Light-type high-strength steel wire rope core conveyor belt

A technology for steel cord cores and conveyor belts, applied in the field of rubber conveyor belts, which can solve the problems of thick conveyor belts, large diameters of steel cords, and heavy weights, and achieve the effects of enhanced strength, reduced unit weight, and material cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

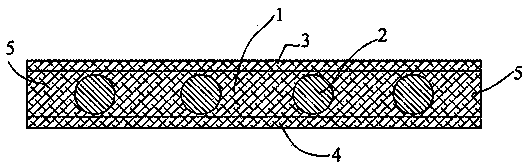

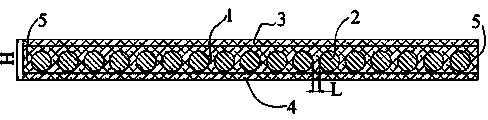

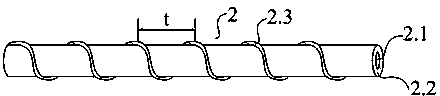

[0019] refer to Figure 2 to Figure 4 As shown, the light-duty high-strength steel cord conveyor belt in this embodiment includes a core rubber 1, a steel cord core, an upper cover rubber 3, a lower cover rubber 4 and a side rubber 5, and the steel cord core is located between the upper cover rubber 3 and the lower cover rubber. It includes a plurality of steel wire ropes 2 arranged in parallel along the width direction of the conveyor belt, and the core rubber 1 is between adjacent steel wire ropes 2 . Steel wire rope 2 includes rope core 2.1 and multi-strand steel wire A2.2 twisted along the length direction of rope core 2.1 around rope core 2.1. It also includes a steel wire B2.3, the steel wire B2.3 is spirally wound along the length direction of the steel wire rope on the periphery of the multi-strand steel wire A2.2, and the twisting of the steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com