Air conditioner and method for assembling the same

A technology for air conditioners and filters, applied in the field of indoor units, can solve problems such as poor installation, disengagement of air filters, and increased interval between filter guides and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

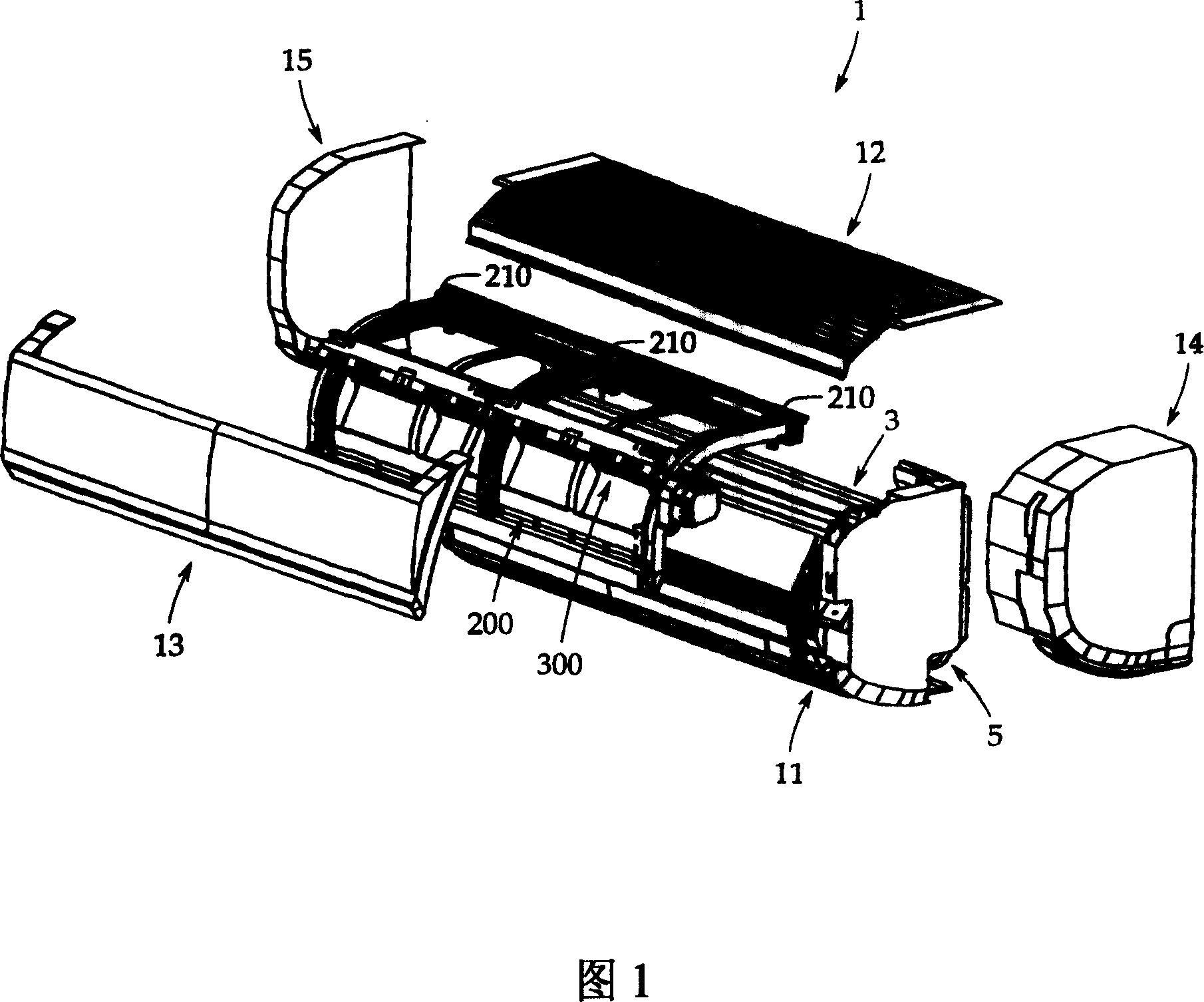

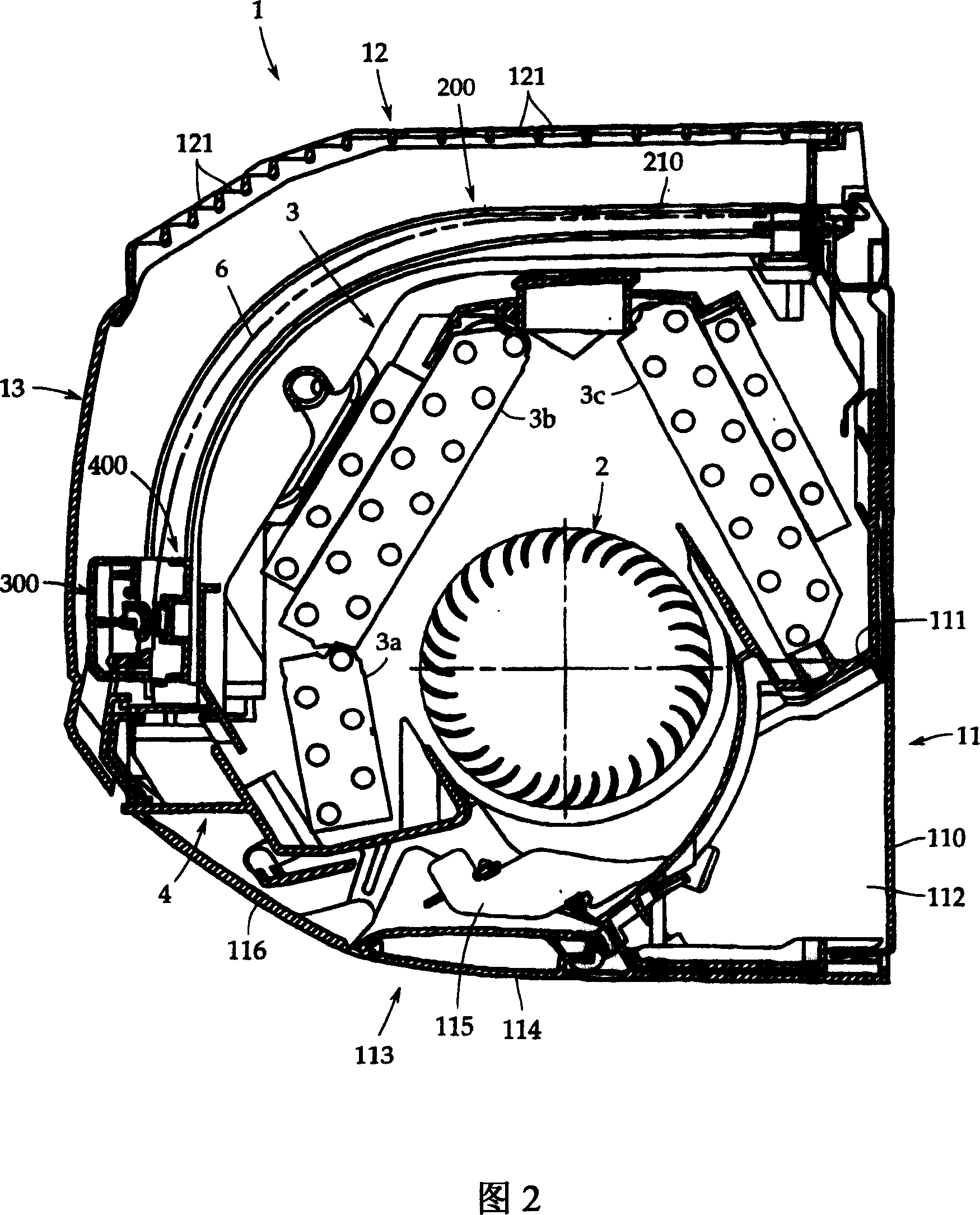

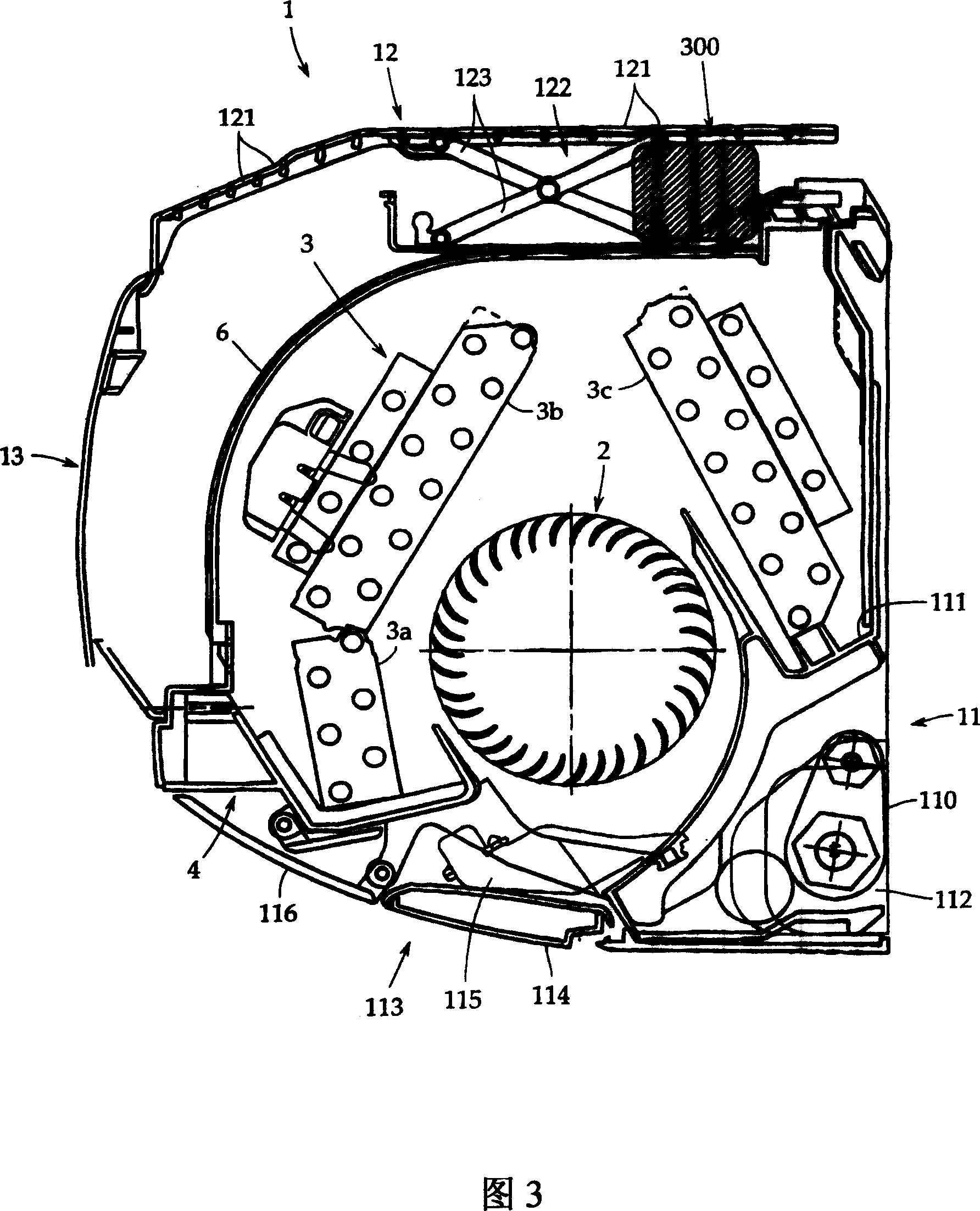

[0160] Hereinafter, embodiments of the present invention will be described with reference to the drawings. FIG. 1 is an exploded perspective view of an air conditioner according to an embodiment of the present invention. Fig. 2 is a longitudinal sectional view of the air conditioner.

[0161] As can be seen from Fig. 1 and Fig. 2, the fuselage casing 1 of this air conditioner comprises: the back plate 110, the base plate 11, the upper panel 12, the front panel 13, the right side that are fixed on the wall with fixing screws (not shown). Panel 14, and left side panel 15. All these parts are molded problowers of synthetic resin. The fuselage shell is combined with a transverse air flow fan 2 as a fan, a heat exchanger 3, a drain pan 4, and the like.

