Loading and unloading device capable of automatic clamping

An automatic and active connection technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of workers being bumped by machines, subject to a large degree of subjective influence, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

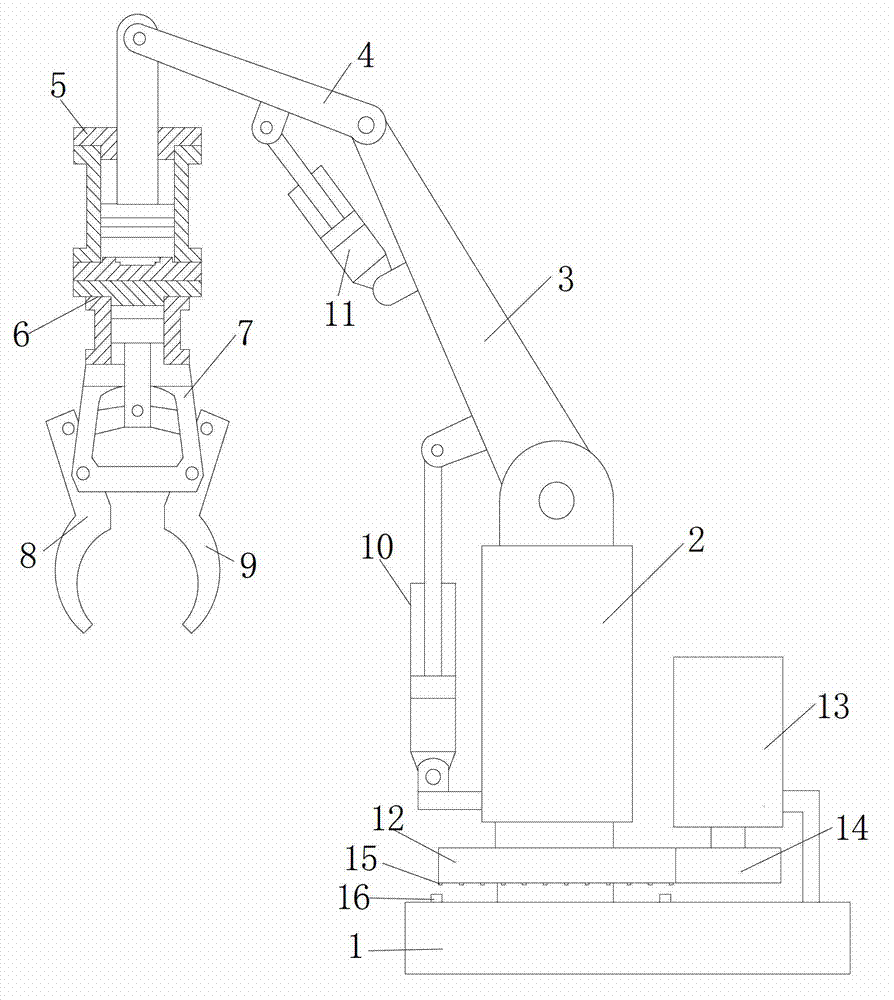

[0012] see figure 1 , the automatic clamping and loading and unloading device, which includes a machine base 1, a column 2 arranged on the machine base 1, and a driving mechanism that drives the column 2 to rotate on the machine base 1, and a first swing arm 3, a first swing arm 3, and a second Two swing arms 4, one end of the first swing arm 3 is movably connected on the column 2, and the other end is movably connected with one end of the second swing arm 4, and the other end of the second swing arm 4 is provided with a lift cylinder 5, and the lift cylinder 5 The piston rod is connected to the second swing arm 4, the clamping cylinder 6 is fixedly arranged under the cylinder body of the lifting cylinder 5, the finger bracket 7 is fixedly arranged on the clamping cylinder, and the clamping left hand is movably connected on the finger bracket i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com