Patents

Literature

189results about How to "Prevent bumping into" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

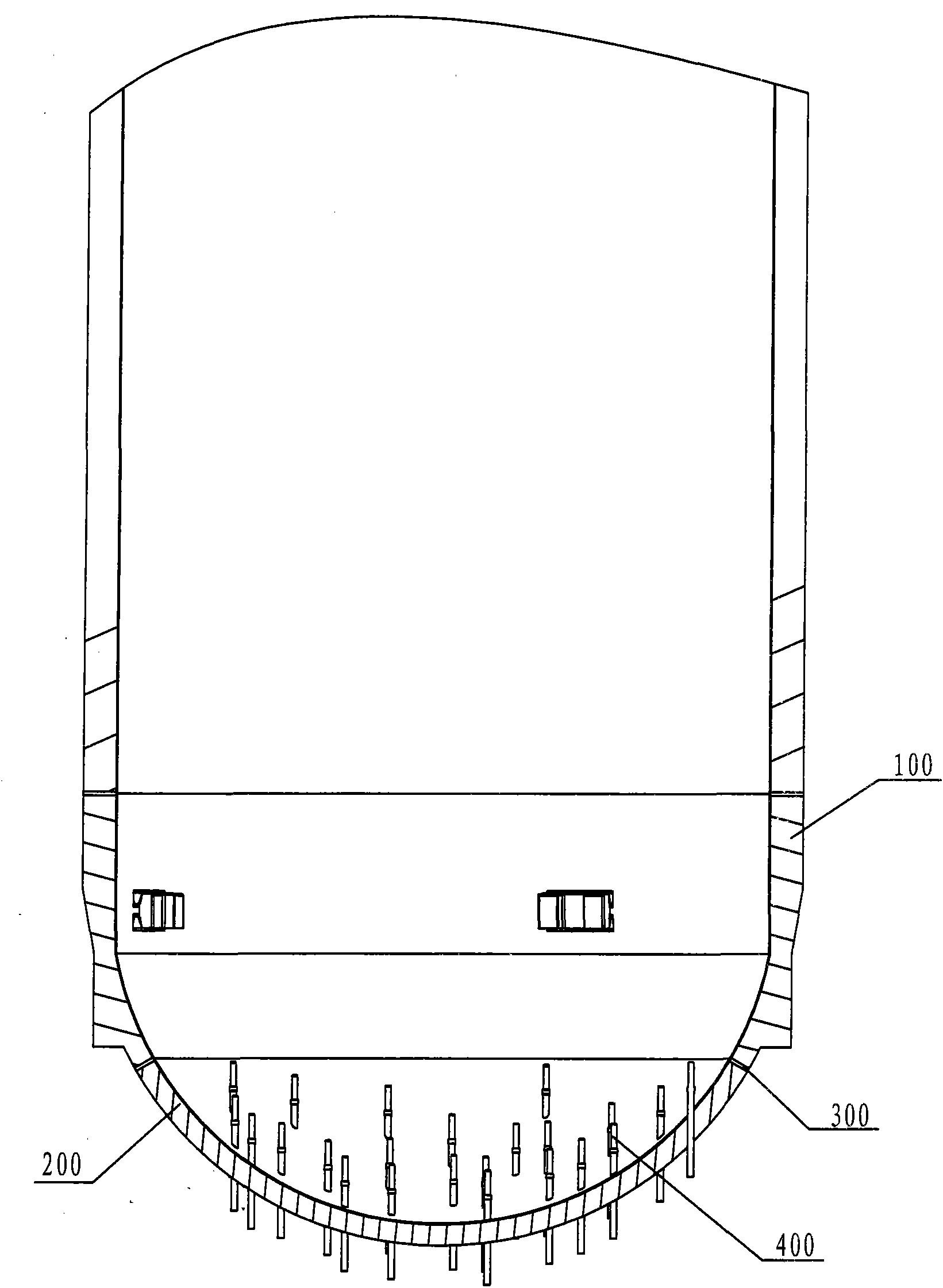

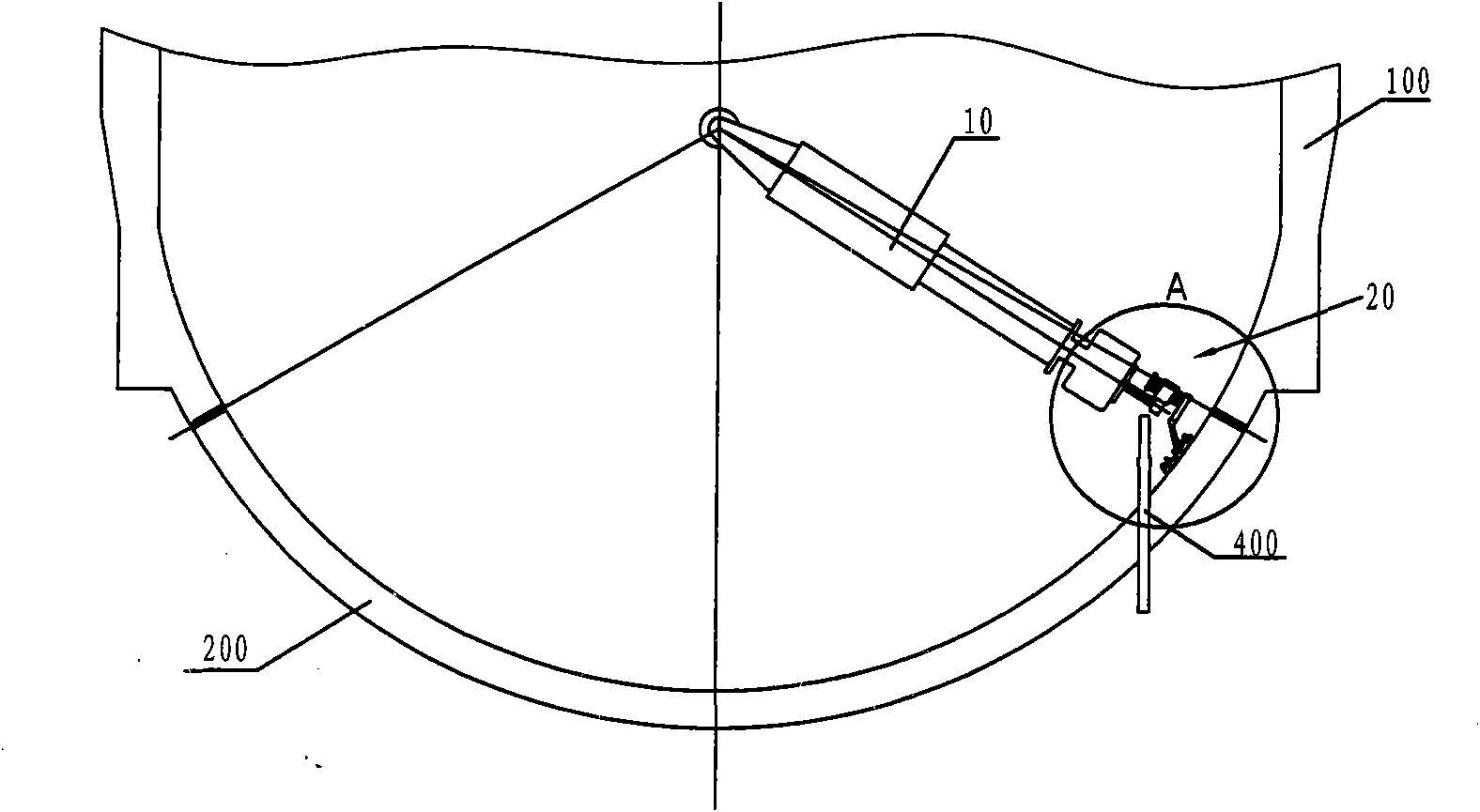

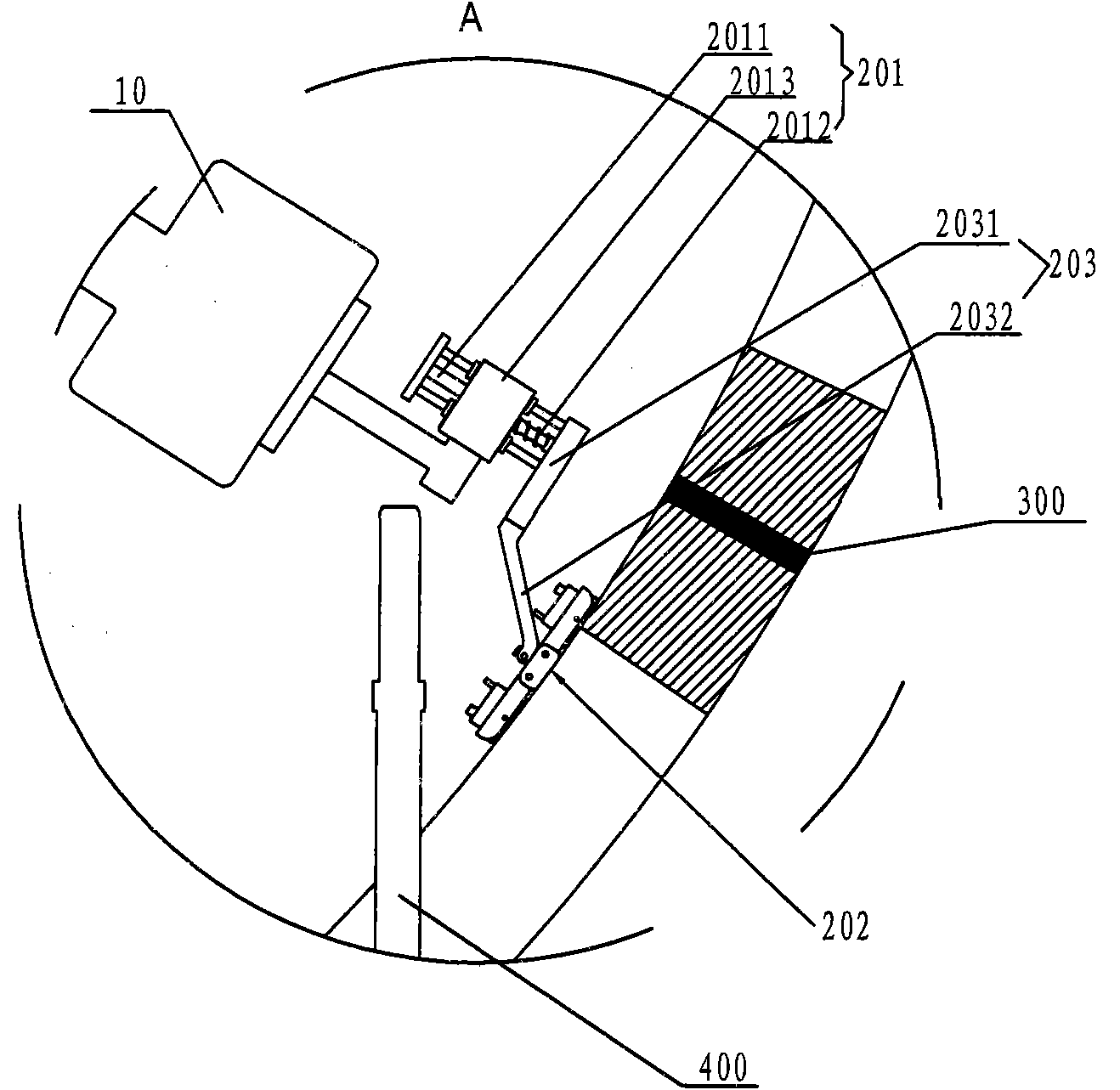

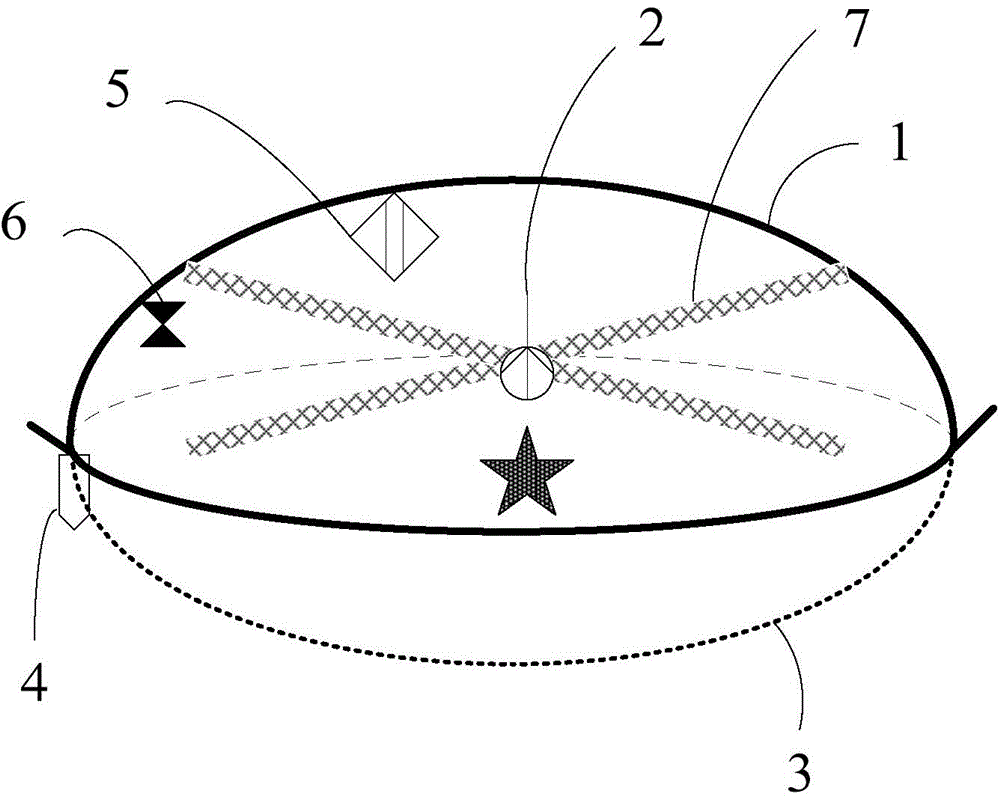

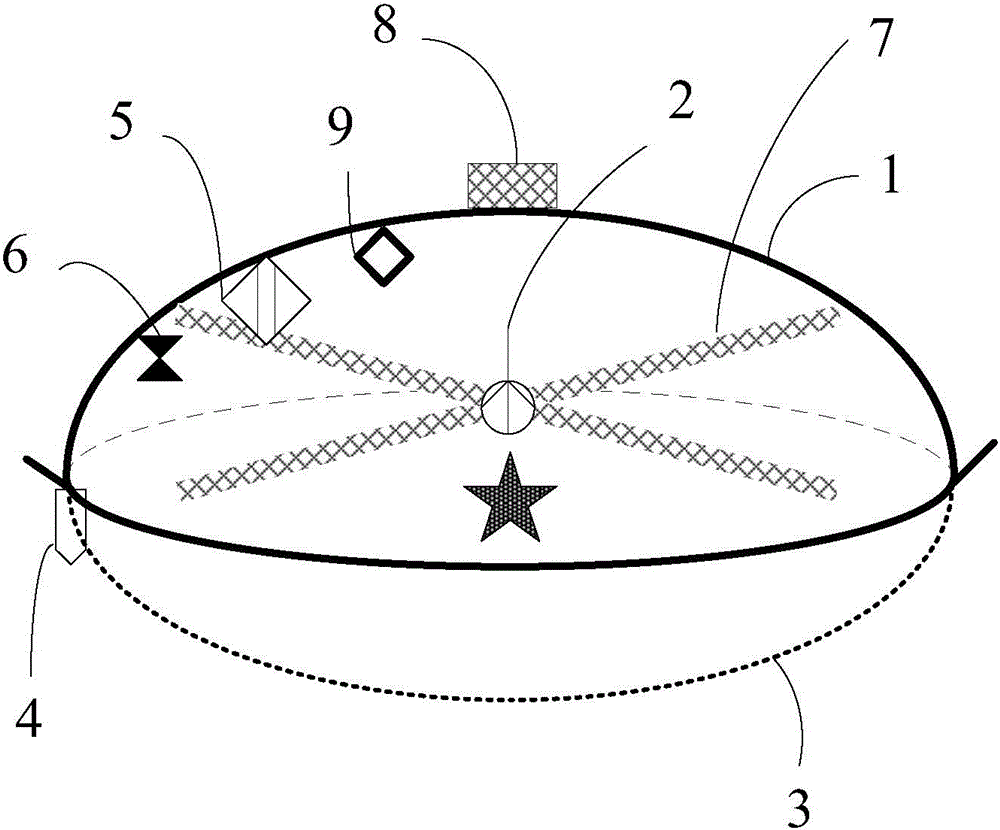

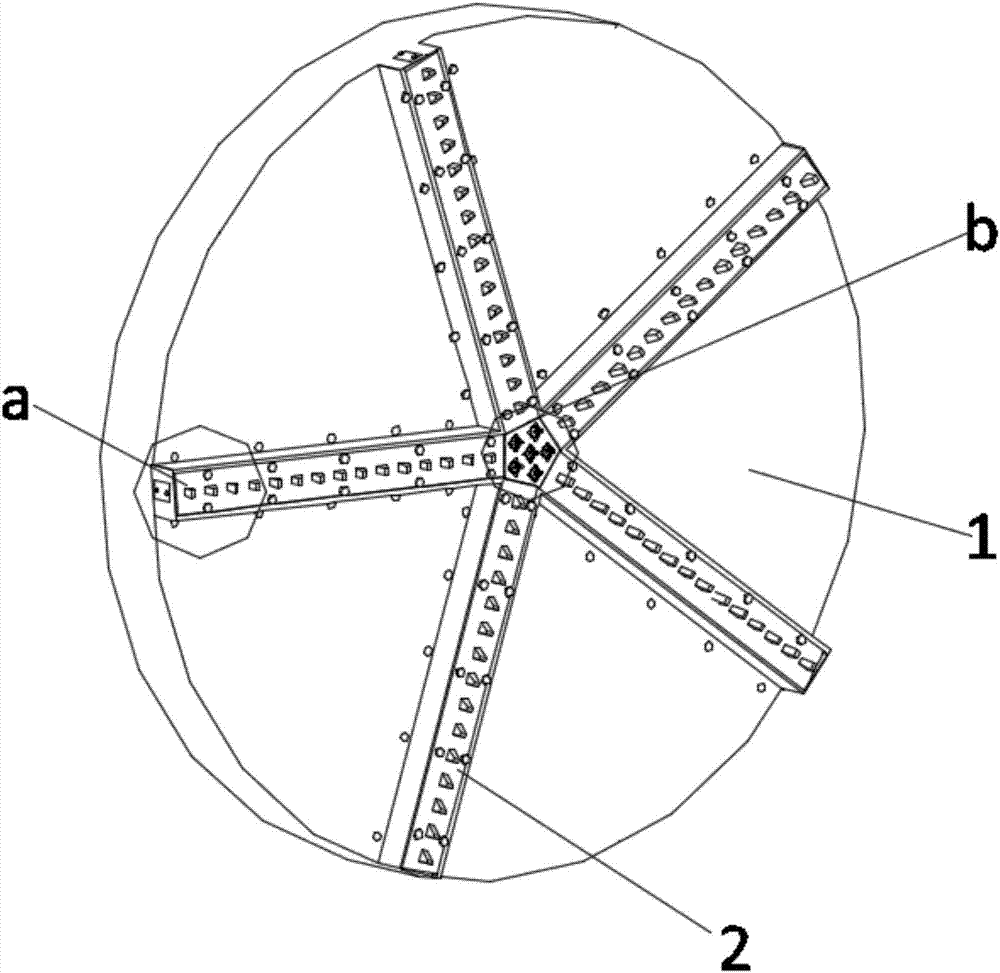

