Thermoplastic composite preimpregnation body plate

A composite material and thermoplastic polymer technology, applied in the field of thermoplastic composite material prepreg sheet, can solve the problems of high polymer melt viscosity, difficult mold preheating, long product forming time, etc., and achieve tensile strength and anti-deformation. Performance improvement, solving the problem of effective impregnation, and the effect of convenient impregnation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Polyurethane emulsion (emulsion is a fine particle, very stable water dispersion) produced by Shandong Aodemei Polymer Material Co., Ltd., ADM-F269D500.2 microns, mixed with water to prepare a solid content of 11% (wt), the fabric is carbon fiber single Xiang cloth, gram weight 200 grams / square meter, carbon fiber is Toray T70012K fiber with a diameter of 7 microns, soak the fabric in the emulsion, drain the excess emulsion, place it on the metal mesh, and place it in an oven at 180°C for 20 minutes. Remove from the oven and cool to room temperature. The prepreg contained 10.3% polymer, and the carbon fiber bundles passed the siphon test after immersion.

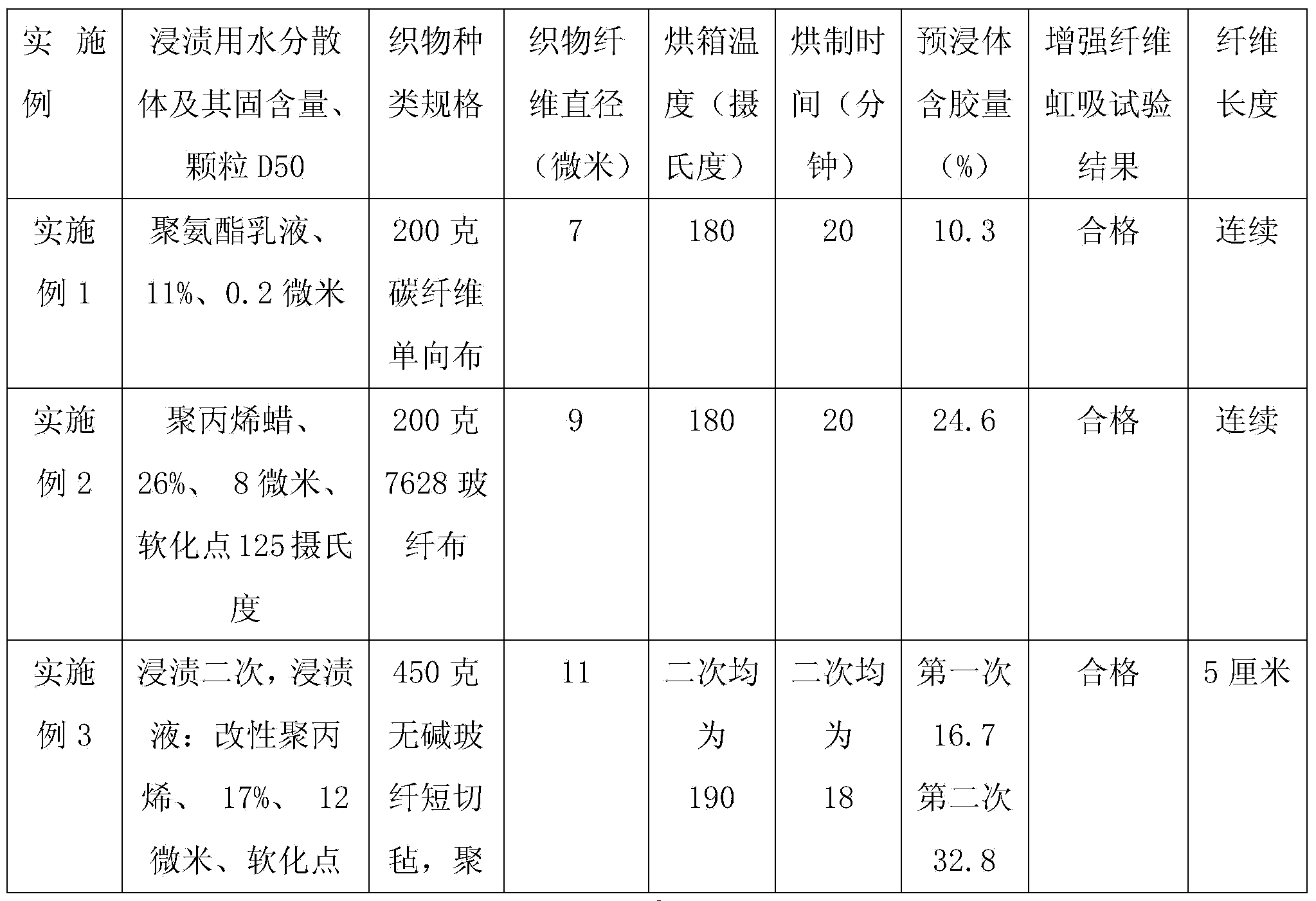

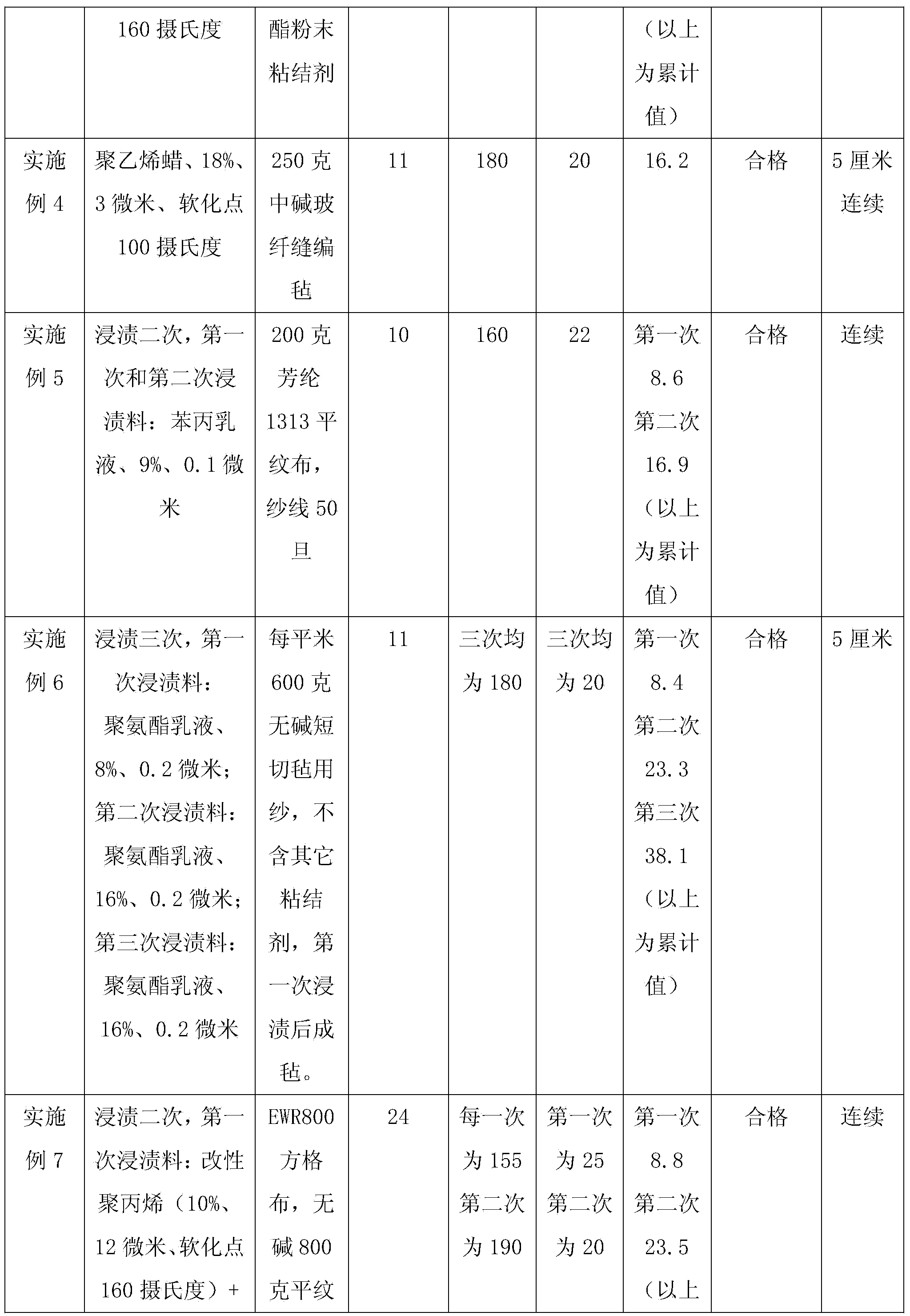

[0053] The prepregs of Example 1 to Example 7 and Comparative Example 1 are shown in Table 1:

[0054] Table 1

[0055]

[0056]

[0057]

[0058] The gel content of the prepreg in Table 1 refers to the content of the thermoplastic polymer after the prepreg is impregnated with an aqueous dispersion of the thermoplastic pol...

Embodiment 2

[0060] Preparation method of polypropylene wax water dispersion used:

[0061] Mix and disperse the following materials evenly:

[0062] 100 grams of polypropylene wax Nanjing Tianshi Experimental Micron Powder Co., Ltd. PPW0902 (melting point: 145°C, particle size: D50: 10 microns)

[0063] 2.5 grams of castor oil twenty carbon polyoxyethylene ether EL-20 Jiangsu Haian Petrochemical Plant

[0064] 3 grams of allyl branched alcohol ten-carbon polyoxyethylene ether APEG-1000 Jiangsu Haian Petrochemical Plant

[0065] 10 g methyl methacrylate

[0066] 10 g dibutyl maleate

[0067] 0.2 g dibenzoyl peroxide

[0068] 0.2 g azobisisobutyronitrile

[0069] 200g water

[0070] Stir the mixture in a four-necked reaction flask equipped with a stirrer, a condenser and a thermometer for 1 hour, then increase the temperature to 95°C for constant temperature reaction for 5 hours, and then lower the temperature to 45°C. Grind the materials in a grinder for 5 hours to obtain the finished product. After tes...

Embodiment 3

[0072] Preparation method of water dispersion:

[0073] The material ratio is:

[0074] 100 grams of KT-1 powder (maleic anhydride modified polypropylene D50: 14 microns)

[0075] 6 grams acrylic

[0076] 5 grams baking soda

[0077] 0.5 g benzoyl peroxide

[0078] 1.3 grams of azobisisobutyronitrile

[0079] 10 g hydroxyethyl acrylate

[0080] 19 grams of styrene

[0081] 230 g water

[0082] Put the above materials directly into the container of the basket sand mill, continue to disperse for 1 hour, then grind, heat up to 95°C for 6 hours at constant temperature, and cool to 45°C to obtain the finished product and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com