Patents

Literature

106results about "Pigment preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

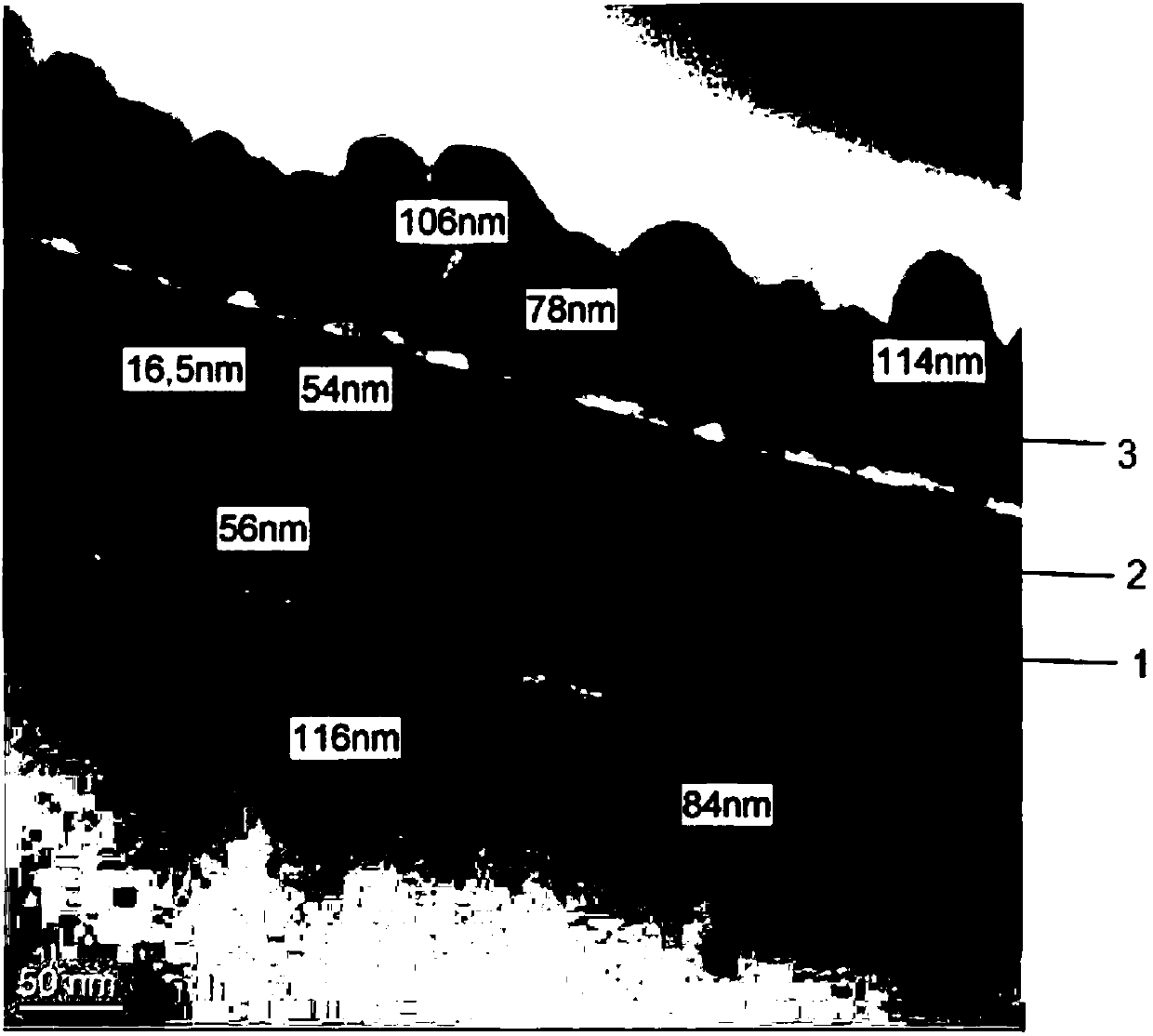

Organic-inorganic hybrid material, optical thin layer of this material, optical material comprising same, and process for producing same

InactiveUS20110003130A1Easy to useMaterial nanotechnologyAnti-reflective coatingsInorganic compoundOptical thin film

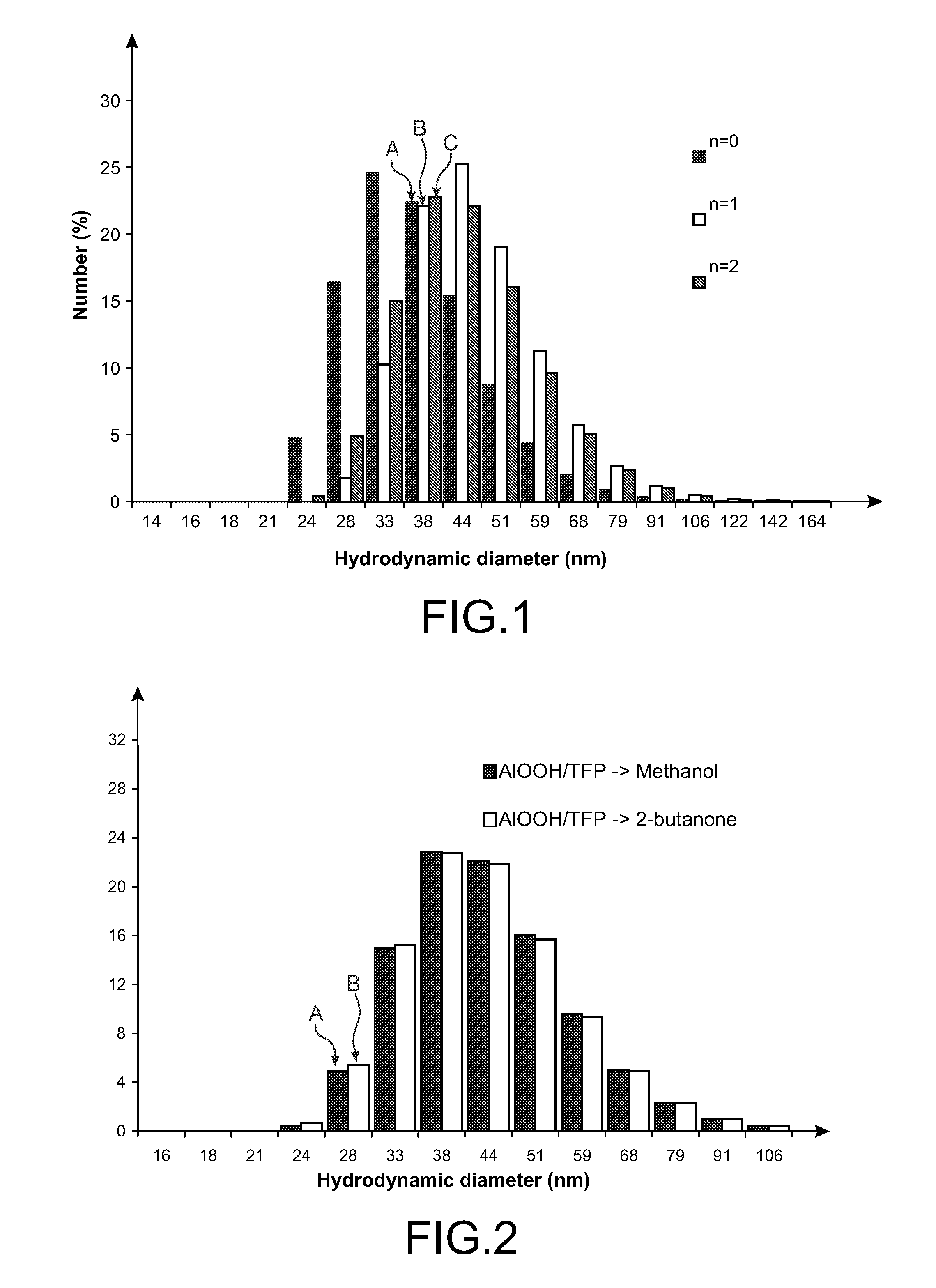

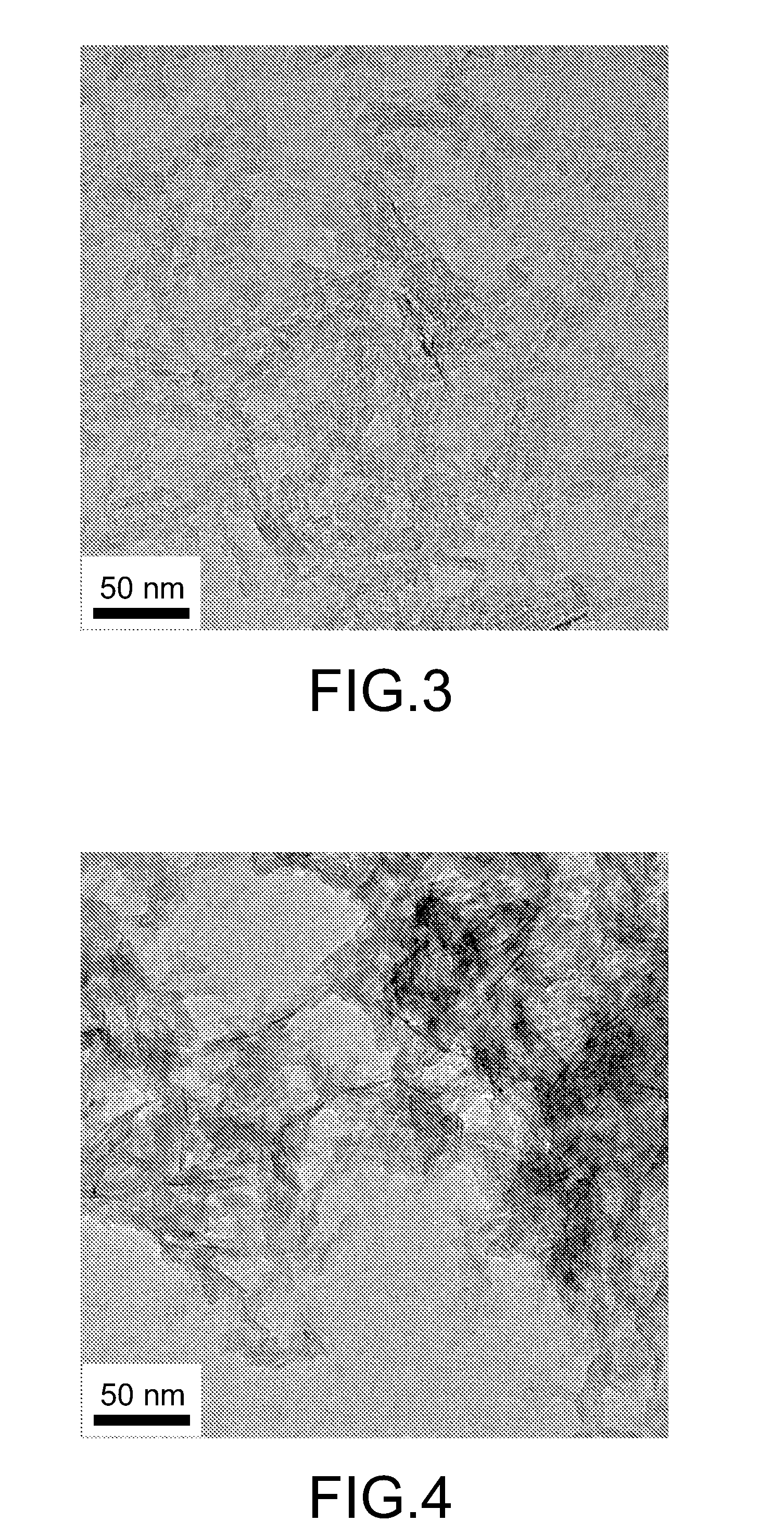

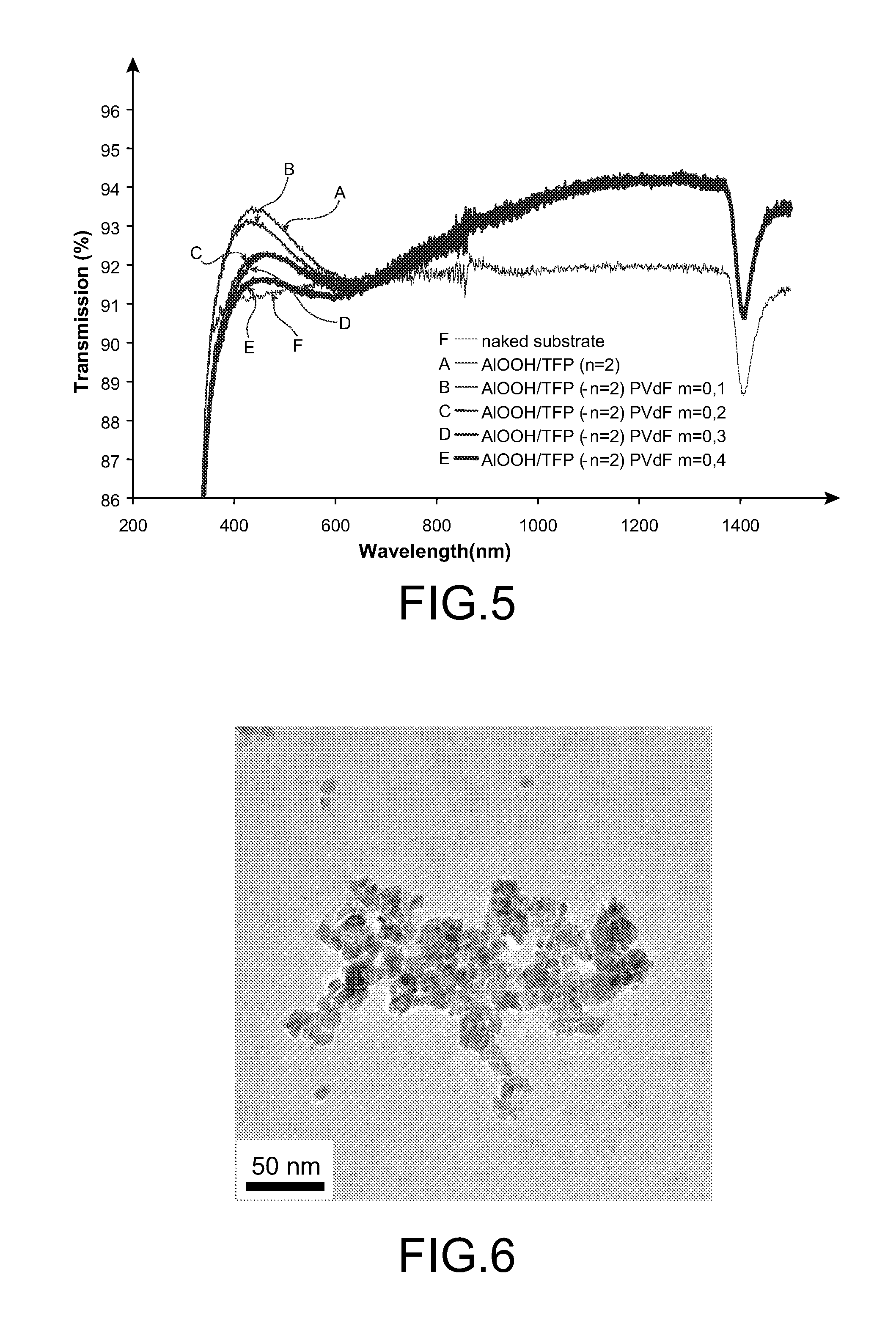

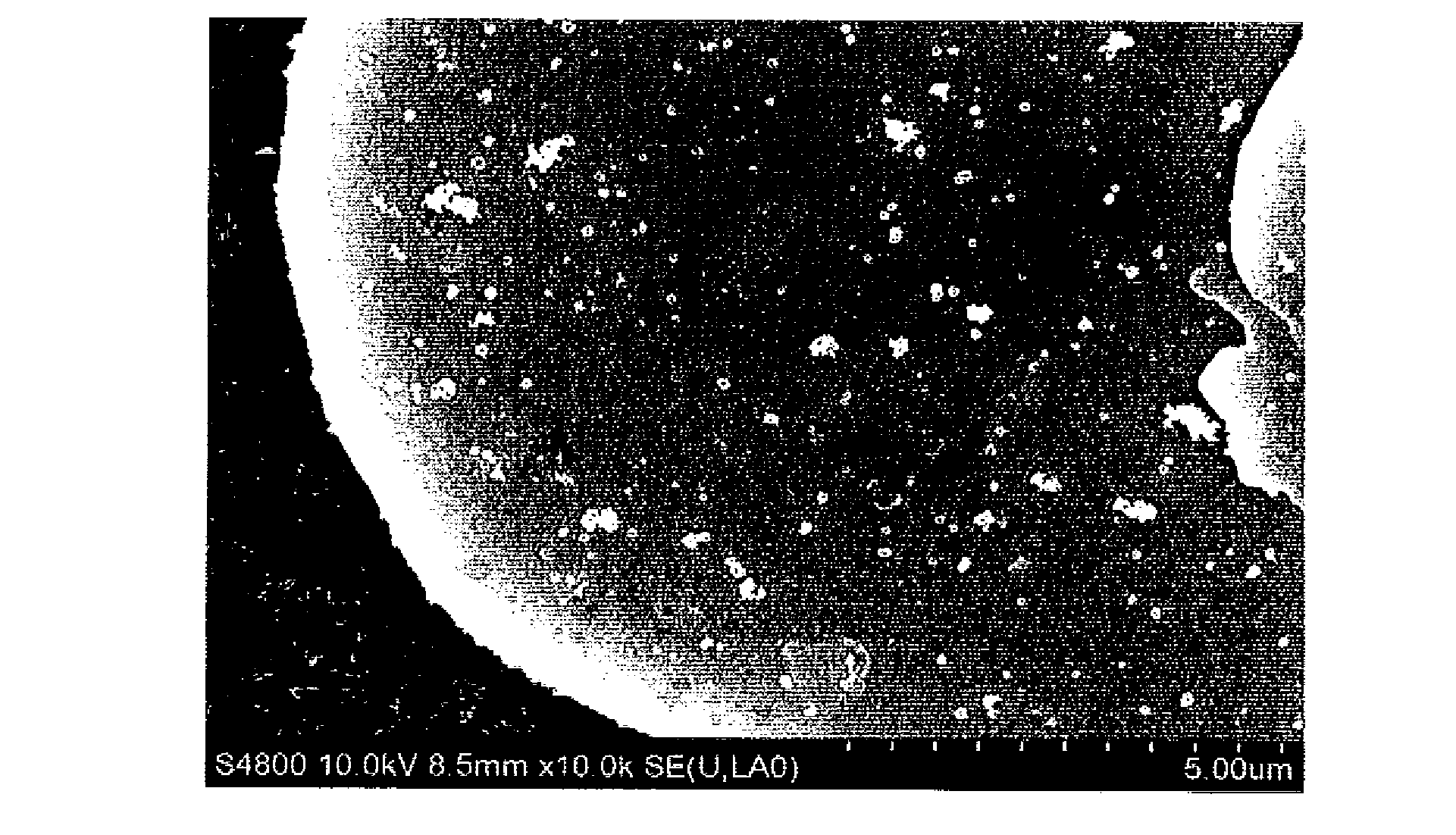

Organic-inorganic composite material comprising:colloidal particles of at least one inorganic compound chosen from metal or metalloid oxides and oxyhydroxides, prepared by means of a process of hydrolysis-condensation in a protic or polar solvent, said particles having been surface-functionalised by reaction with an organic compound;and an organic or inorganic polymer.Process for preparing this composite material and optical material comprising a layer of this composite material.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

