Conductive batch and conductive single fiber

A powder and polyester technology, applied in the manufacture of conductive/antistatic filaments, single-component polyester artificial filaments, melt spinning, etc., can solve the problem of difficult dispersion of carbon nanotubes, loss of original characteristics, polymer base The material is easy to crack and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] Feed the Nanocyl 7000 carbon nanotubes into an ultra-high-speed powder grinder, and grind at a speed of 30,000 rpm for 5 minutes to form carbon nanotube powders with good dispersibility.

[0120] 20 grams (1.00%) of the carbon nanotube powder formed above, 2 grams (0.10%) of the A-C540A dispersant and 2 grams (0.10%) of 2,2'-methylenebis[(4, s)-4-phenyl-2-oxazoline] was added into 1976 g (98.80%) of polybutylene terephthalate (PBT) polymer substrate to obtain a PBT polyester mixture. Afterwards, the polyester mixture is fed into a high-speed composite powder kneader, and kneaded at a speed of 2000rpm, and the mixing time is 30 minutes, so that the Nanocyl 7000 nanometer carbon tube powder can be quickly and evenly dispersed in the PBT polymer. In the ester base material, PBT polyester base material powder containing uniformly dispersed carbon nanotube powder was obtained.

Embodiment 2 to 6

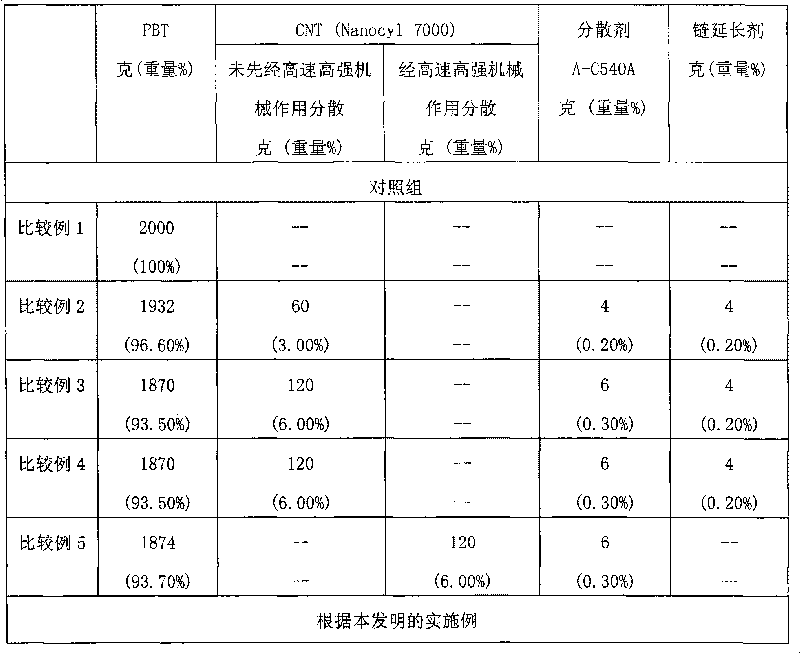

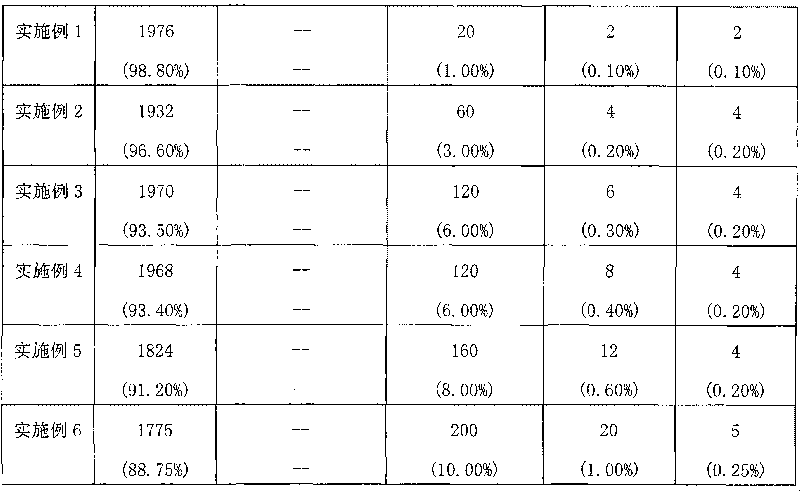

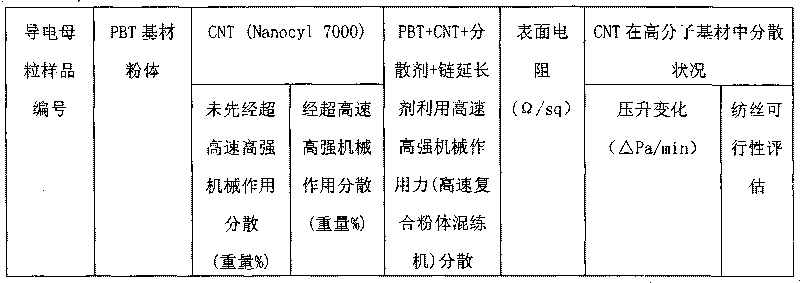

[0122] In the same manner as in Example 1, according to the composition weight ratios listed in Table 1, the PBT polyester substrate powders containing uniformly dispersed carbon nanotube powders in Examples 2 to 6 were obtained.

[0123] Table 1

[0124]

[0125]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com