Preparation method of silica-doped high-performance graphene material

A graphene and silicon doping technology, applied in the field of graphene doping, can solve the problems of mild reaction conditions, no environmental protection, etc., and achieve the effects of mild reaction conditions, low cost, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of silicon-doped high-performance graphene material, described preparation method comprises the steps:

[0034] Step 1, adding graphene oxide to deionized water, and then adding a dispersant to ultrasonically disperse for 20 minutes to obtain a graphene oxide dispersion;

[0035] Step 2, adding the sodium hydroxide solution to the graphene oxide dispersion for 1 hour of microwave reaction to obtain an alkalized graphene oxide dispersion;

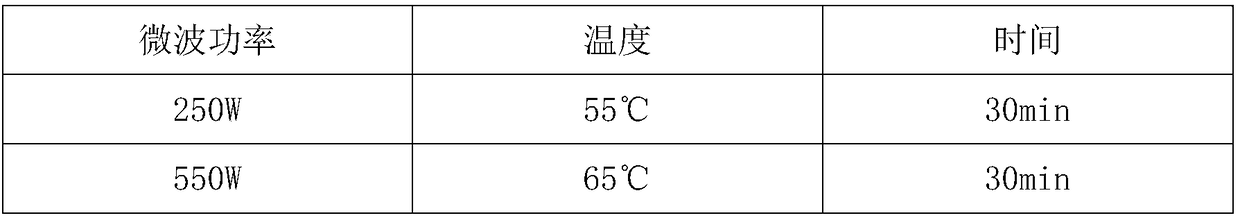

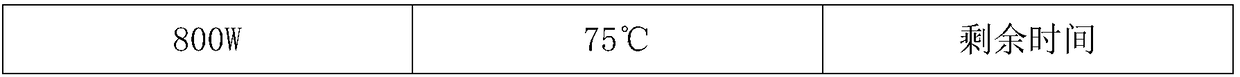

[0036] Step 3, adding ethyl silicate and tea polyphenols to absolute ethanol in sequence, stirring evenly, and slowly adding them dropwise into the alkalized graphene oxide dispersion for gradient microwave reaction for 3 hours to obtain a reaction mixture;

[0037] Step 4, adding hydrochloric acid to the reaction mixture until neutrality is formed, then ultrasonically reacting for 30 minutes, and obtaining graphene precipitation after filtration;

[0038] Step 5, putting the graphene precipitate into abs...

Embodiment 2

[0050] A kind of preparation method of silicon-doped high-performance graphene material, described preparation method comprises the steps:

[0051] Step 1, adding graphene oxide to deionized water, and then adding a dispersant to ultrasonically disperse for 40 minutes to obtain a graphene oxide dispersion;

[0052] Step 2, adding the sodium hydroxide solution to the graphene oxide dispersion and reacting with microwaves for 3 hours to obtain an alkalized graphene oxide dispersion;

[0053] Step 3, adding ethyl silicate and tea polyphenols to absolute ethanol in sequence, stirring evenly and slowly adding them dropwise to the alkalized graphene oxide dispersion for 5 hours of gradient microwave reaction to obtain a reaction mixture;

[0054]Step 4, adding hydrochloric acid to the reaction mixture until neutrality is formed, then ultrasonically reacting for 60 minutes, and obtaining graphene precipitation after filtration;

[0055] Step 5, put the graphene precipitate into abso...

Embodiment 3

[0067] A kind of preparation method of silicon-doped high-performance graphene material, described preparation method comprises the steps:

[0068] Step 1, adding graphene oxide to deionized water, and then adding a dispersant to ultrasonically disperse for 30 minutes to obtain a graphene oxide dispersion;

[0069] Step 2, adding the sodium hydroxide solution to the graphene oxide dispersion and reacting with microwaves for 2 hours to obtain an alkalized graphene oxide dispersion;

[0070] Step 3, adding ethyl silicate and tea polyphenols to absolute ethanol in sequence, stirring evenly, and slowly adding them dropwise into the alkalized graphene oxide dispersion liquid for gradient microwave reaction for 4 hours to obtain a reaction mixture;

[0071] Step 4, adding hydrochloric acid to the reaction mixture until neutrality is formed, then ultrasonically reacting for 50 minutes, and obtaining graphene precipitation after filtration;

[0072] Step 5, put the graphene precipita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com