Power transmitting device for transmitting external force into rotating body, and orbital pipe cutting device and hydraulic chucking device able to freely control cutting tool movement inside rotating body by using the power transmitting device

一种动力传递装置、切削装置的技术,应用在传动装置、流体压力致动装置、卡盘等方向,能够解决不能控制切削工具运动等问题,达到确保耐久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Referring to the accompanying drawings, a description will now be given of a power transmission device that transmits external power to the inside of a rotating body, an orbital pipe cutting device that can freely control the movement of a cutting tool in a rotating body, and a power transmission device that uses The hydraulic clamping device of the power transmission device. This power transmission device corresponds to the driving principle of the orbital pipe cutting device, and thus will be additionally described while describing embodiments of the orbital pipe cutting device.

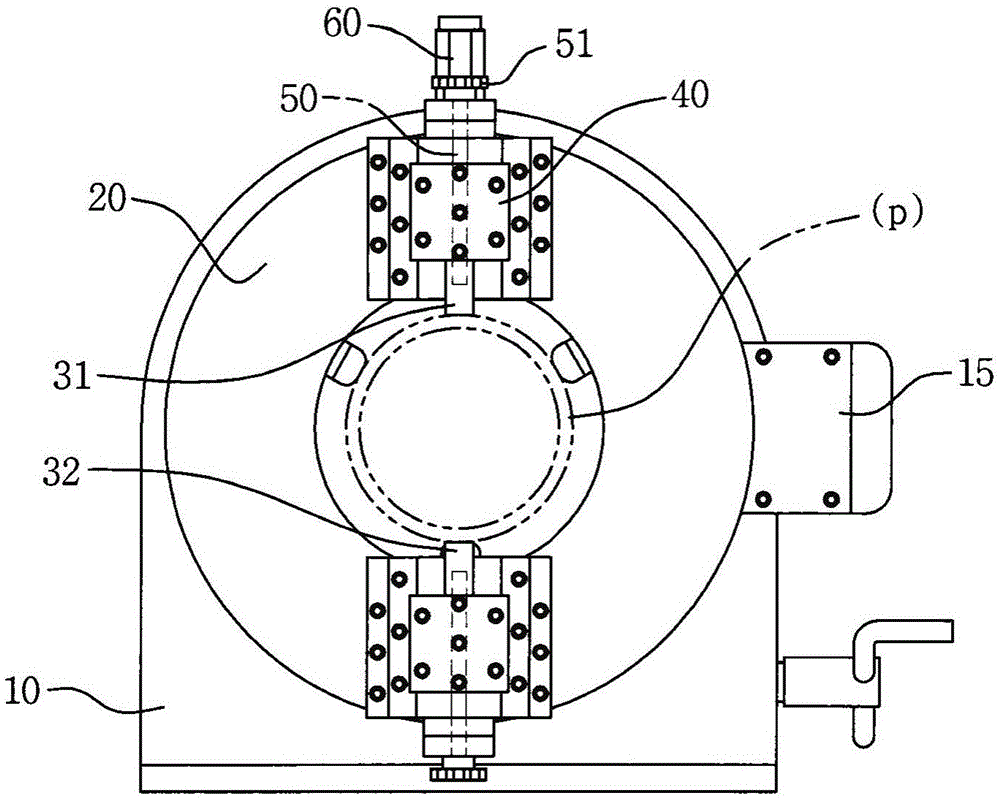

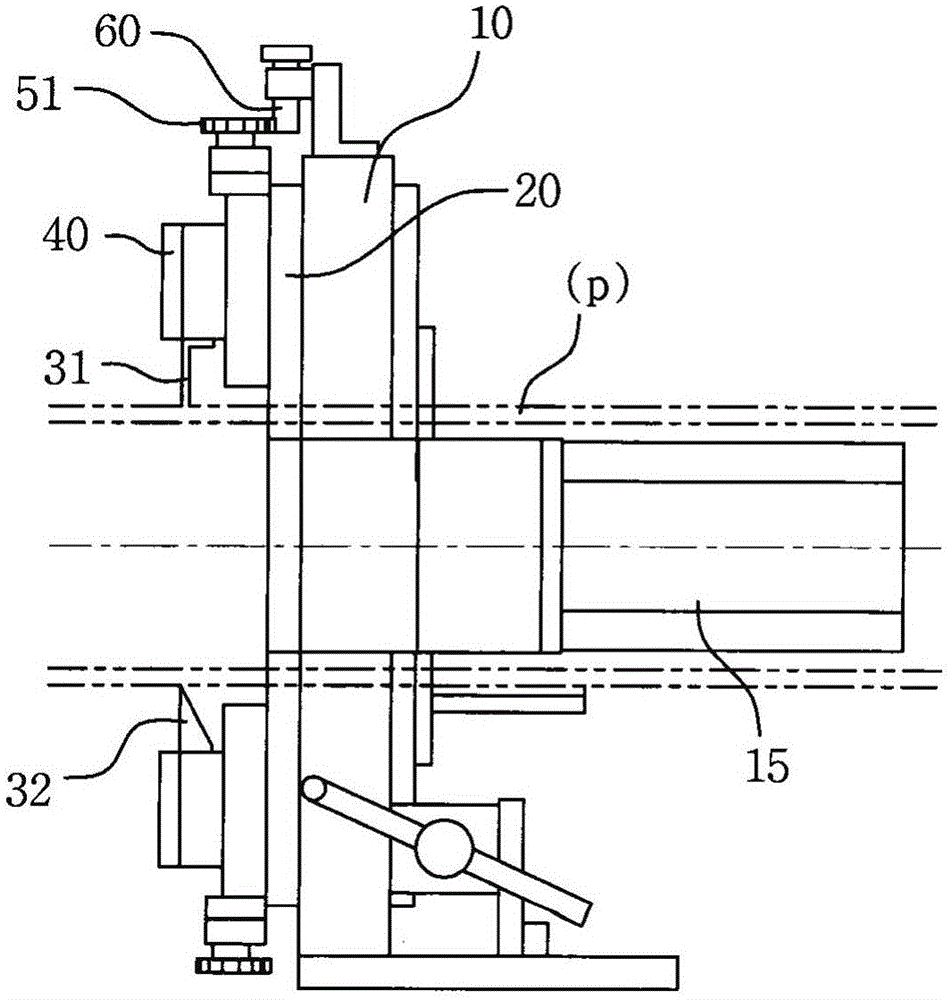

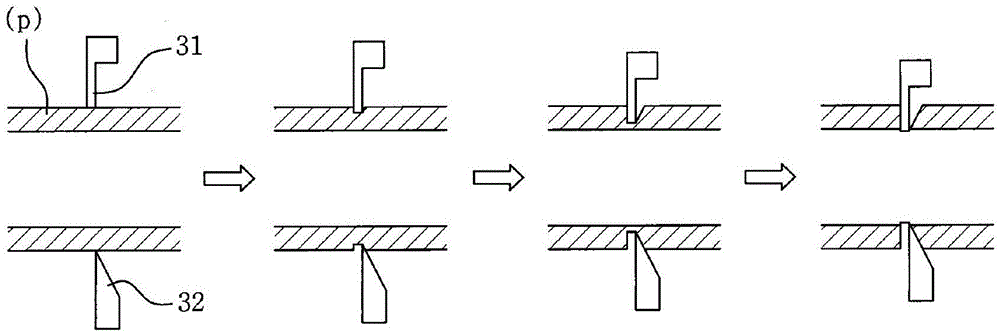

[0071] Figure 9 is a schematic diagram showing the overall configuration of an orbital pipe cutting device according to an embodiment of the present invention. Such as Figure 9 As shown, the orbital pipe cutting device 100 according to the present invention includes a main body 110; a rotating body 120 configured to rotate on one surface of the main body 110; and a cutting tool 130 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com