Method for extracting and separating indium and tin from indium-containing leaching residues

A technology of leaching slag and extraction, which is applied in the field of comprehensive metal recycling and smelting, can solve the problems of low recovery rate, high processing cost, and impact on environmental protection, and achieve the effect of high metal recovery, wide source of raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

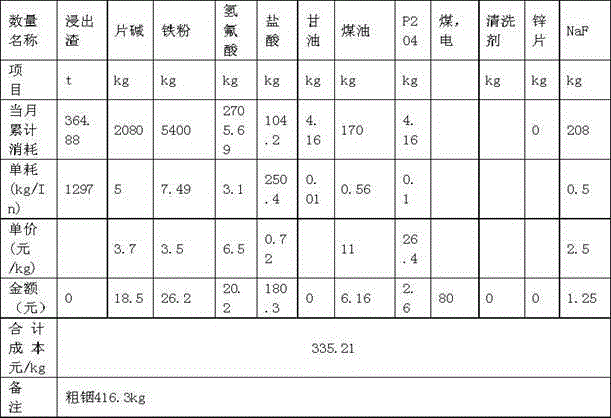

Embodiment 1

[0019] use NH 4 Re-extraction of Sn from P204 Supported Indium Tin with F+HCl

[0020] With 1.5mol / L NH 4 F+1mol / L HCl, according to O / A=3 / 1 back extraction 3 times. 3 times of stripping combined analysis of Sn 14.4g / L, In no color (no In). DescriptionNH 4 F+HCl only back-extracts tin, not indium. The organic phase after anti-tin was treated with 1mol / L H 2 S0 4 Washing, after thoroughly washing away the entrainment of the anti-tin solution in the negative indium organic phase, then use 6mol / L HCl to back-extract the indium, according to the ratio O / A=2 / 1 back-extraction 3 times, the 3-time stripping solution is combined and sampled Analysis: In0.51 g / L, Sn is colorimetric at 100ppm, no color (no Sn). Due to the 6-fold dilution of the stripping solution, the In concentration was very low. Moreover, when P204 extracts low-concentration In from a high-concentration Sn solution, much more Sn is extracted than In, but the effect of complete separation of indium and tin is ...

Embodiment 2

[0022] use NH 4 F+H 2 SO 4 Back extraction of tin from P204 loaded indium tin

[0023] With 2mol / L NH 4 F+0.5mol / L H 2 SO 4 Back-extract the tin in P204 loaded indium tin, according to the ratio O / A=2 / l, first strip for 5 minutes, clarify for 5 minutes to release the water phase pH2.5, analysis contains Sn 19.57 g / L, indium is not detected out. The second back-extraction was performed for 5 minutes, separated for 2 minutes, and the released water phase was analyzed to contain Sn6.25 g / L, and indium could not be detected. The third back-extraction was performed for 5 minutes, separated for 2 minutes, and the released aqueous phase was analyzed to contain Sn1.63 g / L, and indium could not be detected. For the fourth time, use 0.5mo 1 / L H 2 SO 4 Wash the organic phase according to the ratio O / A=2 / 1, the washing water contains Sn400ppm, and then use 6mol / L HCl to reverse the indium twice in the negative indium organic phase after pickling according to the ratio O / A=2 / 1, ...

Embodiment 3

[0025] Back-extraction of tin from P204 loaded indium tin with NaF

[0026] With 1.33mol / L NaF+0. 5mol / L H 2 SO 4 According to the comparison O / A=2 / 1 back extraction tin. The first stripping was carried out for 5 minutes, followed by clarification and phase separation in 1 minute, and the aqueous phase released in 5 minutes contained 10.87 g / L of Sn and no In was detected. The second stripping was carried out for 5 minutes, followed by clarification and phase separation in 1 minute, and the aqueous phase released in 5 minutes contained 9.5 g / L of Sn, and In was not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com