[0162] The base plate 11 is fixed to the back plate 110 with a pair of left and right side plates (not shown) formed to hang from both sides of the heat exchanger 3 to the wall. Between the side plates, a cross-flow fan 2 and a...

no. 2 approach

[0235] In addition, FIG. 18 is a perspective view of a second embodiment of an air conditioner according to the present invention. FIG. 19 is a diagram for explaining a second embodiment of the present invention; FIG. 19A is a first sectional view thereof, and FIG. 19B is an enlarged view of an essential part thereof. Fig. 20 is a second sectional view of a second embodiment of the air conditioner according to the present invention. Fig. 21 is a third sectional view of the second embodiment of the air conditioner according to the present invention. Fig. 22 is a diagram for explaining a third embodiment of an air conditioner according to the present invention; Fig. 22A is a first sectional view thereof, and Fig. 22B is an enlarged view of an essential part thereof. Fig. 23 is a second sectional view of a third embodiment of the air conditioner according to the present invention. Fig. 24 is a third sectional view of a third embodiment of the air conditioner according to the pr...

no. 3 approach

[0255] Now, referring to FIG. 8 and FIGS. 22 to 25 , a description will be given of the configuration and operation as a third embodiment in which the upper panel 1001 b is forcibly opened outward in contact with the dust removing device 1007 .

[0256] As can be seen from FIG. 22A which is the first state, the dust removal device 1007 is configured with a dimension A from the air filter 1004 to the outside of the dust removal device 1007 housing. The dust remover 1007 is accommodated within the range of dimension B from the opposing air filter 1004 to the front panel 1001a, opposite to the lower end of the front of the air filter 1004, in a relationship of "dimension A<dimension B".

[0257] The upper panel 1001b is changed so that it can move vertically through the link mechanism 1010 provided on both sides of the upper panel 1001b, so that the dust removal device does not contact it.

[0258] In addition, the upper panel 1001b is mounted on the upper portion of the air cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com