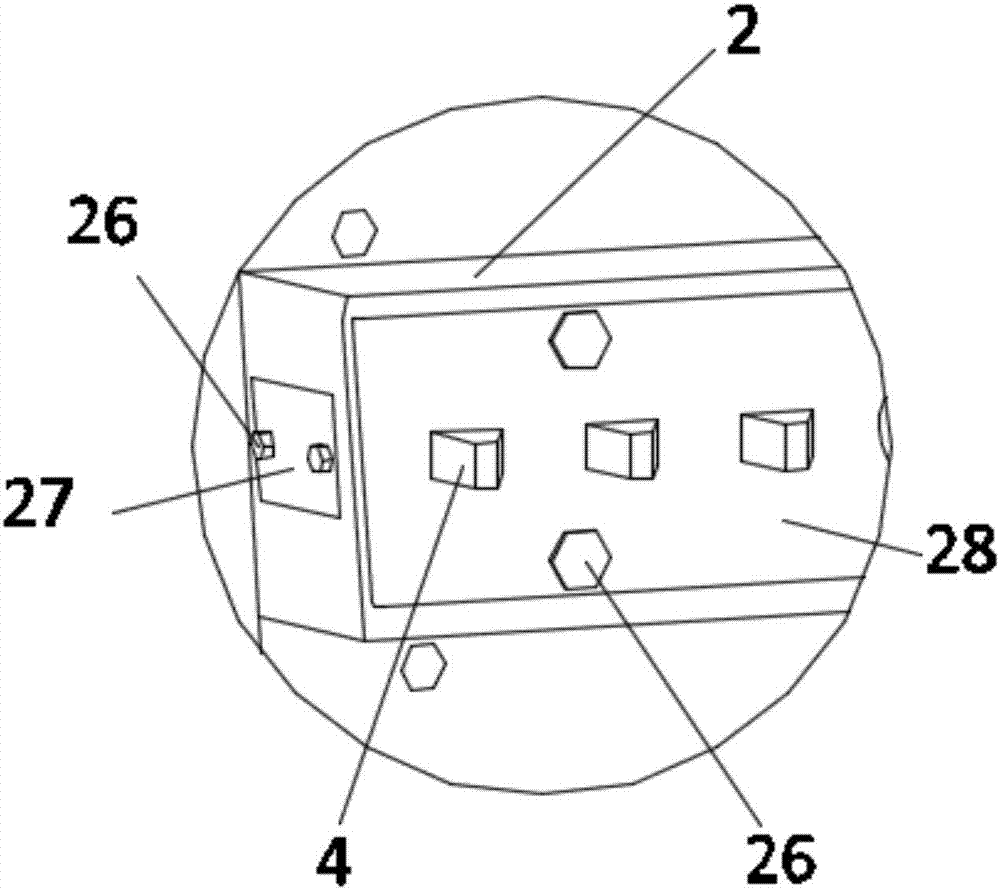

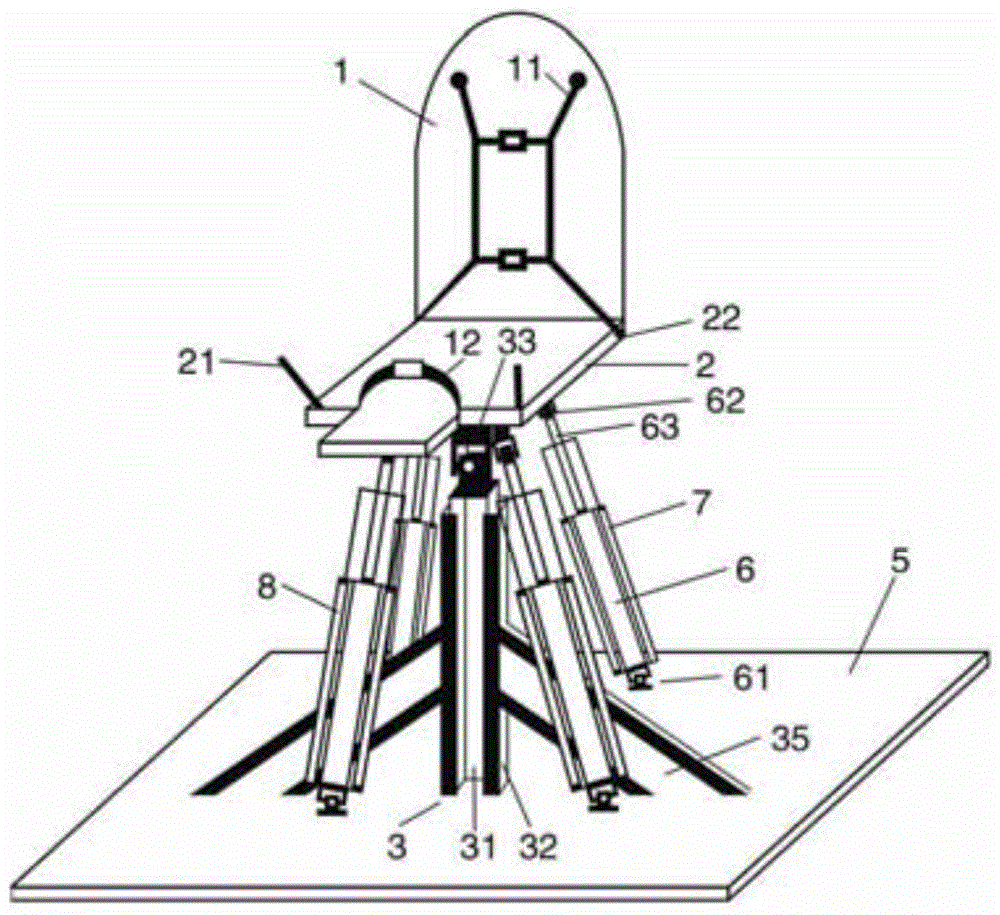

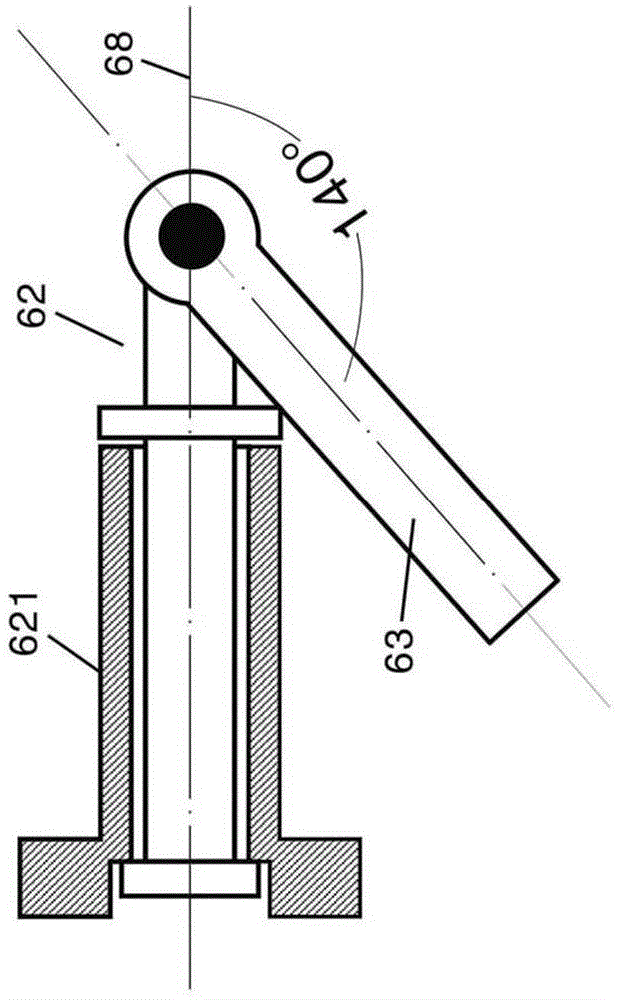

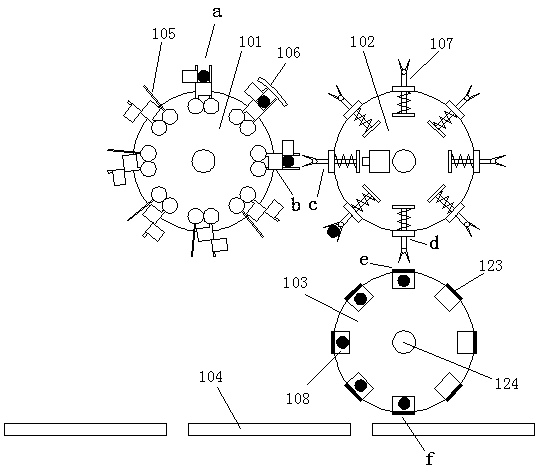

Probe scanning device of reactor pressure vessel inspection machine

ActiveCN101894593APrevent bumping intoGuaranteed full scanNuclear energy generationNuclear monitoringReactor pressure vesselFixed frame