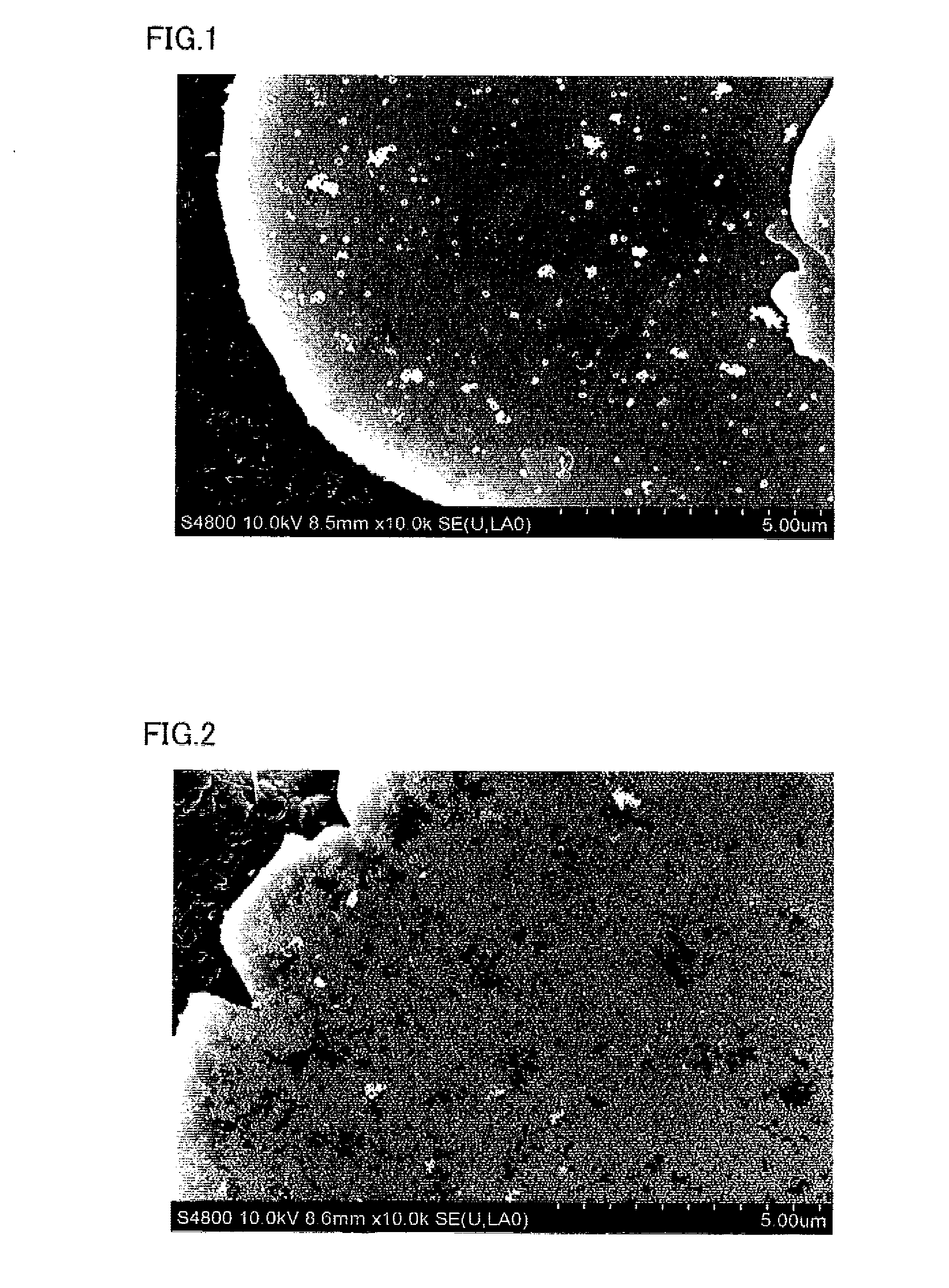

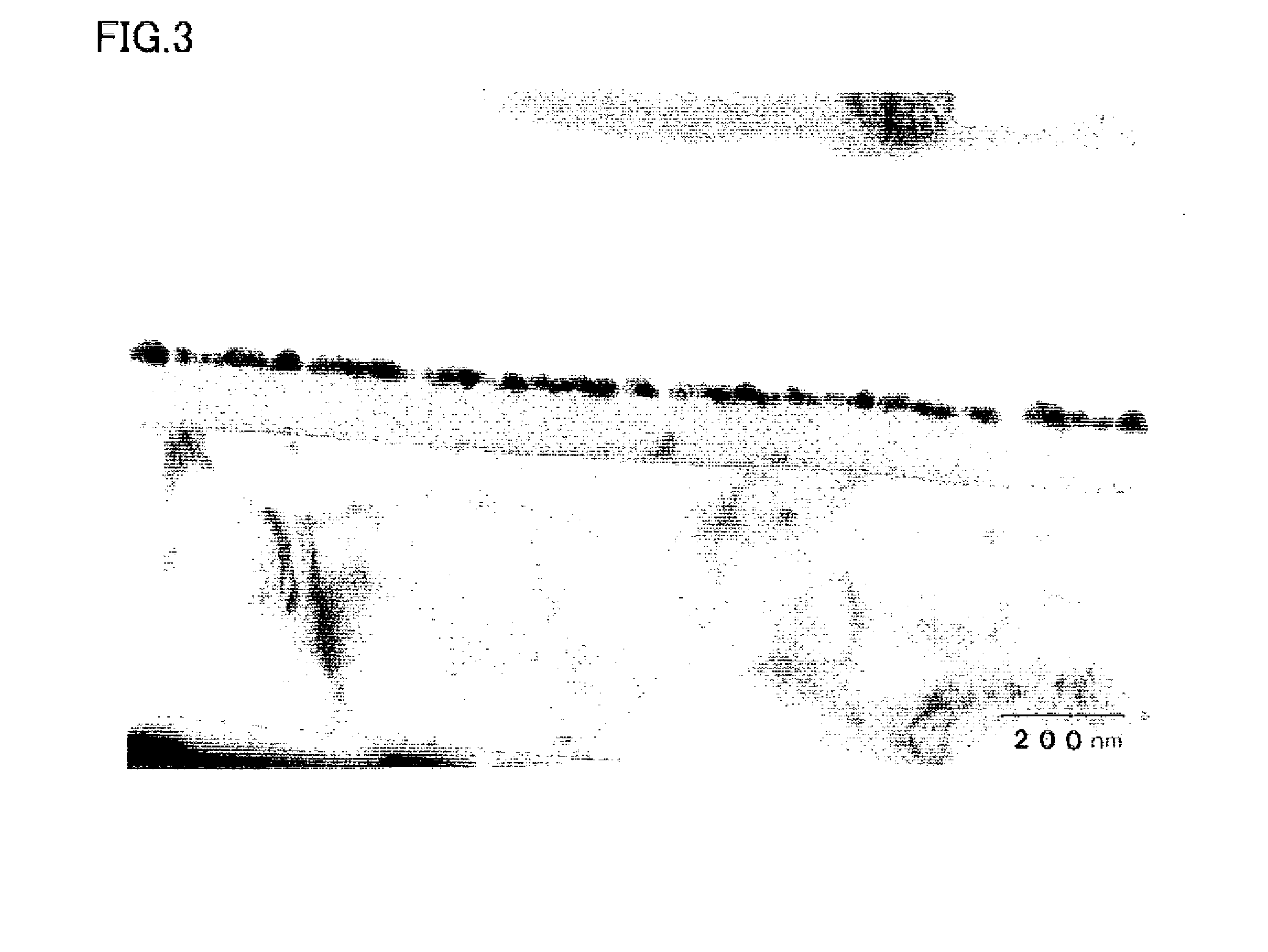

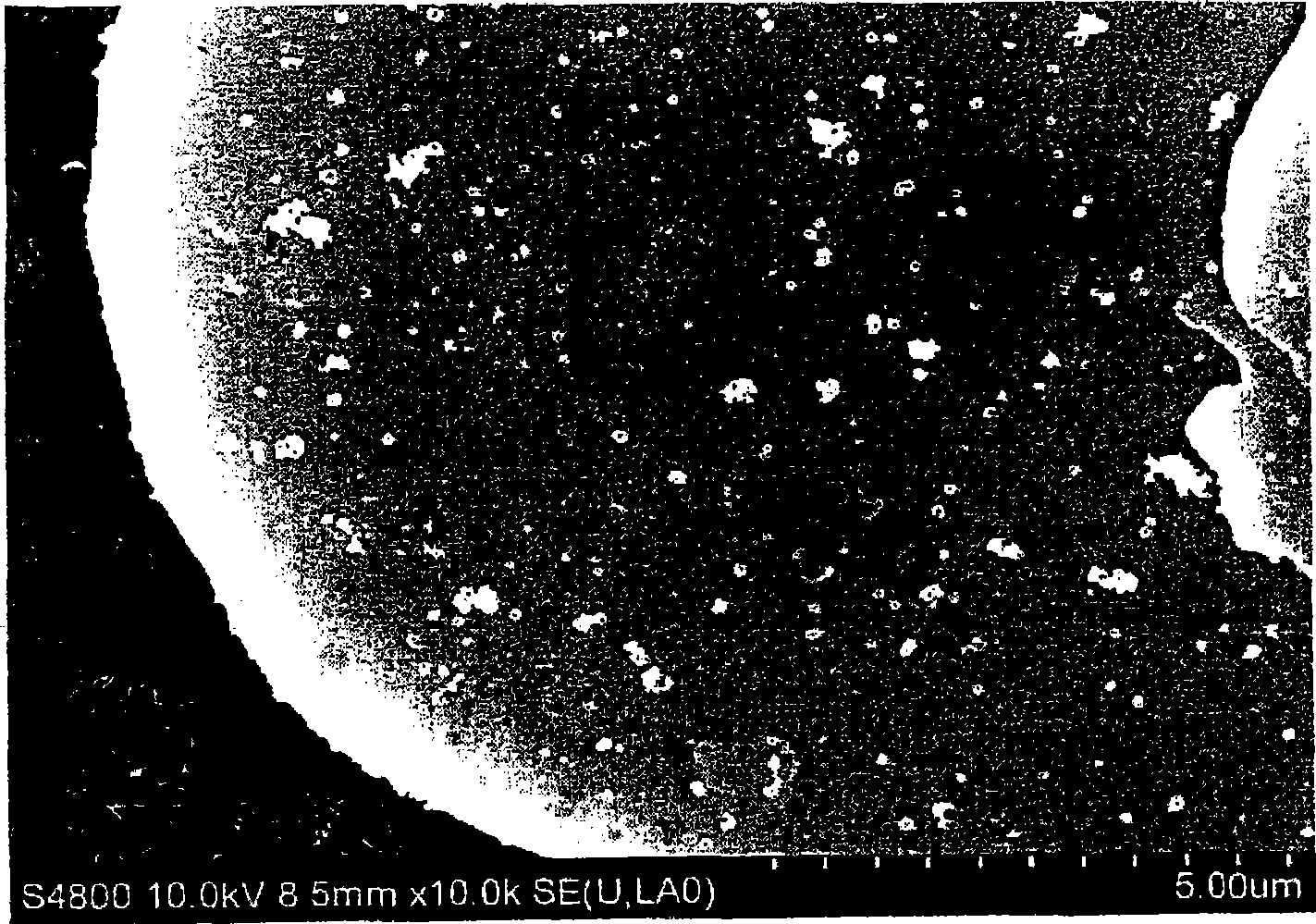

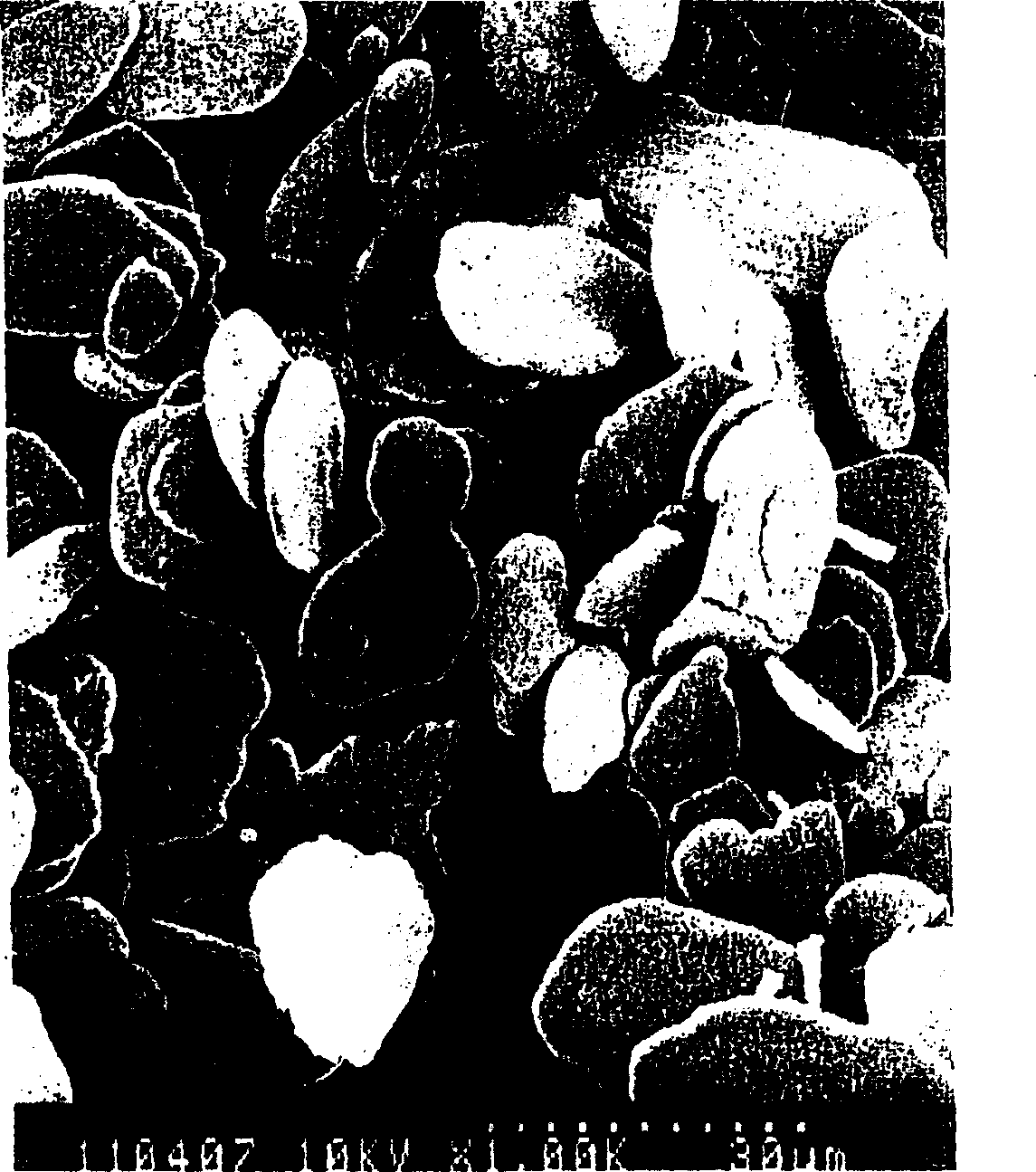

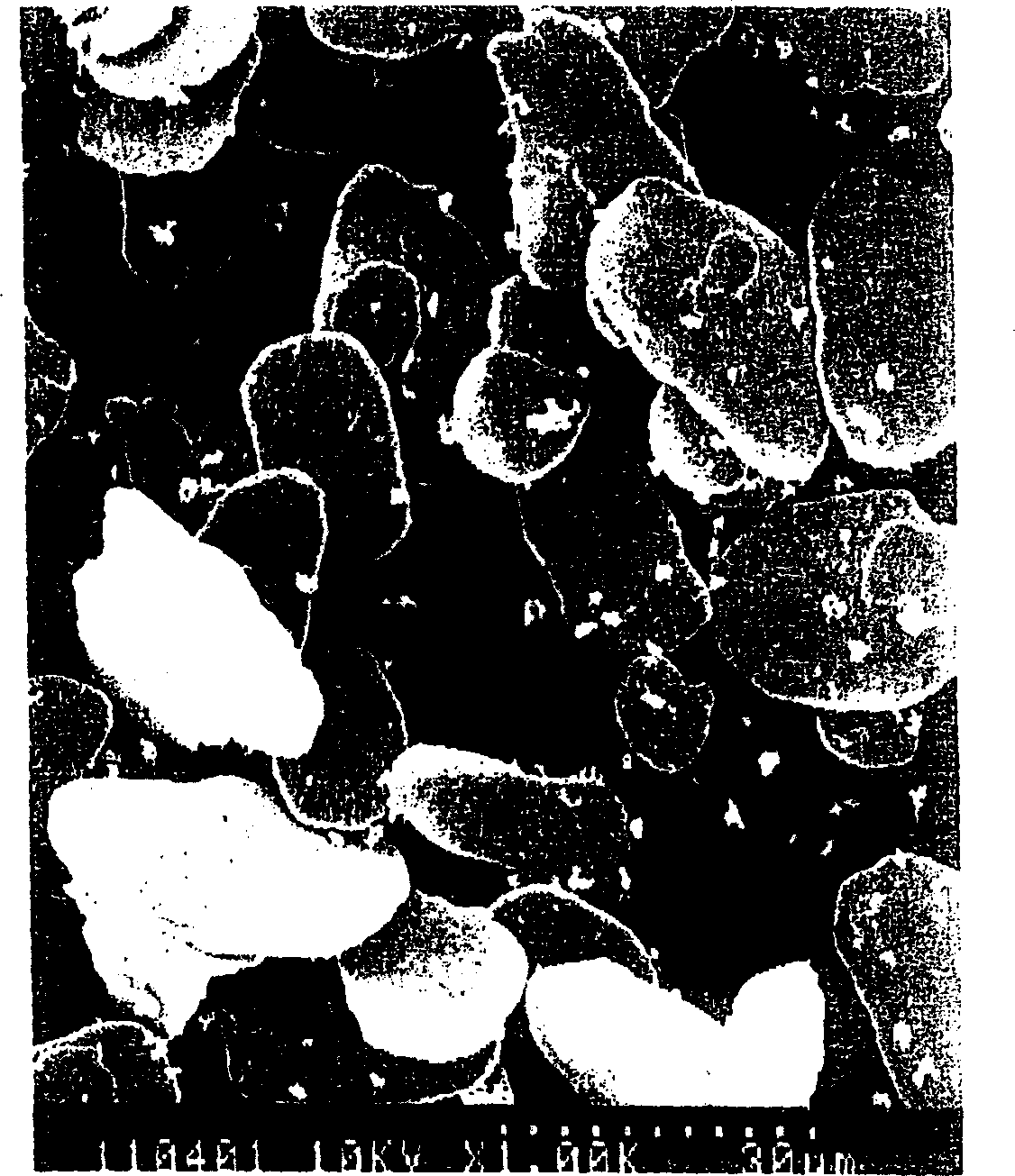

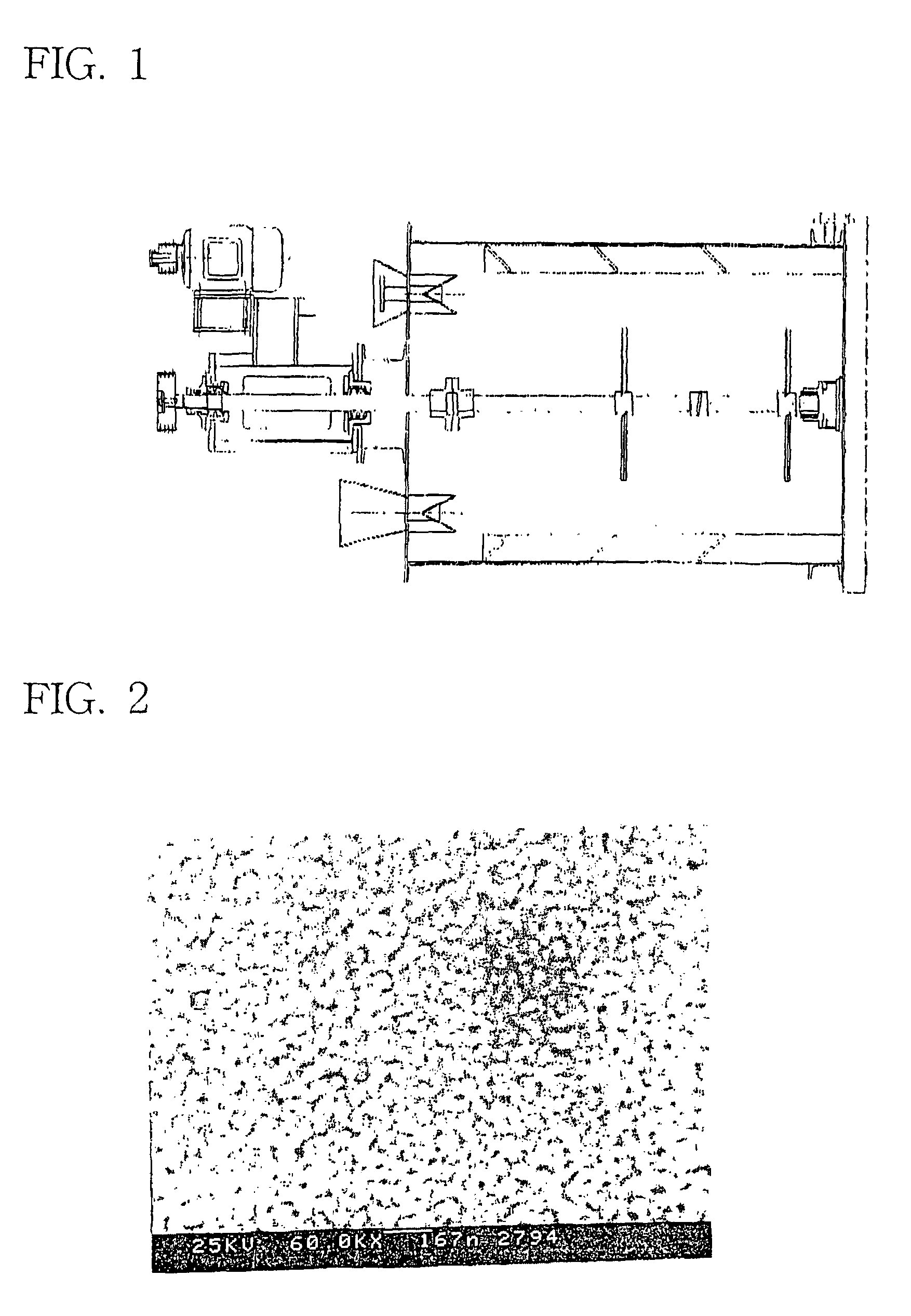

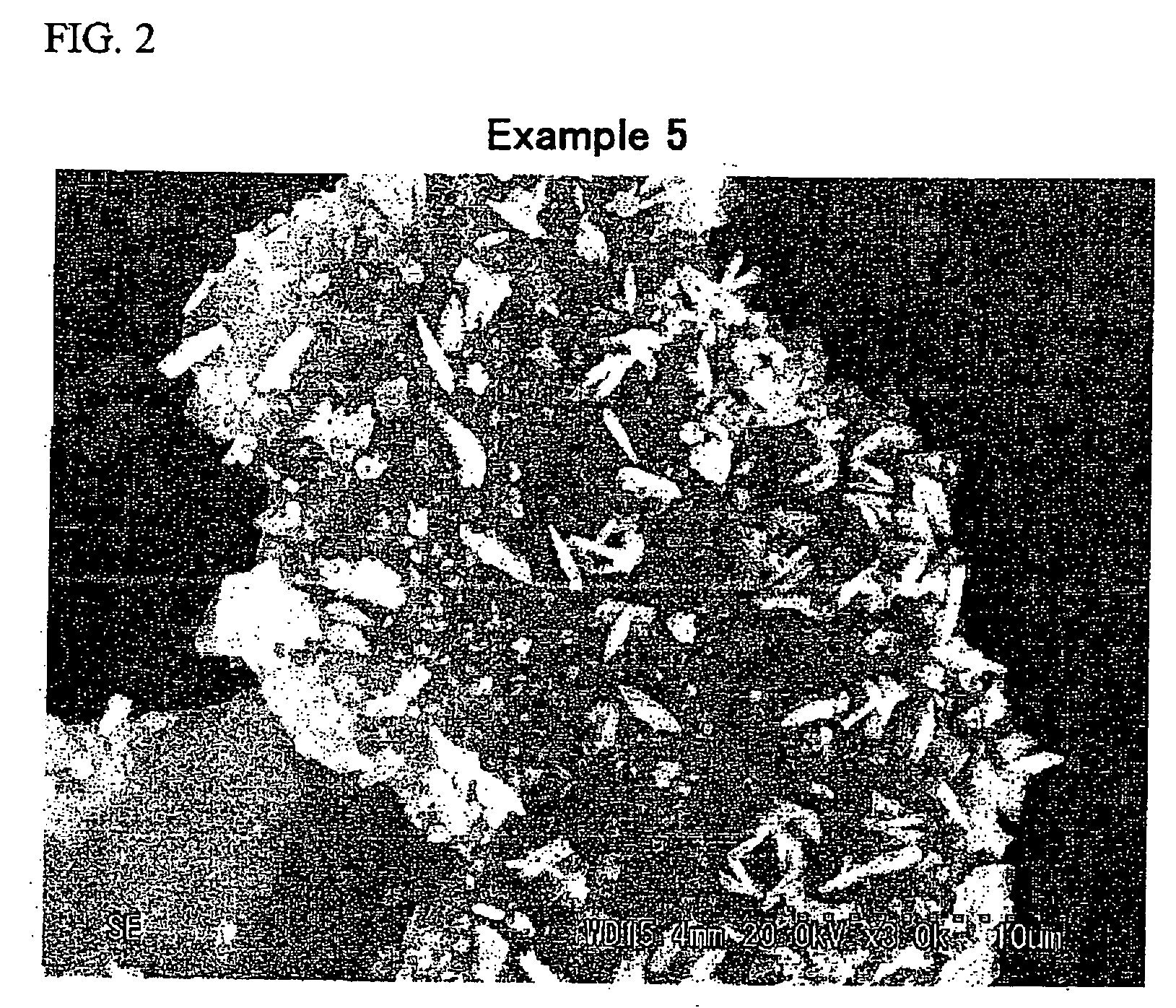

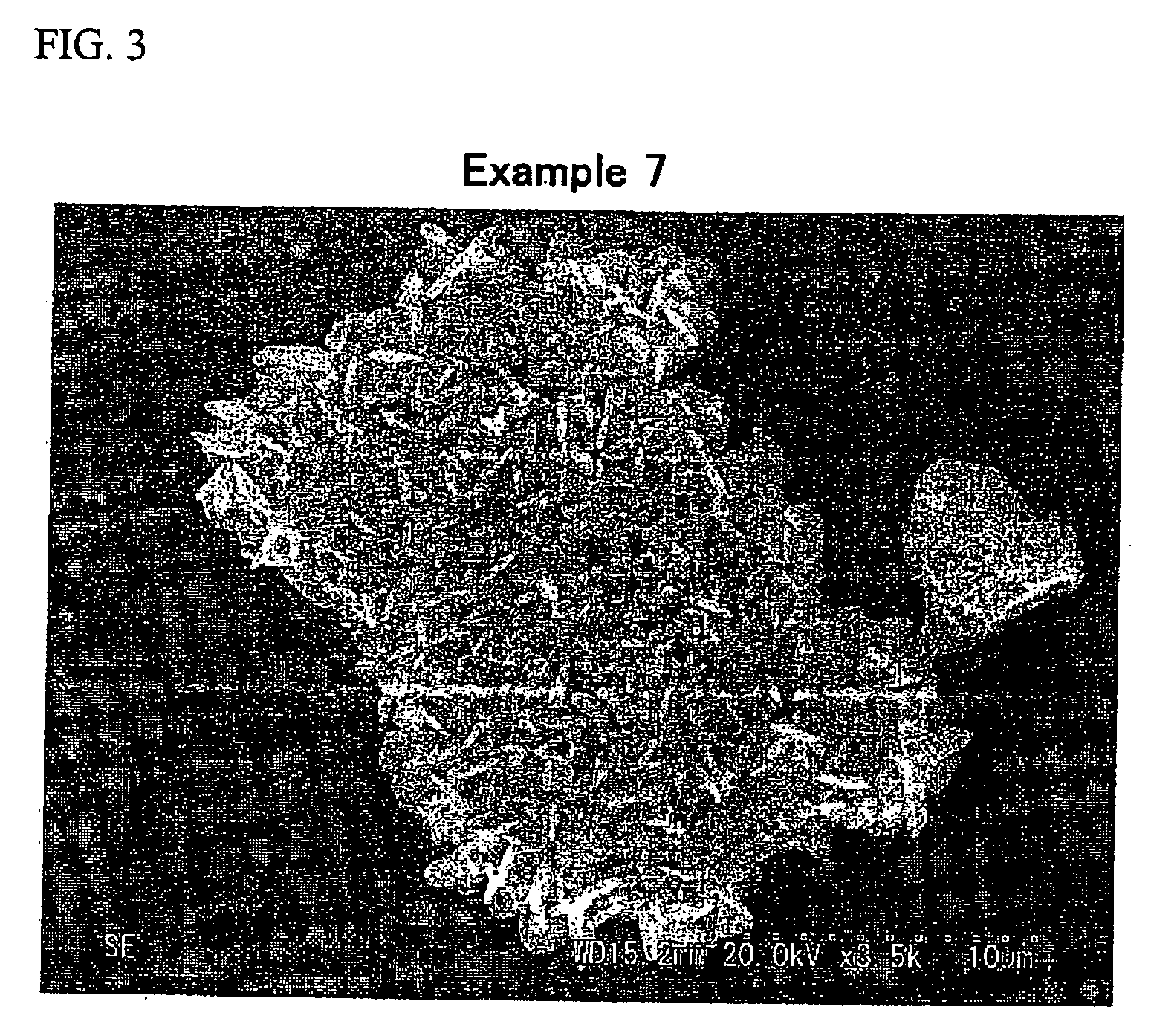

Colored metallic pigment, process for producing the same, and coating composition and cosmetic preparation containing said colored metallic pigment

ActiveUS20090017082A1Excellently maintaining light resistanceExcellently resistance weatherCosmetic preparationsMake-upInterference colorNonferrous metal

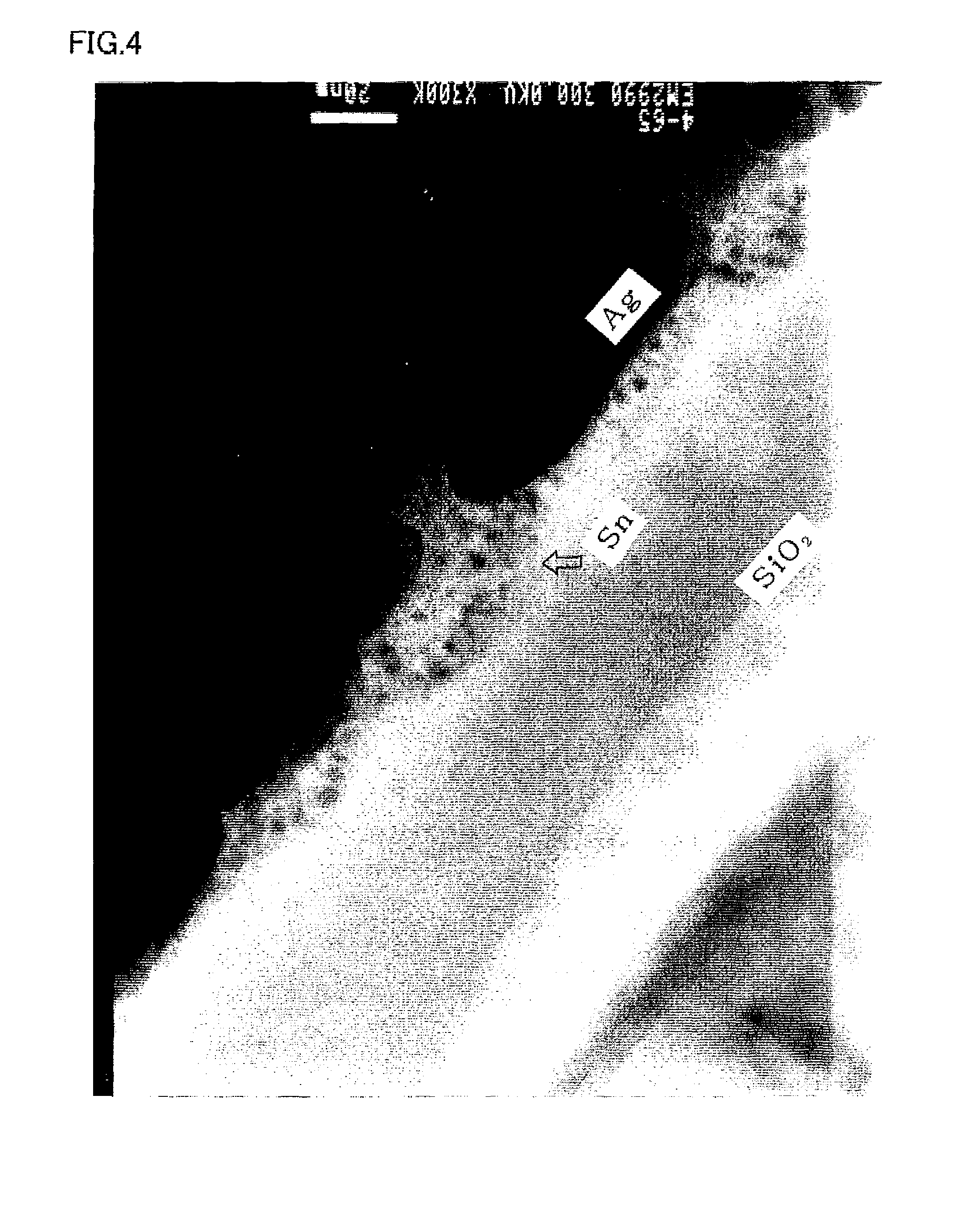

This invention provides a colored metallic pigment, which can develop a variety of colors and varied interference colors while maintaining good lightfastness, weatherfastness and hiding power, a process for producing the same, a coating composition containing the colored metallic pigment and capable of providing a coating film having excellent finished appearance, and a cosmetic preparation containing the colored metallic pigment, having excellent hiding power, and capable of providing sharp hue. The colored metallic pigment comprises at least a metallic pigment, an amorphous silicon oxide film layer provided on the surface of the metallic pigment, a metal layer provided on the surface of the amorphous silicon oxide film layer, and metallic particles provided on the surface of the metal layer. The metallic particles are provided so as to directly cover a part of the surface of the metal layer. In the colored metallic pigment, the metal layer preferably comprises at least one metal selected from Sn, Pd, Pt and Au. The metallic particle preferably comprises at least one metal selected from Cu, Ni and Ag.

