Method and device for generating by using plant straw biological substances and Strling engine

A technology of biomass and plant straw, which is applied in the direction of hot gas variable capacity engine devices, biofuels, machines/engines, etc., can solve the problems of large corrosion of metal materials on the inner wall of the boiler and affect the safe operation of the boiler, and achieve the goal of solving the utilization problem Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

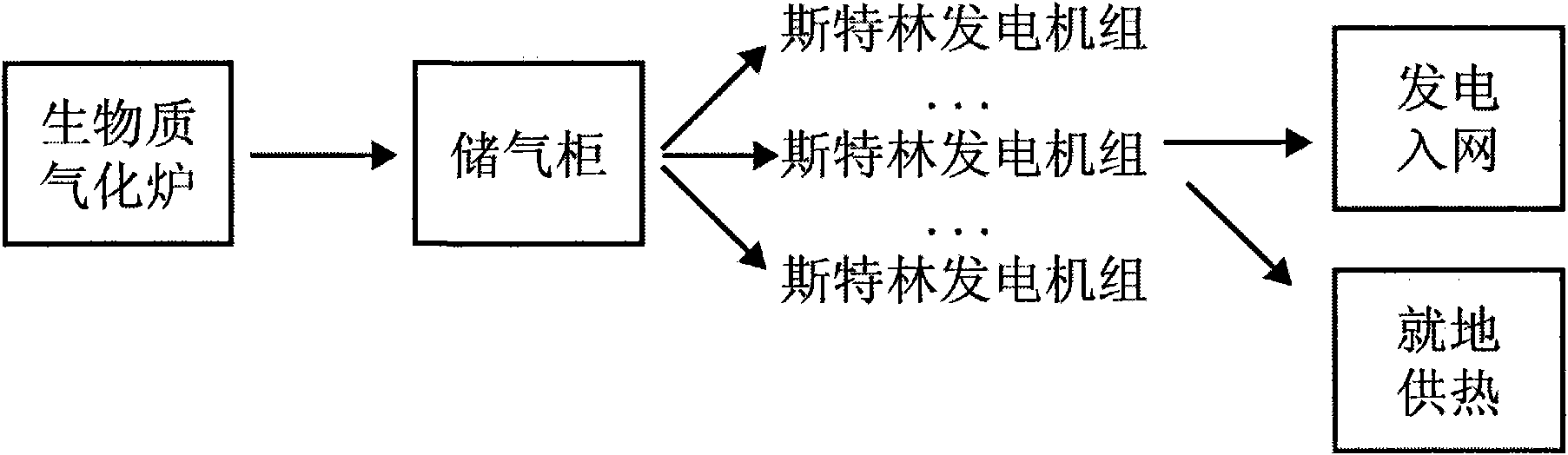

[0024] The present invention is a method for generating electricity by utilizing plant straw biomass and a Stirling machine, comprising the following operation steps:

[0025] (1) Putting plant straw and / or leaves, chaff, sawdust, or bamboo cassava and other biomass into the biomass gasifier. These biomasses include agricultural residues of plant straw, rice husks, husks, corn hearts, bagasse, cotton meal, hemp meal, or tung meal and / or forestry residues of trivial wood, bark, or sawdust; The moisture content of the biomass entering the biomass gasifier should be less than 15%, and its length should be less than or equal to 50mm.

[0026] (2) The biomass is pyrolyzed in a fully enclosed gasifier to generate combustible gas; these pyrolyzed combustible gases ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com