Pearlescent pigments, methods for producing same, and use of such pearlescent pigments

A technology of pearlescent pigment and structure, which is applied in the direction of pigment preparation, inorganic pigment treatment, chemical instruments and methods, etc., which can solve the problems of high cost and achieve the effects of low manufacturing cost, high hiding power and excellent chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

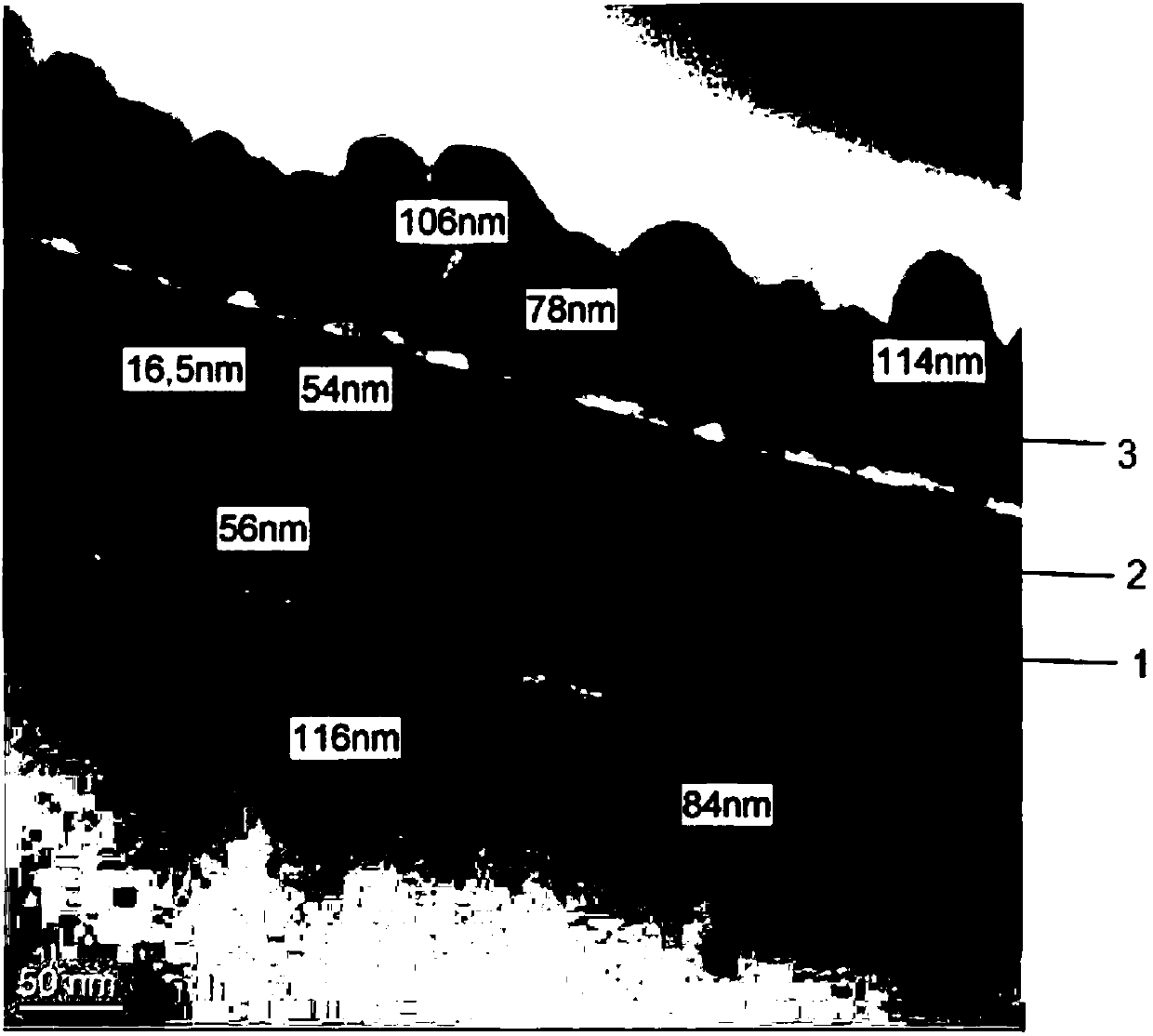

[0100] Example 1 -with SiO 2 (50nm) and iron oxide coated (110nm) aluminum flakes

[0101] First, using tetraethyl orthosilicate (TEOS), 60 g of SiO 2 Coated on a 10g Al flake (thickness (t 50 ) between 10 nm and 20 nm, d50 = 15 μm). In a round bottom flask with reflux condenser and stirrer, these Al flakes were mixed with 500 ml of deionized water and heated to 75 °C with stirring. The pH was adjusted to 3.2 by adding 10% NaOH solution. The reaction mixture was mixed with 700 g of 40% FeCl 3 The solution was mixed and the pH was kept essentially constant at 3.2 by simultaneous addition of 10% NaOH solution. Add FeCl 3 After the solution was complete, the mixture was stirred for an additional 15 min to ensure complete precipitation. The pH was then raised to 7.0 by dropwise addition of 10% NaOH solution for 30 minutes. After stirring for a further 30 minutes, the coated pigment was separated from the supernatant reaction solution by filtration and washed until salt-f...

Embodiment 2-

[0103] Example 2- with SiO 2 (50nm) and iron oxide coated (100nm) aluminum flakes

[0104] First, using tetraethyl orthosilicate (TEOS), 60 g of SiO 2 Coated on a 10g Al flake (thickness (t 50 ) between 10 nm and 20 nm, d50 = 15 μm). In a round bottom flask with reflux condenser and stirrer, these Al flakes were mixed with 500 ml of deionized water and heated to 75 °C with stirring. The pH was adjusted to 3.2 by adding 10% NaOH solution. The reaction mixture was mixed with 650 g of 40% FeCl 3 The solution was mixed and the pH was kept essentially constant at 3.2 by simultaneous addition of 10% NaOH solution. Add FeCl 3 After the solution was complete, the mixture was stirred for an additional 15 min to ensure complete precipitation. The pH was then raised to 7.0 by dropwise addition of 10% NaOH solution for 30 minutes. After stirring for a further 30 minutes, the coated pigment was separated from the supernatant reaction solution by filtration and washed until free o...

Embodiment 3-

[0106] Example 3- with SiO 2 (15nm) and iron oxide coated (100nm) aluminum flakes

[0107] First, using tetraethylorthosilicate (TEOS), 10 g of SiO 2 Coated on a 10g Al sheet (thickness (t 50 ) between 20 nm and 30 nm, d50 = 20 μm). In a round bottom flask with reflux condenser and stirrer, these Al flakes were mixed with 500 ml of deionized water and heated to 75 °C with stirring. The pH was adjusted to 3.2 by adding 10% NaOH solution. The reaction mixture was mixed with 400 g of 40% FeCl 3 The solution was mixed and the pH was kept essentially constant at 3.2 by simultaneous addition of 10% NaOH solution. Add FeCl 3 After the solution was complete, the mixture was stirred for an additional 15 min to ensure complete precipitation. The pH was then raised to 7.0 by dropwise addition of 10% NaOH solution for 30 minutes. After stirring for a further 30 minutes, the coated pigment was separated from the supernatant reaction solution by filtration and washed until free of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com