A coated bismuth oxy halide-based pigment

一种卤氧化铋、颜料的技术,应用在基于卤氧化铋的颜料领域,能够解决缺乏热稳定性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

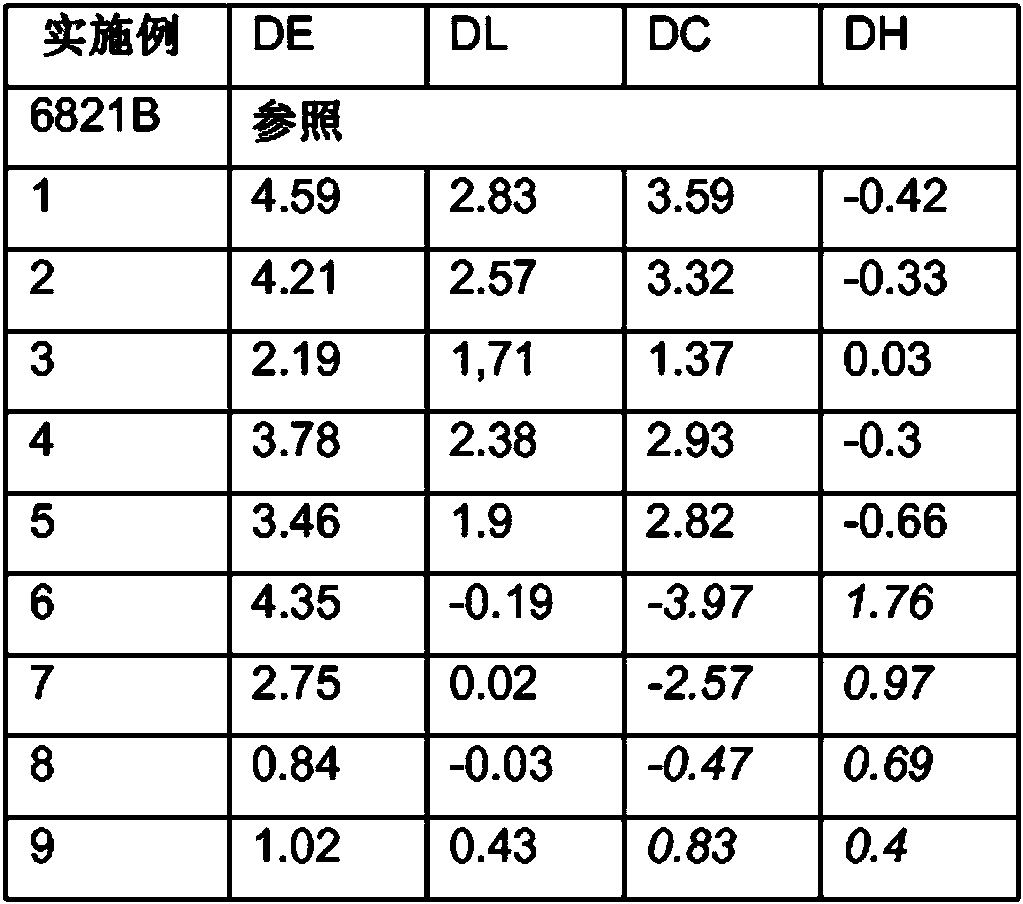

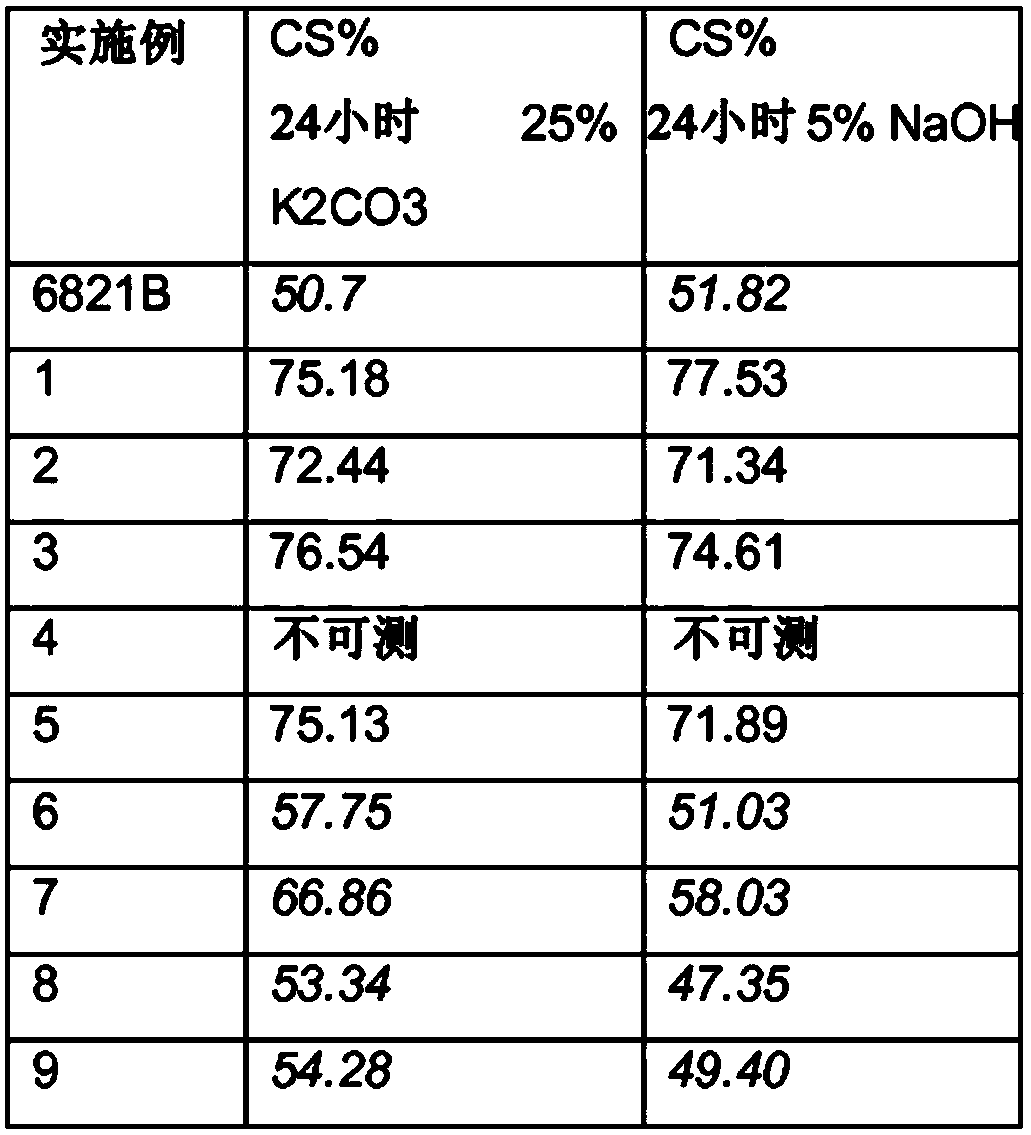

Examples

Embodiment 1

[0073] 180 g of LYSOPAC ORANGE 6821B pigment and 18.1 g of a 25% by weight silicate solution were dispersed in 820 ml of water. The volume was then adjusted to 8600 ml by adding a mixture of water and 1 g of sodium hydroxide and the temperature was raised to 90° C. (1° C. / min). 199.6g 25% (weight) sodium silicate (Na 2 SiO 3 ) solution diluted with water to a volume of 360ml and then added to the reactor over a period of 30 minutes to 1 hour. Then 7.2 g of amino-3-propyltriethoxysilane were added, and then the pH was adjusted to 2.5 over 2.5 hours. Then 3.6 g of amino-3-propyltriethoxysilane were added to the reactor. A mixture of 16 g of organomodified polysiloxane emulsion and 65 ml of water was added to the reactor. 18.6 g calcium chloride (CaCl 2 2H 2 O) and 52.9g aluminum sulfate (Al 2 (SO 4 ) 3 ·xH 2 O, calculated as 17 wt% Al 2 o 3 ) mixture and stir for at least 5 minutes. In the presence of 0.86 g of nonionic surfactant (ethoxylated alcohol), a dispersion...

Embodiment 2

[0075] 180 g of LYSOPAC ORANGE 6821B pigment and 18.1 g of a 25% by weight silicate solution were dispersed in 820 ml of water. The volume was then adjusted to 8600 ml by adding a mixture of water and 1 g of sodium hydroxide and the temperature was raised to 90° C. (1° C. / min). 