Owner:TOYO ALUMINIUM KK

Colored metallic pigment, process for producing the same, and coating composition and cosmetic preparation comprising said colored metallic pigment

ActiveCN101384674AGood weather resistanceIncrease coverageCosmetic preparationsHair removalInterference colorAmorphous silicon

This invention provides a colored metallic pigment, which can develop a variety of colors and varied interference colors while maintaining good lightfastness, weatherfastness and hiding power, a process for producing the same, a coating composition containing the colored metallic pigment and capable of providing a coating film having excellent finished appearance, and a cosmetic preparation containing the colored metallic pigment, having excellent hiding power, and capable of providing sharp hue. The colored metallic pigment comprises at least a metallic pigment, an amorphous silicon oxide film layer provided on the surface of the metallic pigment, a metal layer provided on the surface of the amorphous silicon oxide film layer, and metallic particles provided on the surface of the metal layer. The metallic particles are provided so as to directly cover a part of the surface of the metal layer. In the colored metallic pigment, the metal layer preferably comprises at least one metal selected from Sn, Pd, Pt and Au. The metallic particle preferably comprises at least one metal selected from Cu, Ni and Ag.

Owner:TOYO ALUMINIUM KK

Method for preparing a pearlescent pigment by coating metal oxides on the synthesized mica

InactiveUS6899757B2Good chromaFine lusterLiquid surface applicatorsCoatingsSurface-active agentsAqueous solution

Disclosed is a method for preparing a pearlescent pigment by coating metal oxides on the synthesized mica, involving the steps of grinding the synthesized mica by agitating the mica with water in a water mixer to a particle size between 100 and 500 μm and separating the mica, dispersing the separated particles of the synthesized mica in water and adding acid thereto to adjust pH between 1 and 4, adding the metal oxide precursors and a basic aqueous solution thereto while maintaining said pH range until the desired color is attained, and thereby forming at least one hydrous metal oxide layer on the particles of the synthesized mica, and filtering, water-washing, drying and calcining the synthesized mica coated with the metal oxide layer. The method may further involve the step of further pulverizing the synthesized mica roughly ground in a water mixer by using a conventional wet pulverizer so that less than 100 μm of the synthesized mica may be used as a base material. The suitable surfactants can be used in a water mixer as well as a conventional wet pulverizer. The pearlescent pigment prepared according to the present invention has excellent luster and chroma, since a coating layer of metal oxides is smooth and the dispersibility of the particles is excellent.

Owner:CQV

Coated pearlescent pigments with SiO2 and cerium oxide

The invention relates to pearlescent pigments comprising a metal oxide-containing, lamellar substrate that is provided with a first and a second protective layer, the metal oxide having a refractive index of more than 1.8. A first protective layer comprising cerium oxide and / or cerium hydroxide as well as a second protective layer which is made of SiO2 and onto which an organic-chemical secondary coating containing at least one silane with at least one functional binding group and at least one silane without a functional binding group is applied, are provided, metal oxide layers that are different from cerium oxide and SiO2 being optionally placed between the first and the second protective layer. The invention also relates to a method for producing the disclosed pigments and the use thereof.

