Automatical disassembling device for spool

A technology for automatic loading and unloading of the I-shaped wheel, which is applied in the field of the device for loading and unloading the winding I-shaped wheel of the I-shaped wheel take-up machine, which can solve the problems of large energy consumption, damage to the machine tool pallet, tedious and laborious operation process, etc., and reduce labor. Intensity, obvious effect, and the effect of reducing the labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

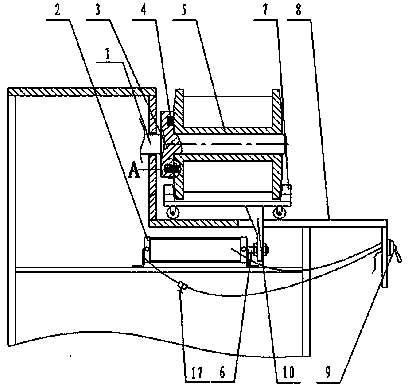

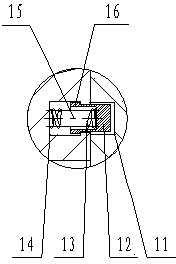

[0017] see figure 1 and figure 2 As shown, a kind of I-shaped wheel automatic loading and unloading device of the present invention comprises take-up shaft 3, I-shaped wheel 5, permanent magnet 4, magnet seat, transmission shaft 1, and the I-shaped wheel is provided with a transmission hole 11, and the take-up shaft 3 is provided with A magnet seat and a dial pin 12 are arranged, and the dial pin 12 can fit into the transmission hole 11 on the I-shaped wheel 5, the permanent magnet 4 is fixed in the magnet seat, the transmission shaft 1 is provided with a threaded hole, and the take-up shaft 3 and the transmission shaft 1 The threaded hole on the transmission shaft 1 is connected with screws; it also includes a rail car 7 carrying the I-shaped wheel and a worktable 8 carrying the reciprocating motion of the rail car 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com