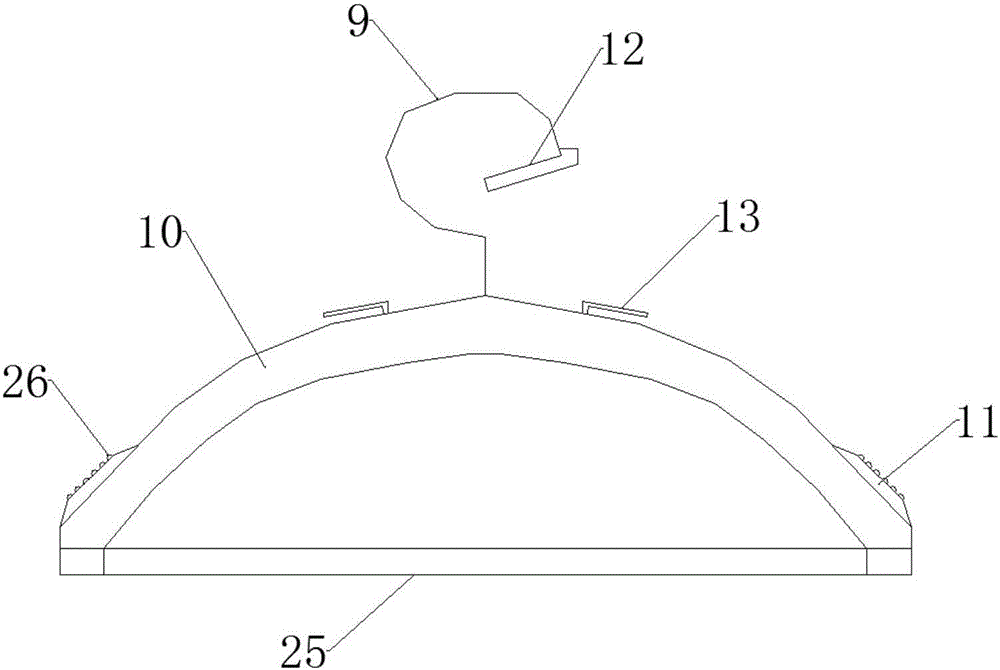

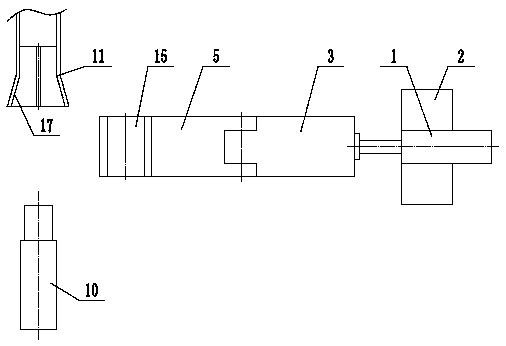

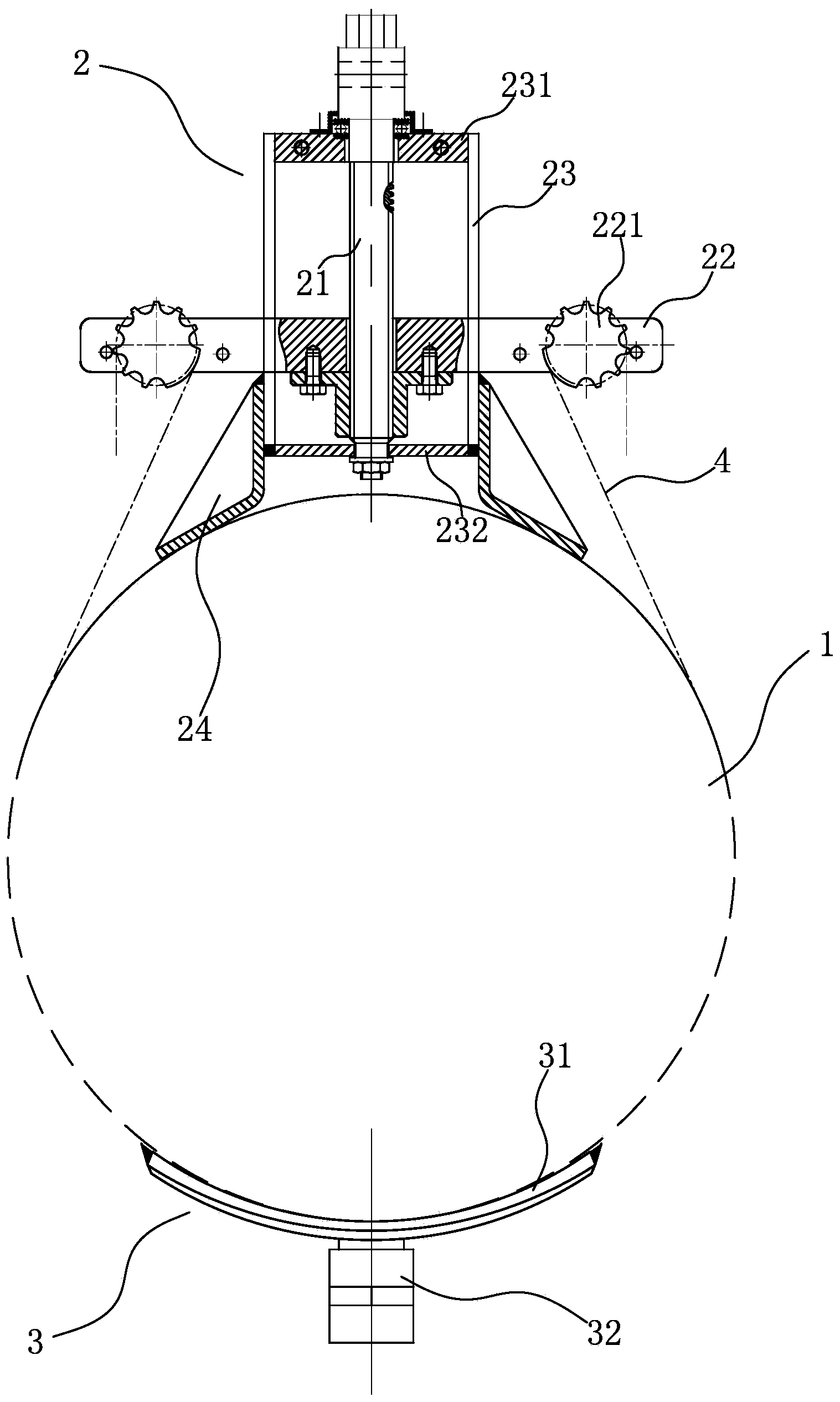

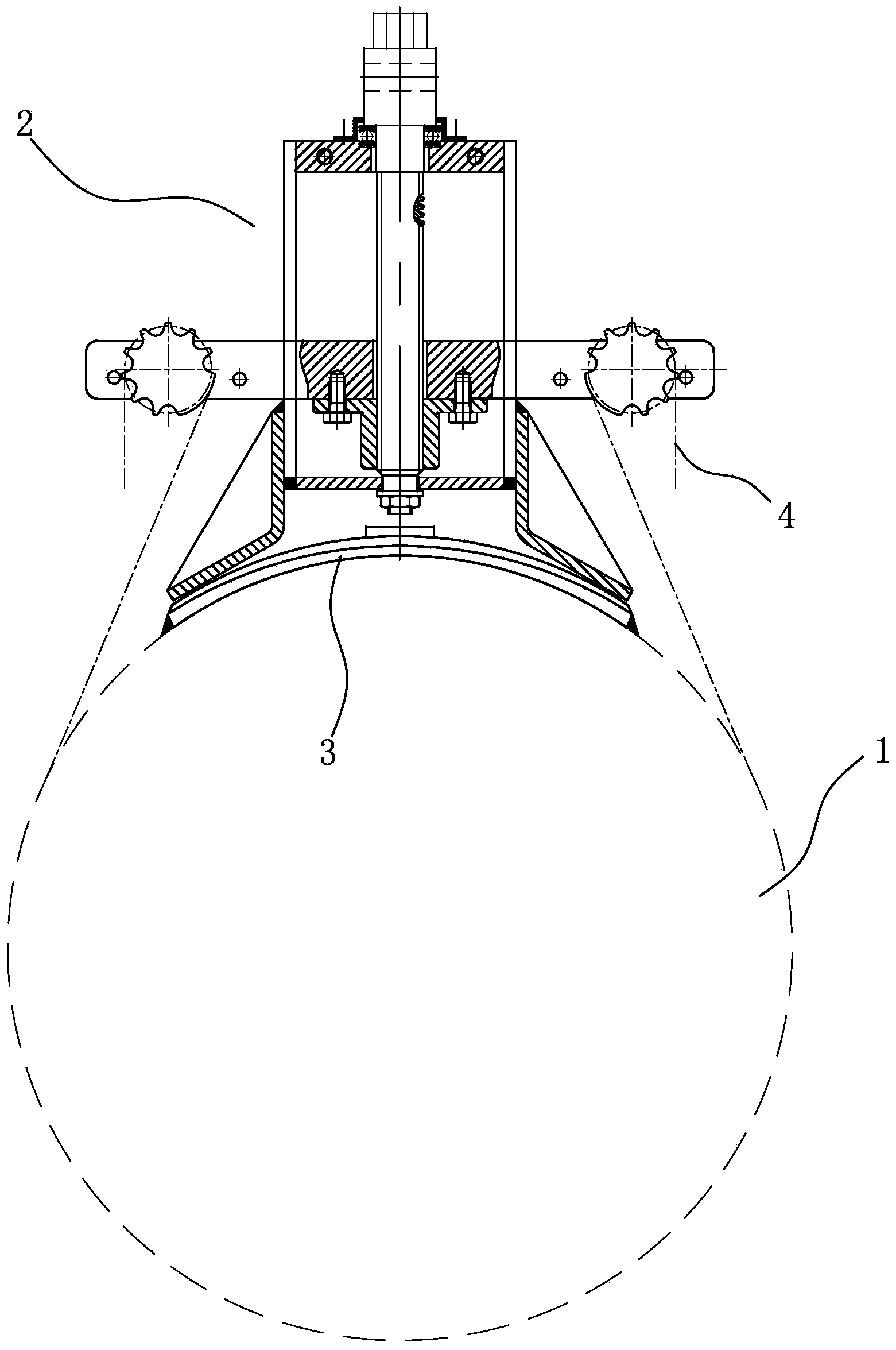

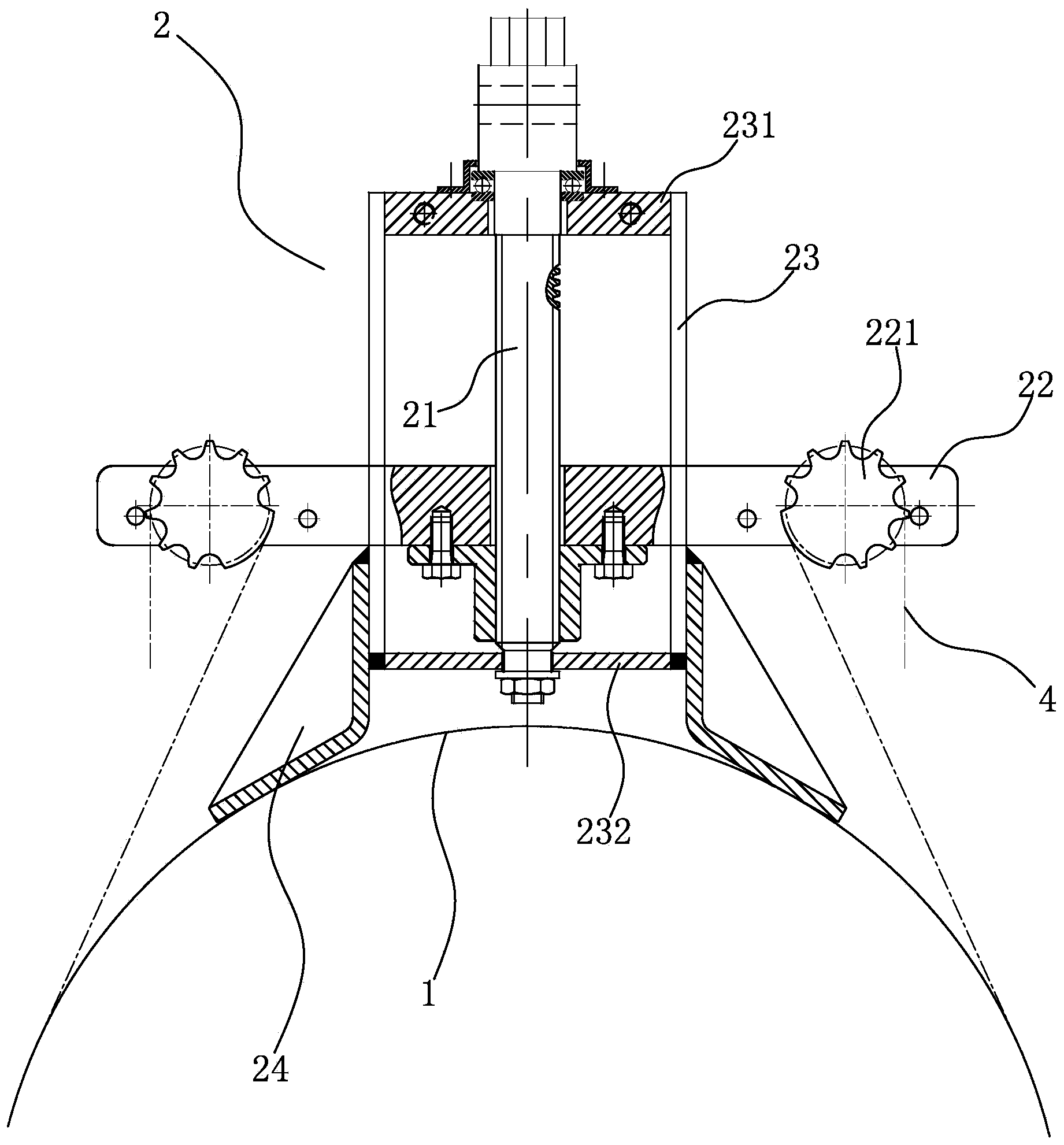

The invention relates to a probe scanning device of a reactor pressure vessel inspection machine, comprising an inspection arm and at least one probe assembly connected with the front end of the inspection arm. Each probe assembly comprises a probe mechanism coupled with a spherical surface area to be scanned, a spring cushion test bed used for providing a pressing force for the probe mechanism in the radial direction of the spherical surface and a descending bracket connecting the spring cushion test bed and the probe mechanism; the probe mechanism comprises at least one ultrasonic probe body and a probe fixing frame used for limiting the position of the ultrasonic probe body; the descending bracket comprises a horizontal part and an inclining part which aslant extends to the spherical surface; and the inclining part is pivoted with the probe fixing frame. The probe scanning device prevents the probe mechanism from touching a penetration member and ensures the overall scanning of the area to be scanned, and the ultrasonic probe body can be tightly coupled, which ensures the scanning continuity as well as the reliability and the accuracy of scanning results.

Owner:CGNPC INSPECTION TECH +2

Intelligent helmet and intelligent helmet system

InactiveCN106690632AProtection from electric shock hazardReduce risk of sheddingClosed circuit television systemsHatsEngineeringAlarm device

The invention provides an intelligent helmet and intelligent helmet system, wherein the intelligent helmet comprises a helmet body, a pressure sensor, a tether, a tension sensor, a detector, and an alarm device. The helmet body is used for protecting a head of an operator from the impact of an external object. The pressure sensor is arranged inside the helmet body and used for sensing the pressure of the head of the operator from the helmet body. The tether is connected to the helmet body and used for tying the jaws of operators to prevent the intelligent helmet from falling off. The tension sensor is connected to the tether and used for sensing and outputting the tension that the tether bears. The detector is connected to the pressure sensor and the tension sensor, and used for outputting an alarm command when detecting that the pressure is not zero and the tension is zero. The alarm device is connected to the detector and used for sending an alerting signal when the alarm command is received. The intelligent helmet and intelligent helmet system has the advantages of various functions, being safe and reliable, and being easy for the operator to use.

Owner:BEIJING ELECTRIC POWER RES INST HUAYUANELECTRIC POWER TECH

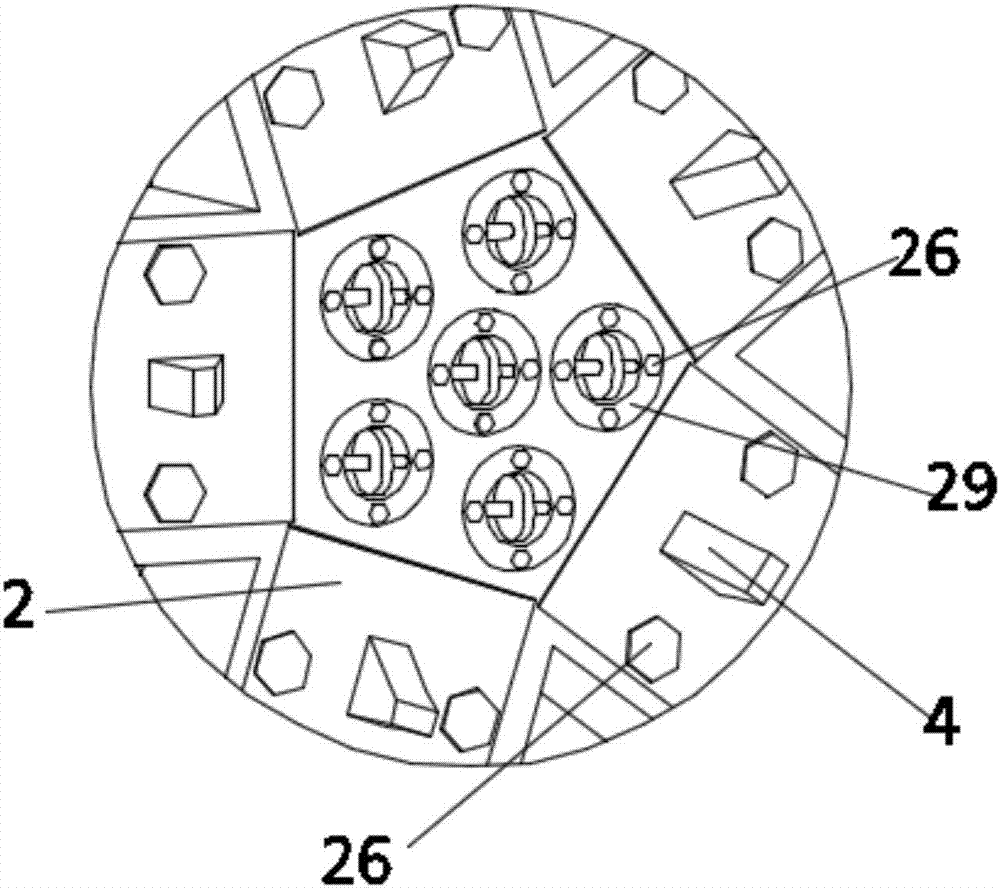

Shield tunneling machine cutter capable of being quickly replaced

PendingCN107218051APrevent bumping intoPrevent frictional looseningTunnelsTransmission beltEngineering

The invention discloses a shield tunneling machine cutter capable of being quickly replaced. The shield tunneling machine cutter capable of being quickly replaced comprises a cutter disc, wherein cutter frames are fixed on the cutter disc, and each cutter frame is provided with first cutters; the bottom of each cutter handle is provided with two first grooves, and each first groove is internally provided with a fixing plate; a cog is meshed with a first gear, and a first rotary shaft drives a second gear through a transmission belt; the second gear is meshed with a third gear fixedly connected with a fourth gear, and the fourth gear is meshed with the cog on the fixing plate; one end of each second rotary shaft extends into a second groove, and the upper surface of each cutter frame is provided with pads provided with bolts which pass through the pads and the fixing plates and are fixedly connected to one cutter frame. According to the shield tunneling machine cutter capable of being quickly replaced, the cutters are clamped through the fixing plates and the pads and fastened with the bolts, the cutter frames are circumferentially distributed on the cutter disc, and therefore the number of the needed cutter frames can be selected based on demands; besides, the cutter handles and bits of the first cutters can be detachably replaced, so that the cost is saved; each pad is provided with a third groove, so that collision of the pads can be avoided when the cutters are in use, and the cutters can be fixed more tightly.

Owner:薛飞

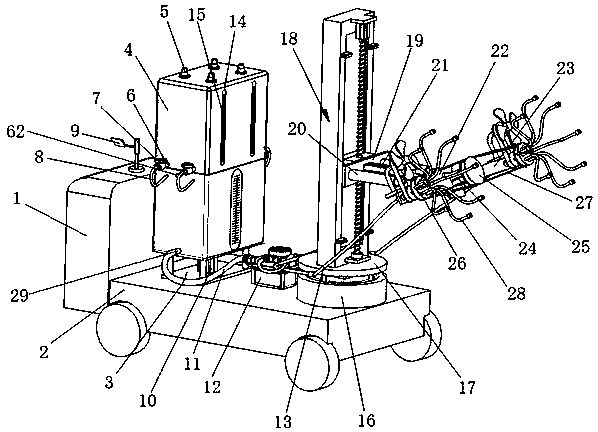

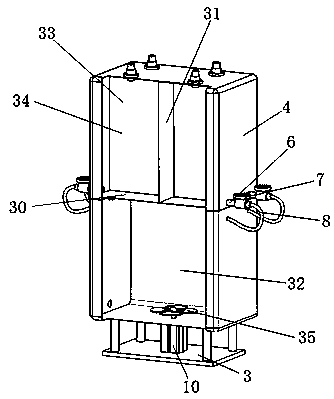

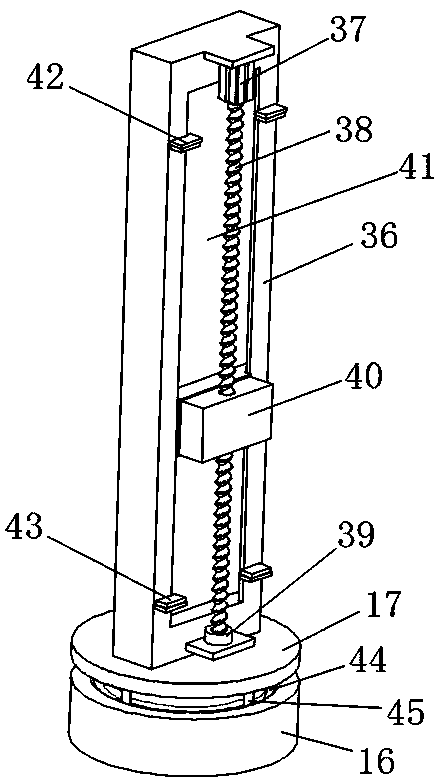

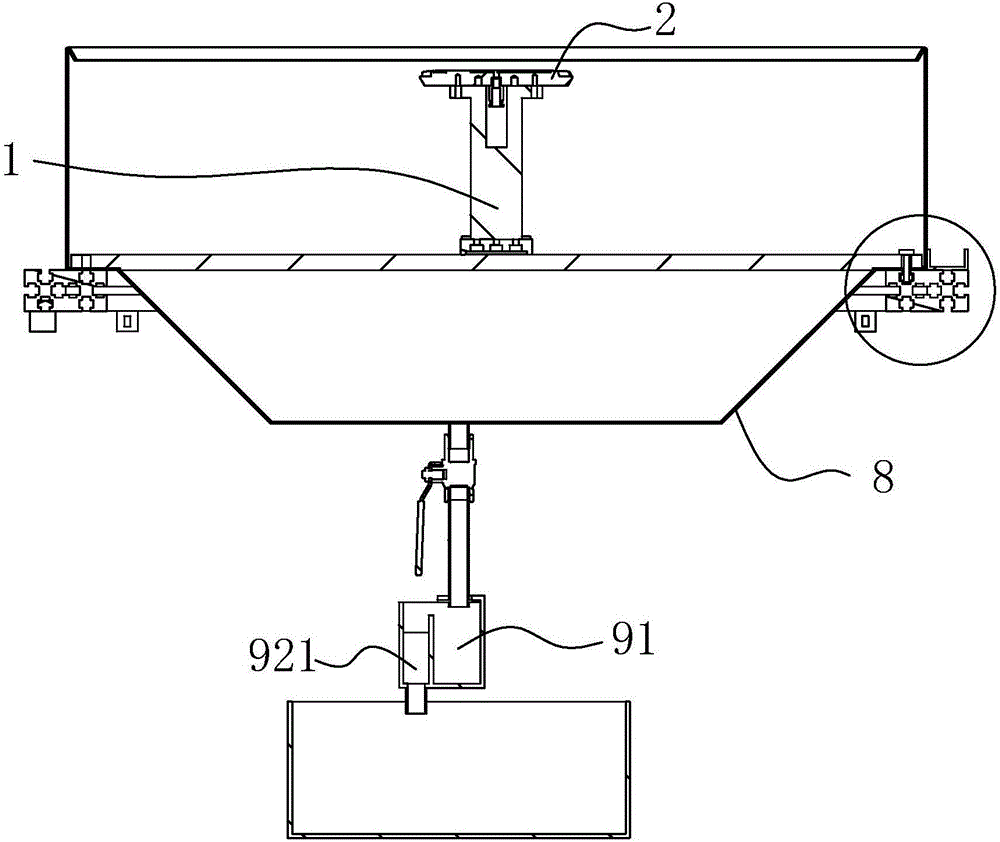

Pesticide sprayer

The invention discloses a pesticide sprayer. The sprayer comprises a vehicle body, a medicine box base is arranged on the vehicle body, a box body is arranged on the medicine box base, a water inlet and a liquid outlet are formed in the side of the box body, the water inlet is formed above the liquid outlet, and a second pipe is connected to the liquid outlet; the vehicle body is further providedwith a rotating base, a first stepping motor is embedded in the rotating base, an output shaft of the first stepping motor is connected with a rotating disc, the top of the rotating disc is provided with a lifting mechanism, an output end of the lifting mechanism is connected with a first transverse plate, one end of a pipe connecting member of the first transverse plate is provided with a steel pipe, a hollow passive pulley at the end of the steel pipe is provided with a spray pipe, and the other end of the pipe connecting member is provided with a third pipe; the vehicle body is further provided with a power spray pump, an input end of the power spray pump is connected to the second pipe, and the output end of the power spray pump is connected to the third pipe. The sprayer provides convenience for real-time blending of mixed pesticides, has a wide spraying range and is suitable for large-scale pesticide spraying operation.

