Multiple layered pigments exhibiting color travel

A technology of pigments and interference pigments, applied in the direction of pigment preparation, fibrous fillers, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

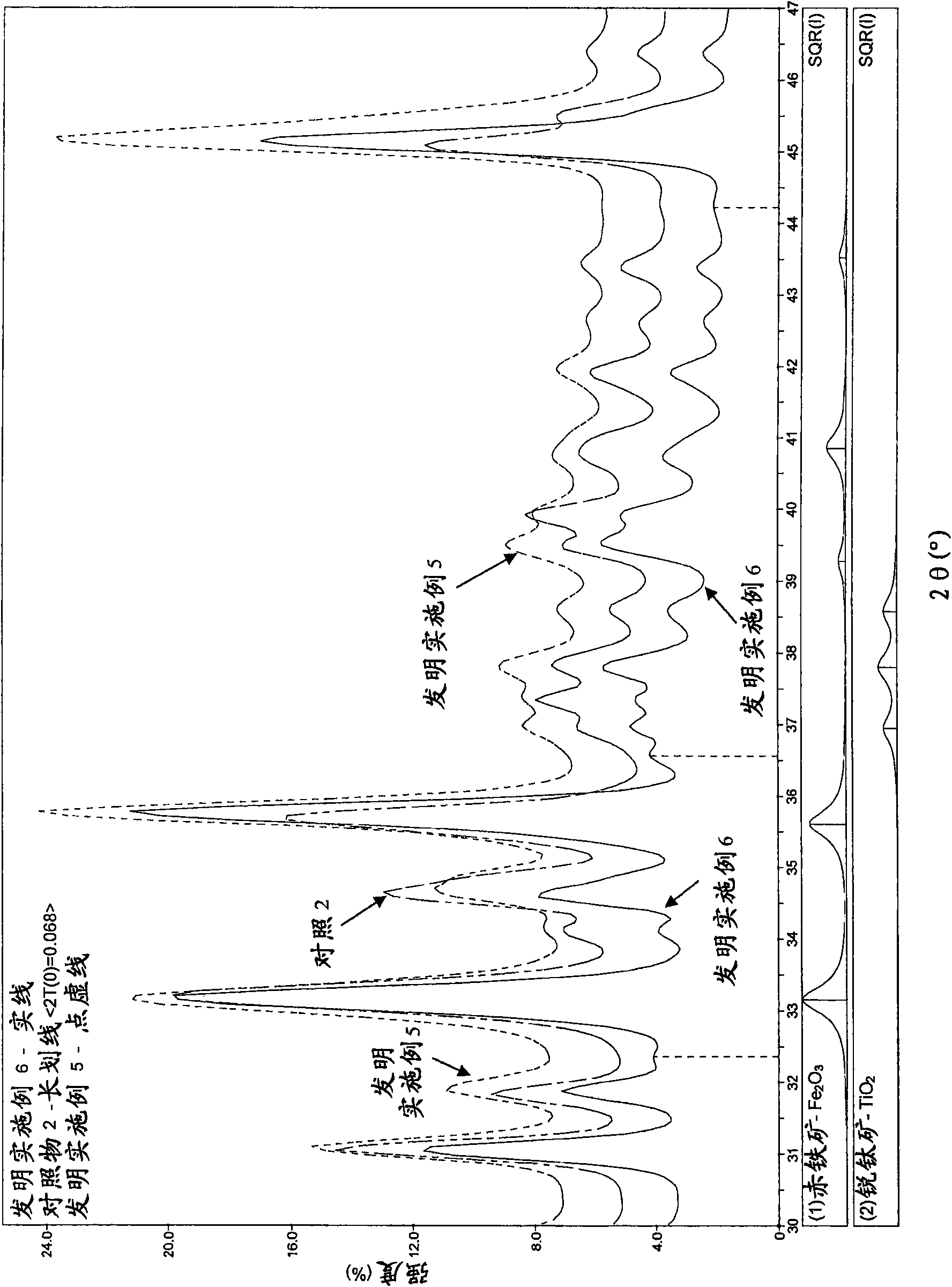

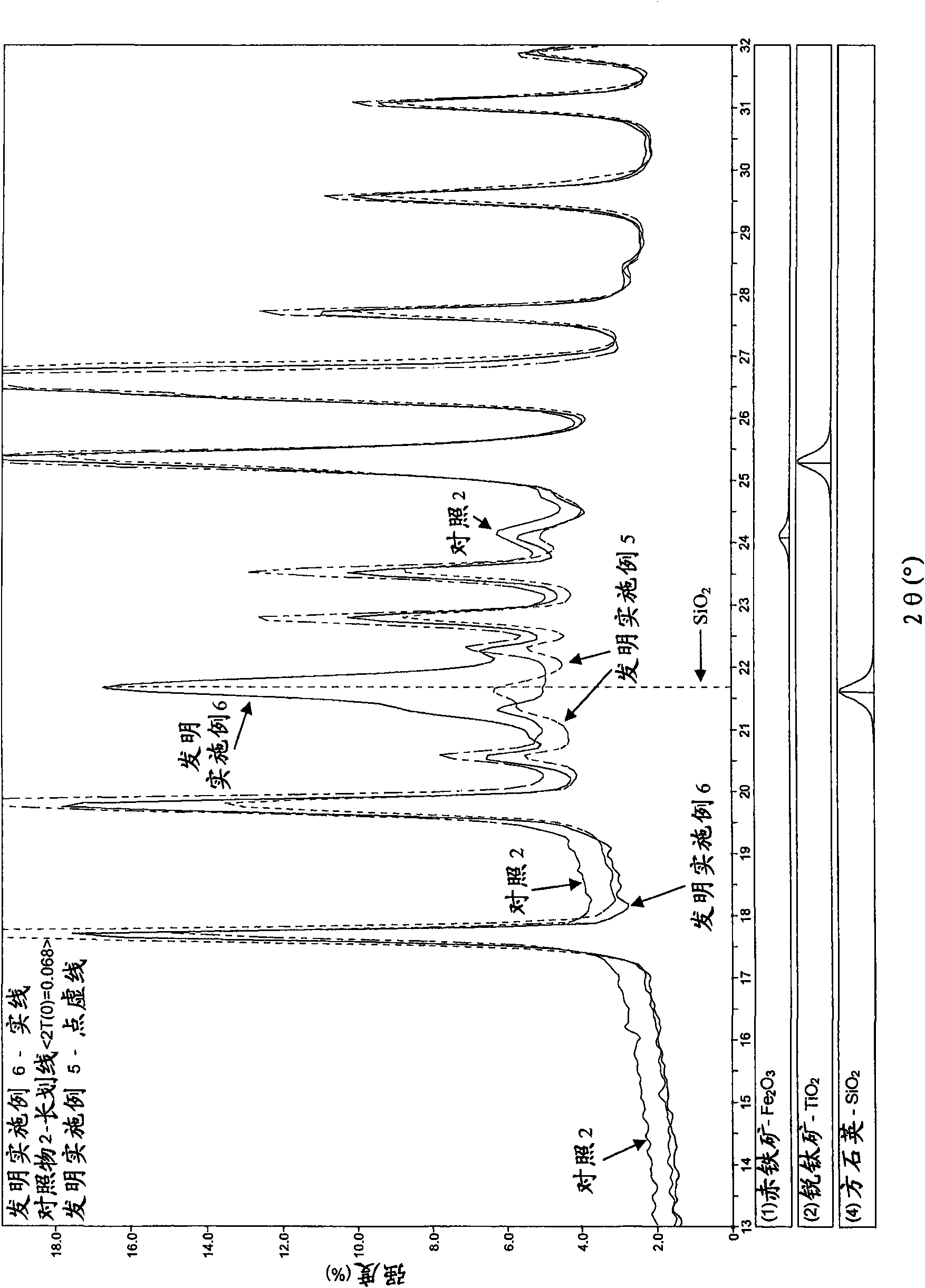

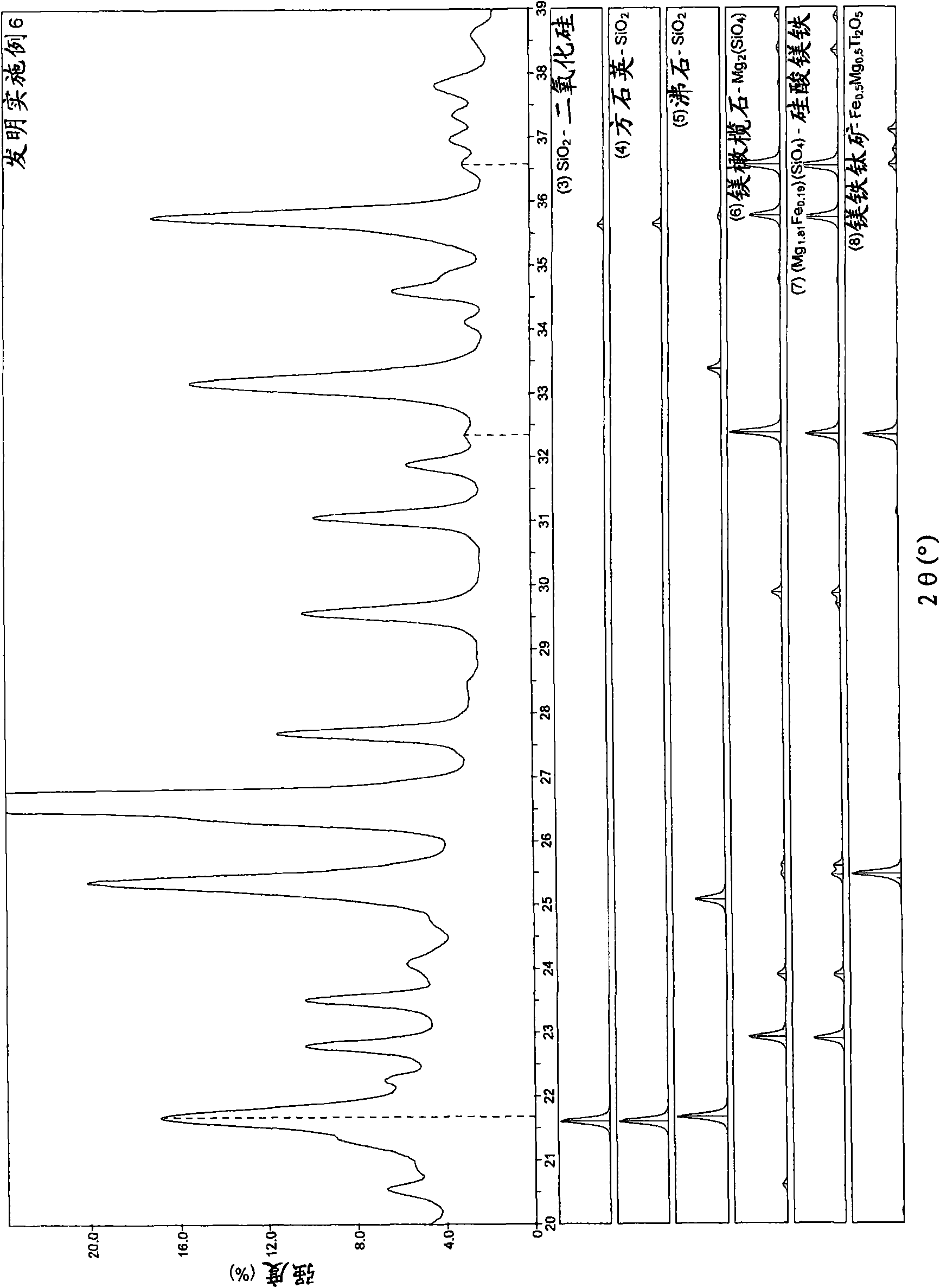

[0051] Invention Example 1 and Comparison 1

[0052] 200 grams of natural mica (average particle size 45-50 microns) was slurried with 1.0 liter of deionized water and stirred at 250-300 rpm. At room temperature, add 2.0-4.0 g of 39% FeCl 3 to pH 3.2. The slurry was heated to 75°C (nucleation step). At this temperature, 200.0 g of 39% FeCl was added at 1.0 mL / min at pH 3.2 3 (38.0 g Fe 2 o 3 ). The pH was adjusted to 8.25 with 35% NaOH. Add 3000.0 g sodium metasilicate x 9H at 5.0 ml / min at pH 8.25 2 O (176.0 g SiO 2 ). The pH was maintained with 17% HCl. Add 180.0 g TiCl at 1.5 mL / min at a constant pH 1.9 (maintained with 