Coal ash slag comprehensive utilization device and comprehensive utilization method

A technology of slag and coal ash, which is applied in the field of comprehensive utilization devices for coal ash and slag, and can solve problems such as the inability to deal with solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

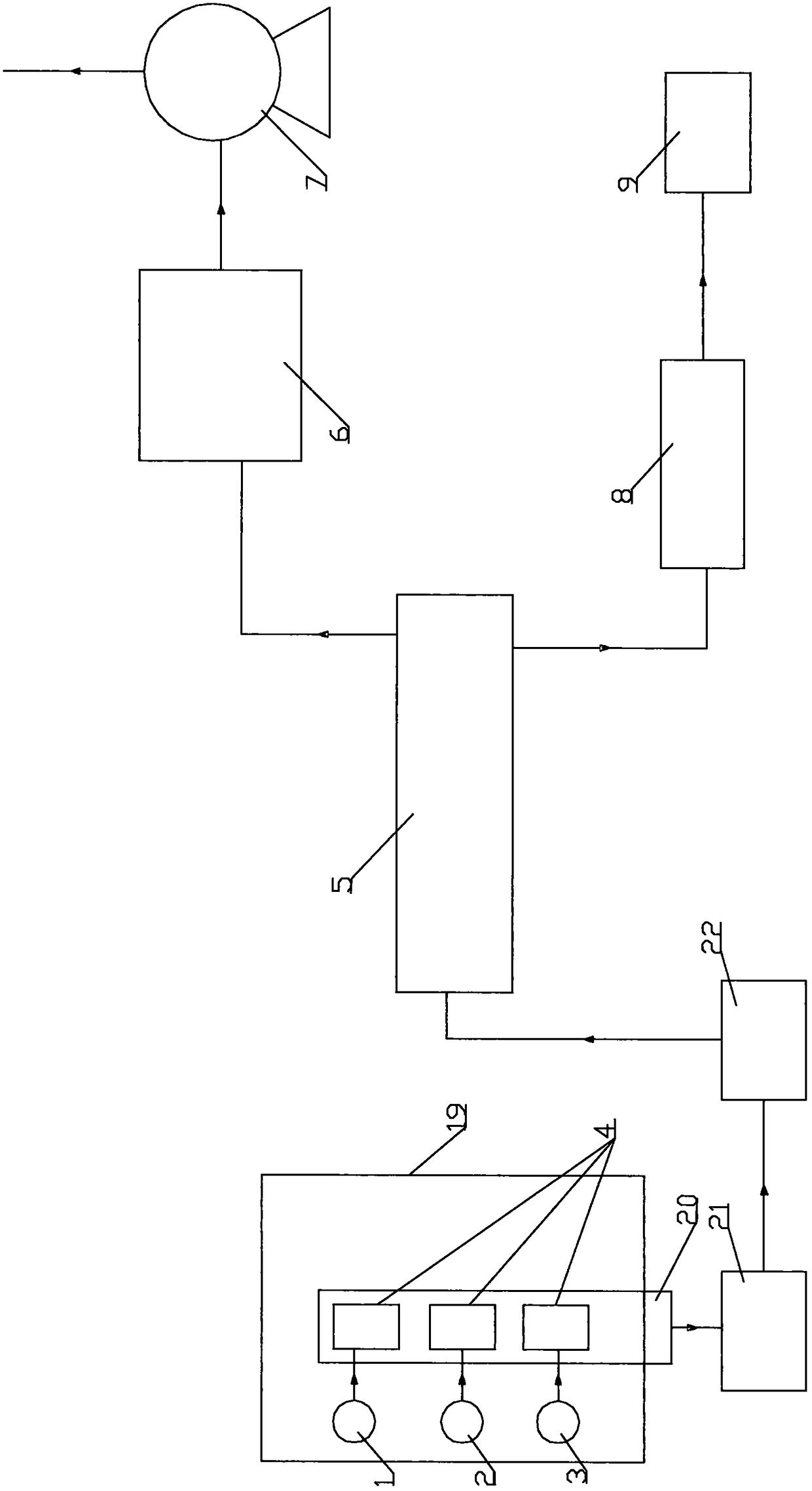

[0104] A comprehensive utilization method of a coal ash and slag comprehensive utilization device, the comprehensive utilization method comprising the following steps:

[0105] Step 1: Start the belt scales 4 corresponding to the boiler slag raw material bin 1, the gas-forming slag raw material bin 2 and the gasification slag raw material bin 3, so that the boiler slag, gas-making slag and gasification slag enter in a ratio of 1:1:1 In the first belt conveyor 20, and enter in the ball mill 5 by the first belt conveyor 20, the fourth elevator 21 and the second belt conveyor 22;