Owner:WENZHOU UNIVERSITY

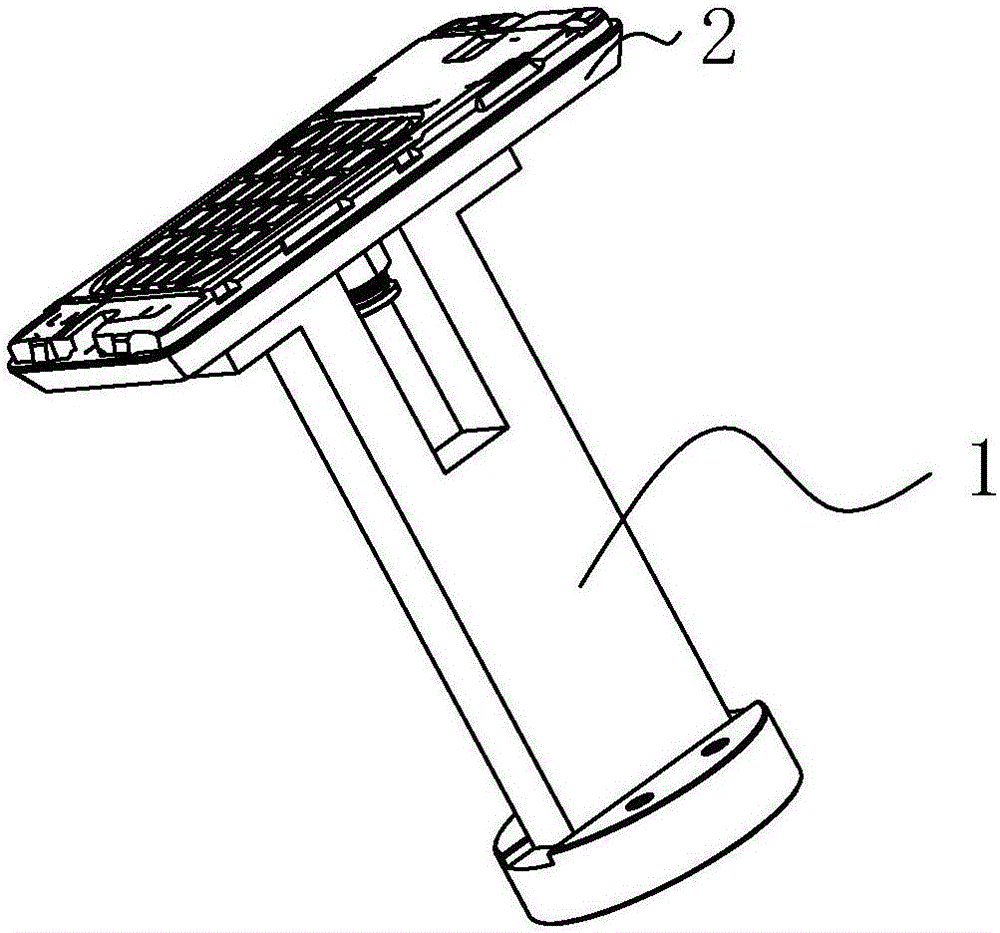

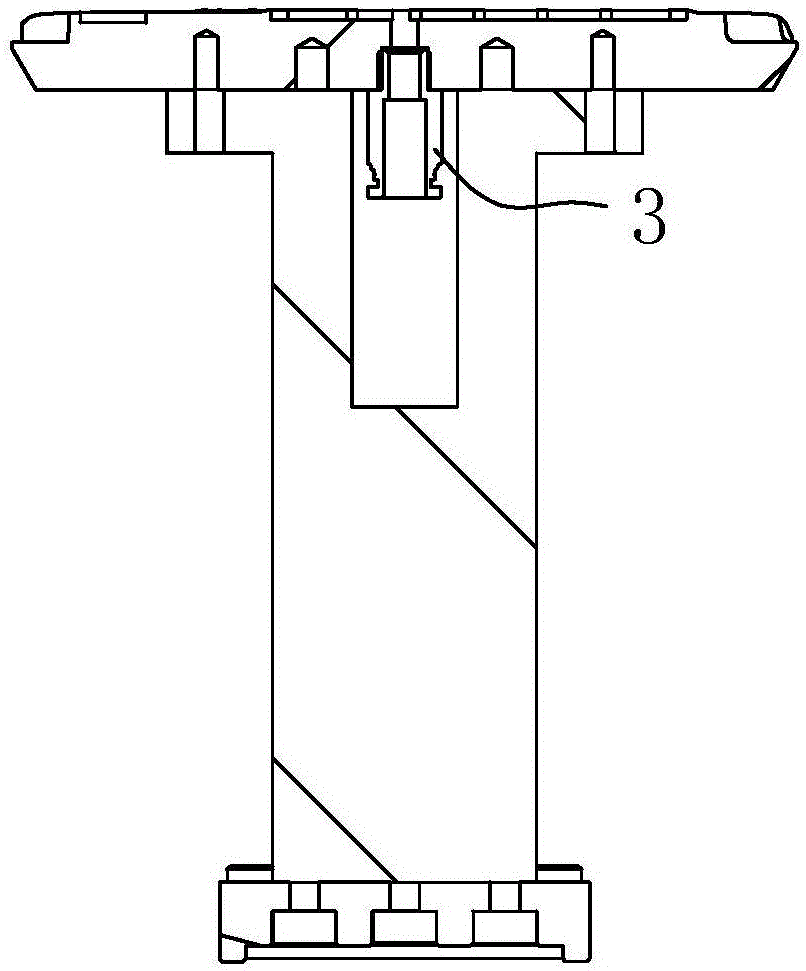

Simulator dynamic seat

The invention relates to a simulator dynamic seat in film videos and games, wherein a plurality of universal lifting cylinders capable of rotating according to the seat requirement are supported between a bottom frame and a seat fixation frame, the load is reduced through a gravity canceling device, and a balance frame reinforced by a metal beam or metal plate matches with a deep cross shaft coupling with an extension pipe so as to make the dynamic seat achieve the safe and large inclination angle. According to the present invention, the simulator dynamic seat has characteristics of low cost, energy saving, and high film and action synchronization, and can safely achieve the anteversion, hypsokinesis, left wing or right wing rotation inclination angle of 100 DEG C, such that the head of the people sitting on the seat inclines toward the bottom so as to increase the somatosensory authenticity and increase the stimulation degree.

Owner:李程

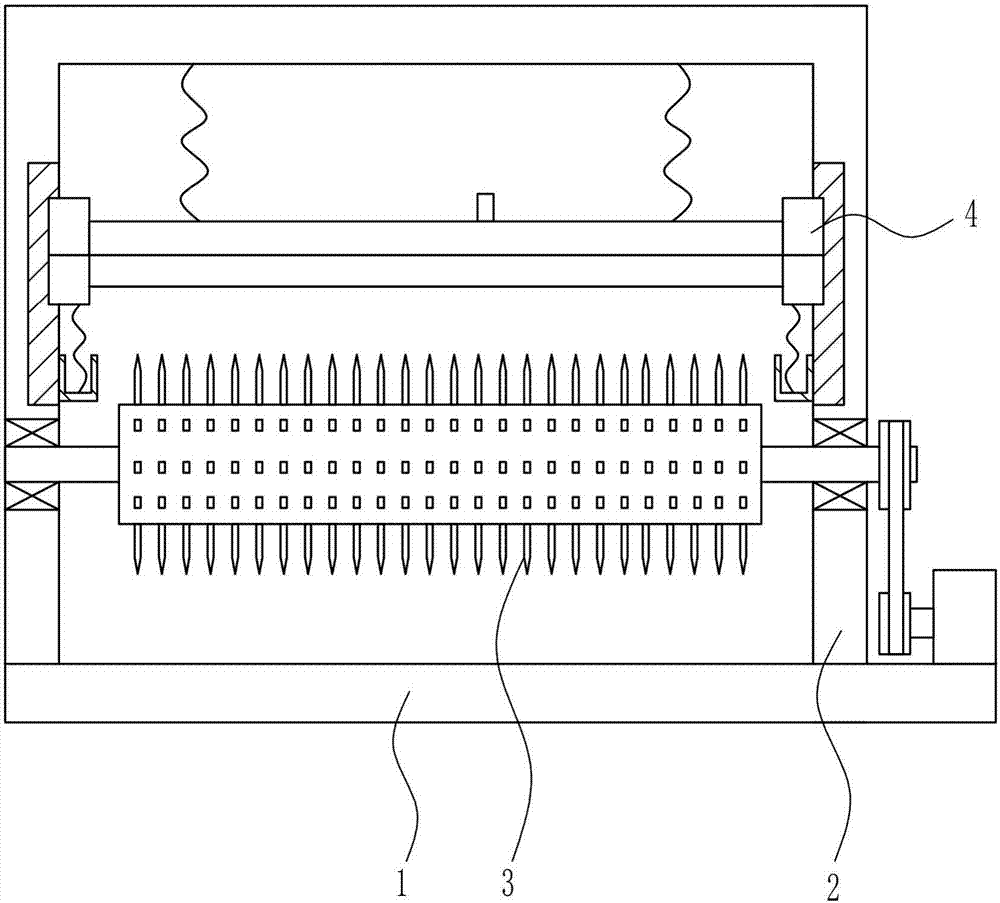

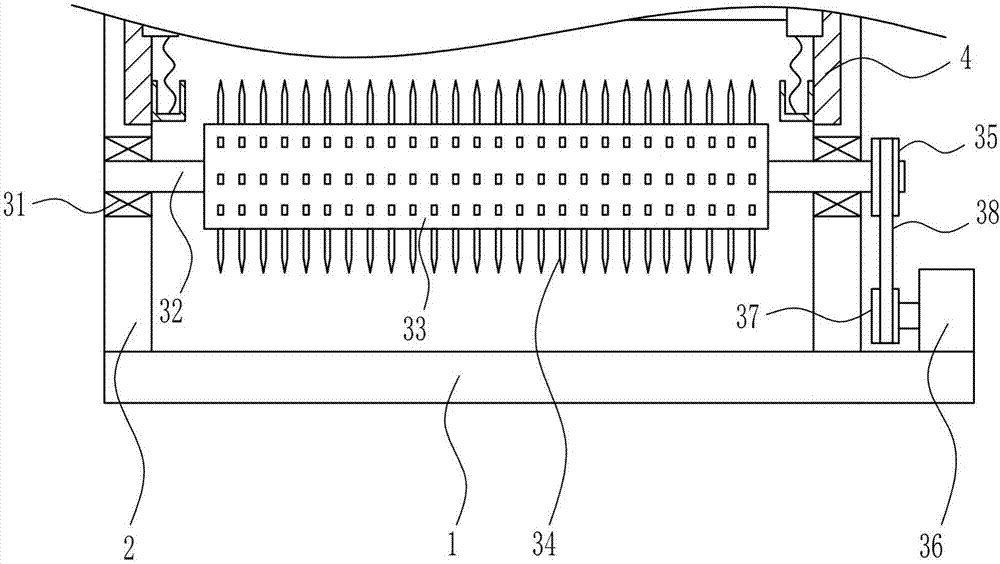

Wool carding equipment for wool fabric production

The invention relates to carding equipment, in particular to wool carding equipment for wool fabric production. The wool carding equipment comprises a bottom plate and the like and is characterized in that a mounting rack is mounted at the top of the bottom plate, a carding device is arranged on the lower portion in the mounting rack, and a fixing device is arranged on the upper portion in the mounting rack. The wool carding equipment has the advantages that impurities in wool can be comprehensively removed through carding, and the carding equipment is high in work speed; the wool can be carded quite conveniently and comprehensively by the coordination of the fixing device and the carding device, and a pressing plate does not need to be pressed constantly during carding by the coordination of a nut and a bolt.

Owner:天津纳清新材料科技有限公司

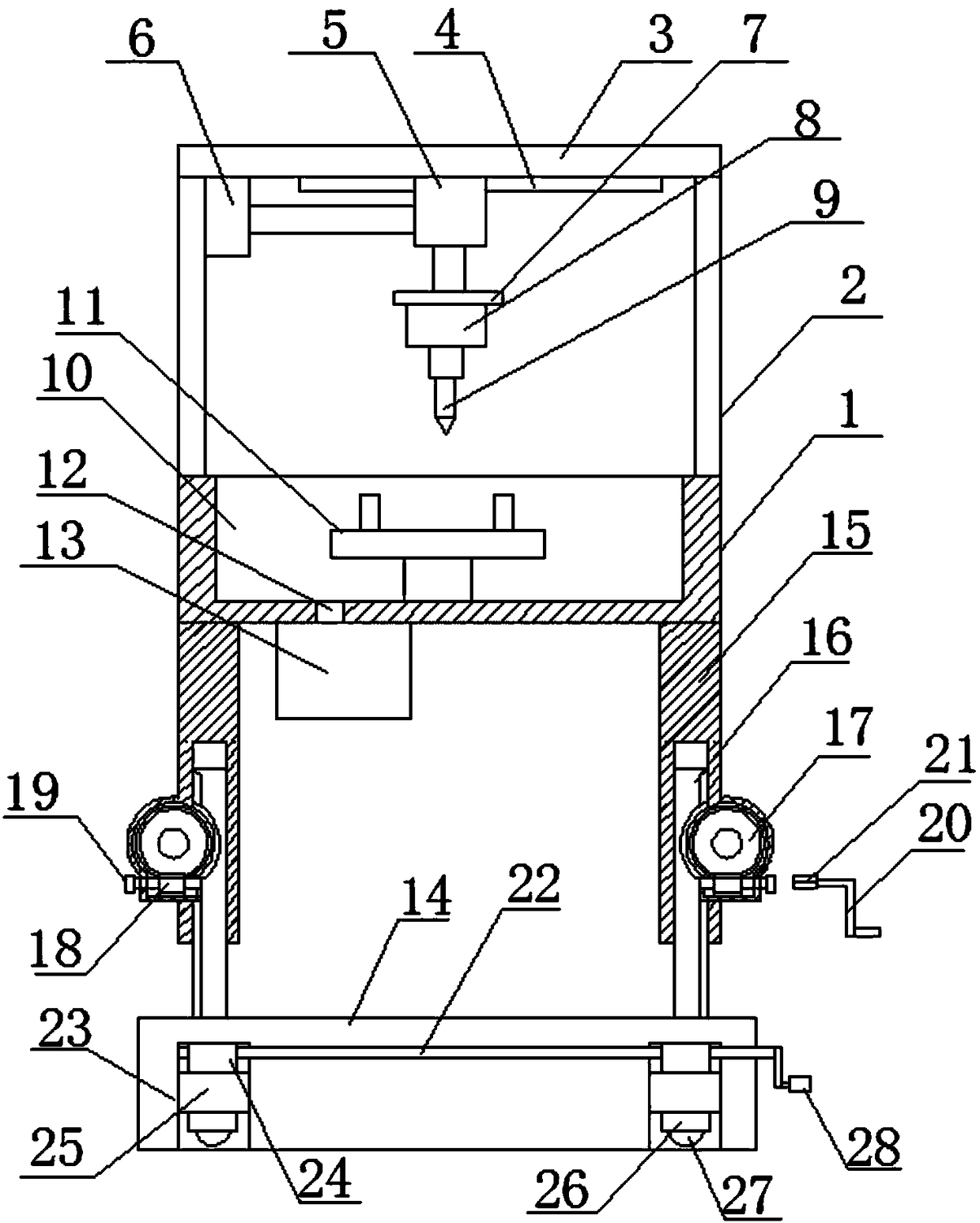

Drilling machine for household electrical appliance parts processing

InactiveCN108057908AReduce the temperatureQuality improvementBoring/drilling componentsMaintainance and safety accessoriesGear wheelEngineering

The invention discloses a drilling machine for household electrical appliance parts processing. The drilling machine for household electrical appliance parts processing comprises a machine base, a base and a crank handle. A water tank is arranged on the upper side of the machine base; a movable fixture is arranged in the water tank; a drainage pipe is arranged on the lower end of the water tank; the lower end of the drainage pipe is connected with a filter tank arranged on the lower side of the machine base; a support shell is arranged on the lower side of a working table; a gear shaft is arranged on the lower end in the support shell; a turbine is arranged in the middle of the support shell and is matched with the gear shaft; a worm is arranged on the lower end of the turbine; an inner hexagon socket is arranged on the left end of the worm; the upper side of the base is connected with the lower end of the gear shaft; grooves are left-and-right symmetrically formed in the lower side ofthe base; a rotary shaft crossing the two grooves is arranged on the base; an eccentric wheel connected with the rotary shaft is arranged in each groove; a connecting seat is movably arranged in eachgroove; a wheel seat is arranged on the lower end of each connecting seat; and a universal wheel is arranged on each wheel seat. The drilling machine for household electrical appliance parts processing provided by the invention is simple in structure, convenient to use, convenient to move, high in drilling quality, capable of collecting scrap materials, and beneficial to reducing waste.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

Novel automatic adjustment laundry rack

InactiveCN106245289AImprove intelligenceConvenient lightingOther drying apparatusTextiles and paperMicrocomputerMicrocontroller

The invention discloses a novel automatic adjustment laundry rack. The novel automatic adjustment laundry rack comprises a machine shell and an illumination sensor; the illumination sensor is mounted at the lower end of the machine shell; a driving motor is arranged in the machine shell, and is connected with a single-chip microcomputer controller; the single-chip microcomputer controller is connected with the illumination sensor; a driving shaft is arranged on the driving motor and is connected with a driving belt; the driving belt is connected with rotating shafts; the lower end of each rotating shaft is connected with a clothes hanger main body; each clothes hanger main body comprises a clothes hanger hook; a clothes hanger skeleton is arranged at the lower end of each clothes hanger hook; a silica gel antiskid pad is arranged at each of the two ends of the clothes hanger skeleton; a fixing buckle is arranged on each clothes hanger hook; positioning clamps are arranged on each clothes hanger skeleton; the illumination sensor is designed and is matched with the driving motor for driving the laundry rack to rotate, so that the laundry rack can be adjusted to a very good angle; therefore, clothes can receive better illumination; the intelligence of the laundry rack is greatly improved; the tediousness caused by manual adjustment is avoided; the clothes drying efficiency is greatly improved; the novel automatic adjustment laundry rack has very good practical value and is worth being popularized.

