Automatic punching machine assembly line system for PVC floor

An automatic flushing and assembly line technology, which is applied to conveyor objects, conveyors, mechanical conveyors, etc., can solve problems such as reducing work efficiency and increasing labor, and achieve the effect of improving work efficiency, reducing labor, and realizing intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

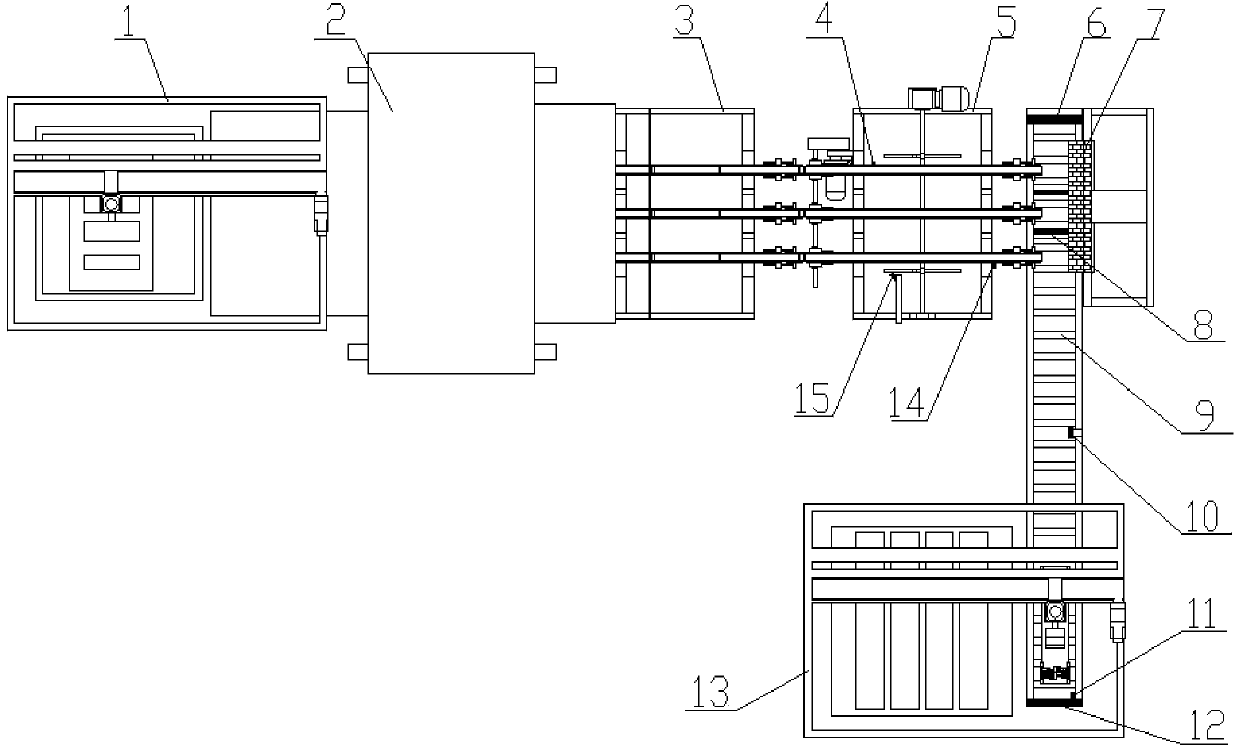

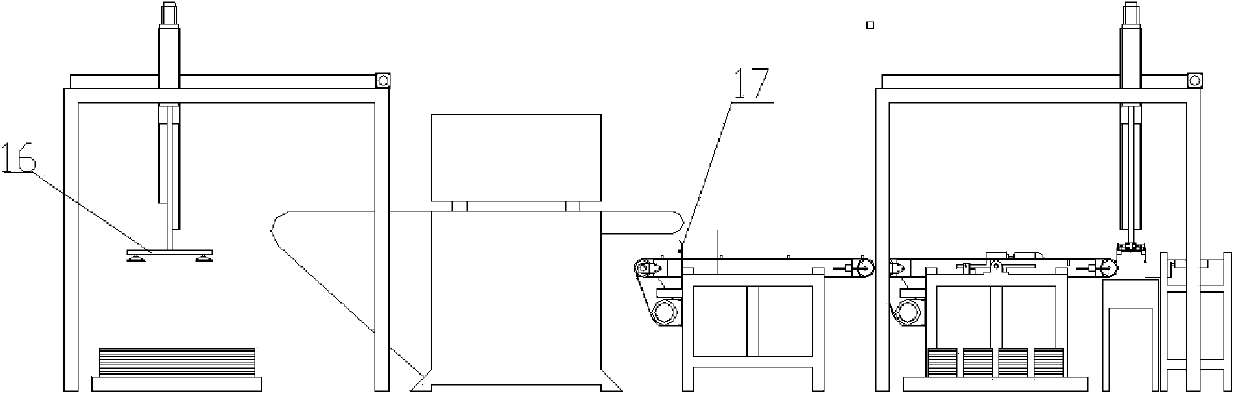

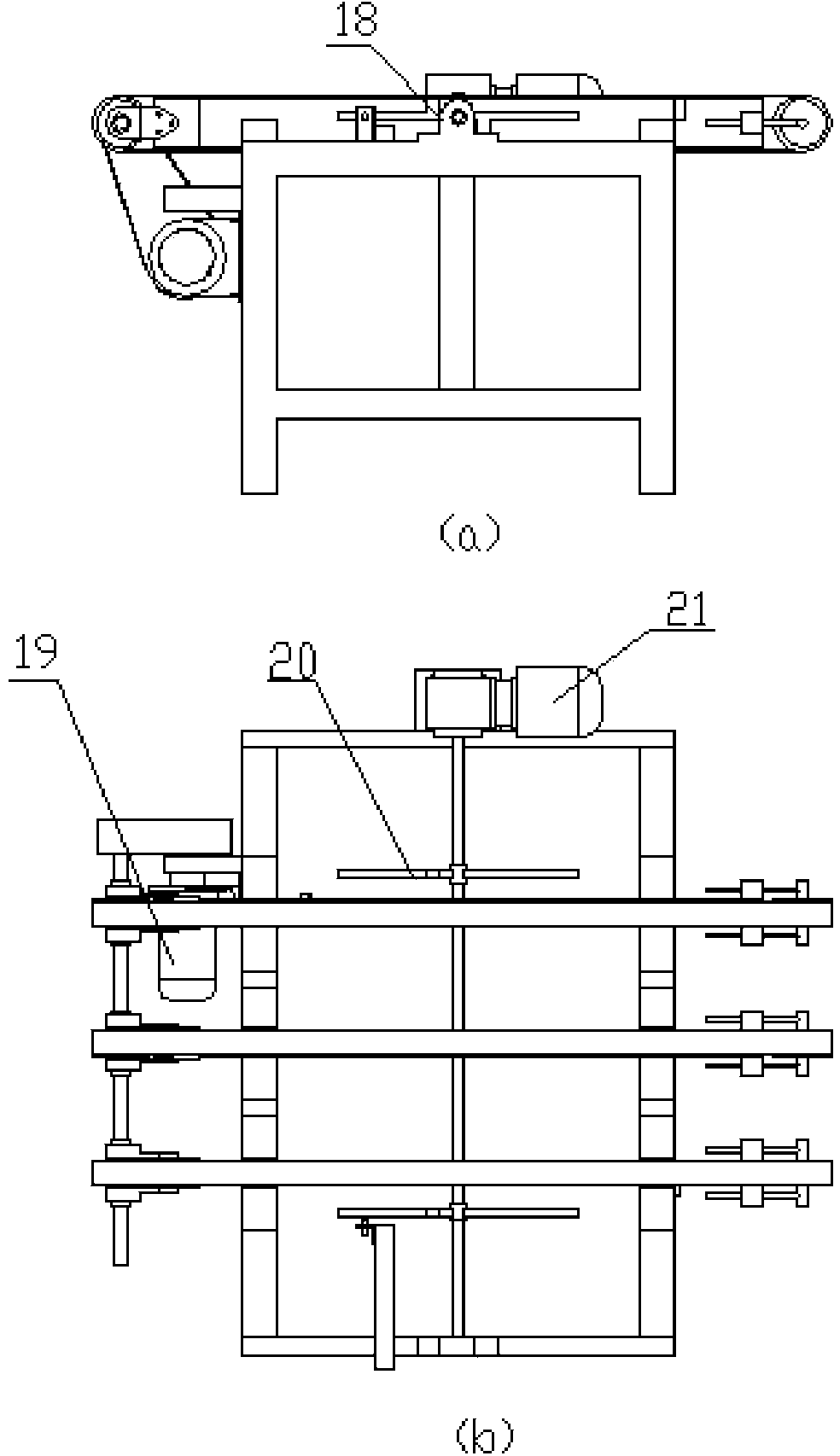

[0023] see figure 1 , figure 2 , image 3 , Figure 4 , a PVC floor automatic punching assembly line system of the present invention is composed of a loading and palletizing machine system, an automatic punching machine system, a fixed-distance slicer system, a 180° turning machine system, a rolling bed conveying system, and a feeding and palletizing system connected in sequence The machine system is composed of; the fixed-distance slicing machine system is equipped with the first light-sensing system; the 180° turning machine system is equipped with a turning plate photoelectric switch, a turning plate proximity switch and a turning plate counter system; the roller bed conveying system is equipped with a pneumatic Lifting plate system, pneumatic splicing plate system and second light sensing system; the first light sensing system is used to sense each floor to achieve equidistant conveying; the flap counter system is used to count PVC floors, flap photoelectric switches an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com