Aluminum alloy formwork trapezoid cross section profile and unit formwork structure of aluminum alloy formwork

A technology of aluminum alloy formwork and trapezoidal section, which is applied in the direction of formwork/formwork member, sheet/board, building element, etc. Simple forming, quick and easy disassembly and assembly, and the effect of reducing the unit weight of the profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

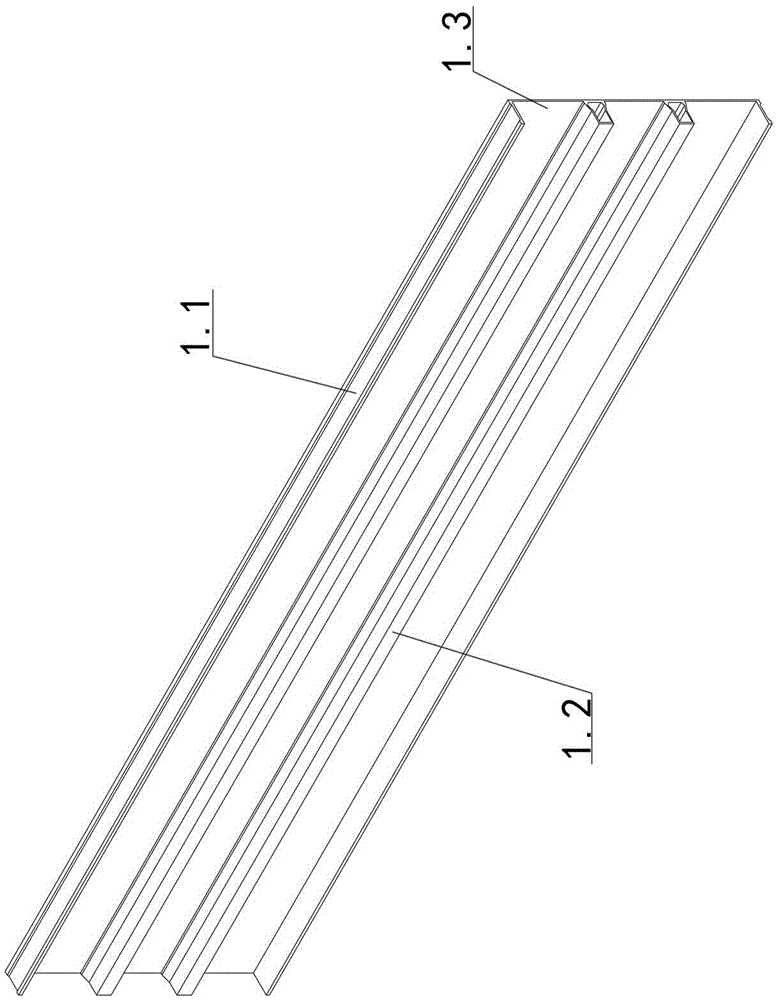

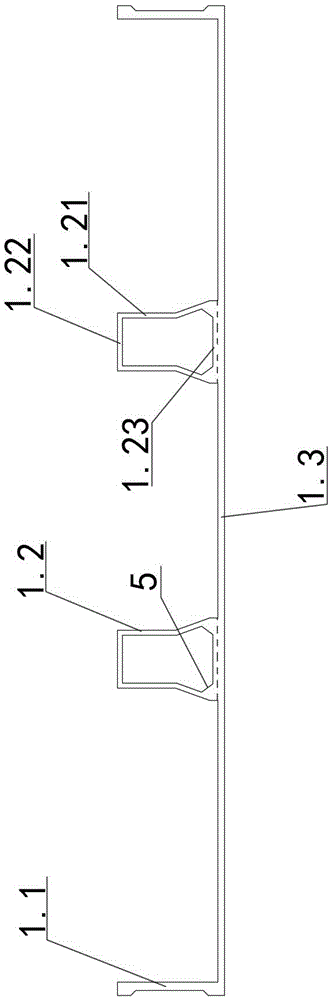

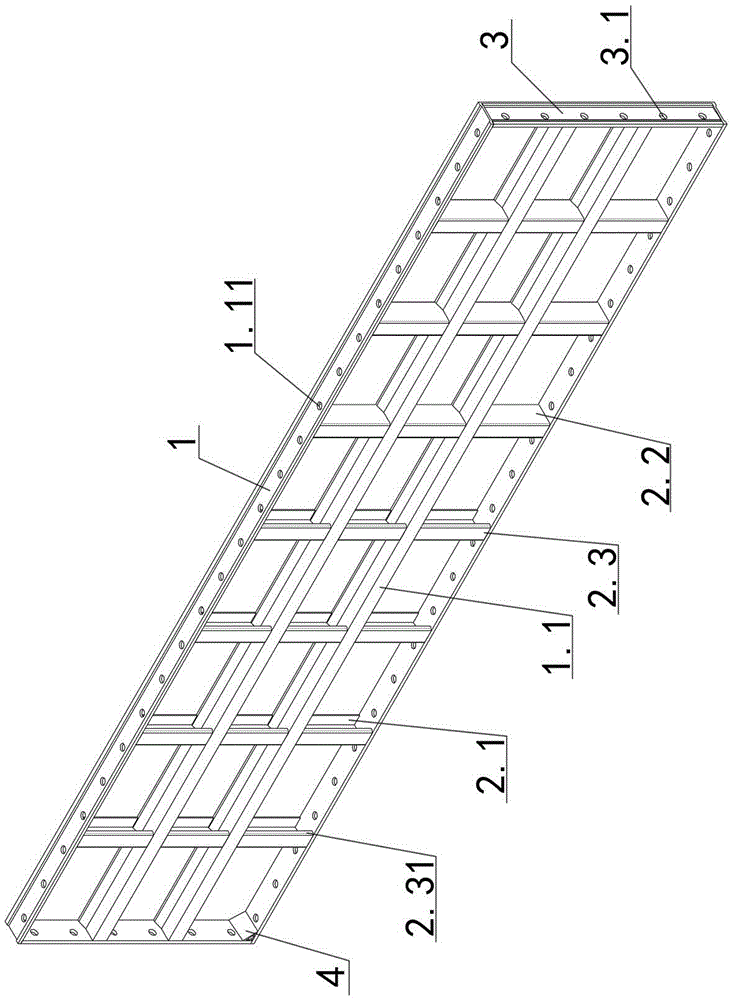

[0028] Examples see Figure 1-2 As shown, an aluminum alloy formwork trapezoidal cross-section profile is an aluminum alloy special-shaped plate 1 extruded as a whole. The aluminum alloy special-shaped plate 1 is formed by a rectangular panel 1.3 and two opposite longitudinal side frames 1.1 on the back of the panel. The tank body and the longitudinal reinforcing ribs 1.2 arranged on the bottom of the tank body, the longitudinal reinforcing ribs 1.2 are arranged in the center or more than two channels are arranged equally in the space of the tank body, the longitudinal reinforcing ribs 1.2 and the longitudinal side frames 1.1 Equal height and length, the cross-section of the longitudinal reinforcing rib 1.2 is a hollow special-shaped quadrilateral, the special-shaped quadrilateral is approximately trapezoidal, and the two waists 1.21 of the trapezoid are folded inward so that the upper bottom 1.22 of the trapezoid is at right angles to the two waists, and the lower bottom 1.23 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com