Owner:WUHU SUNRISE NEW BUILDING MATERIALS TECH

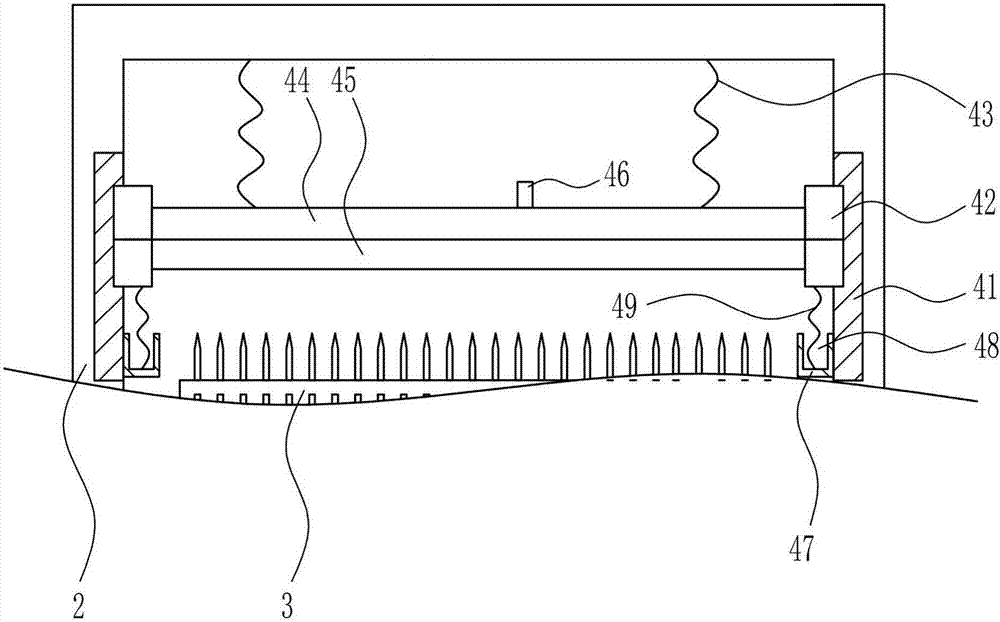

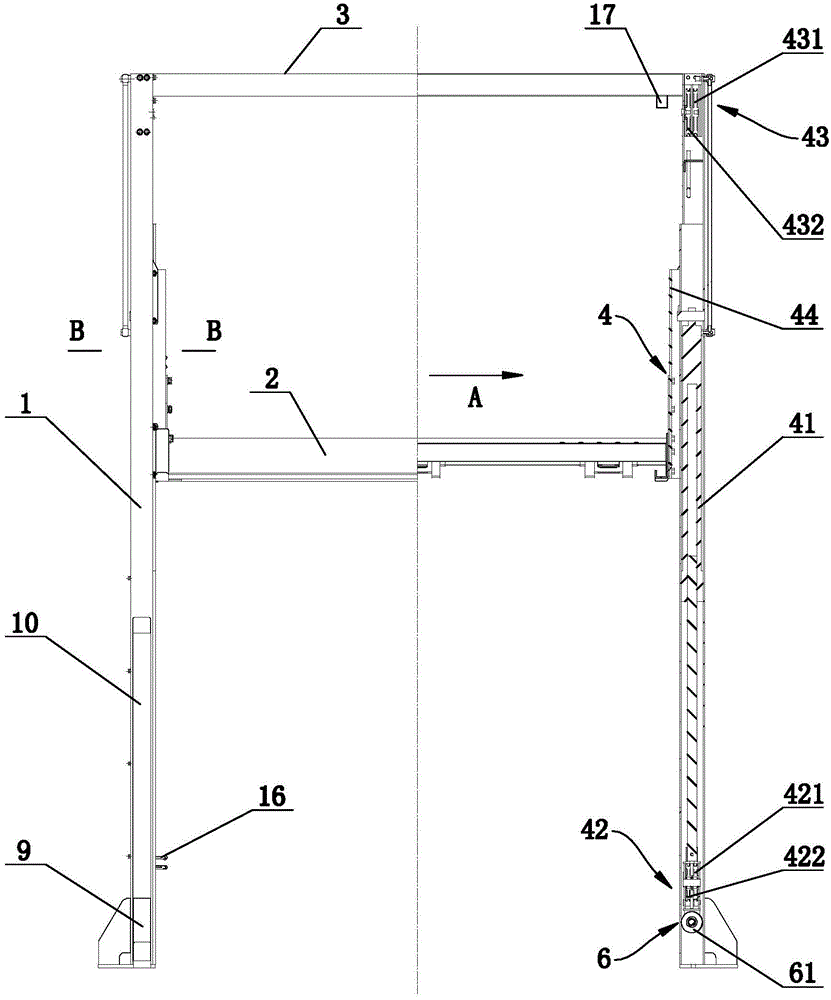

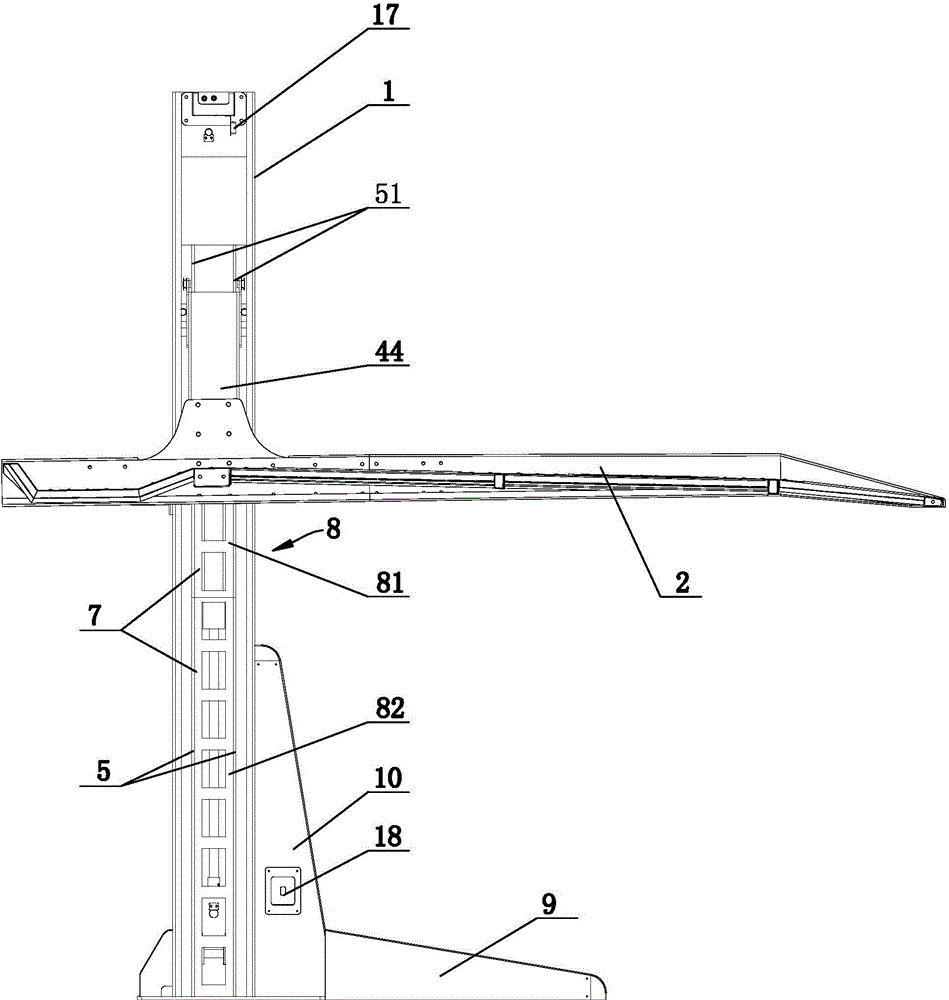

Domestic dual-layer stereo garage

The invention discloses a domestic dual-layer stereo garage, and belongs to the technical field of stereo garages. The domestic dual-layer stereo garage comprises two vertical columns, a vehicle carrying plate and a transverse beam, wherein the vertical columns have hollow structures; lifting mechanisms and piston guide rails are arranged in the hollow parts of the two vertical columns; each lifting mechanism comprises a hydraulic oil cylinder, a movable pulley block, a fixed pulley block, a lifting frame and a steel wire rope; one end of each steel wire rope is fixedly connected to each vertical column; the other end of each steel wire rope is fixedly connected to the lifting frame across the movable pulley block and the fixed pulley block; a piston rod of each hydraulic oil cylinder is provided with a guide mechanism; each guide mechanism is arranged on each piston guide rail in a restrained way. According to the domestic dual-layer stereo garage, the lifting mechanisms, the guide mechanisms and the piston guide rails are arranged inside the vertical columns, so that space is saved, and equipment is simple and clear in appearance; the domestic dual-layer stereo garage is simple in structure and low in cost, and is particularly suitable for domestic use.

Owner:DAYANG PARKING CO LTD

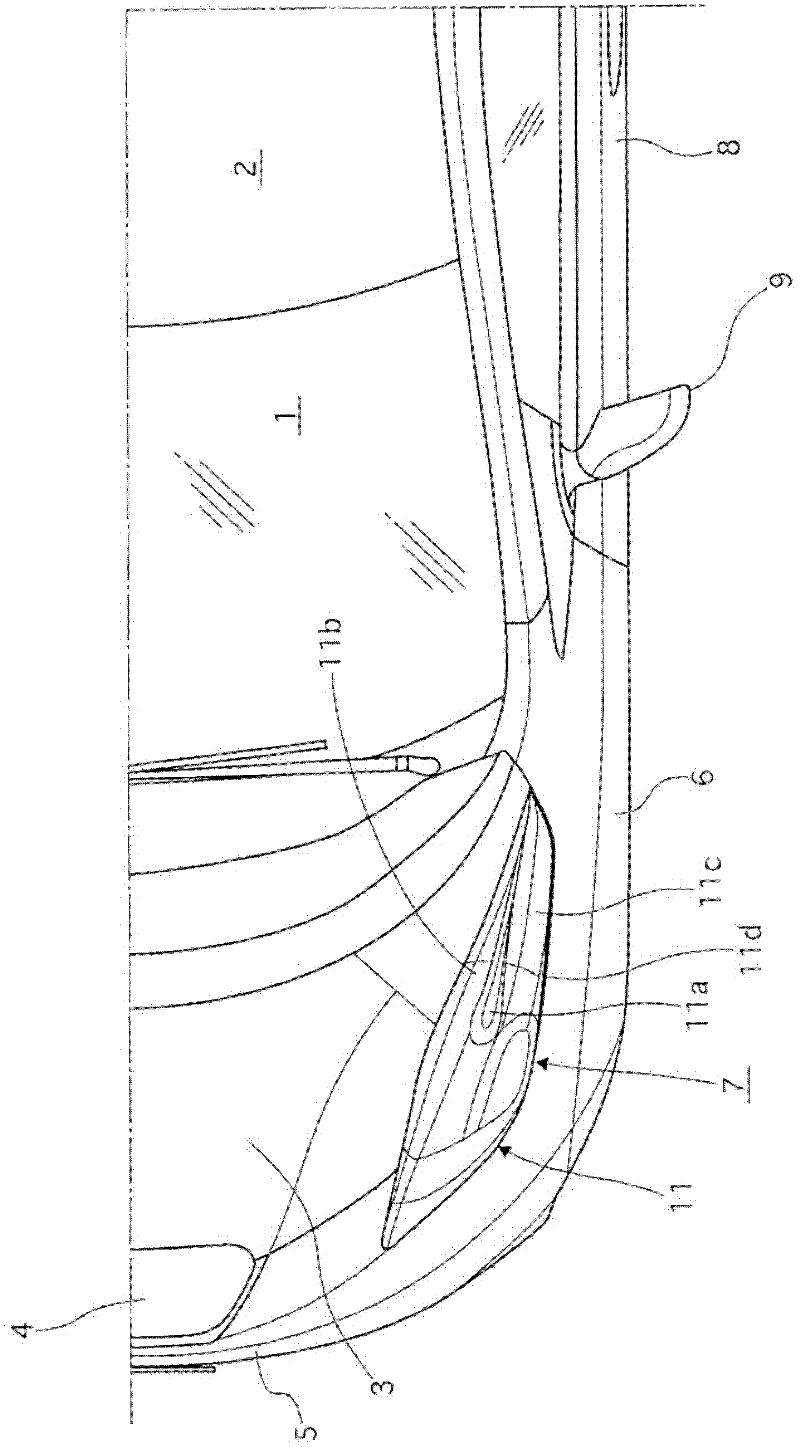

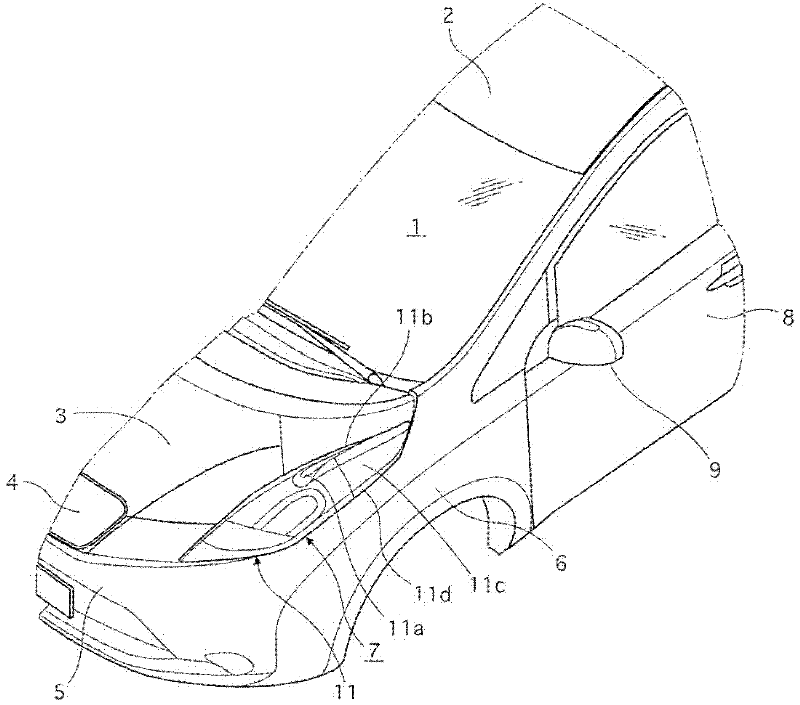

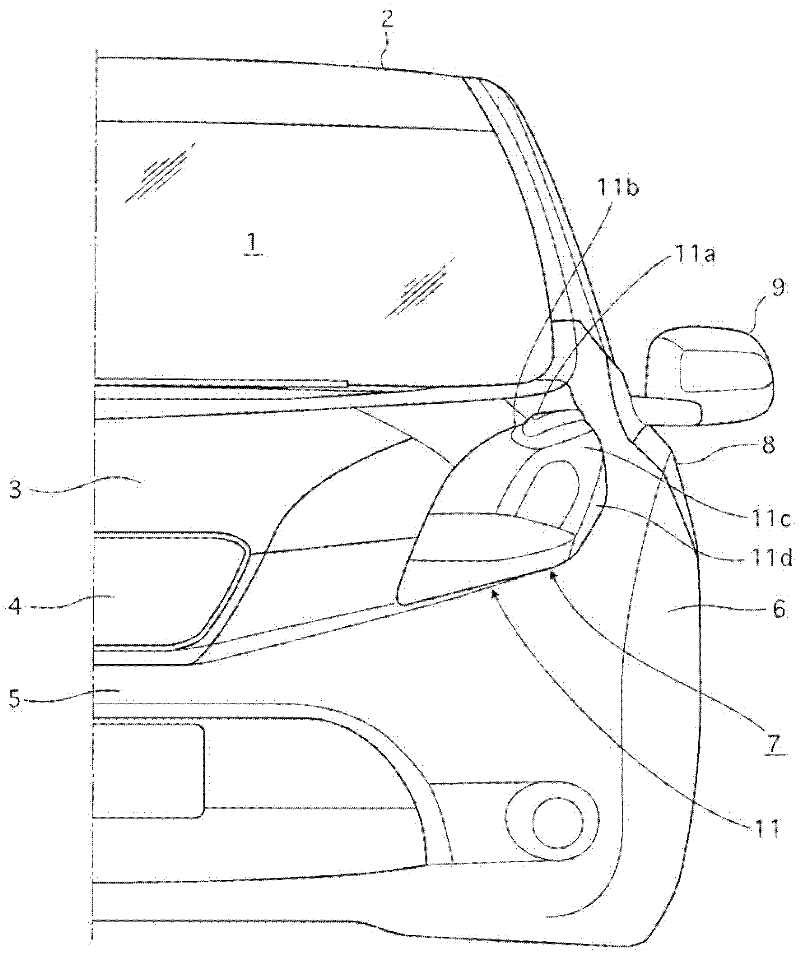

Vehicl boundary layer air flow control structure

ActiveCN102470903AMovement Resistance IncreasedReduce wind noiseVehicle body stabilisationOptical signallingEngineeringBody region

A vehicle boundary layer air flow control structure is provided with a vehicle body and a side view mirror (9). The vehicle body includes an exterior contoured surface with an air flow deflector (11). The side view mirror (9) is attached to the vehicle body to provide a diagonally rearward direction to be viewed from a driver's seat. The air flow deflector (11) has a downward air flow guiding surface (11c) provided in a vehicle body region of the exterior contoured surface of the vehicle body along which an air flow heading toward the side view mirror (9) passes. The downward air flow guiding surface extends in an air flow direction of the air flow with respect to the side view mirror (9) to divert the air flow underneath the side view mirror (9).