Owner:ECKART GMBH & CO KG

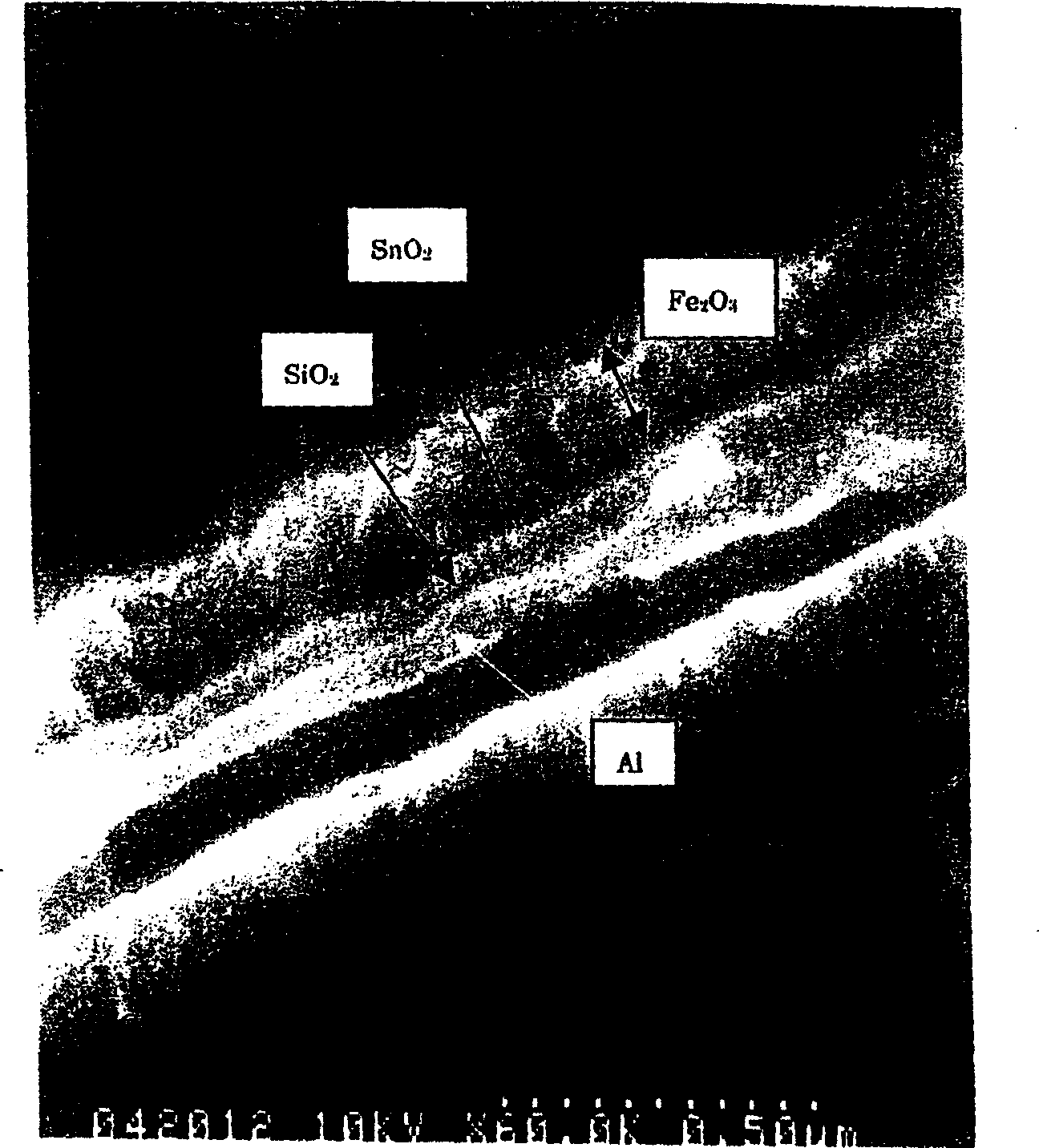

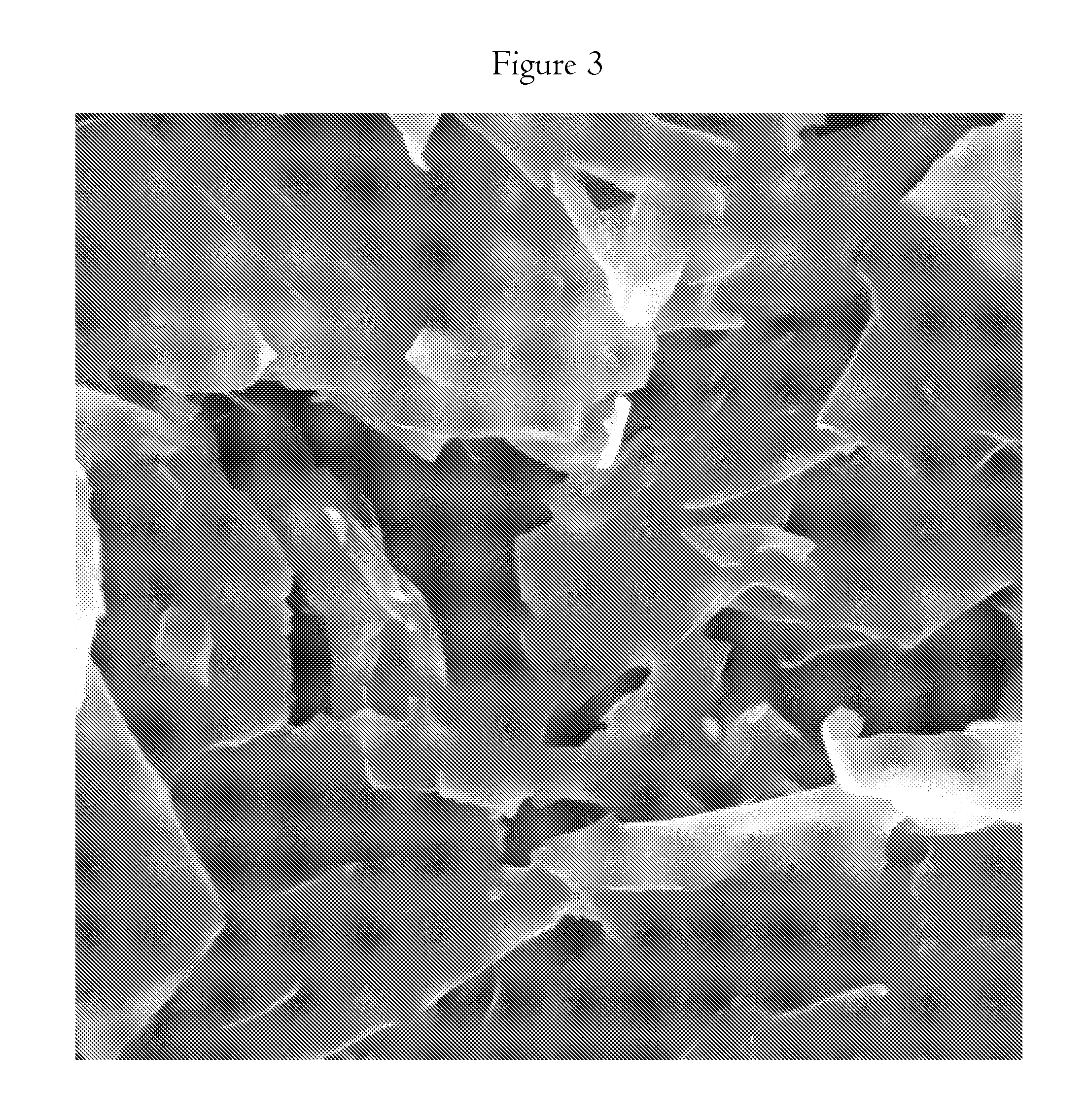

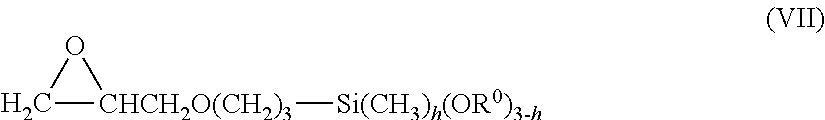

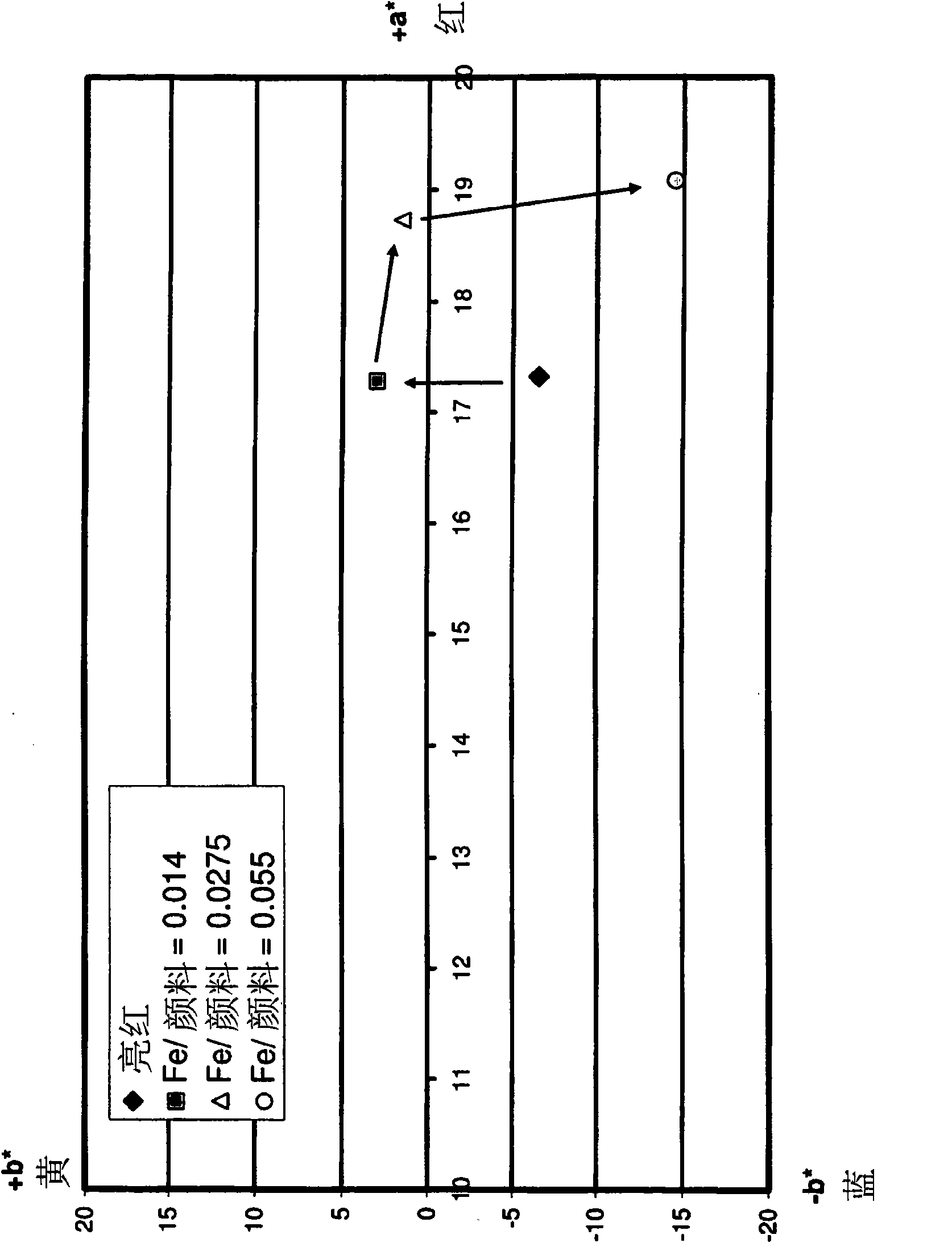

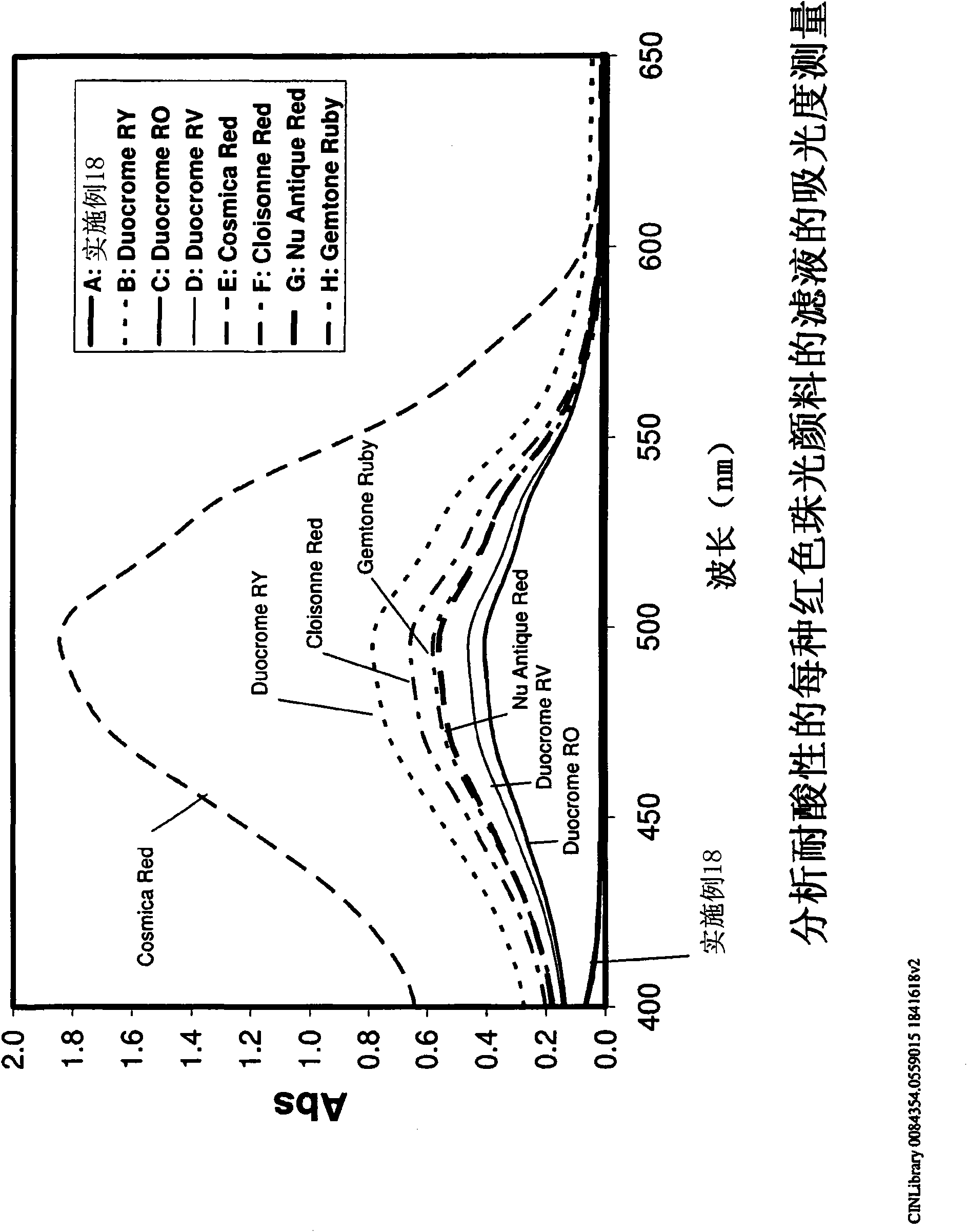

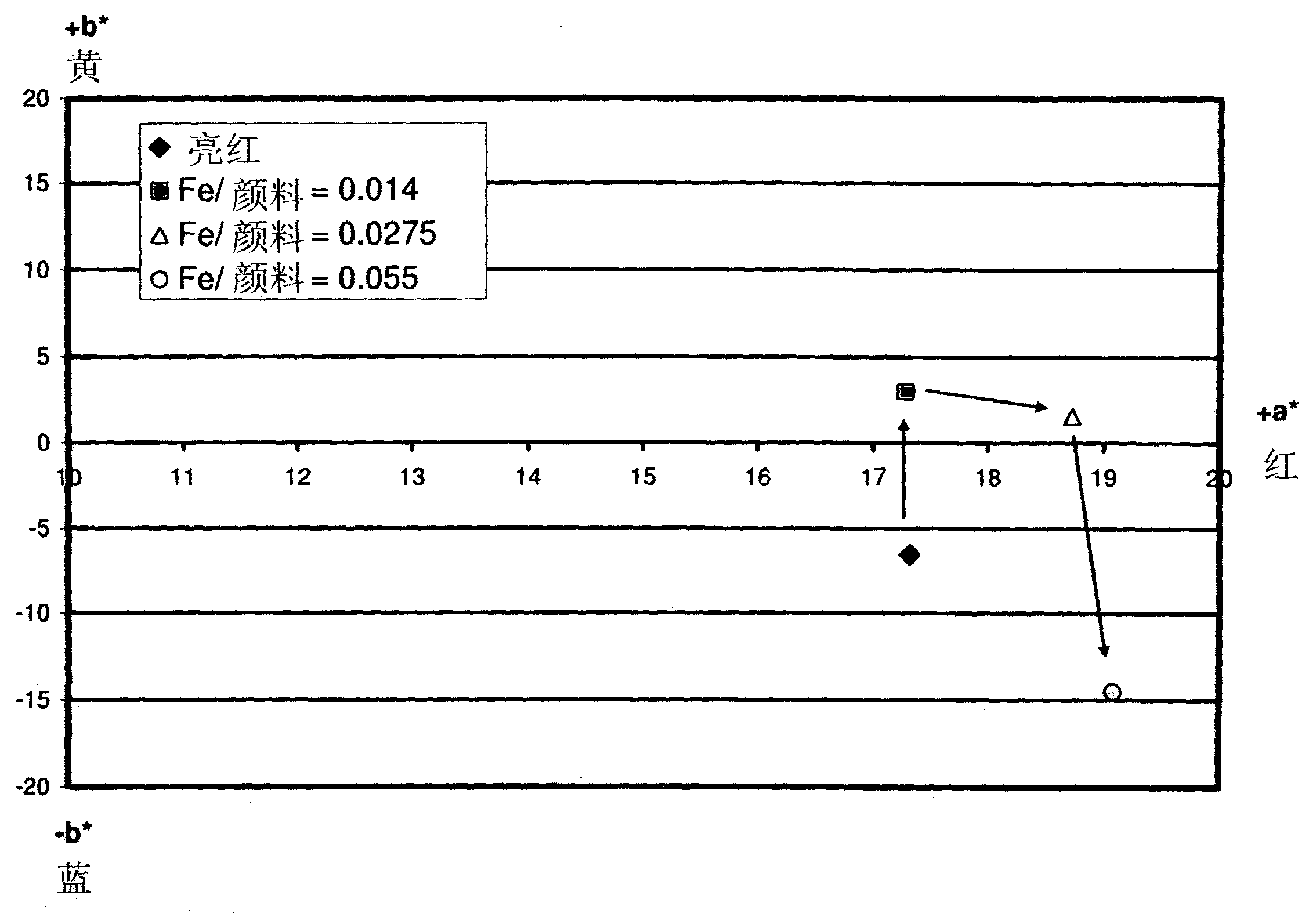

Colored interference pigments having metallic luster, preparing method and use of same

InactiveCN1673284AHigh glossSimple processInorganic pigment treatmentInksFerric oxide hydrateMetal substrate

Colored interference pigments having metallic luster comprising, on the surface of a thin platelet-like metal substrate a layer of an anti-corrosive treatment in a non-aqueous system, and, thereon (1) an intermediate binder layer comprising hydrated tin oxide (first layer); and, thereon, (2) a hydrated iron oxide layer (second layer), exhibiting a reddish color and improved adhesion and denseness of the hydrated iron oxide layer, a process for producing same and their use.

Owner:MERCK PATENT GMBH

Process for the preparation of metal oxide coated organic material by microwave deposition

InactiveUS7459182B2Pretreated surfacesLiquid/solution decomposition chemical coatingSuspended organic matterSolvent

A process for the preparation of organic material comprising an organic substrate and at least one dielectric layer consisting of one or more oxides of a metal selected from groups 3 to 15 of the periodic table, which comprises the steps of:(a) suspending the organic material in an aqueous solution of fluorine scavenger;(b) adding an aqueous solution of one or more fluorine containing metal complexes which are the precursors of the desired metal oxide coating; and(c) subjecting said suspension to microwave radiation to deposit the metal oxide onto said organic material, wherein steps (b) and (c) can optionally be repeated using different fluorine containing metal complexes to produce one or more metal oxide layers.The substrate can be optionally dissolved with solvent to yield free metal oxide or mixed metal oxides that have a plane-parallel structure.

Owner:CIBA SPECIALTYCHEM

Pigment of multi-gradition discolour at diffierent direction and production process thereof

InactiveCN1597793ALow priceEasy to get materialsInorganic pigment treatmentPigment preparationRefractive indexColor changes

The invention provides a multilayer disclour pigment with different colors according to different viewing angle and its producing method, using synthetic thin glass plate as a substrate, alternatively coating the surface of the thin glass plate with at least three metal oxide layers with refractivity greater than 1.8 and less than 1.8, where the metal oxide layer with refractivity less than 1.8 is always between the other two ones with refractivity greater than 1.8. The invention uses chemical hydrolyzation process to alternatively coat high- and low- refractivity oxide layers on the surface of the thin glass plate. It has low price, wide color change range, and simple manufacture process.

Owner:SHANTOU LONGHUA PEARL LUSTRE PIGMENTS CO LTD

Method for preparing a pearlescent pigment by coating metal oxides on the synthesized mica

InactiveUS20040096579A1Good dispersionExcellent in weatherproof and chemical resistance and physical propertyLiquid surface applicatorsCoatingsSURFACTANT BLENDChromia

Disclosed is a method for preparing a pearlescent pigment by coating metal oxides on the synthesized mica, involving the steps of grinding the synthesized mica by agitating the mica with water in a water mixer to a particle size between 100 and 500 mum and separating the mica, dispersing the separated particles of the synthesized mica in water and adding acid thereto to adjust pH between 1 and 4, adding the metal oxide precursors and a basic aqueous solution thereto while maintaining said pH range until the desired color is attained, and thereby forming at least one hydrous metal oxide layer on the particles of the synthesized mica, and filtering, water-washing, drying and calcining the synthesized mica coated with the metal oxide layer. The method may further involve the step of further pulverizing the synthesized mica roughly ground in a water mixer by using a conventional wet pulverizer so that less than 100 mum of the synthesized mica may be used as a base material. The suitable surfactants can be used in a water mixer as well as a conventional wet pulverizer. The pearlescent pigment prepared according to the present invention has excellent luster and chroma, since a coating layer of metal oxides is smooth and the dispersibility of the particles is excellent.

Owner:CQV

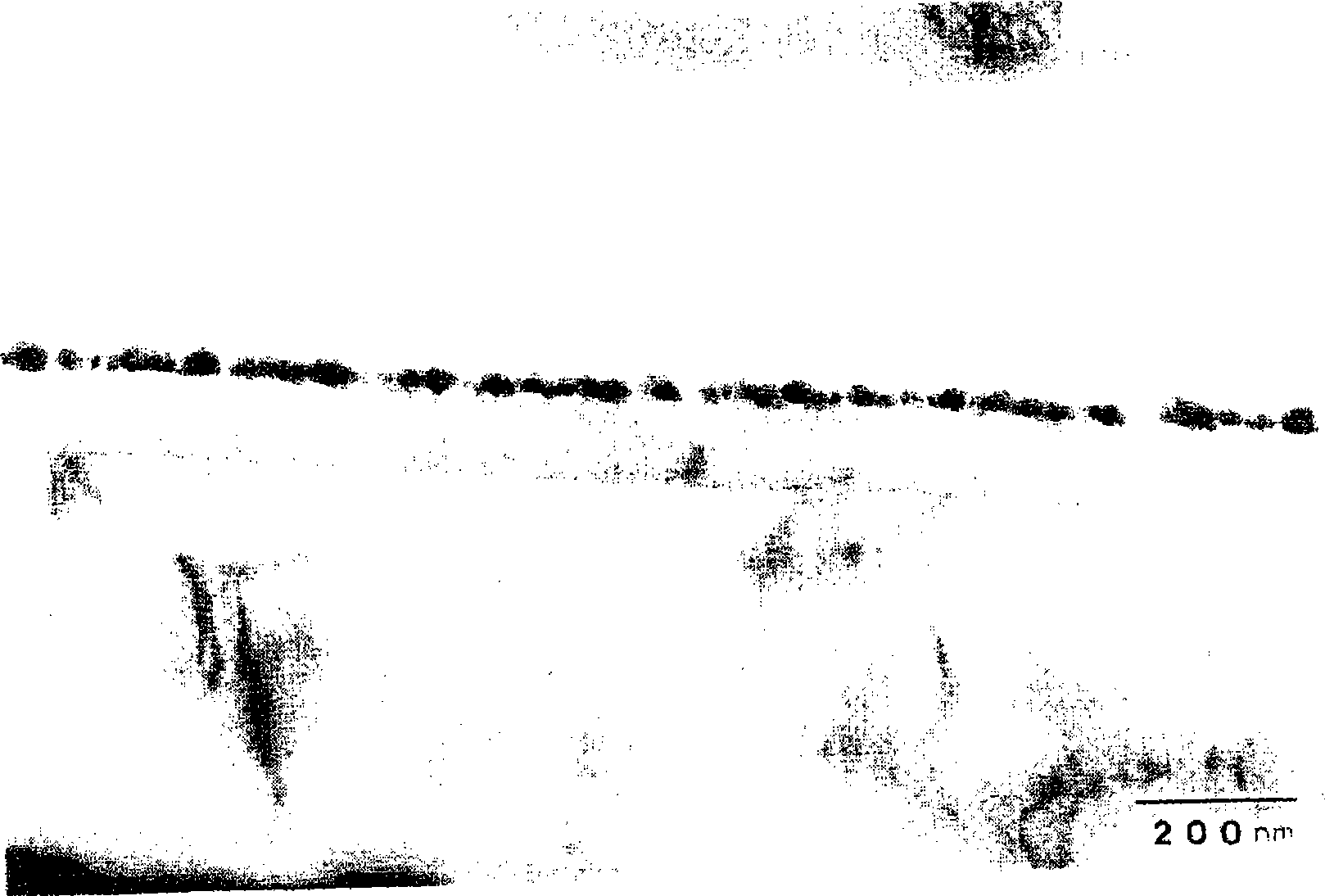

Colored metallic pigment, process for producing the same, and coating composition and cosmetic preparation containing said colored metallic pigment

ActiveUS7998266B2Excellent finished appearanceLight resistanceCosmetic preparationsLiquid surface applicatorsInterference colorNonferrous metal

This invention provides a colored metallic pigment, which can develop a variety of colors and varied interference colors while maintaining good lightfastness, weatherfastness and hiding power, a process for producing the same, a coating composition containing the colored metallic pigment and capable of providing a coating film having excellent finished appearance, and a cosmetic preparation containing the colored metallic pigment, having excellent hiding power, and capable of providing sharp hue. The colored metallic pigment comprises at least a metallic pigment, an amorphous silicon oxide film layer provided on the surface of the metallic pigment, a metal layer provided on the surface of the amorphous silicon oxide film layer, and metallic particles provided on the surface of the metal layer. The metallic particles are provided so as to directly cover a part of the surface of the metal layer. In the colored metallic pigment, the metal layer preferably comprises at least one metal selected from Sn, Pd, Pt and Au. The metallic particle preferably comprises at least one metal selected from Cu, Ni and Ag.

Owner:TOYO ALUMINIUM KK

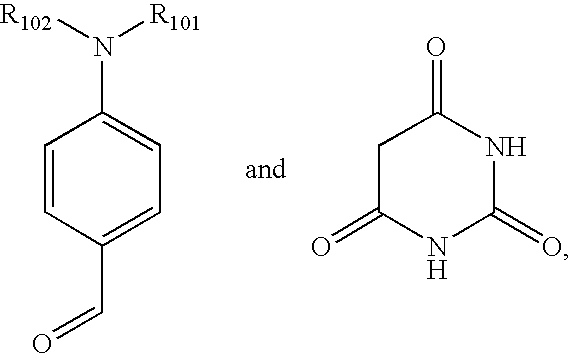

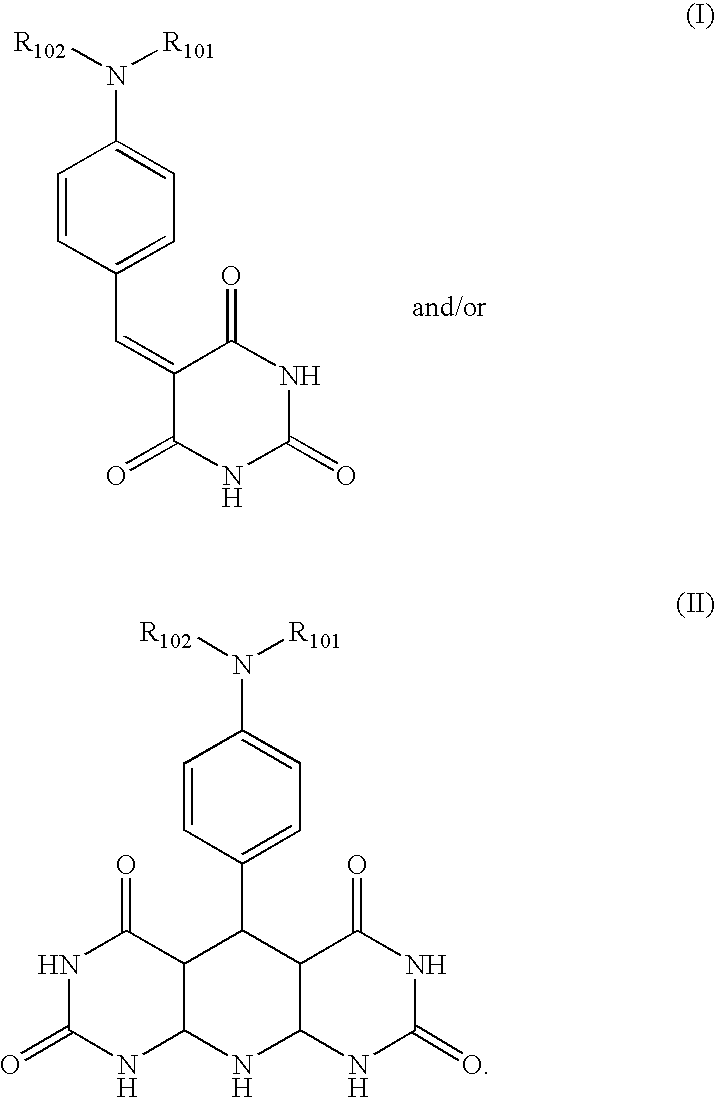

Pigment mixtures

InactiveCN101891969AEasy to operateCosmetic preparationsBody powdersBoron nitrideBismuth oxychloride

Disclosed are pigment mixtures containing at least two components, where component A contains bismuth oxychloride (BiOCl) or boron nitride (BN) and component B contains synthetic flakes treated with at least one metal soap or mineral flakes treated with at least one metal soap and to the use thereof especially in cosmetic formulations.

