Method for preparing calcium soap by utilizing quick lime and method for processing produced emulsified compound

A technology of quicklime and mixture, which is applied in the field of preparation of calcium soap with quicklime and the treatment of the emulsified mixture produced, which can solve the problems of extraction agent consumption, extraction agent loss, large production cost, etc., and achieve low operating cost, reduced consumption, and connection convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The process parameters are as follows:

[0036] Take the ammonium chloride wastewater whose concentration is 4mol / L on the production line: 200ml; industrial grade quicklime: 30g; the blank P507 (organic phase) whose concentration is 1.5mol / L: 3.0L.

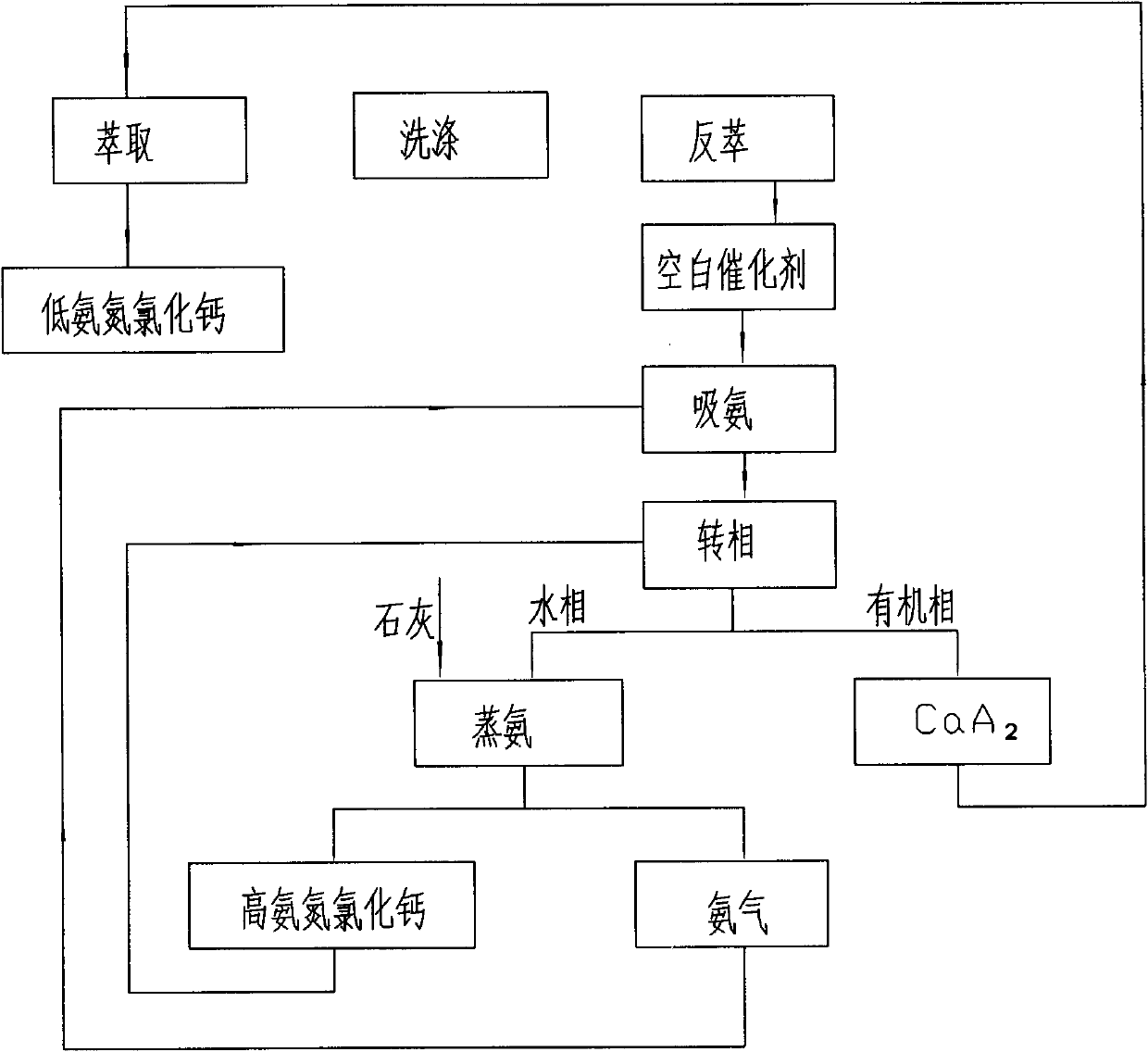

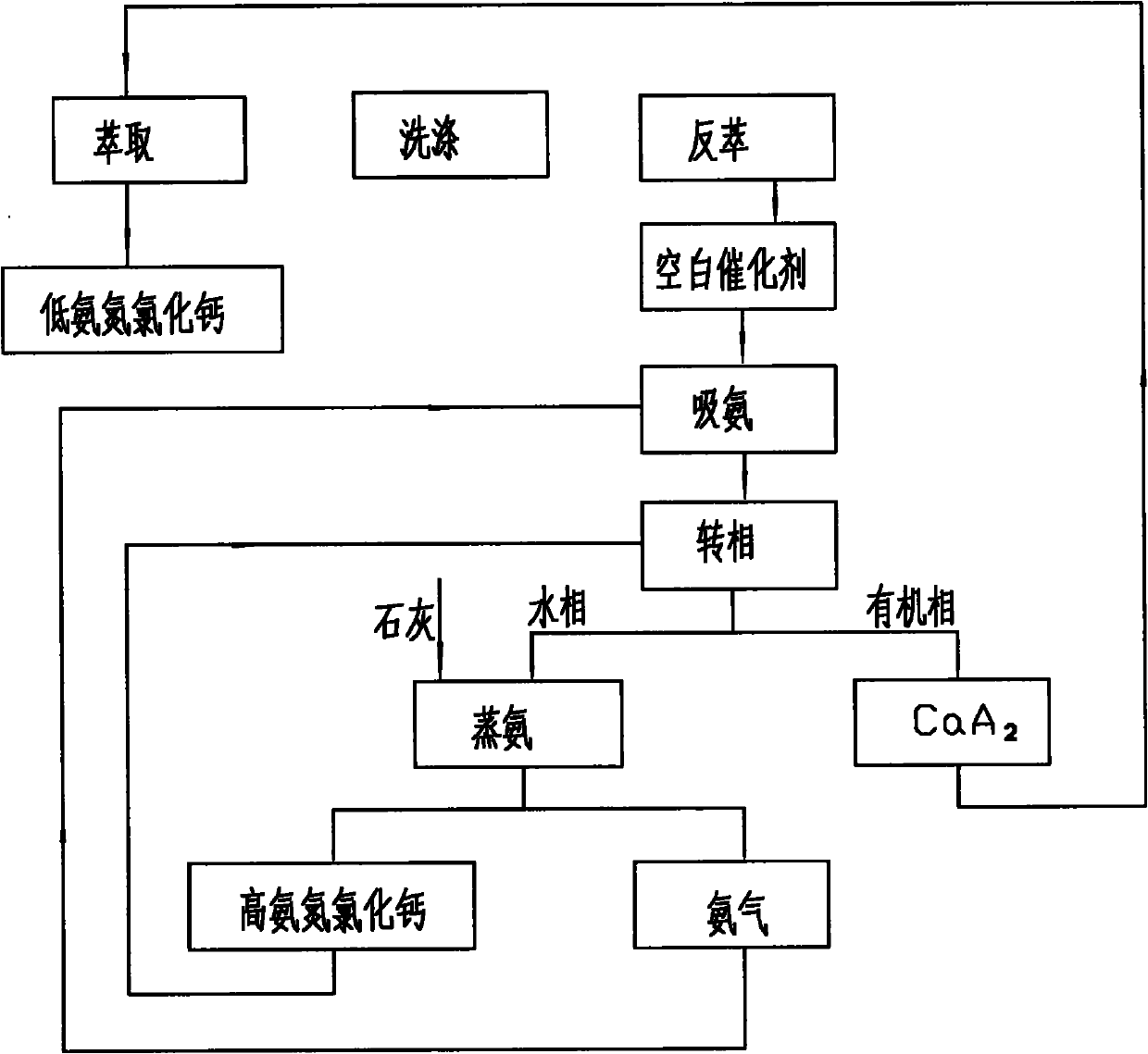

[0037] Refer to attached Figure 1~2 , the process steps are as follows:

[0038] a. Ammonia steaming-ammonia absorption

[0039] In a distillation bottle, mix quicklime (CaO) with ammonium chloride wastewater, and heat to distill ammonia. Absorb the evaporated ammonia gas with 3.0L blank P507 with a concentration of 1.5mol / L to form ammonium soap, and the degree of saponification of the ammonium soap is 25% as measured by titration; after the reacted solution is filtered or clarified, high-concentration ammonia nitrogen calcium chloride is obtained solution.