Owner:NISSAN MOTOR CO LTD

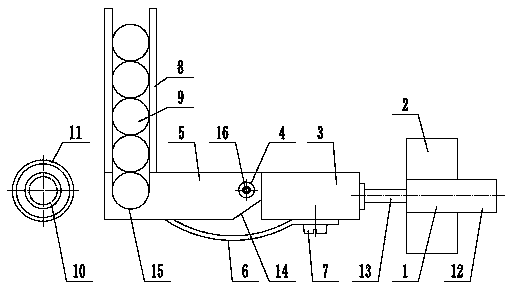

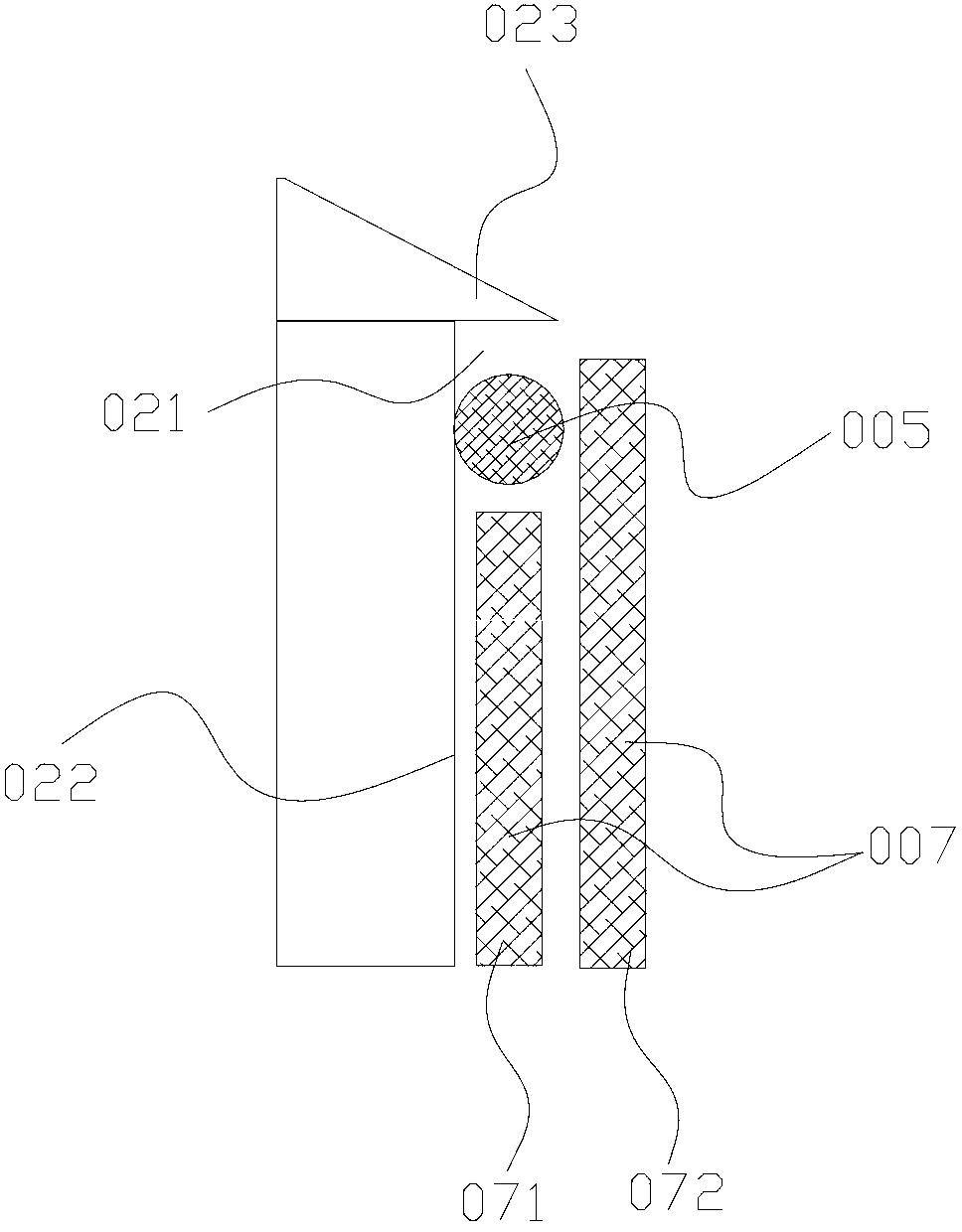

Bobbin feeding mechanism

ActiveCN105366380ARealize automatic feeding processAvoid crackingLoading/unloadingConveyor partsBobbinSlide plate

The invention provides a bobbin feeding mechanism and belongs to the technical field of textile machines. The bobbin feeding mechanism comprises a driving air cylinder, an air cylinder support, a sliding plate, a pin shaft, a supporting plate, a leaf spring, a fastening screw, a bin, bobbins, an ejector rod air cylinder and a spring collet. A cylinder body of the driving air cylinder is installed on the air cylinder support. A piston rod of the driving air cylinder is connected with the right end of the sliding plate. The right end of the supporting plate is hinged to the left end of the sliding plate through the pin shaft. A notch is formed in the lower end of the right side of the supporting plate. One end of the leaf spring is installed under the sliding plate through the fastening screw, and the other end of the leaf spring is tightly attached to the lower portion of the supporting plate. A containing groove is formed in the left end of the supporting plate. The bin is arranged over the containing groove. The bobbins are arranged inside the bin. The ejector rod air cylinder and the spring collet are both arranged on the left side of the supporting plate coaxially. According to the bobbin feeding mechanism, the bobbins can be fed automatically, the structure is simple, and the cost is low.

Owner:浙江银汇高纤材料股份有限公司

Self-protected under-pressure leakage plugging device and method for rushing to repair pipeline by using self-protected under-pressure leakage plugging device

The invention discloses a self-protected under-pressure leakage plugging device and a method for rushing to repair a pipeline by using the self-protected under-pressure leakage plugging device, and relates to a pipeline leakage plugging device, in particular to a leakage plugging plate and a clamp for plugging leakage of a gas pipeline, as well as a rushing-to-repair method, and aims to provide a self-protected under-pressure leakage plugging device which is simple in structure, low in cost, simple and convenient to operate, high in environment adaption property and high in leakage plugging sealing property, does not need to stop pipeline conveying and can ensure the hooping force. The self-protected under-pressure leakage plugging device comprises a clamp (2), a leakage plugging plate (3) and a chain (4), wherein the clamp (2) is used for hooping the leakage plugging plate (3) through the chain (4) on a pipeline (1); the clamp (2) is used for tightening the chain (4) by virtue of a screw rod structure; the pressure at a leakage part of the pipeline (1) to the leakage plugging plate (3) is reduced by virtue of a ball locking structure.

Owner:BEIJING GAS GRP

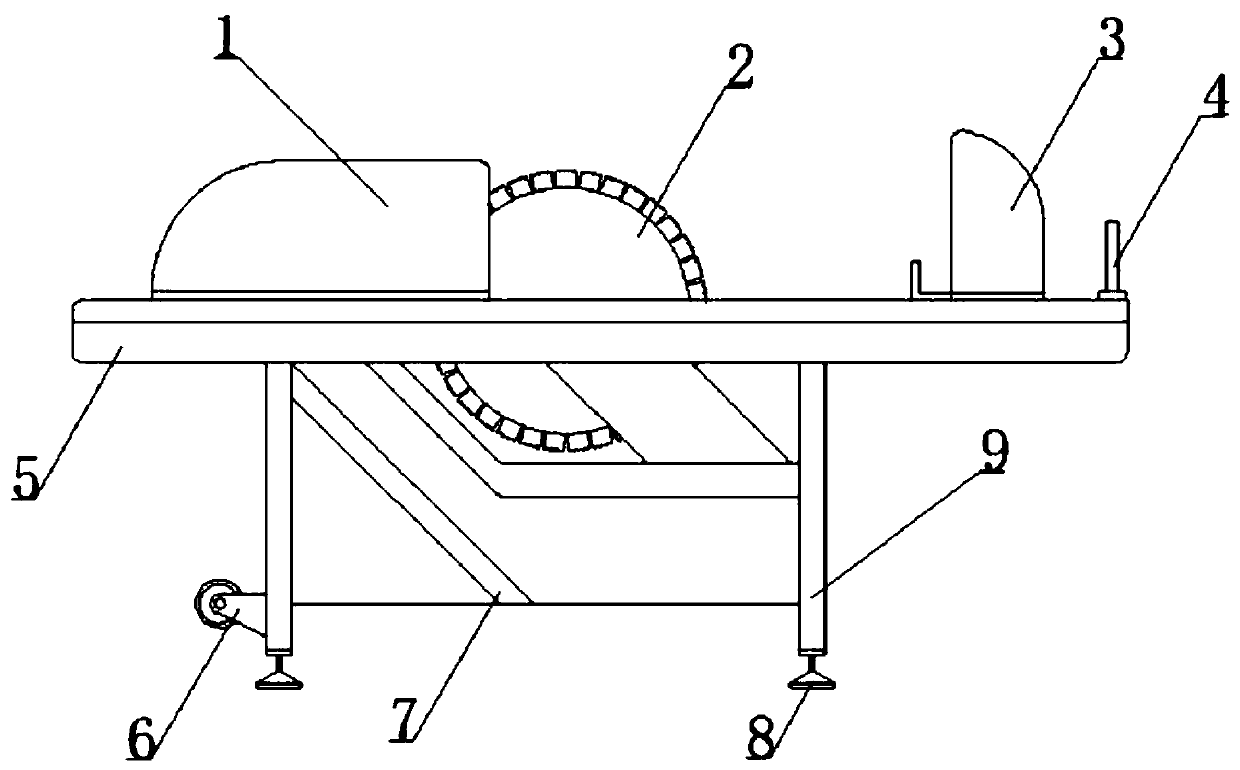

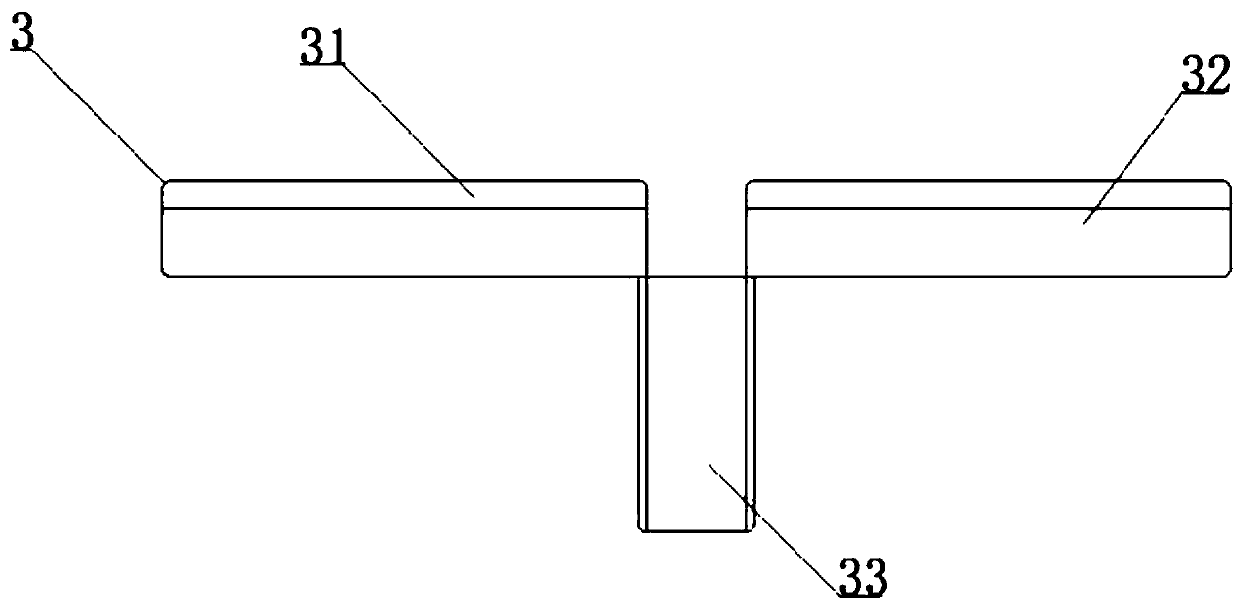

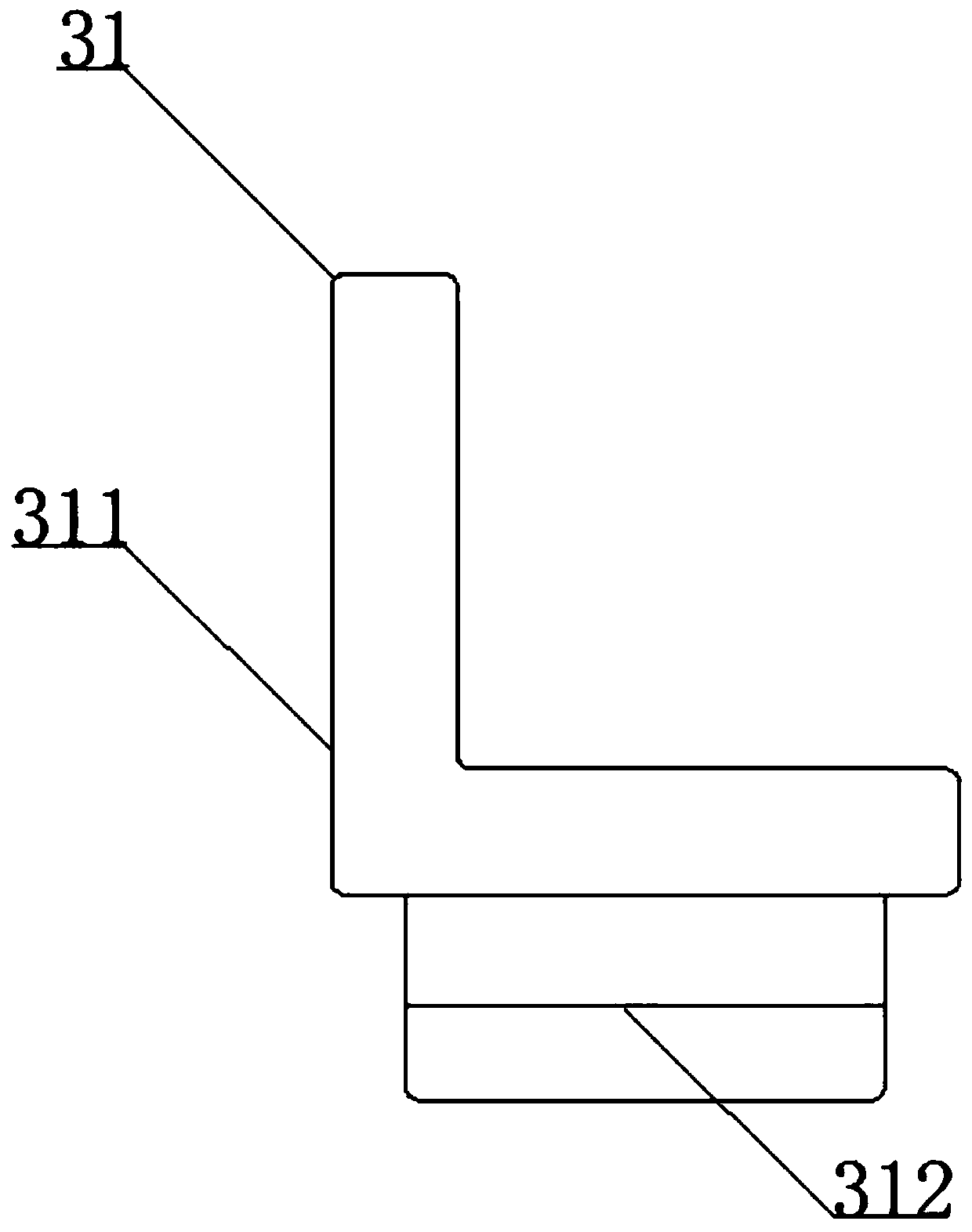

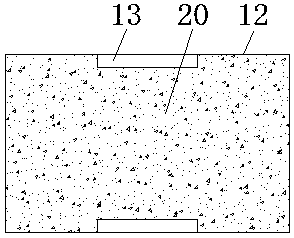

Concrete building block cutting device

PendingCN110435013AProtection securityPrevent bumping intoWorking accessoriesStone-like material working toolsArchitectural engineering

The invention discloses a concrete building block cutting device. A left pushing-pulling device and a right pushing-pulling device are adopted to push a concrete building block, so that a worker doesnot need to manually push the concrete building block, and a protective blade protection cover can be prevented from being touched by a saw tooth cutting blade in a pushing process very well, and therefore, safety of a worker is protected very well. The concrete building block cutting device is provided with a stable workbench which consists of a left blocking bulge, a middle cutting notch, a right blocking bulge, a right horizontal slide slot, a left horizontal slide slot and a workbench table board, wherein the left horizontal slide slot and the right horizontal slide slot are adopted to block a movable slide block and a slide block on the bottom of the right pushing-pulling device, and the left pushing-pulling device and the right pushing-pulling device can move in the left horizontal slide slot and the right horizontal slide slot; and the left blocking bulge and the right blocking bugle can prevent the left pushing-pulling device and the right pushing-pulling device, so that the protective blade protective cover is prevented from being in contact with the saw tooth cutting blade, and therefore, safety, during concrete building block cutting, of a worker is protected.

