Gas type fine reduction furnace for steel strips

A reduction furnace, gas-fired technology, applied in the field of gas-fired steel strip fine reduction furnaces, to achieve the effects of increasing production capacity, consistent quality of iron powder reduction, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

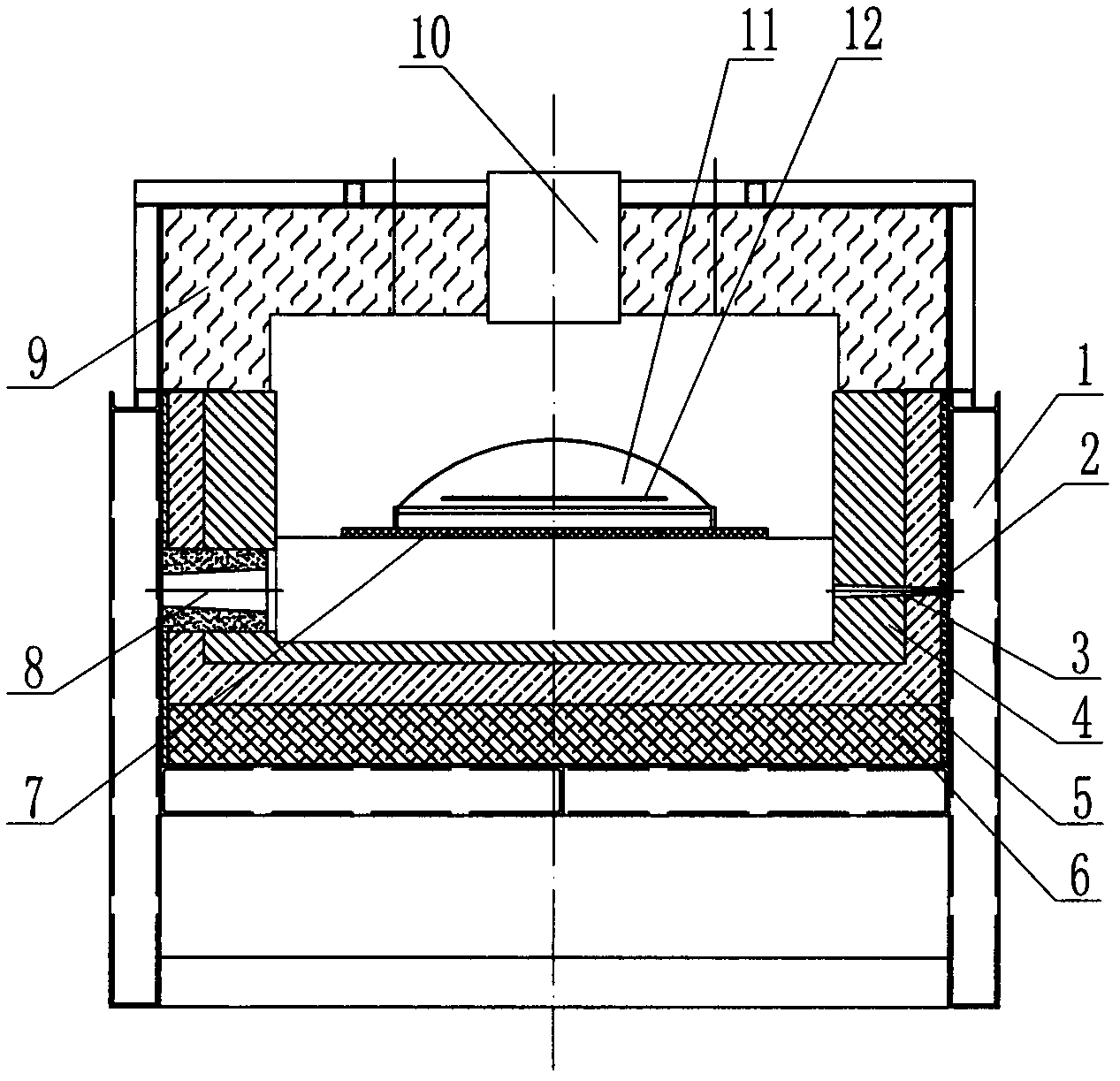

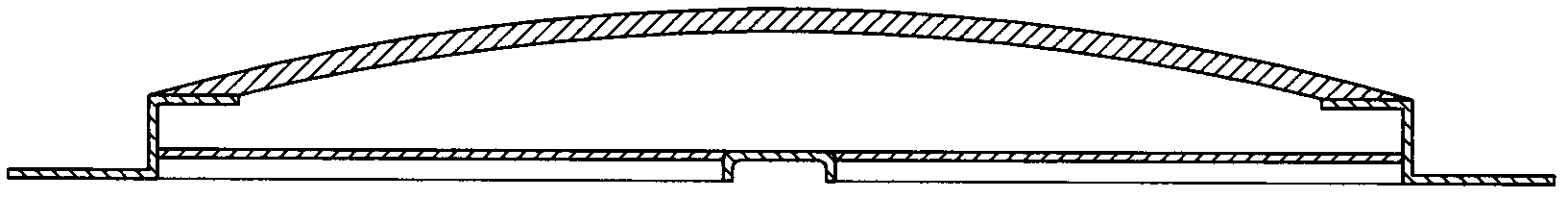

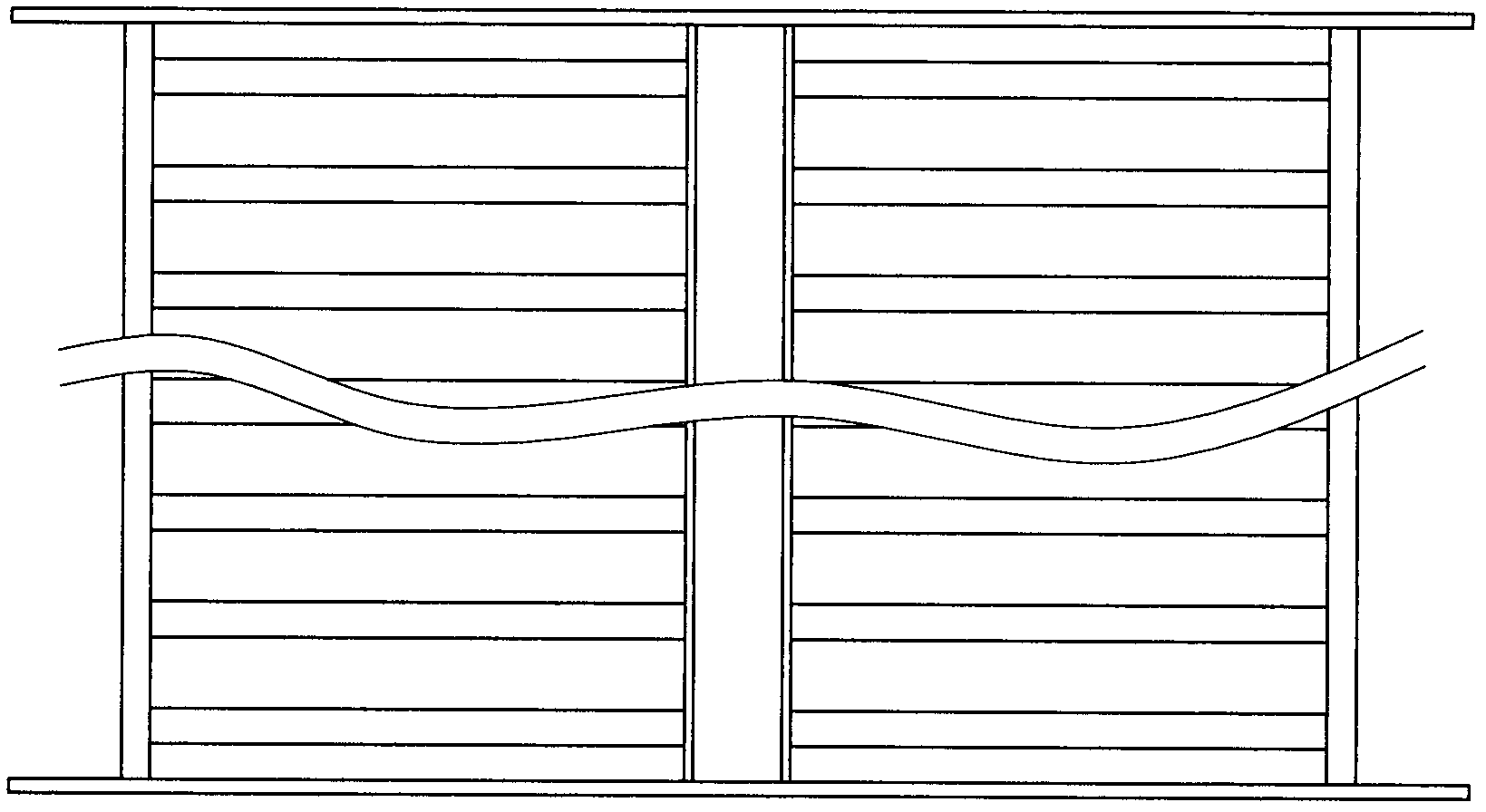

[0017] The gas-fired steel strip fine reduction furnace is the main component of the iron powder reduction production line. The gas-fired steel strip fine reduction furnace is a long strip furnace body, and its transverse section is as follows: figure 1 As shown, it includes a bracket 1, an outer shell 2, an observation hole 3, an inner furnace wall 4, an outer furnace wall 5, a substrate 6, a heat storage plate 7, a nozzle 8, a furnace roof 9, an exhaust hole 10 and a muffle tube 11 . The outer casing 2 is made of metal sheet material to place a horizontal rectangular box, the outer casing 2 is supported by the bracket 1, and the inner cavity of the outer casing 2 is provided with a bottom lining 6 tiled with light heat insulating bricks as a heat insulation layer, based on the bottom lining 6 Attach upwards to the inner walls on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com