Owner:MERCK PATENT GMBH

Multilayer effect pigment

InactiveUS7993443B2Appreciable degree of transparencySynthetic resin layered productsPencil leadsRefractive indexComputational physics

A multilayer effect pigment includes a transparent substrate, a layer of high refractive index material on the substrate, and alternating layers of low refractive index and high refractive index materials on the first layer, the total number of layers being an odd number of at least three, all adjacent layers differing in refractive index by at least about 0.2 and at least one of the layers having an optical thickness which is different from all of the other layers. The resulting multilayer effect pigment is not a quarter-wave stack.The present multilayer effect pigment may be used in cosmetics or personal care products.

Owner:BASF CATALYSTS LLC

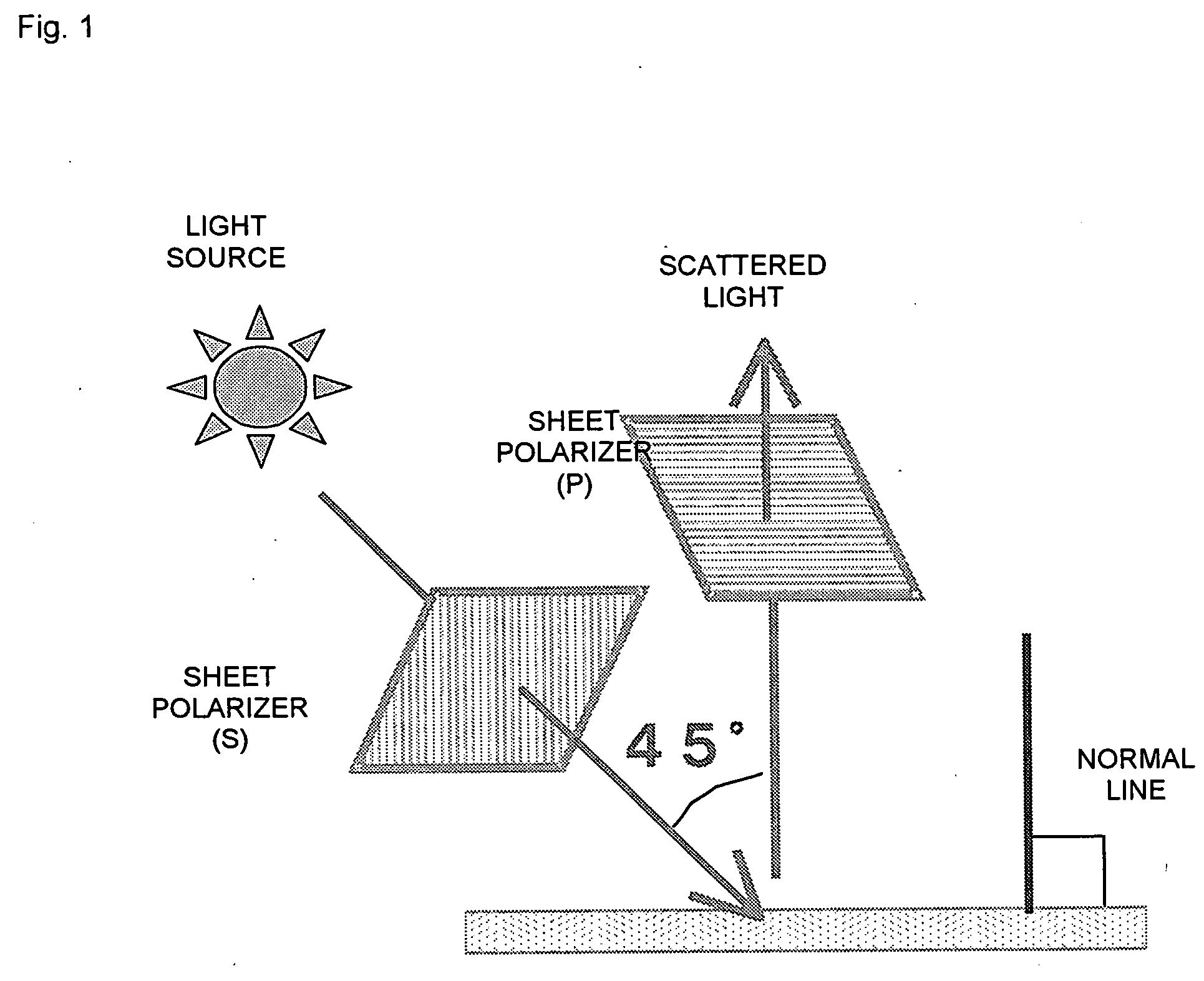

Pearlescent pigment

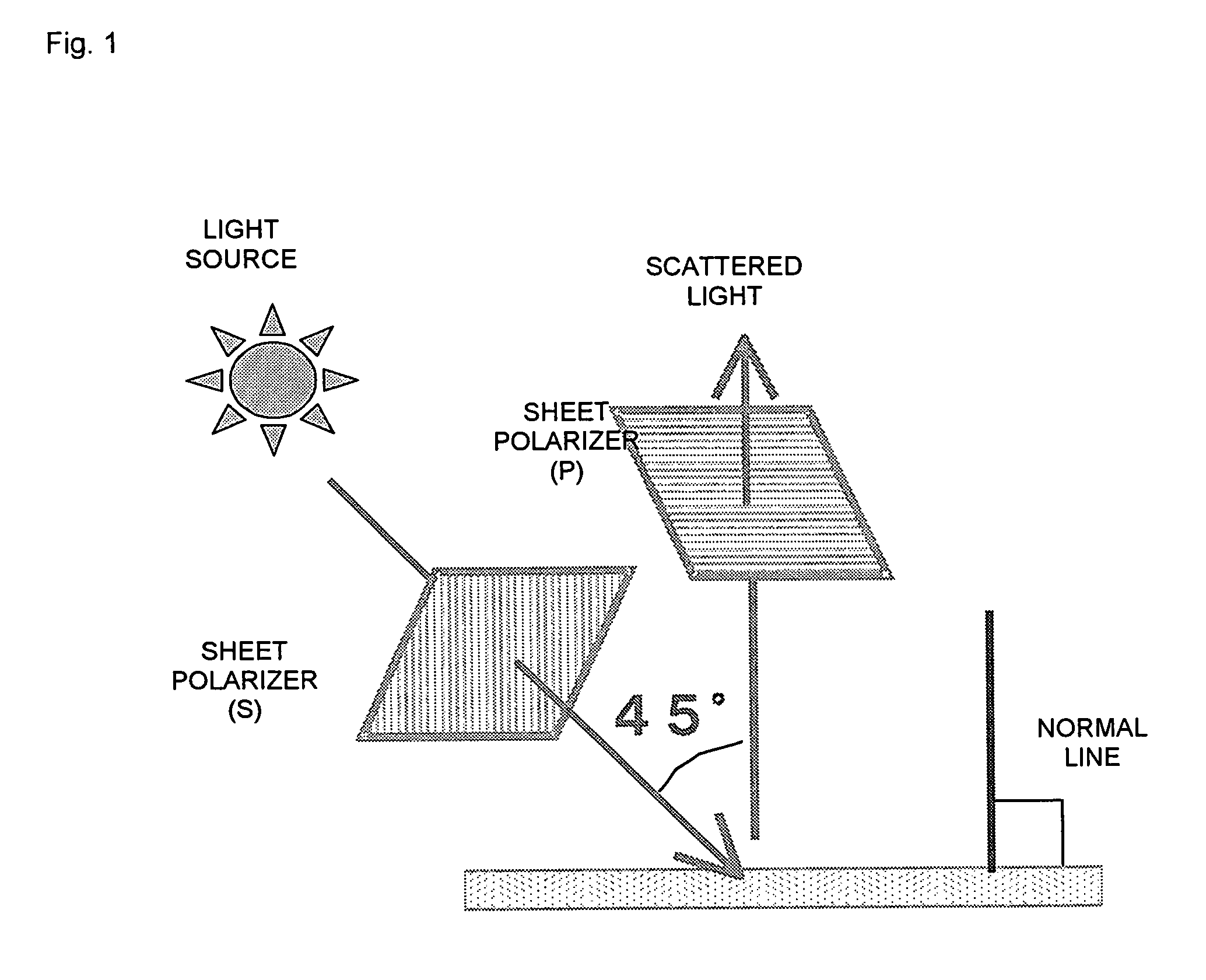

The present invention relates to a pearl pigment obtained by coating the surface of a flaky powder with a colored metal or a colored metal oxide and further coating the surface of the above colored metal- or colored metal oxide-coated flaky powder with a colorless metal or a colorless metal oxide, wherein when the pearl pigment is applied onto the surface of black artificial leather in an average amount of 0.05 mg / cm2 and the intensity of light reflected from the pearl pigment is measured using illuminant C at a 2° viewing angle with a spectrophotometric colorimeter which is provided with a sheet polarizer S on the light incident side and a sheet polarizer P on the light receiving side, the powder reflection light which is incident to the pearl pigment as a measurement sample at an angle of 45° to the direction normal to the surface of the sample and is received in the direction normal to the surface of the sample has absolute values a* and b* of 10 or less, and make-up cosmetics containing the pearl pigment.

Owner:KAO CORP +1

Inorganic composite powder and cosmetic comprising the same

InactiveUS6482419B1Suppress light reflectionHigh transparencyCosmetic preparationsImpression capsRefractive indexLength wave

An inorganic composite powder is formed of a scaled substrate, and at least three inorganic oxide layers having different refractive indexes respectively and sequentially laminated in an order of high refractive index to low refractive index from a surface of the scaled substrate to an utmost outer layer. A refractive index of an inorganic oxide used for forming the utmost outer layer is 1.73 or less, and a difference in the refractive indexes between the utmost layer and a layer adjacent thereto is 0.6 or less. Alternatively, the thickness of at least one of a second or higher inorganic oxide layer is within ±20% of a value d given by an equation: d=(lambdxX / 4) / n, wherein lambd indicates a wavelength of visual light, X indicates an odd integer, and n indicates the refractive index of the inorganic oxide.

Owner:CATALYSTS & CHEM

Multilayer pigments based on glass flakes

The present invention relates to multilayer pigments based on glass flakes and to a method for the production of such pigments. The resulting pigment can be used in any application for which pearlescent pigments have been heretofore used such as, for example, in plastics, paints, inks, cosmetic formulations, coatings including solvent or waterborne automotive paint systems, powder coatings, inks and agriculture foils, for the laser-marking of papers and plastics.

Owner:MERCK PATENT GMBH

Flaky pigments coated with a coupling agent and a perfluoroalkyl phosphate

InactiveUS7160374B2Excellent in interlaminar adhesionMaintain good propertiesInksOrganic dyesSilane compoundsPhosphate

A flaky pigment excellent in leafing properties and in adhesion between pigment particles and a coating (resin) was obtained by coating the surface of a flaky pigment with a coupling agent and a phosphate having a perfluoroalkly group or a silane compound. Accordingly, the flaky pigment is excellent as a pigment for coating or printing ink of which brightness and durability are required.

Owner:MERCK PATENT GMBH

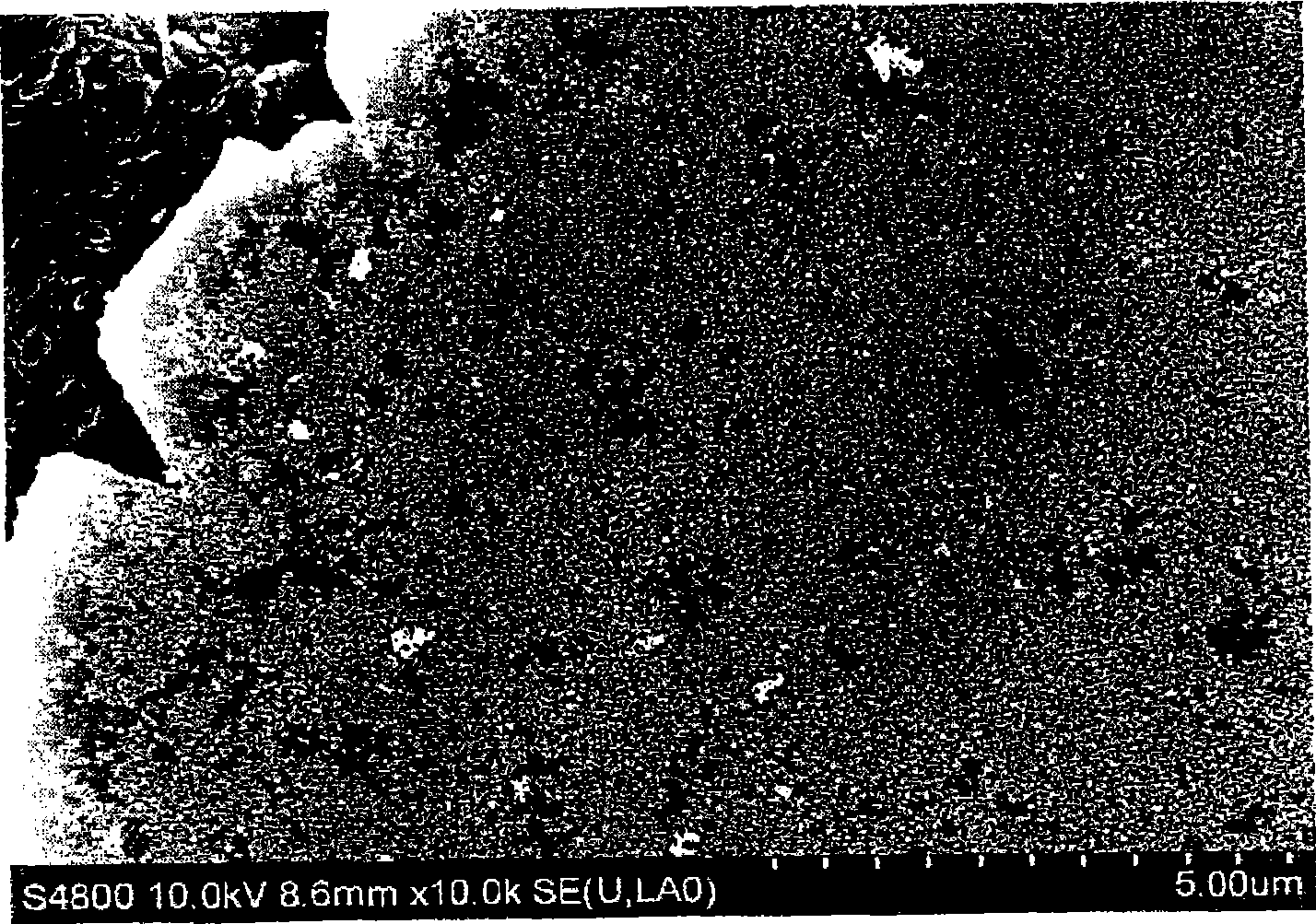

Composite powder, cosmetics containing the same, and process for producing composite powder

ActiveUS20050158257A1Increased durabilityUnevenness in colorCosmetic preparationsBody powdersSkin colorZinc

An object of the present invention is to provide a composite powder, cosmetics containing the same, and the production method of the same. When blended into cosmetics, the above-described composite powder corrects skin surface unevenness and imperfections in skin color, renders a natural finish, and have durability in finished makeup. In order to achieve the above-mentioned object, the composite powder of the present invention comprises flaky substrate powder and barium sulfate particles or zinc oxide particles that adhere to the surface, in protrusions, of the substrate powder.

Owner:SHISEIDO CO LTD

Pearlescent pigments, methods for producing same, and use of such pearlescent pigments

ActiveCN107567484AFlexible productionEasy to produceCosmetic preparationsToilet preparationsPlateletRefractive index

The invention relates to semitransparent pearlescent pigments, to methods for producing same, and to the use of such pearlescent pigments, wherein the pearlescent pigments are monolithically constructed substrate platelets composed of a metal oxide having an average thickness of 1 to 40 nm and a form factor, expressed by the ratio of the average size to the average thickness, of at least 80, whichare encased by at least one substantially transparent coating A composed of at least one low-refractive-index metal oxide and / or metal oxide hydrate, which has a refractive index of less than 1.8, and comprise at least one interference layer in the form of a coating B composed of at least one high-refractive-index metal oxide, which has a refractive index of at least 1.8.

