Automatic feeding and discharging device for machine tool

An automatic loading and unloading, machine tool technology, applied in the direction of automatic in/out of workpieces, metal processing machinery parts, metal processing, etc., can solve the problems of high labor intensity of workers, limited production efficiency, endangering workers' life safety, etc., to save manpower, The effect of improving production efficiency and reducing the incidence of personal accidents of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A specific embodiment is enumerated below in conjunction with the accompanying drawings to further illustrate the present invention.

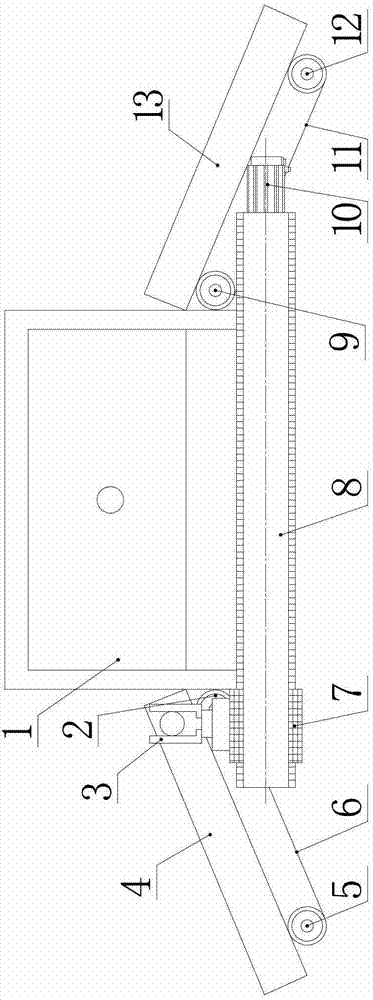

[0026] This embodiment is an automatic loading and unloading device for machine tools, such as figure 1 As shown, it includes working platform 1, manipulator, pusher, feeding roller table, and unloading roller table.

[0027] The working platform includes: a servo motor, a ball screw 8 and a linear guide rail, the ball screw 8 is driven by a servo motor, the ball screw 8 is matched with a nut, the linear guide is matched with a slider, and the nut 7 is fixedly connected with the slider.

[0028] The manipulator includes: an air gripper 3 and an air gripper seat, and the air gripper 3 is fixedly connected to the air gripper seat. In this embodiment, the sliders of the air gripper seat are fixedly connected together.

[0029] The pusher includes: a material shifting plate connected to a pneumatic device and driven by an air cylinder.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com