Flaky pigment coated with coupling agent and perfluoralkyl phosphate

A perfluoroalkyl, flake-like technology used in pigment preparation, fibrous fillers, inorganic pigment treatment, etc. Coatings are prone to delamination and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

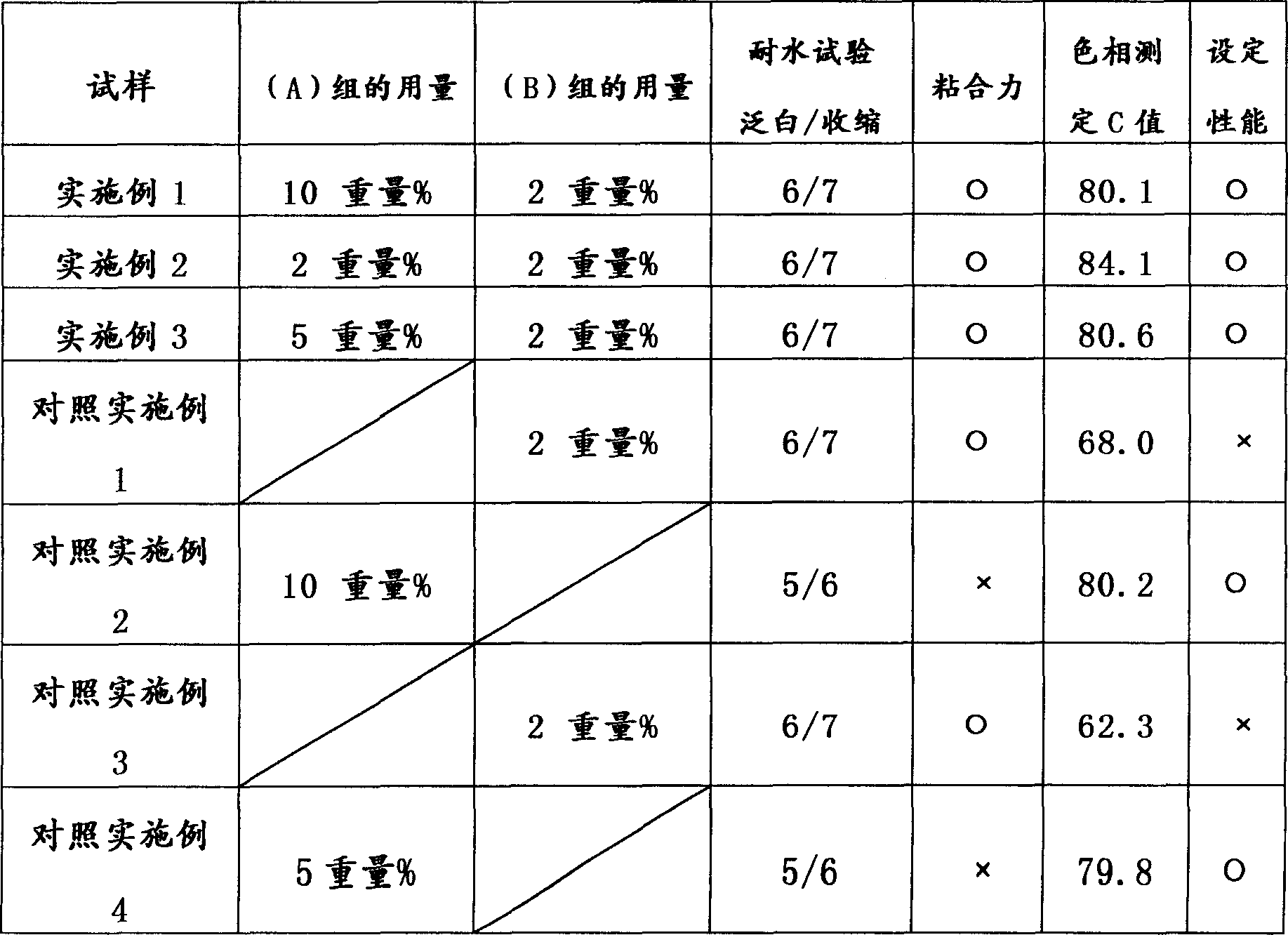

Examples

Embodiment 1

[0089] Will contain 5.68 grams of sodium hypophosphite (NaH 2 PO 2 ·H 2 O) aqueous solution was gradually added to the stirring at room temperature containing 5.76 g of zirconium oxychloride (ZrOCl 2 ·8H 2 O) in the 3% by weight aqueous solution so as not to produce white precipitates, and make a transparent aqueous solution. Then, 6.0 g of 35-37% aqueous hydrochloric acid solution is added to prepare a mixed solution of zirconyl chloride and sodium hypophosphite.

[0090]Separately, 100 grams of rutile titanium dioxide coated mica titanium flakes (IRIODIN225 Rutile Blue, manufactured by E. Merck) with a particle size of 10-60 microns, blue reflection color and yellow transmission color, were suspended in 1000 ml of water, under stirring The temperature was increased to 75°C. Adjust the pH of the suspension to 3 with hydrochloric acid, and add 1.14 g of 10% by weight cerium chloride (CeCl 3 ·7H 2 O) Aqueous solution, adding the mixed solution of zirconyl chloride and sodium hypoph...

Embodiment 2

[0093] Follow the same steps as Example 1, except that 2 grams of perfluoroalkylsilane CF 3 (CF 2 ) 7 (CH 2 ) 2 Si(OCH 2 CH 3 ) 3 (Toray Dow Corning Ltd. / AY43-158E) In place of perfluoroalkyl phosphate, the same 100g rutile type with a particle size of 10-60 microns and a blue reflection color and a yellow transmission color was used as in Example 1. Mica titanium flakes of titanium dioxide (IRIODIN225 Rutile Blue, manufactured by E. Meck) and other same materials in the same amount to prepare pearlescent pigments.

[0094] Through the above steps, a powdery pearlescent pigment with blue reflection color and yellow transmission color and excellent dispersibility is prepared. When the pigment is suspended in low-polarity organic solvents such as toluene and xylene, the pigment particles will float on the surface of the solvent and oriented densely. According to this, the extremely high reflected color brightness exhibited by the pearlescent pigment can prove that the setting is obt...

Embodiment 3

[0096] Will contain 5.68 grams of sodium hypophosphite (NaH 2 PO 2 ·H 2 O) aqueous solution was gradually added to the stirring at room temperature containing 5.76 g of zirconium oxychloride (ZrOCl 2 ·8H 2 O) in a 3% by weight aqueous solution, so that no white precipitate is produced and a transparent aqueous solution is prepared. Then, 6.0 g of 35-37% hydrochloric acid aqueous solution is added to prepare a mixed solution of zirconyl chloride and sodium hypophosphite.

[0097] Separately, 100 g of iron oxide-coated mica flakes (IRIODIN 504 Red, manufactured by E. Merck) with a particle size of 10-60 microns and a wine-red reflection color were suspended in 1000 ml of water, and the temperature was increased under stirring To 75°C. The pH value of the suspension was adjusted to 3 with hydrochloric acid, and the mixed solution of zirconyl chloride and sodium hypophosphite was added dropwise to the suspension within about 1 hour, while the suspension was adjusted with a 32% by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com