35% NaOH) 4 (30.0 g TiO 2 ). The paste has optically variable properties (OVP), changing from red to gold to green in the reaction flask. The slurry was divided into two equal parts; one part: Control 1, samples calcined at 500, 750 and 850 °C, the other part: Inventive Example 1, post-treated with Mg as follows:

[0053] The slurry was adju...

Embodiment 2

[0054] Invention Example 2 and Control 1a

[0055] Inventive Example 1 was repeated, but with 1.0-1.5% Ca added. Similar results were observed. Control 1a was prepared by the method described for Control 1. The samples were calcined at various temperatures (see Table 1).

[0056] Invention Example 3 and Control 1b

[0057] Inventive Example 1 was repeated, but with the addition of 1.0-2.0% Zn. Similar results were observed. Control 1b was prepared by the method described for Control 1 . The samples were calcined at various temperatures (see Table 1).

Embodiment 4

[0059] As a means of further comparison, Table 1 is presented showing the effect of Ca, Mg, Zn on the optical stack in terms of surface area densification (BET) as a function of Ca / Mg / Zn content and calcination temperature compared to the control sample. In Table 1, the unit of BET is square meters per gram.

[0060] Table 1

[0061]

[0062] Although the addition of Ca, Mg or Zn results in extreme densification at 850°C, these additives advantageously produce the ability to densify metal oxide surfaces at temperatures much lower than normal calcination temperatures. For example, the Ca control sample achieved a BET of 7.5 m2 / g at 650 °C, while its Ca-treated counterpart reached a value of 3.2 m2 / g at the same temperature. Even at 350 °C, the Ca-coated product was much denser than its control counterpart. As shown, the Mg and Zn treated samples behaved similarly. Therefore, this technique is unique and cost-effective without compromising the OVP characteristics of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com