[0040] b. Phase inversion

[0041] Add ammonium soap and high-concentration ammonia nitrogen calcium chloride solution into a separatory funnel, mix and stir, an...

Embodiment 2

[0045] The process parameters are as follows:

[0046] Take the ammonium chloride wastewater whose concentration is 4mol / L on the production line: 300ml; milk of lime: 40g; the blank P507 (organic phase) whose concentration is 0.8mol / L: 10.0L.

[0047] The process steps are as follows:

[0048] a. Ammonia steaming-ammonia absorption

[0049] In a retort, milk of lime (Ca(OH) 2 ) mixed with ammonium chloride wastewater, and heated to distill ammonia. Absorb the evaporated ammonia gas with 10.0L of blank P507 with a concentration of 0.8mol / L to form ammonium soap, and measure the degree of saponification of the ammonium soap to be 35%; after the reacted solution is filtered or clarified, a high-concentration ammonia nitrogen calcium chloride solution is obtained .

[0050] b. Phase inversion

[0051] Add ammonium soap and high-concentration ammonia nitrogen calcium chloride solution into a separatory funnel, mix and stir, and then separate into layers. The phase inversion ...

Embodiment 3

[0055] The process parameters are as follows:

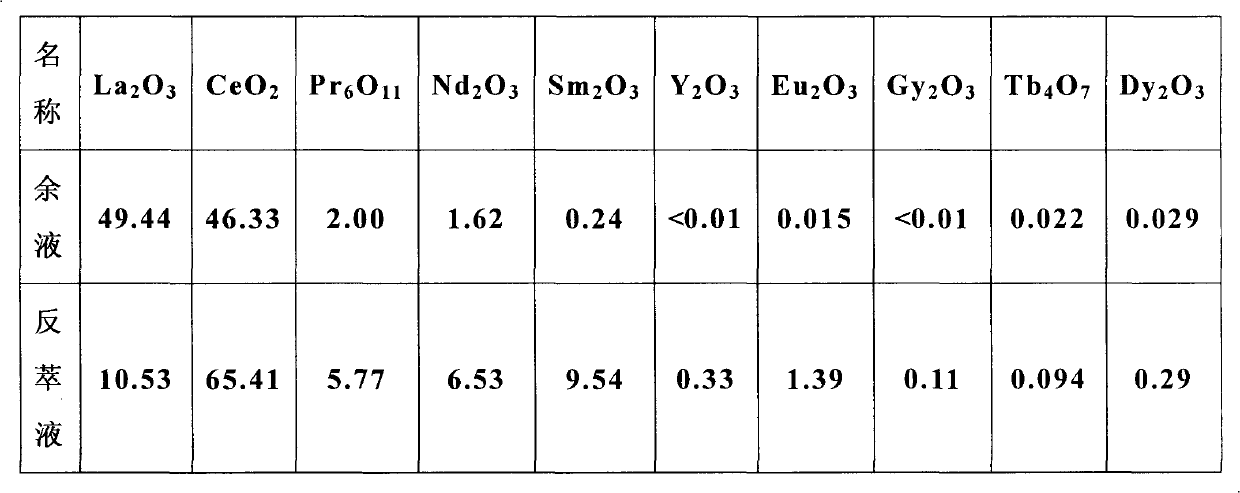

[0056] Get the ammonium chloride waste water that concentration is 4mol / L on the production line: 250ml; Industrial grade unslaked lime: 35g; Concentration is the blank P204 of 1.0mol / L: 6.0L, concentration is the (LaCe)Cl of 1.2mol / L 3 Feed liquid: 20ml.

[0057] The process steps are as follows:

[0058] a. Ammonia steaming-ammonia absorption

[0059] In the distillation bottle, mix quicklime and ammonium chloride wastewater, and heat to distill ammonia. It is 1.0mol / L blank P204 to absorb the ammonia gas that evaporates to form ammonium soap with 6.0L concentration, and the measured ammonium soap saponification degree is 32%.

[0060] b. Phase inversion

[0061] Add ammonium soap and high-concentration ammonia-nitrogen calcium chloride solution into the separating funnel, mix and stir, and then separate into layers, and perform phase inversion operation one by one. The shaking time is 5 minutes each time. 20ml / time; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com