Owner:SCHLENK METALLIC PIGMENTS GMBH

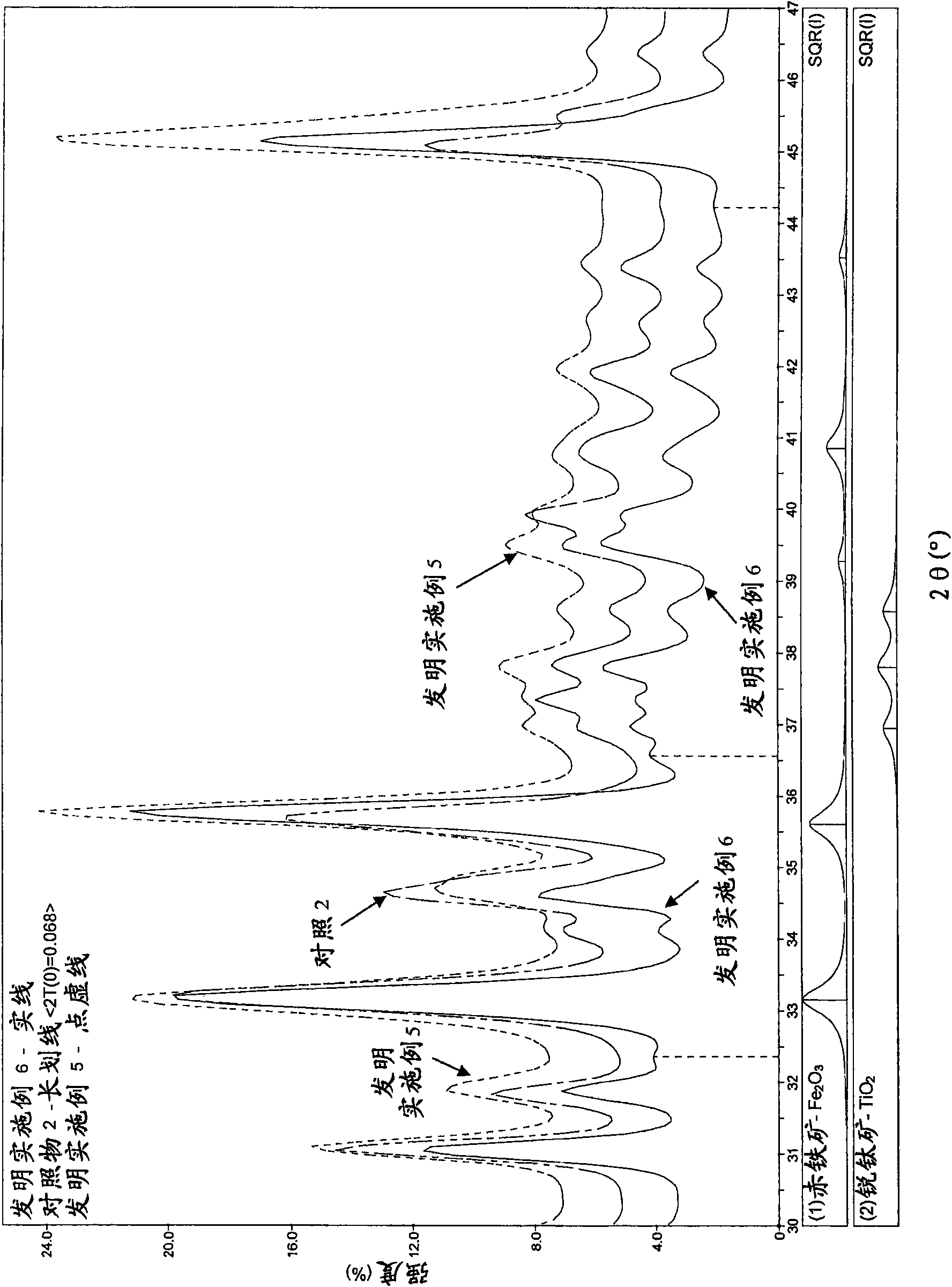

Orange pearlescent pigments

An orange pearlescent pigment comprising a substrate and a first layer containing FeOOH, and a second layer containing Fe2O3 located between the substrate and the first layer. The color of the pigment is such that a homogeneous coating of the pigment, measured over a white background, has a CIELAB hue angle, hab, from about 40 to about 60 degrees, and the chroma value is greater than 50. The pigment may be used in a cosmetic, coating, or ink composition.

