Pigment mixtures

A technology for mixtures and pigments, which is applied in the preparation of pigments, the treatment of dyed low-molecular-weight organic compounds, and fibrous fillers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1 : Treatment of natural mica

[0075] At 65°C, wet-milled natural muscovite with a quantity of 200 g and a particle size of 2-19 μm was suspended in deionized water by stirring at a ratio of about 10%. Put in and dissolve 4.0 g sodium stearate (Brenntag) enough to form 2% magnesium stearate. Then 1.3 g of magnesium chloride (hexahydrate) was added. The suspension of precipitated magnesium stearate can be elutriated with deionized water to remove sodium chloride salt by sedimentation and / or filtration, and then the wet mixture is dried and the product is ready for mixing.

[0076] The processed natural mica exhibits a good skin feel.

Embodiment 2

[0077] Example 2 : Treatment of synthetic mica

[0078] Repeat the method used in Example 1, but replace natural mica with synthetic mica with a particle size of 5-25 μm.

[0079] The treated synthetic mica exhibits a good skin feel.

Embodiment 3

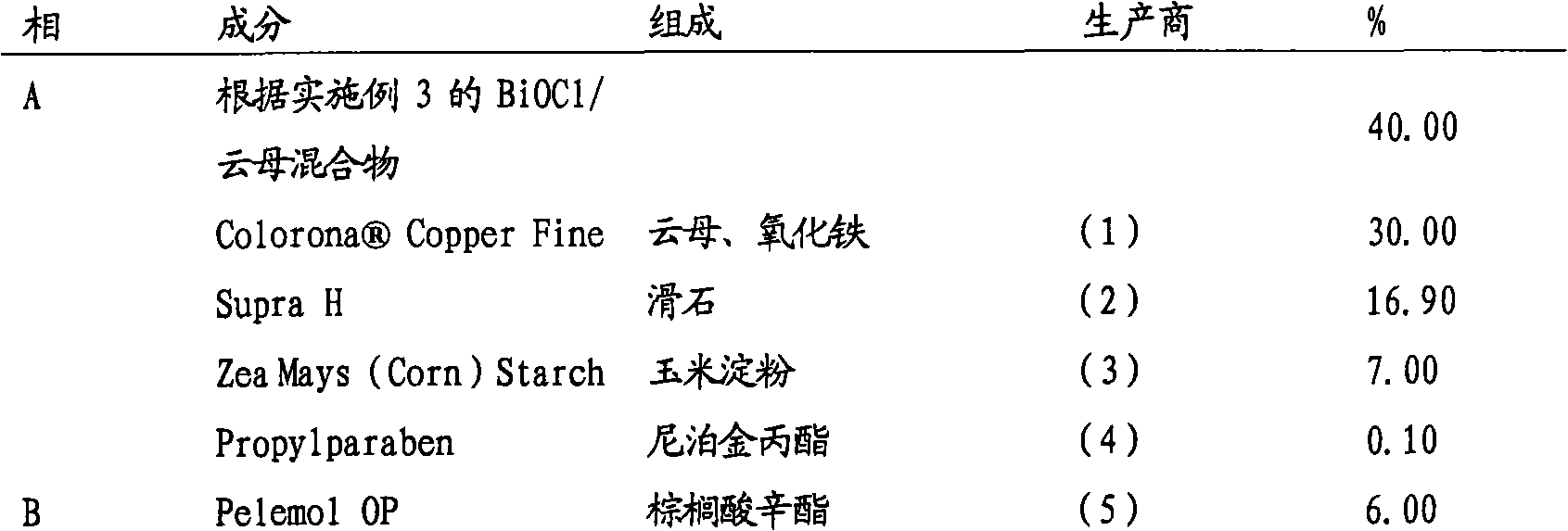

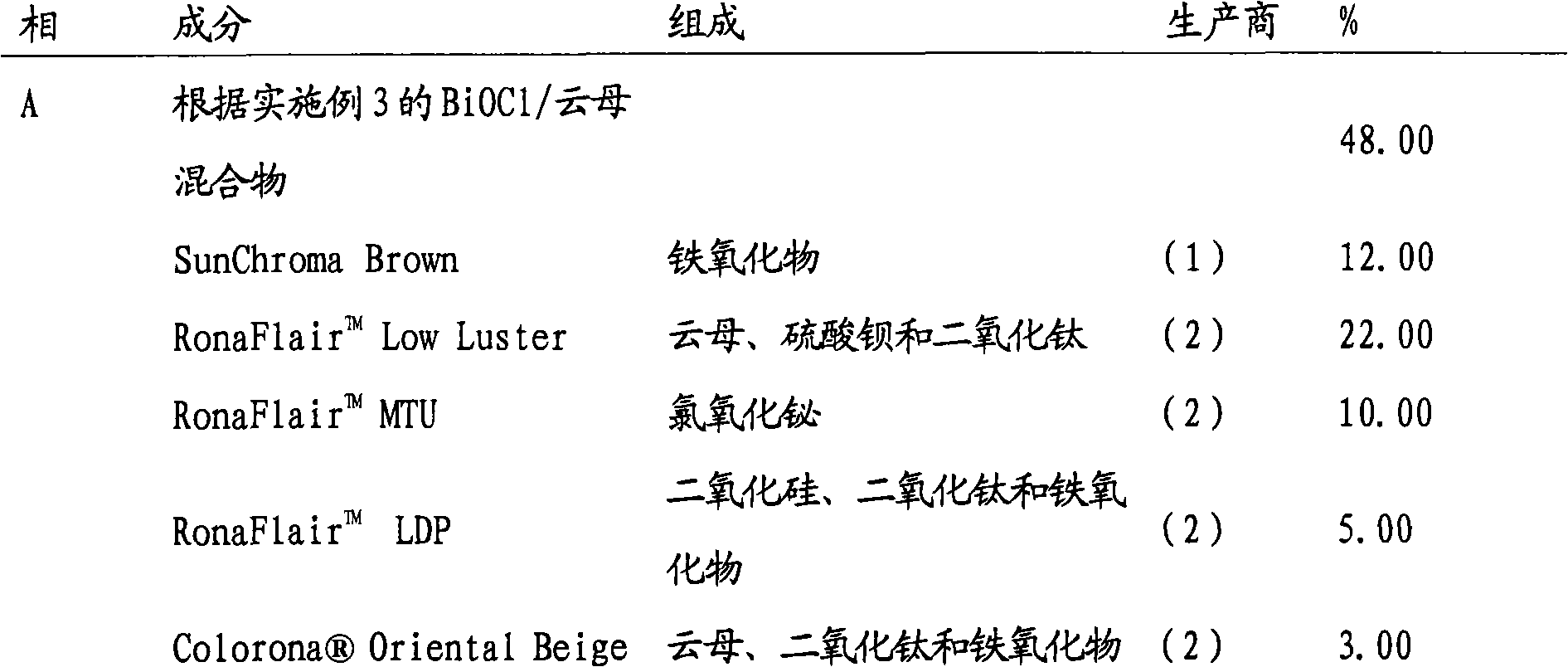

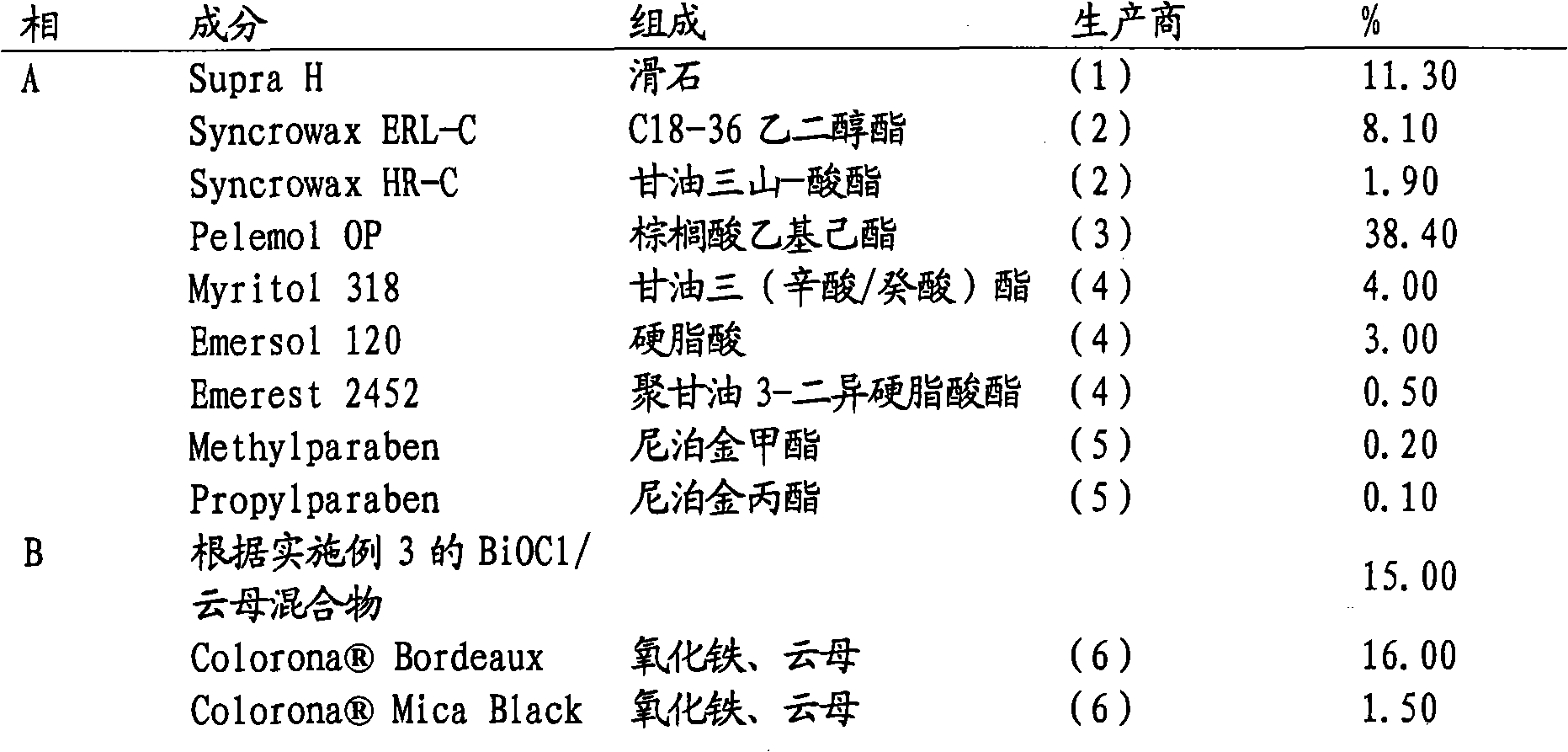

[0080] Example 3 :Mixture of 49% synthetic mica / 50% BiOCl / 1% magnesium stearate

[0081] The mica treated according to Example 2 was mixed with cosmetic grade BiOCl at the same weight in a laboratory mixer (Waring or Oster).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com