Fixing device of coil framework of miniature transformer and method for winding coils

A micro-transformer, coil bobbin technology, applied in the direction of transformer/inductor coil/winding/connection, inductor/transformer/magnet manufacturing, coil manufacturing, etc., to reduce stretching and bending deformation, improve winding efficiency, and be widely used in Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

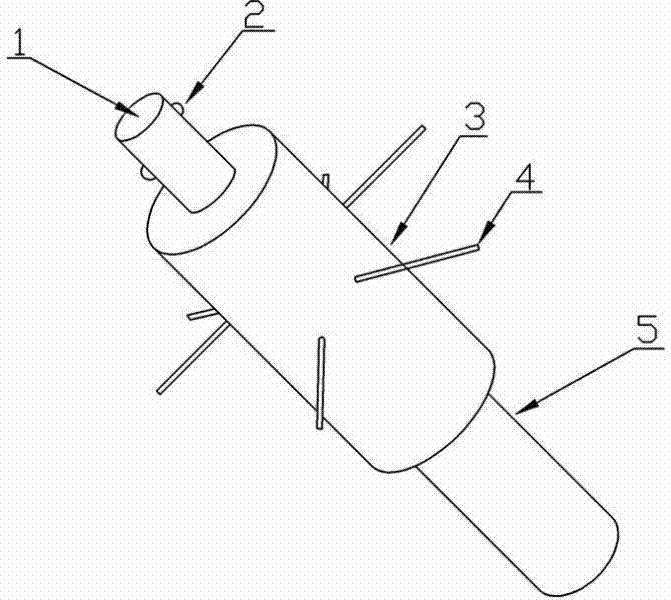

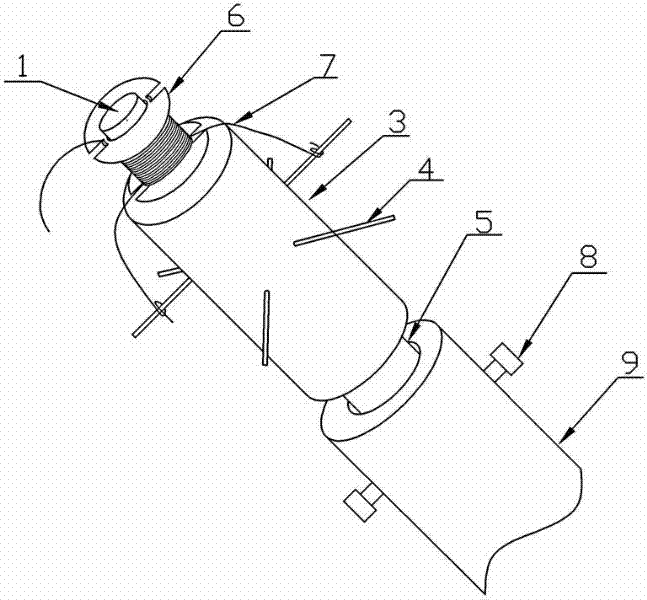

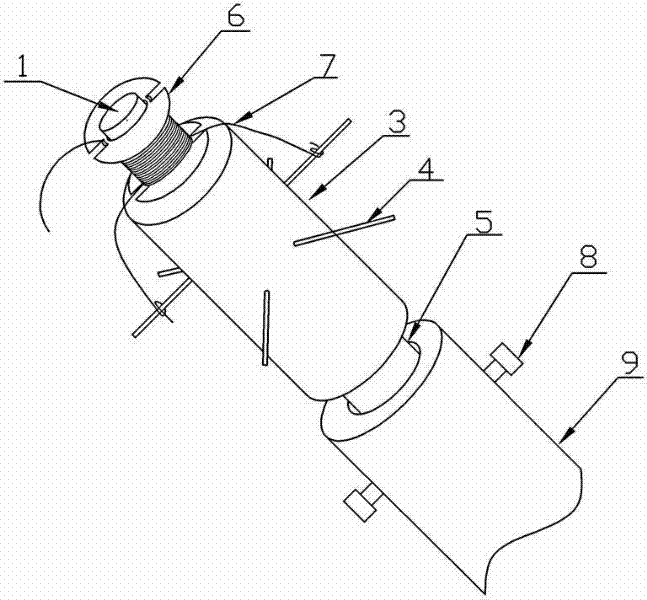

[0030] Such as figure 1 As shown, a miniature transformer coil bobbin fixing device includes a shaft body, the shaft body is divided into upper, middle and lower parts, and the shaft body diameters of the upper and lower parts of the shaft body are smaller than the shaft body diameter of the middle part. The upper part of the shaft body is the skeleton fixed shaft 1 that fixes the coil skeleton, and the peripheral surface of the skeleton fixed shaft 1 is provided with a locking device 2 to connect with the coil bobbin. A circle of tap fixing rods 4 is evenly arranged on the surface, and the described one ring of tap fixing rods 4 is preferably composed of six tap fixing rods 4, which are distributed on the tap fixing shaft 3 at an angle of 60 degrees for fixing the taps of the enameled wire; The lower part of the shaft body is the connecting shaft 5, which is used to connect the winding machine.

[0031] The locking device 2 includes holes arranged symmetrically in the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com