Owner:SUN CHEM CORP

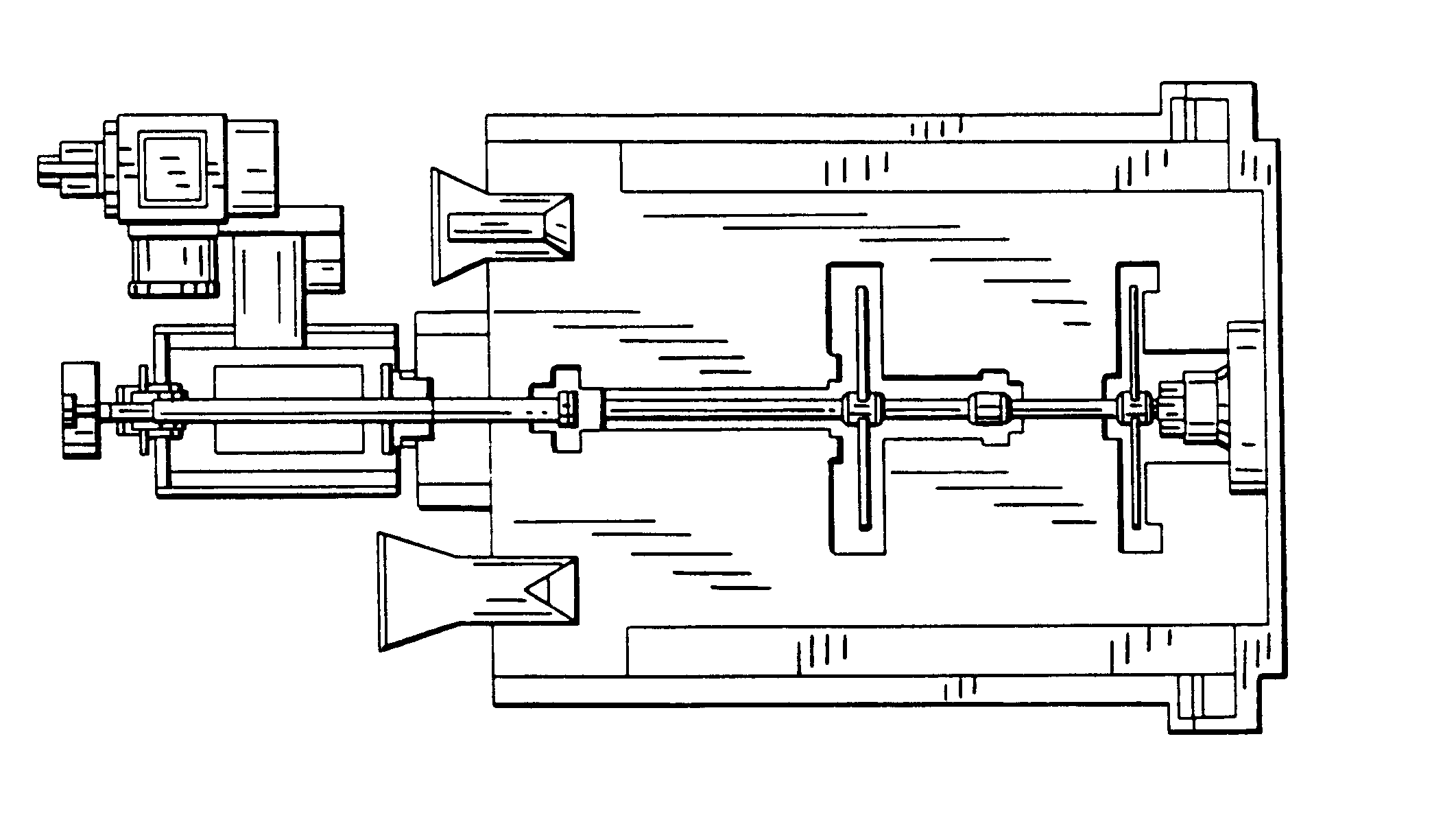

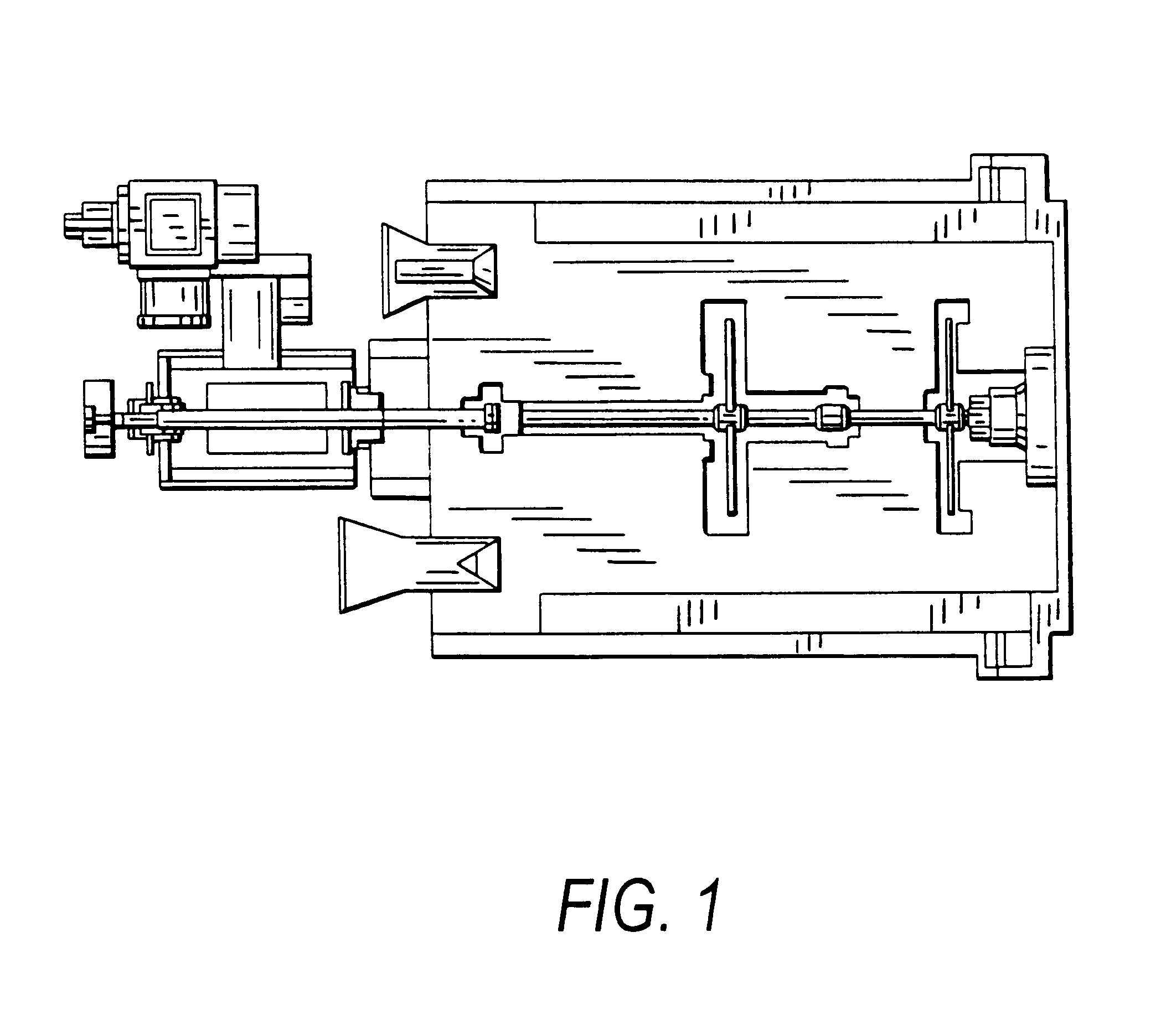

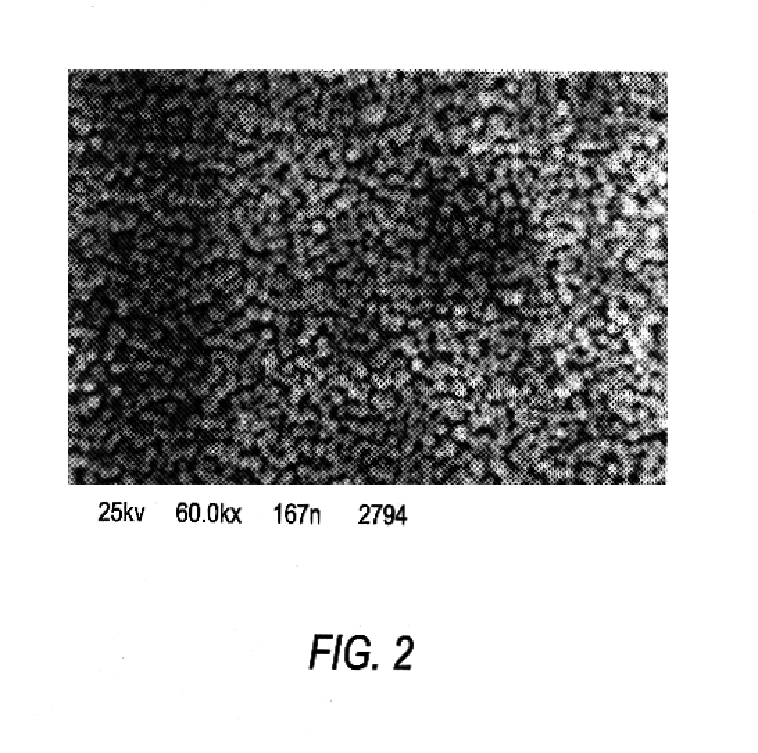

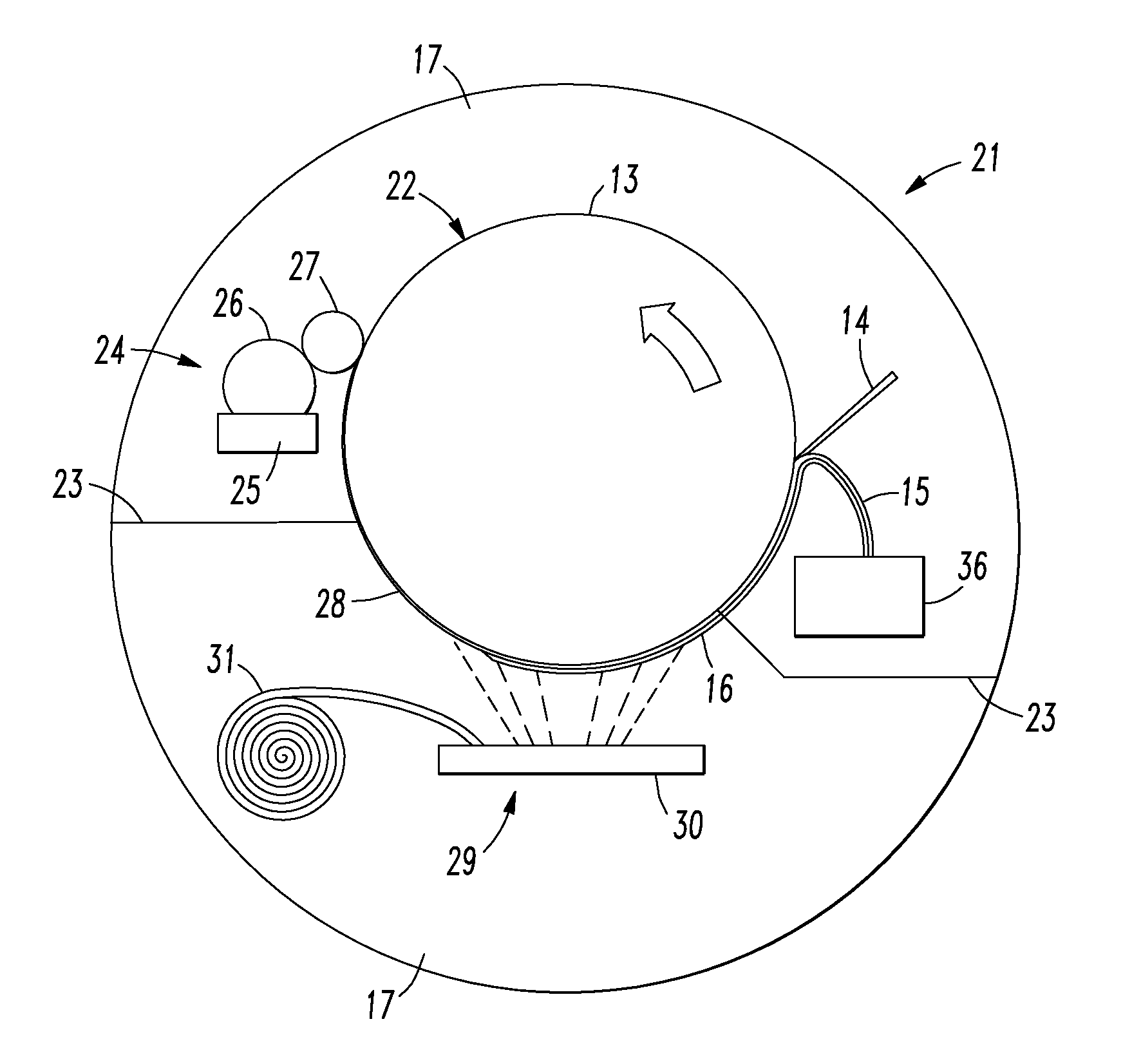

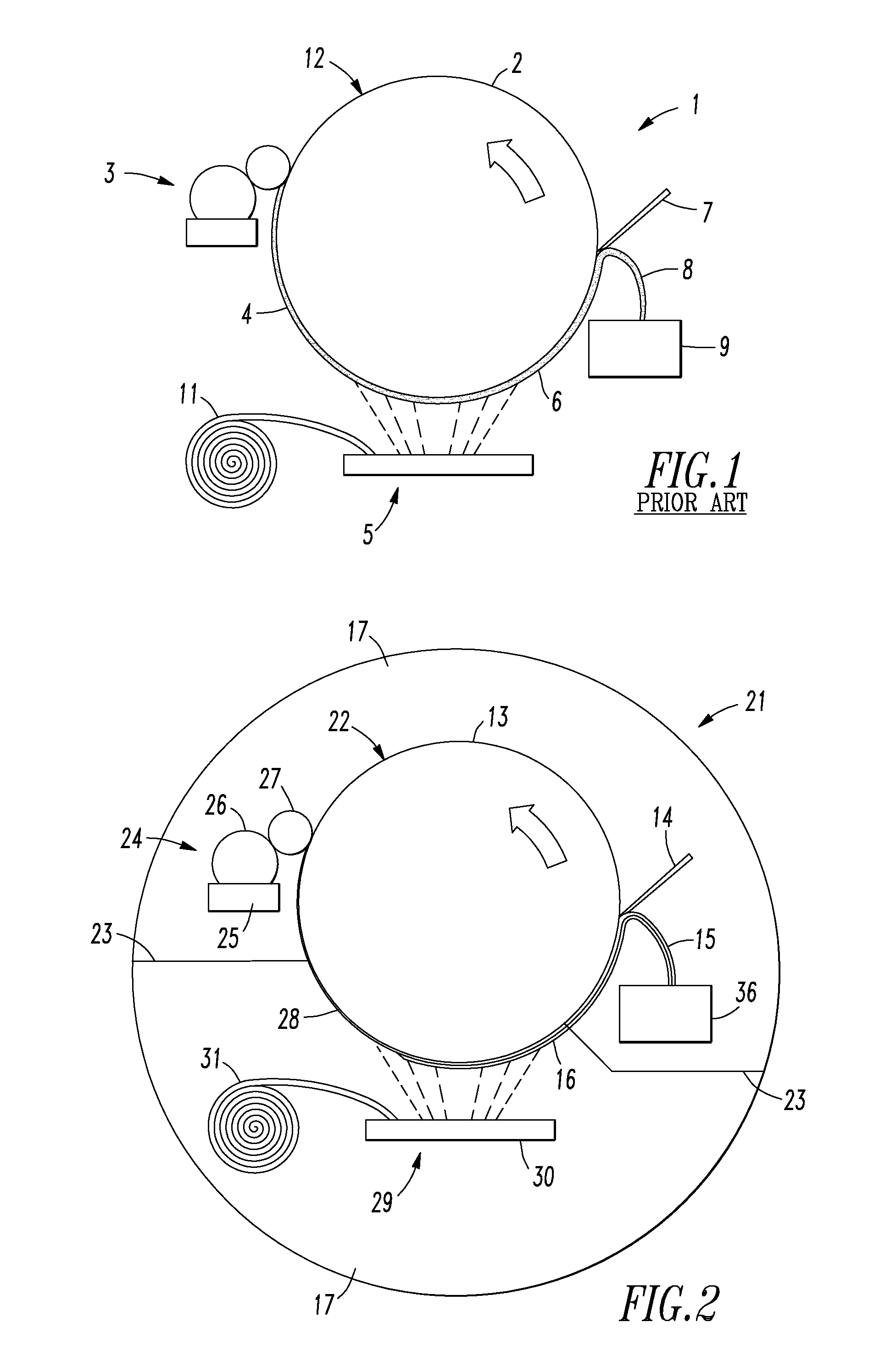

Method for Producing Thin Flake

InactiveUS20120007271A1Thinness of substantially reduces and eliminatesMaterial granulationPigment preparationSolventThin membrane

A process for forming thin flake particles includes coating the liquid release agent over a base substrate, forming a multilayer structure by depositing a thin film over the liquid release agent, collecting the multilayer structure, and separating the thin flake from the multilayer structure using a suitable solvent. The liquid release agent comprises a curable compound that can form a solidified layer less than 0.001 mm thick onto which the thin film can be deposited. Separation requires little solvent because of the thinness of the solidified layer.

Owner:VAST FILMS

Multiple layered pigments exhibiting color travel

InactiveCN101563427AImprove mechanical stabilityGood chemical stabilityPigment preparationCredit cardRefractive index

The present invention relates to interference pigments on the basis of multiply coated, platelet-shaped substrates which comprise at least one layer sequence comprising: (A) a metal oxide coating having a refractive index n = 2.0, (B) a colorless metal oxide or fluoride coating having a refractive index n = 1.8, (C) a nonabsorbing metal oxide coating of high refractive index, and, wherein the pigment further comprises (D) an oxide of calcium, magnesium, or zinc. The present pigment may be used in paints, printing inks, and for producing counterfeit-protected documents of value, such as bank notes, cheques, cheque cards, credit cards, identity cards, etc.

Owner:BASF CORP

A coated bismuth oxy halide-based pigment

InactiveCN108699351AReduce warpagePromote migrationCosmetic preparationsToilet preparationsPhosphoric Acid EstersAlkaline earth metal

The present invention is directed to a coated bismuth oxy halide-based pigment having a coating comprising an antioxidant, said antioxidant is being a phenol based, a phosphite or phosphonate based, or a thioether based stabilizer, and the coating comprising an inner coating and an outer coating, wherein the outer coating comprises the antioxidant, and wherein the inner coating comprises a first layer consisting of one or more salts, or one or more oxides, heteropolyacids, organic acids, sulphites, sulfides, sulfates, phosphates, pyrophosphates, polyphosphates, hydrates, carbonates, or a combination thereof, selected from the group of alkali-earth metals, metals, non-metals, transition metals or lanthanides. Further, the present invention is directed to a composition comprising a paint, alacquer, an ink, a cosmetic, a resin, a plastisol or a polymer formulation, and such pigment. In addition, the present invention is directed to a method for manufacturing a coated bismuth oxy halide-based pigment, said method comprising the steps of: - providing a dispersion of a bismuth oxy halide-based pigment, adding a dispersion of an antioxidant, mixing and drying.

Owner:FELLOWES INC

Weather-resistant pearlescent pigments, process for the production and use thereof

The present invention relates to a weather-resistant pearlescent pigment which consists of a platelet-shaped substrate coated with one or more highly refractive metal oxides, the platelet-shaped substrate being selected from the group consisting of synthetic mica flakes, glass flakes, SiO2 flakes, Al2O3 flakes, synthetic boehmite flakes, BiOCl flakes and mixtures thereof, and a top layer, wherein the top layer consists of the following layers: a) a cerium-containing layer, selected from the group consisting of cerium oxide, cerium hydroxide, hydrated cerium oxide, and mixtures thereof, the cerium-containing layer being applied directly to the highly refractive metal oxide layer, and b) an organic-chemical compatibilizing layer, which comprises the reaction products of oligomeric silanes, wherein the oligomeric silanes have one or more amino groups, the organic-chemical compatibilizing layer being applied directly to the cerium-containing layer a).

Owner:ECKART GMBH & CO KG

Multi-colored lustrous pearlescent pigments

A pearlescent pigment, wherein the pigment is an inorganic material and the color of a homogeneous coating of the pigment, measured over a white background, is selected from the group consisting of: a CIELAB L* value of about 30 or less and a chroma value of about 3 or less; a CIELAB hue angle, hab, from about 50 to about 80 degrees, wherein L* is not more than about 85, and the chroma value is greater than 22; a CIELAB hue angle, hab, from about 80 to about 275 degrees, wherein L* is not more than about 80, and the chroma value is greater than about 10; and a CIELAB hue angle, hab, from not less than about 275 to not more than about 50 degrees, wherein L* is not more than about 85, and the chroma value is greater than about 9. The pigments may be used in a variety of applications including cosmetics, plastics, automotive, or architectural coatings.

Owner:SUN CHEM CORP

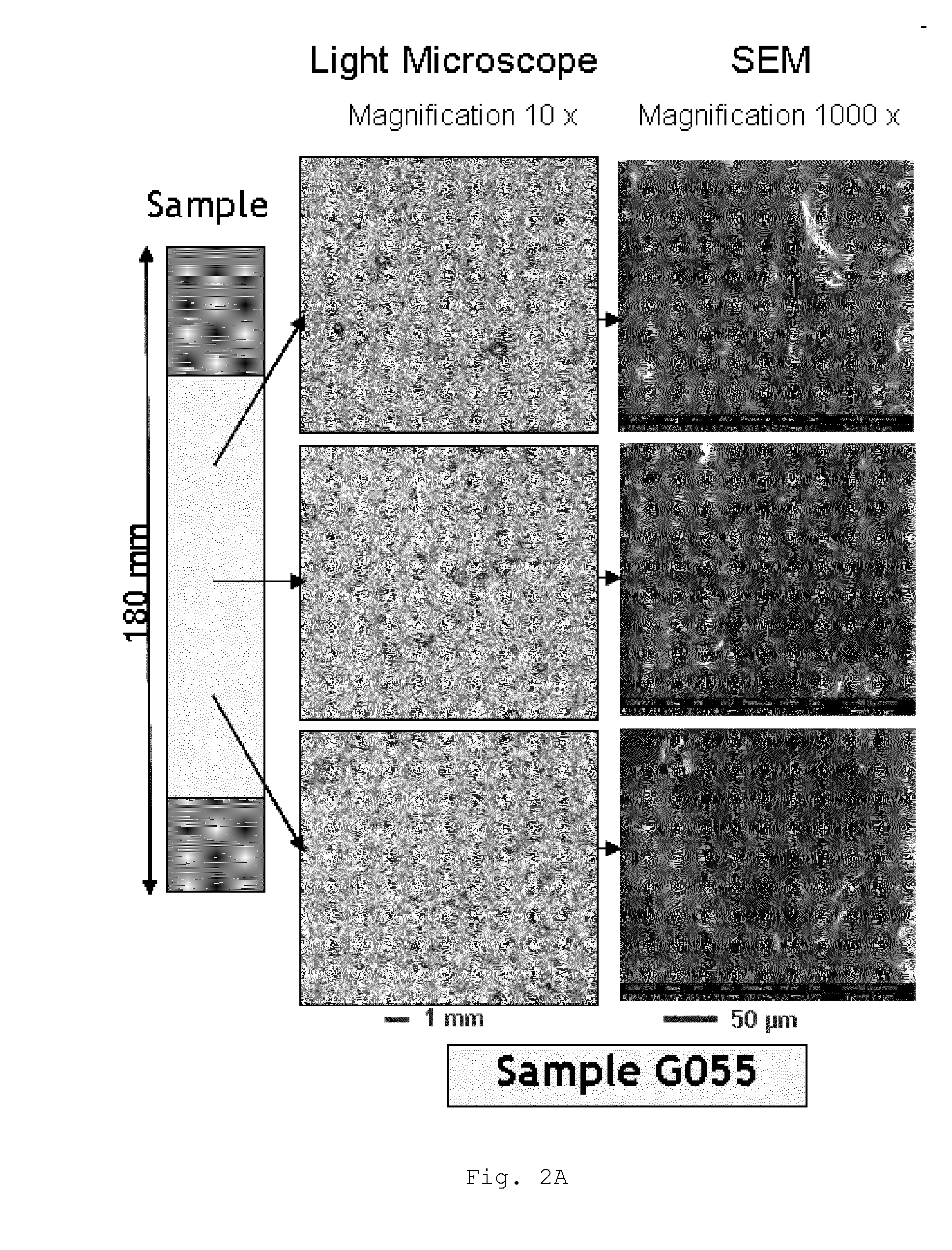

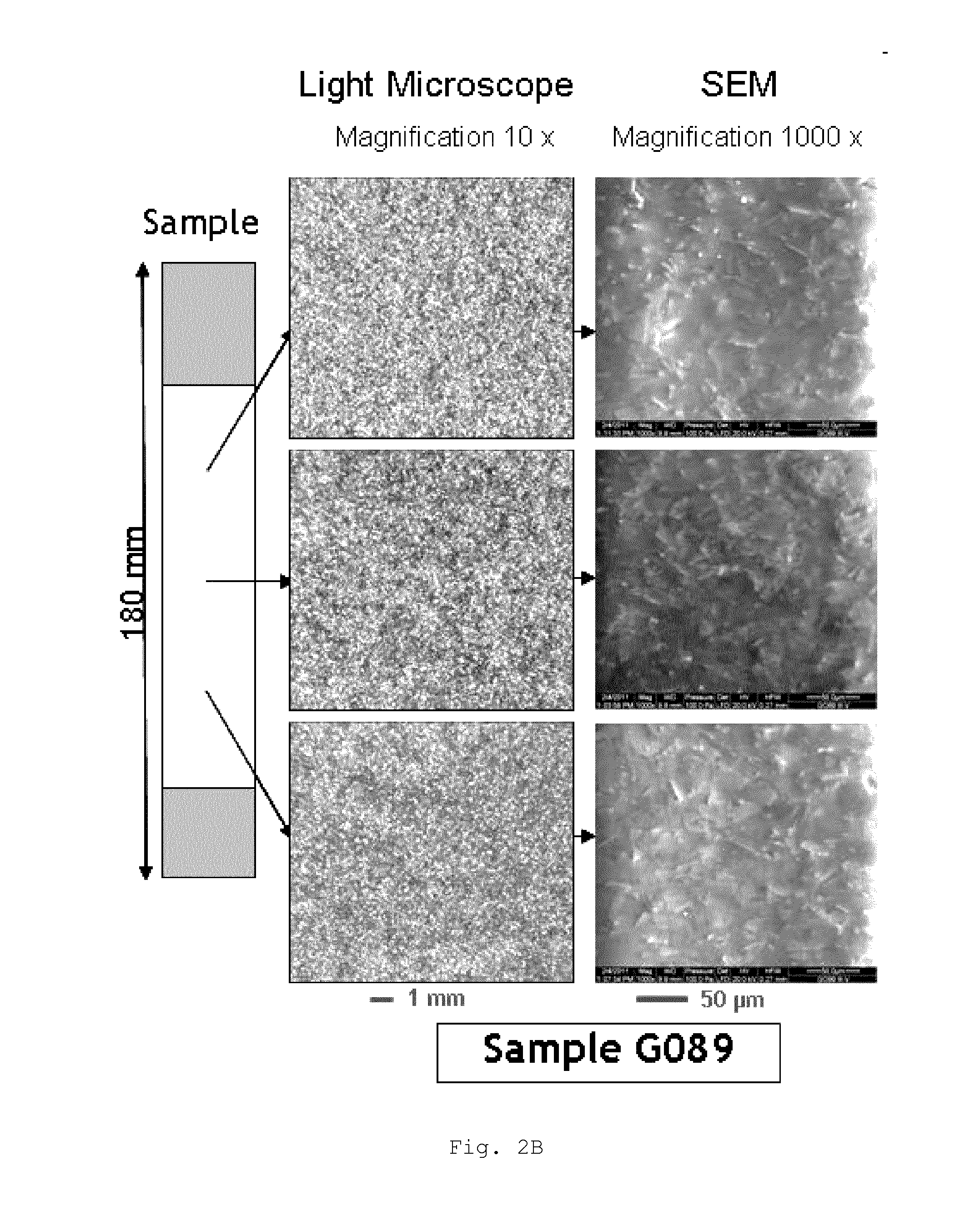

Highly Structured Composite Material and Process for the Manufacture of Protective Coatings for Corroding Substrates

ActiveUS20140329080A1Improve adhesionImprove barrier propertiesLayered productsPretreated surfacesOrganic solventPolyresin

A highly structured composite material, which can be applied and cured as a protective layer on corroding metal substrates, particularly on steel is provided. Due to its highly structured composition it is a particularly effective barrier to protect metals against attack by corrosive sub-stances such as hydrogen sulfide, carbon dioxide and sea water, if necessary under hydrothermal conditions. At the same time it is also abrasion stable, for example against a grinding effect by sand, as well as resistant to the impact of mechanical load e.g. by tools. This is achieved by a coating composition comprising a binder comprising at least one cross-linkable resin, wherein the resin comprises at least one of polar group; at least one type of hydrophilic flakes with an aspect ratio of more than 10, wherein the surface of the flakes at least partially comprises a metal oxide; and an organic solvent.

Owner:INST FUR NEUE MATERIALIEN GEMEINNUTZIGE GMBH

Coated perlite flakes

The present disclosure relates to a method of making coated perlite flakes comprises: (i) providing perlite flakes; (ii) applying a layer of tin oxide on the perlite flakes to obtain tin oxide coated perlite flakes; (iii) applying a layer titanium dioxide on the tin oxide coated perlite flakes obtained in step (ii) to obtain titanium dioxide and tin oxide coated perlite flakes; and (iv) applying a layer of iron oxide to the titanium dioxide and tin oxide coated perlite flakes to obtain the coated perlite flakes. The present disclosure also relates to coated perlite flakes comprising: perlite flakes with layer of tin oxide, then a layer of titanium dioxide, and then a layer of iron oxide.

Owner:太阳化学私人有限公司

Pearlescent pigment

The present invention relates to a pearl pigment obtained by coating the surface of a flaky powder with a colored metal or a colored metal oxide and further coating the surface of the above colored metal- or colored metal oxide-coated flaky powder with a colorless metal or a colorless metal oxide, wherein when the pearl pigment is applied onto the surface of black artificial leather in an average amount of 0.05 mg / cm2 and the intensity of light reflected from the pearl pigment is measured using illuminant C at a 2° viewing angle with a spectrophotometric colorimeter which is provided with a sheet polarizer S on the light incident side and a sheet polarizer P on the light receiving side, the powder reflection light which is incident to the pearl pigment as a measurement sample at an angle of 45° to the direction normal to the surface of the sample and is received in the direction normal to the surface of the sample has absolute values a* and b* of 10 or less, and make-up cosmetics containing the pearl pigment.

Owner:KAO CORP +1

Flaky pigment coated with coupling agent and perfluoralkyl phosphate

InactiveCN1489623APigment preparationPigment treatment with non-polymer organic compoundsSilane compoundsPhosphate

A flaky pigment excellent in leafing properties and in adhesion between pigment particles and a coating (resin) was obtained by coating the surface of a flaky pigment with a coupling agent and a phosphate having a perfluoroalkyl gorup or a silane compound. Accordingly, the flaky pigment is excellent as a pigment for coating or printing ink of which brightness and durability are required.

Owner:MERCK PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com