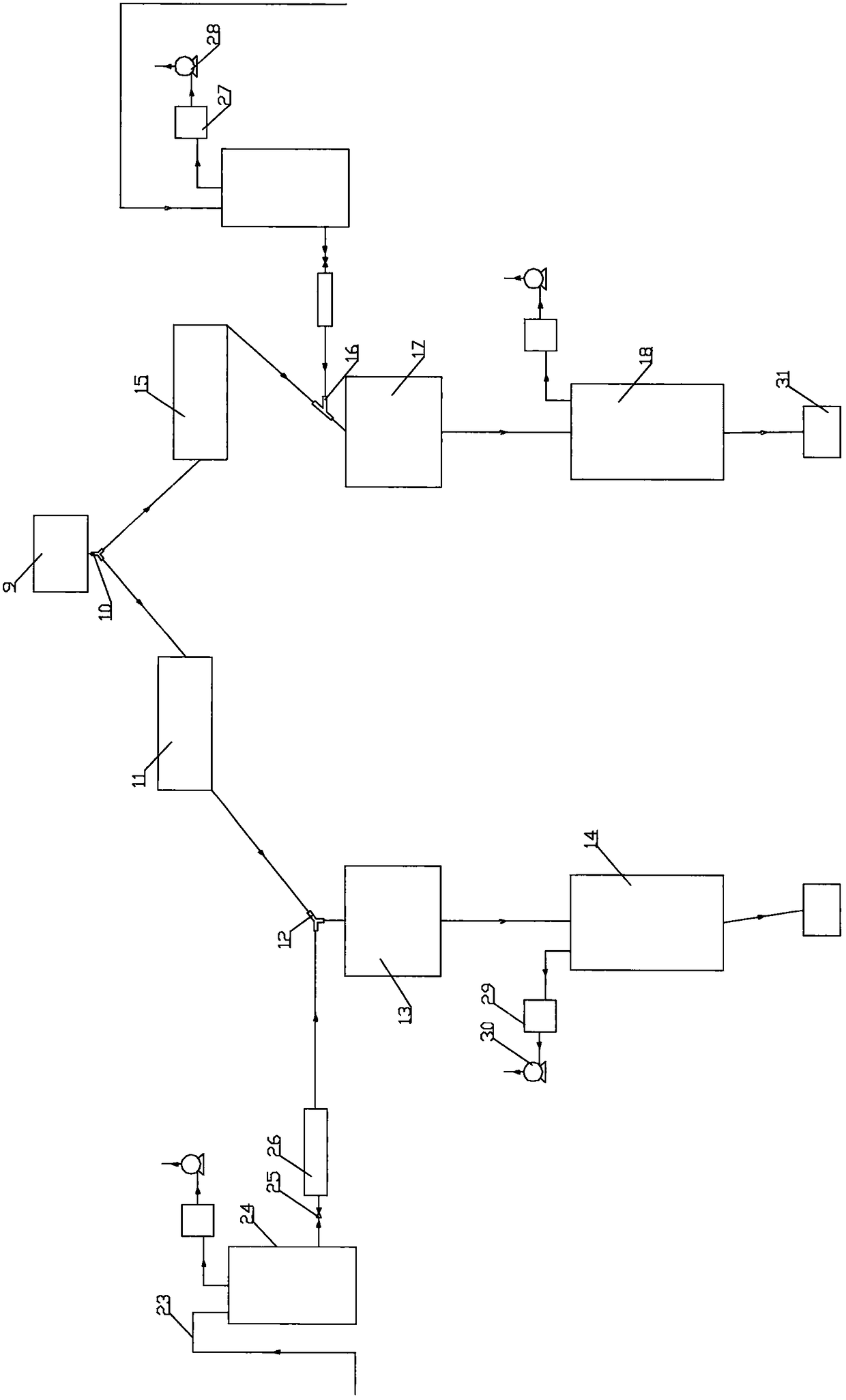

[0106] Step 2: Boiler slag, gas-making slag and gasification slag are mixed and ground in ball mill 5, and after three-stage grinding, the fineness reaches the fineness of secondary ash; the gas dust in ball mill 5 passes through the gas outlet at the top of ball mill 5, The first bag filter 6 and the first induced draft fan 7 discharge the atmosphere; the material in the ball mill 5 enters the first air...

Embodiment 2

[0116] A comprehensive utilization method of a coal ash and slag comprehensive utilization device, the comprehensive utilization method comprising the following steps:

[0117] Step 1: Start the belt scales 4 corresponding to the boiler slag raw material bin 1 and the gas-making slag raw material bin 2, so that the boiler slag and gas-making slag enter the first belt conveyor 20 at a ratio of 1:1, and pass through the first belt conveyor 20. The fourth elevator 21 and the second belt conveyor 22 enter the ball mill 5;

[0118] Step 2: Boiler slag and gas-making slag are mixed and ground in ball mill 5, and after three-stage grinding, the fineness reaches the fineness of secondary ash; the gas dust in ball mill 5 passes through the gas outlet at the top of ball mill 5, the first bag type The dust collector 6 and the first induced draft fan 7 exhaust the atmosphere; the materials in the ball mill 5 enter the first air delivery chute 8, the first hoist 9 and the tee 10;

[0119]...

Embodiment 3

[0128] A comprehensive utilization method of a coal ash and slag comprehensive utilization device, the comprehensive utilization method comprising the following steps:

[0129] Step 1: Start the belt scales 4 corresponding to the boiler slag raw material bin 1 and the gasification slag raw material bin 3, so that the boiler slag and gasification slag enter the first belt conveyor 20 at a ratio of 1:1, and pass through the first belt conveyor 20. The fourth elevator 21 and the second belt conveyor 22 enter the ball mill 5;

[0130] Step 2: Boiler slag and gasification slag are mixed and ground in ball mill 5, and after three-stage grinding, the fineness reaches the fineness of secondary ash; the gas dust in ball mill 5 passes through the gas outlet at the top of ball mill 5, the first bag type The dust collector 6 and the first induced draft fan 7 exhaust the atmosphere; the materials in the ball mill 5 enter the first air delivery chute 8, the first hoist 9 and the tee 10;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com