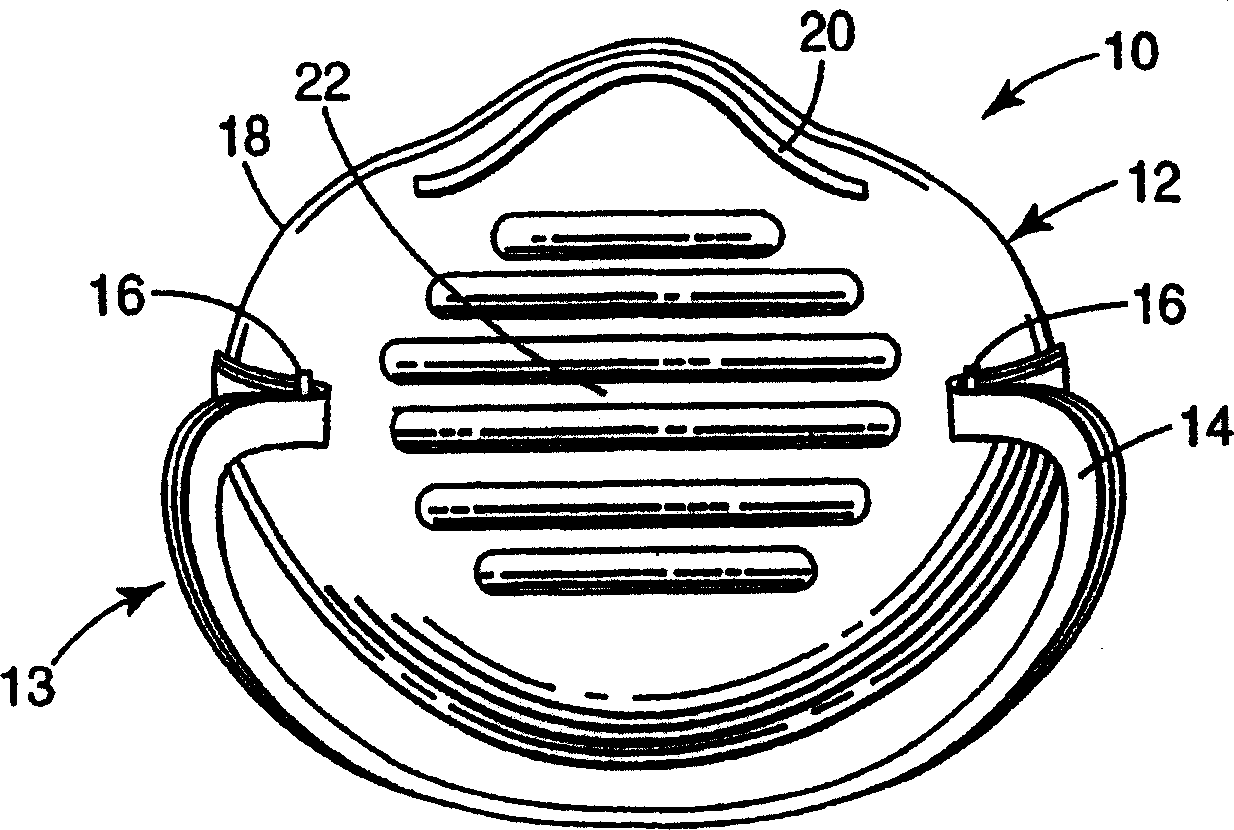

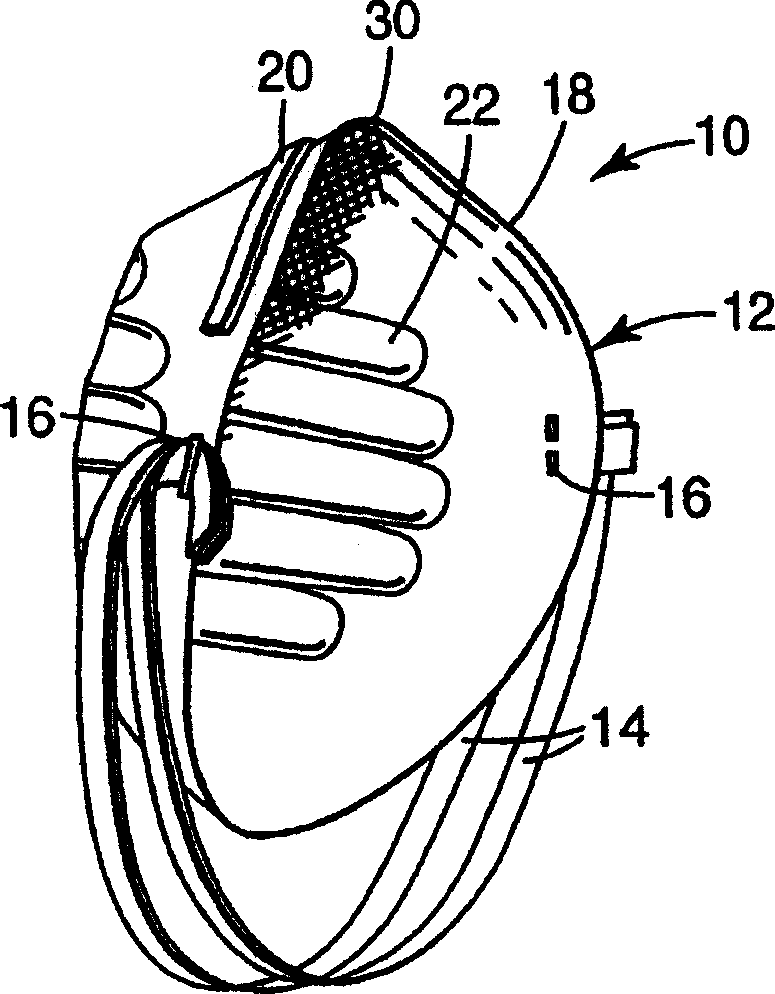

Crush resistant filtering face mask

A filter mask and filter layer technology, which is applied in the direction of breathing filters, breathing masks, respiratory protection containers, etc., to achieve the effect of high filtering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

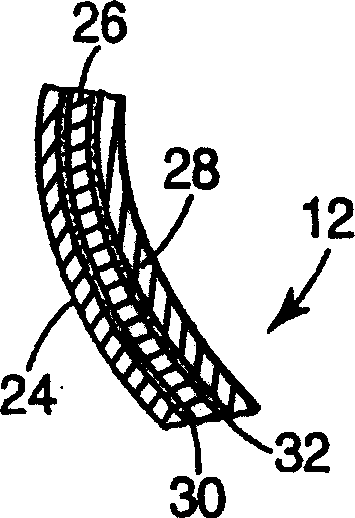

[0070] The cup-shaped mask of the present invention is prepared as follows: First, the shaping layer, the belt and the filter material are formed into a layer in the order of S·A·F·A·S, wherein S represents the shaping layer, A represents the adhesive layer, and F represents filter layer. The forming layer material was thermally bonded staple fiber [T-254, 4 denier, cut to 38 mm length, composition: PET core, PET copolyester sheath] purchased from Kosa Corporation of Charlotte, Carolina. Form the fibers of the forming layer into a unit weight of 63g / m 2 The mesh, inner and outer layers use Air Rando Webber products. The adhesive layer was a nonwoven adhesive web PE-85-12 available from Bostik Findley, Middleton, MA. The unit weight of the filter is 35g / m 2, fiber size: effective fiber diameter (EFD) 4.7 microns (according to Davies C.N.'s article "Separation of Airborne Dust Particles" published in "Institution of Mechanical Engineers London Journal" (1B, 1952) by Davies C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com