Owner:JIANGSU WANXIANG CONSTR ENG GRP CO LTD

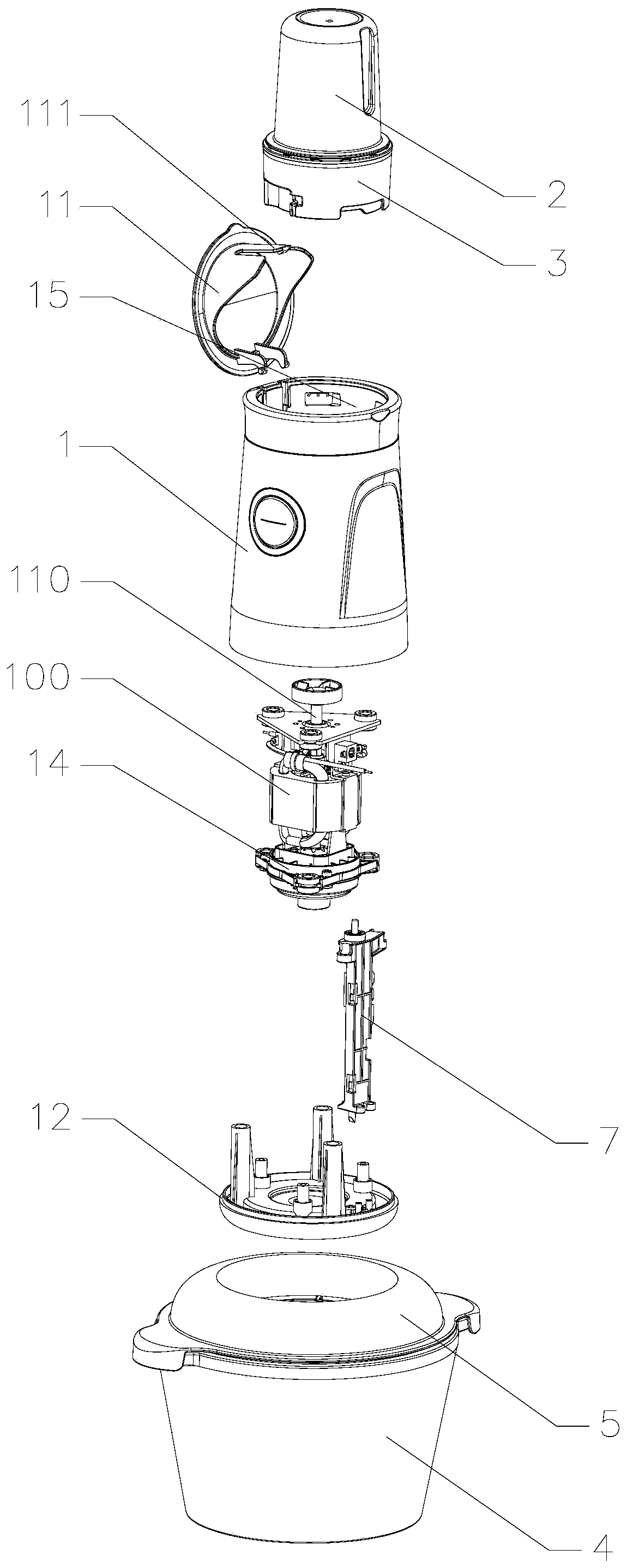

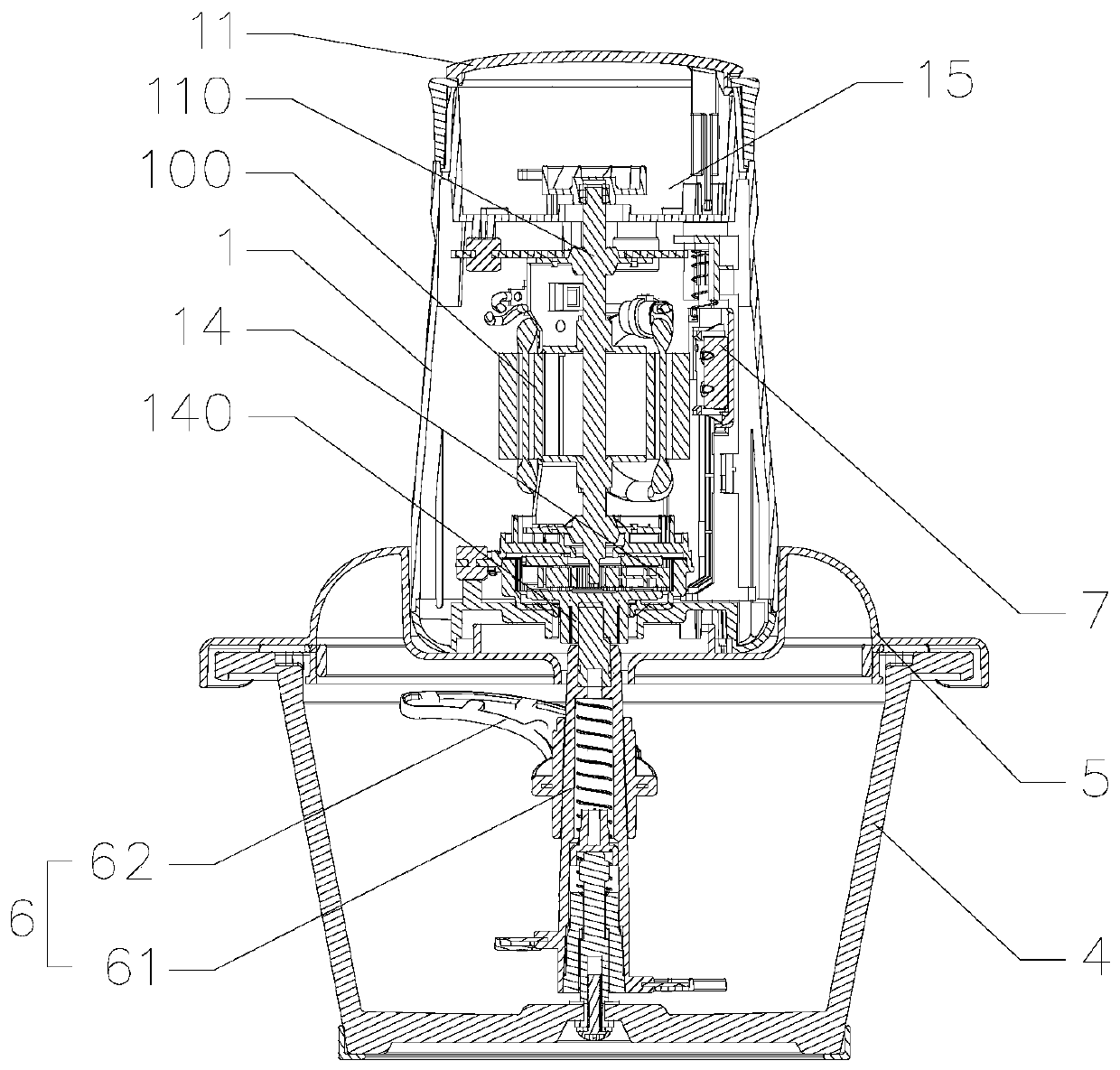

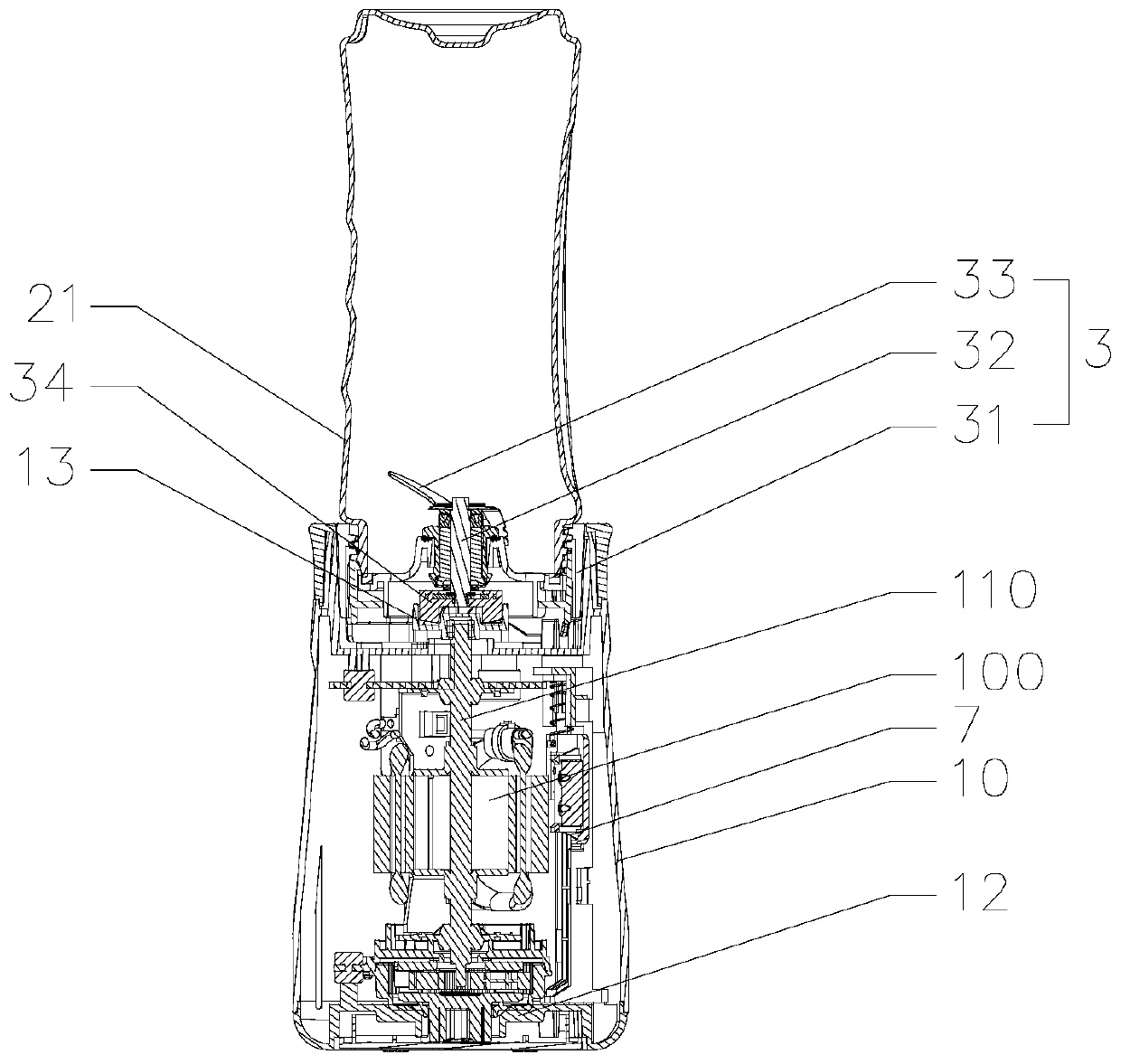

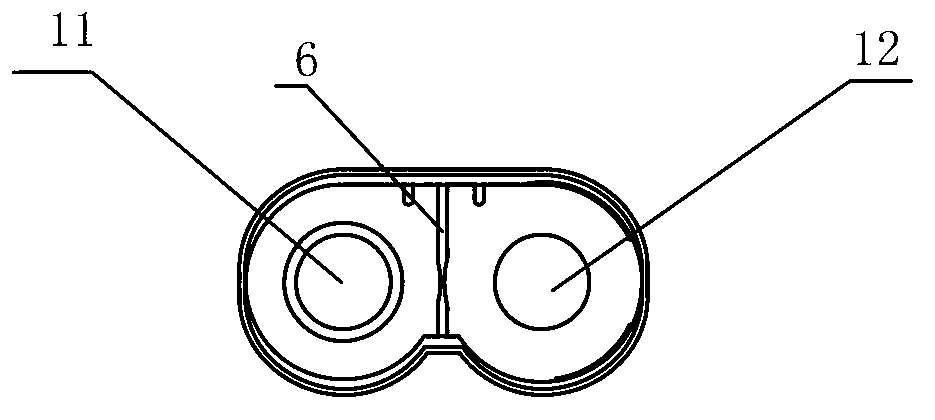

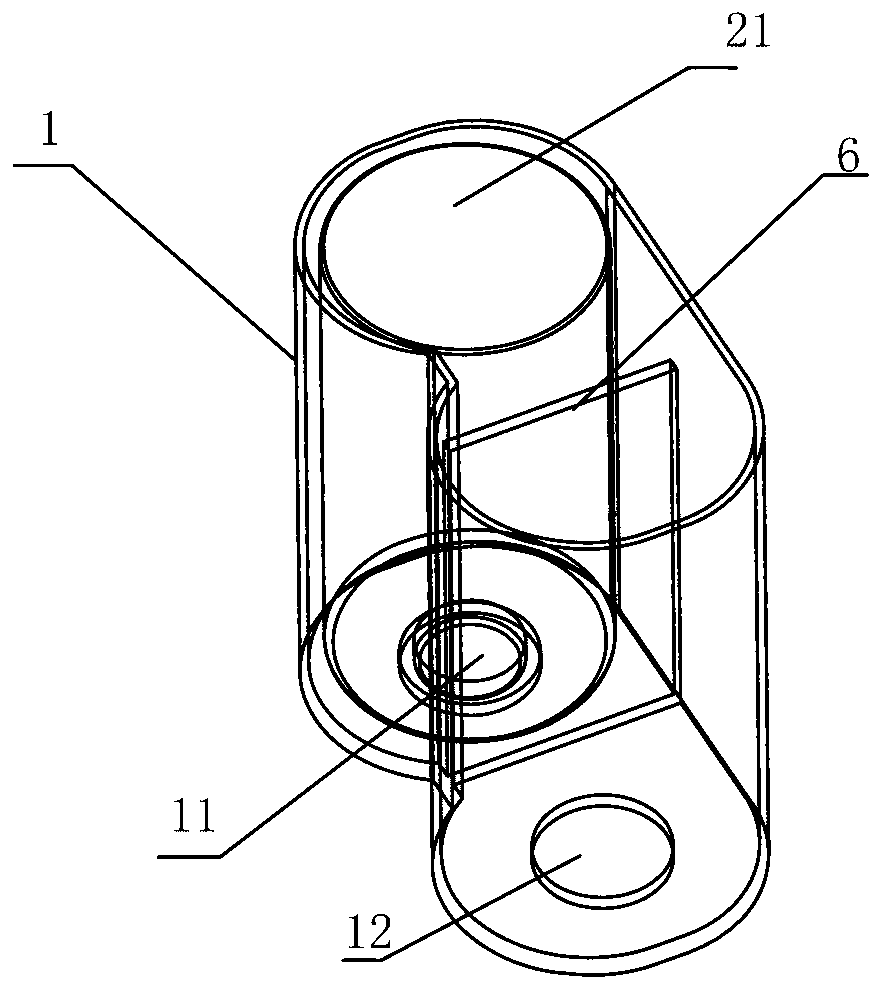

Food processor safe to use

ActiveCN110974054AEnsure safetyPrevent bumping intoKitchen equipmentGrain treatmentsElectric machineryProcess engineering

The invention provides a safe food processor. The safe food processor comprises a machine base, a first stirring cup connected to the bottom of the machine base, and a second stirring cup arranged atthe top of the machine base. A vertically arranged motor is arranged in the machine base; a motor comprising a motor shaft, two ends of the motor shaft extend out of the motor; a safety bottom cover is arranged at the bottom of the machine base; a safety top cover is arranged at the upper end of the machine base, a safety switch assembly is arranged in the machine base, the upper end of the safetyswitch assembly is in linkage with the safety top cover or the second stirring cup, the lower end of the safety switch assembly is in linkage with the safety bottom cover or the first stirring cup, and the food processor can work only after the second stirring cup and the safety bottom cover are arranged in place; or the food processor can work only after the first stirring cup and the safety topcover are arranged in place. The safety top cover and the safety bottom cover guarantee that the two ends of the motor shaft cannot be exposed in the working process of the food processor, and the safety of a user is guaranteed; and meanwhile, motor damage caused by overlarge load when the first stirring cup and the second stirring cup are mounted at the same time can be avoided.

