the visual inspection and marking system 30 are all connected to the control system 40, and the joint robot system drives the vision-guided engine cylinder head destacking 10 to move At the upper part of the loading station to be unstacked, the control system 40 judges and calculates the position information of the workpiece to be unstacked, and sends the position information to the joint robot system, and the vision-guided engine cylinder head unstacking 10 Perform appearance inspection on the surface of the workpiece to be destacked, the joint robot system drives the vision-guided engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com