Automatic loading and unloading production line

A material production line, automatic technology, applied in metal processing and other directions, can solve problems such as insufficient automation, affecting production plans, and reducing delivery deadlines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

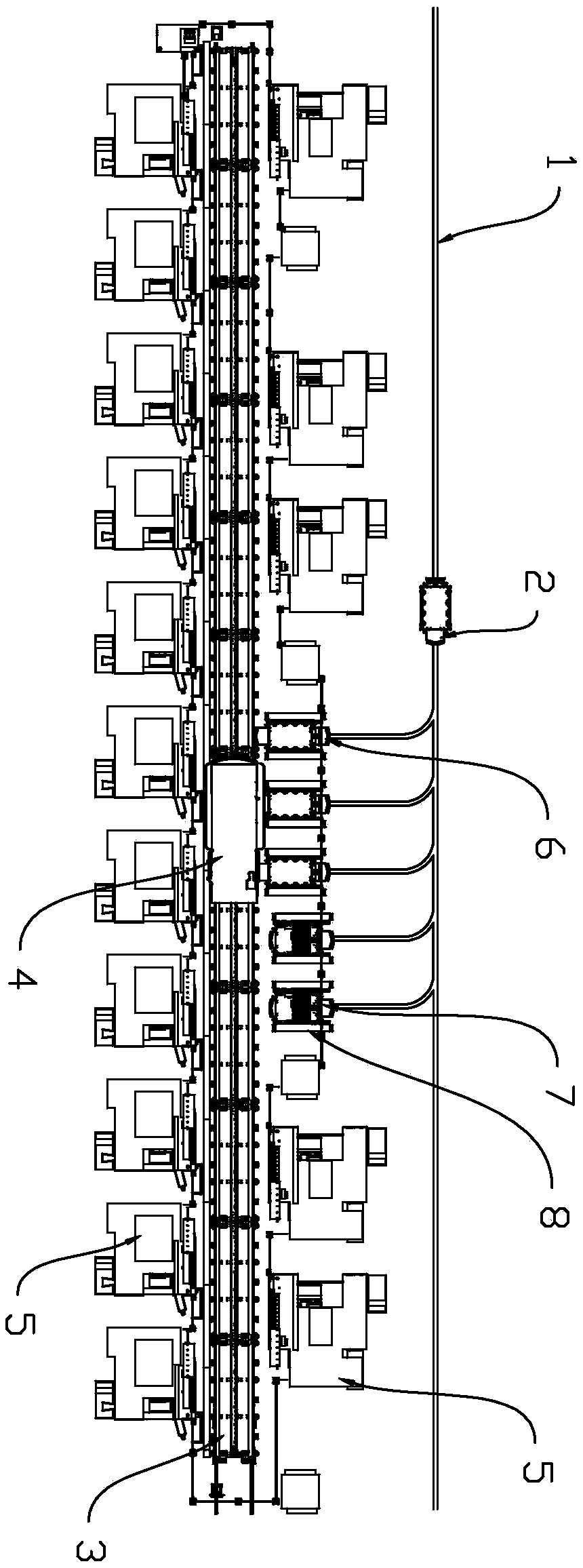

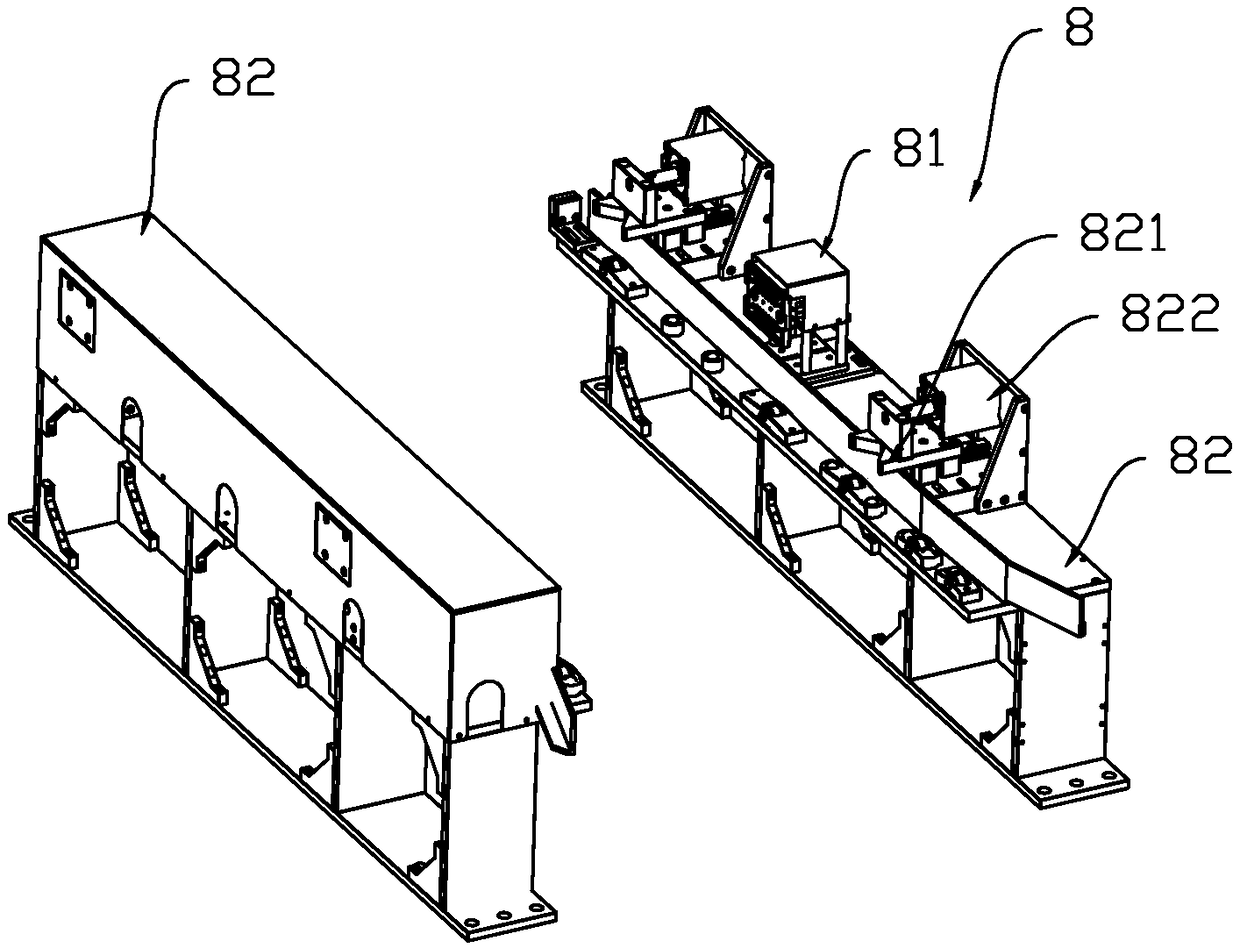

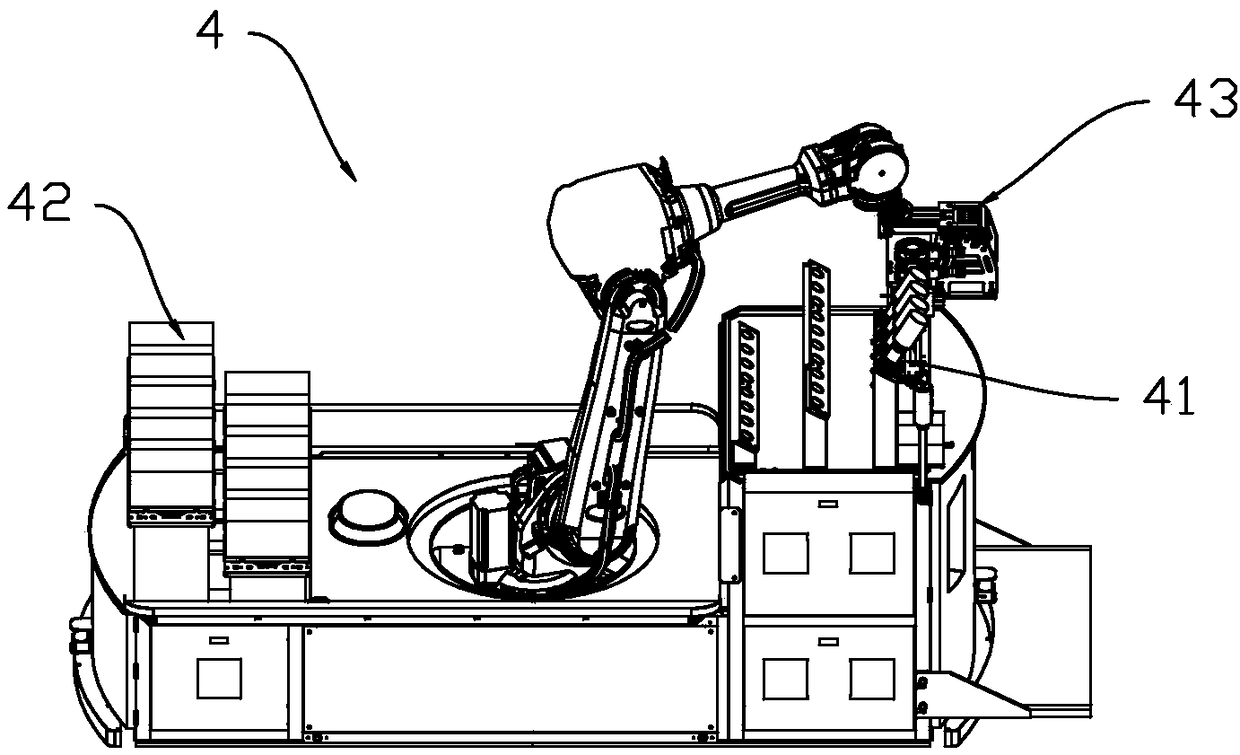

[0030] refer to Figure 1 to Figure 7 , the present invention is an automatic loading and unloading production line, including an AGV track 1 and an AGV car 2 arranged on the AGV track 1, an RGV track 3 and an RGV car 4 arranged on the RGV track 3, and the RGV car 4 is equipped with an intelligent The manipulator, the side of the RGV track 3 is equipped with a number of CNC machine tools 5, and also includes a material cart 6 for transporting materials. The side of the RGV track 3 is provided with a number of parking docks 8, and the feeder car 6 is movably connected with the AGV trolley 2. A first docking piece 81 and a second docking piece 61 that match each other are respectively provided on the wharf 8 and the skip 6 .

[0031] Specifically, AGV is the abbreviation of (Automated Guided Vehicle), which means "automatically guided transport vehicle". Transport vehicles with various transfer functions. RGV is the English abbreviation of Rail Guided Vehicle, also known as ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com