199.6g 25% (weight) sodium silicate (Na 2 SiO 3 ) solution diluted with water to a volume of 360ml and then added to the reactor over a period of 30 minutes to 1 hour. Then 7.2 g of amino-3-propyltriethoxysilane were added, and then the pH was adjusted to 2.5 over 2.5 hours. Then 3.6 g of amino-3-propyltriethoxysilane were added to the reactor. A mixture of 16 g of organomodified polysiloxane emulsion and 65 ml of water was added to the reactor. 18.6 g calcium chloride (CaCl 2 2H 2 O) and 52.9g aluminum sulfate (Al 2 (SO 4 ) 3 ·xH 2 O, calculated as 17 wt% Al 2 o 3 ) mixture and stir for at least 5 minutes. In the presence of 0.86 g of nonionic surfactant (ethoxylated alcohol), 7.2 g of tri...

Embodiment 3

[0076] Embodiment 3 (comparative example)

[0077] 180 g of LYSOPAC ORANGE 6821B pigment and 18.1 g of a 25% by weight silicate solution were dispersed in 820 ml of water. The volume was then adjusted to 8600 ml by adding a mixture of water and 1 g of sodium hydroxide and the temperature was raised to 90° C. (1° C. / min). 199.6g 25% (weight) sodium silicate (Na 2 SiO 3 ) solution diluted with water to a volume of 360ml and then added to the reactor over a period of 30 minutes to 1 hour. Then 7.2 g of amino-3-propyltriethoxysilane were added, and then the pH was adjusted to 2.5 over 2.5 hours. Then 3.6 g of amino-3-propyltriethoxysilane were added to the reactor. 18.6 g calcium chloride (CaCl 2 2H 2 O) and 52.9g aluminum sulfate (Al 2 (SO 4 ) 3 ·xH 2 O, calculated as 17 wt% Al 2 o 3) mixture and stir for at least 5 minutes. In the presence of 0.86 g of nonionic surfactant (ethoxylated alcohol), a dispersion of 14.4 g of tris(2,4-tert-butylphenyl) phosphite was prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com