Owner:JOYOUNG CO LTD

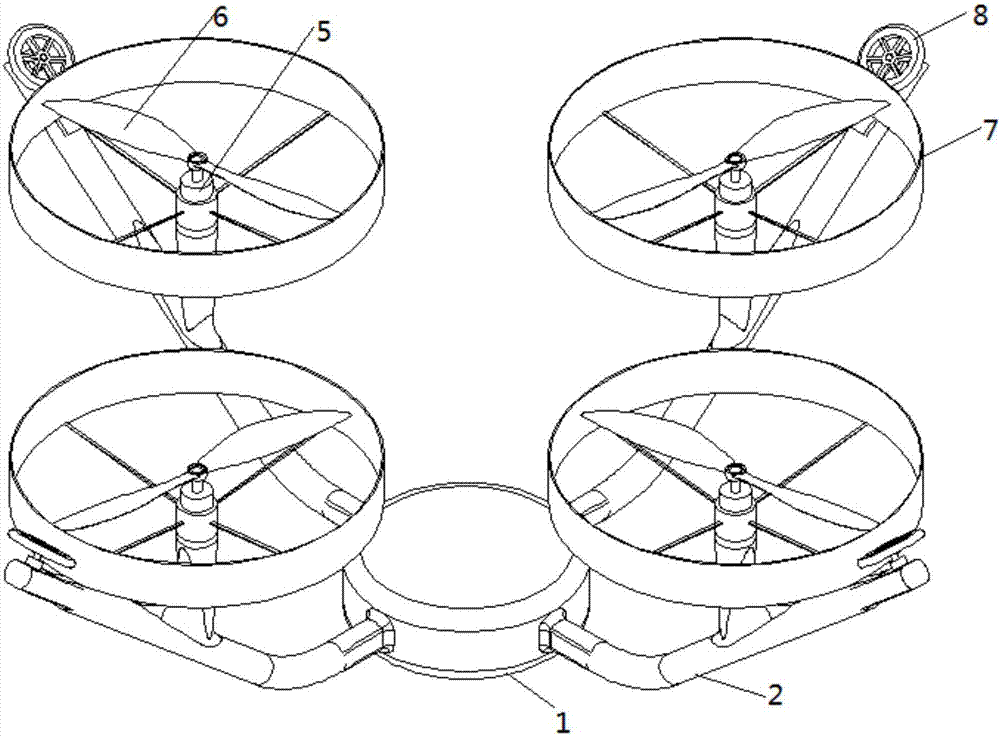

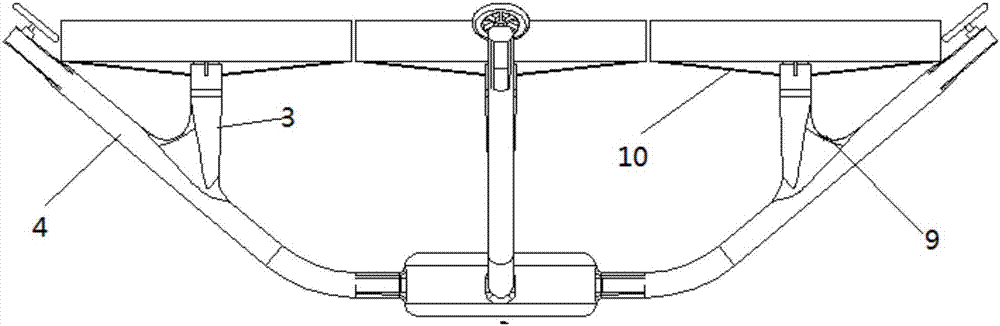

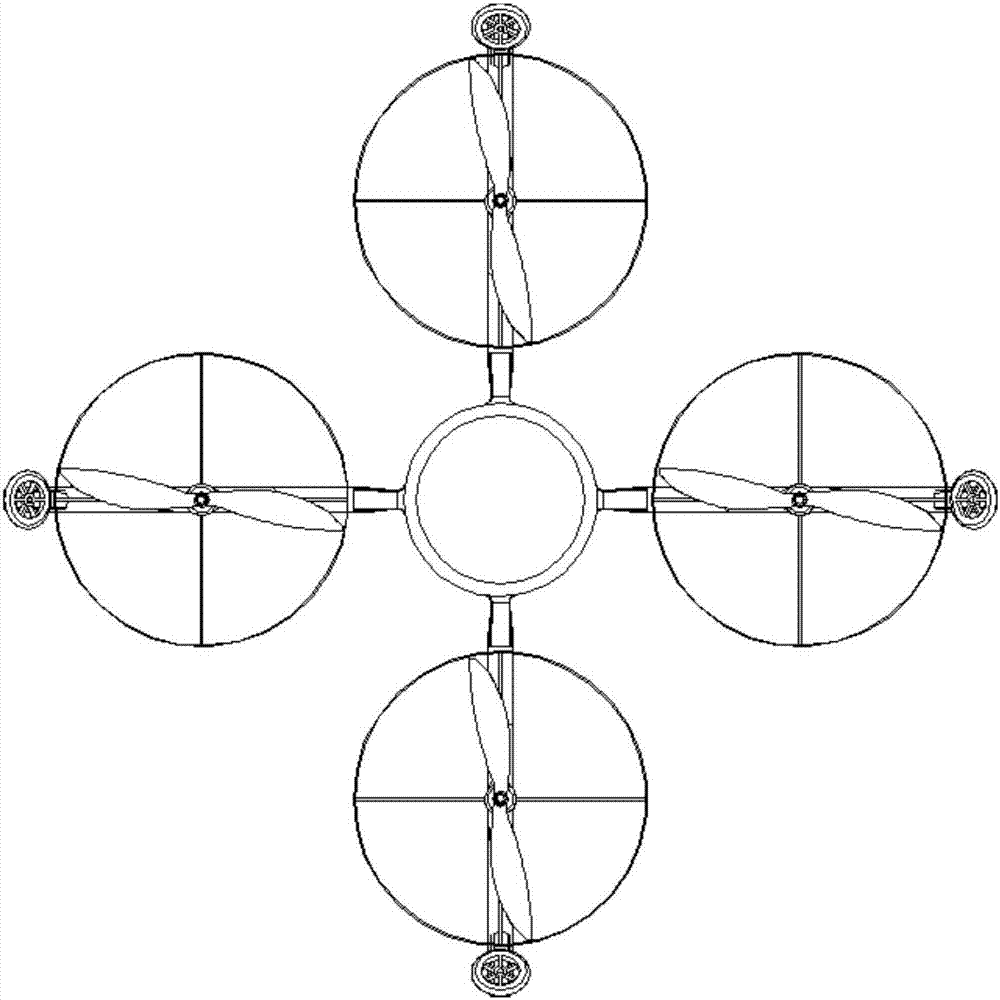

Flyable robot

The invention relates to a flyable robot comprising a fuselage, special-shaped tubular-structure robot arms, rotor wing mechanisms and walking mechanisms, wherein the fuselage is fixedly connected to the special-shaped tubular-structure robot arms, and the multiple special-shaped tubular-structure robot arms are distributed and arranged around the fuselage to form a protected area; the special-shaped tubular-structure robot arms comprise vertical arms and inclined arms; the vertical arms are perpendicular to the horizontal plane of the fuselage, and motor seats and duct fixed support arms are arranged at the upper end of the vertical arms; wheel seats are arranged at the upper end of the inclined arms; the rotor mechanisms comprise electronic speed governors, motors, propellers and ducts; the walking mechanisms comprise servo motors and wheels; and the horizontal height of the rotor wing mechanisms are lower than the horizontal height of the walking mechanisms. With the adoption of the design, the flyable robot is simple in structure and convenient to use, the shaped tube shape structural engine arms can be disassembled, carry is convenient, the complicated environment can be coped with, the detection task is completed efficiently, and the safety performance of buildings such as a bridge can be greatly improved.

Owner:NANJING ZUHANG AVIATION TECH CO LTD

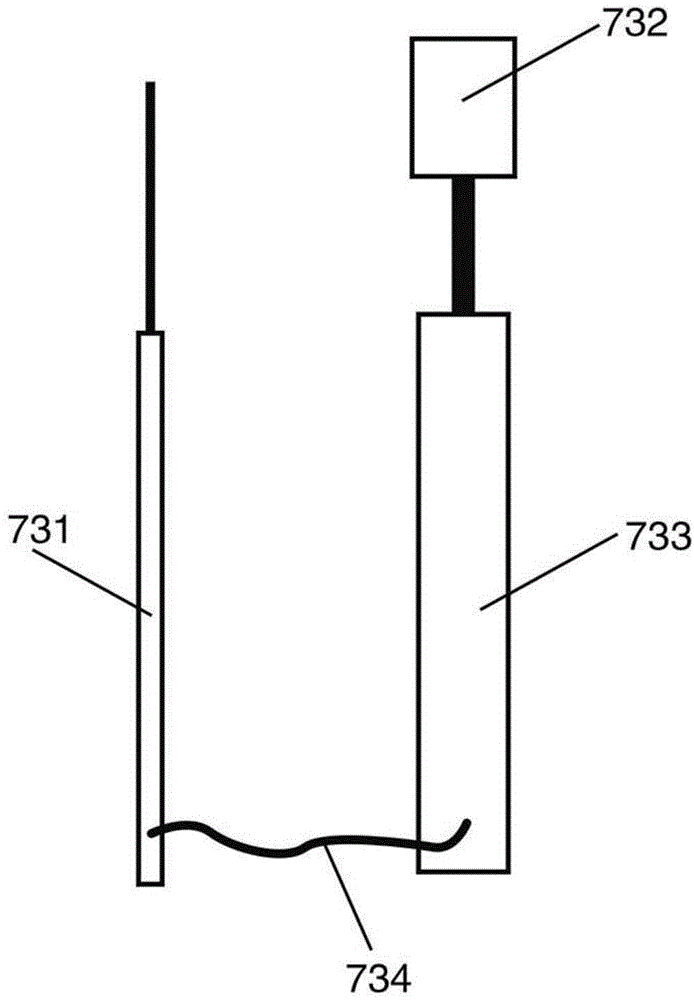

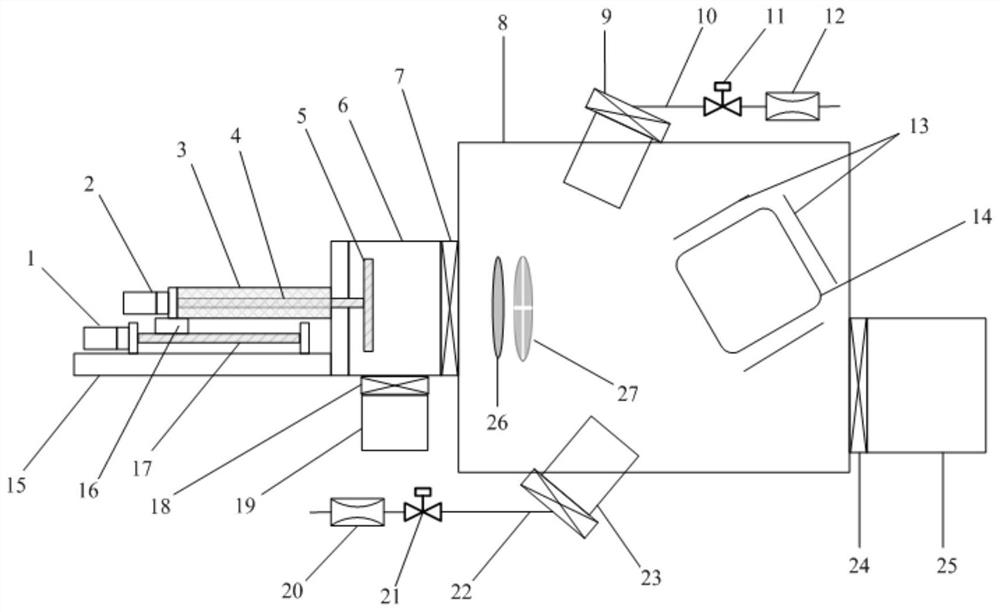

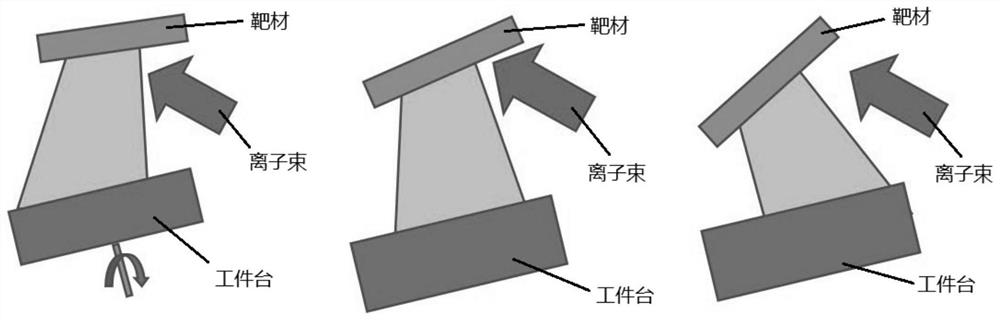

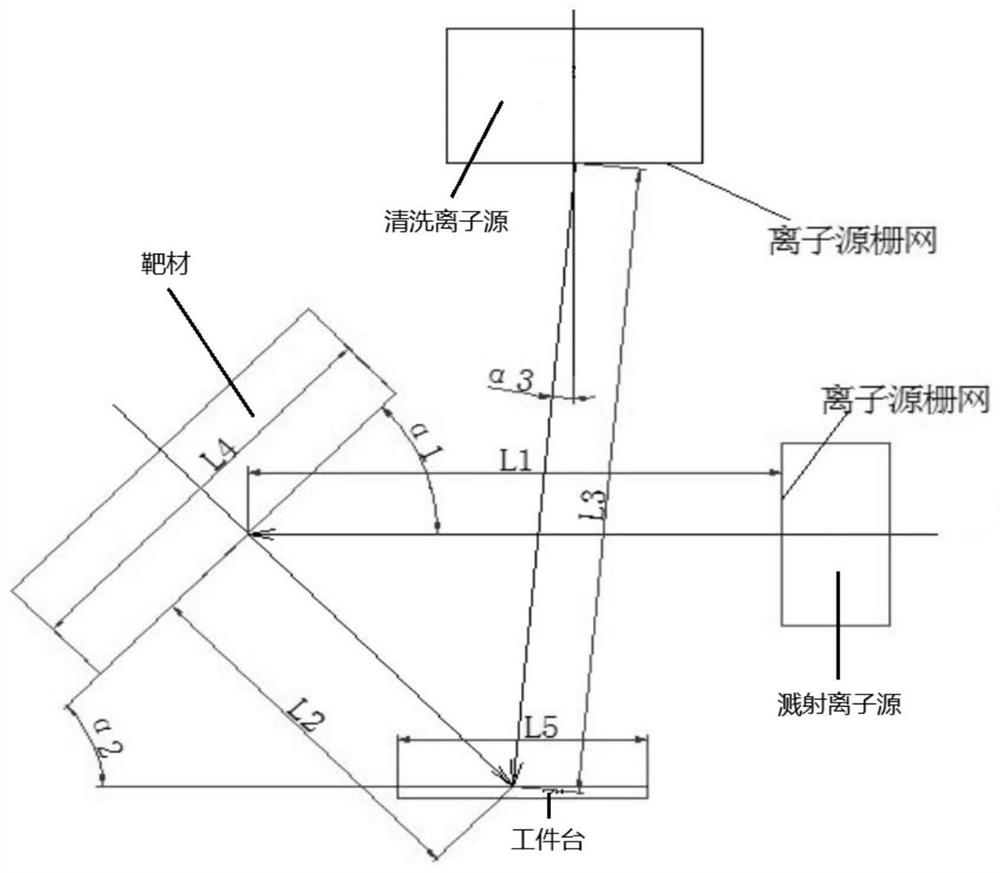

Ion beam deposition equipment for infrared metal film and film deposition method

ActiveCN112159967AImprove adhesionImprove deposition uniformityFinal product manufactureVacuum evaporation coatingPhysicsIon beam deposition

The invention discloses ion beam deposition equipment for an infrared metal film and a film deposition method. The equipment comprises a wafer loading and unloading cavity and a sputtering cavity, wherein a first high-vacuum isolation valve is arranged between the wafer loading and unloading cavity and the sputtering cavity, the wafer loading and unloading cavity is provided with a vacuum sealingdoor, a pushing rod penetrates through the vacuum sealing door, a workpiece table is arranged at the end, on the inner side of the vacuum sealing door, of the pushing rod, a pushing mechanism used forpushing the pushing rod is arranged on the outer side of the vacuum sealing door, and the wafer loading and unloading cavity is connected with a first vacuumizing device. The film deposition method adopts the equipment to perform film deposition. According to the invention, the wafer loading and unloading cavity is arranged, so that the cavity opening and vacuumizing times of the sputtering cavity can be reduced, the vacuumizing time can be shortened, the productivity can be improved, the vacuum environment can be always kept in the sputtering cavity, the target burning times can be reduced,and the utilization rate of a target material can be improved. The ion beam deposition equipment has the advantages of high productivity, high target material utilization rate and the like, can be widely used for depositing infrared metal films, and has very high use values and application prospects.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

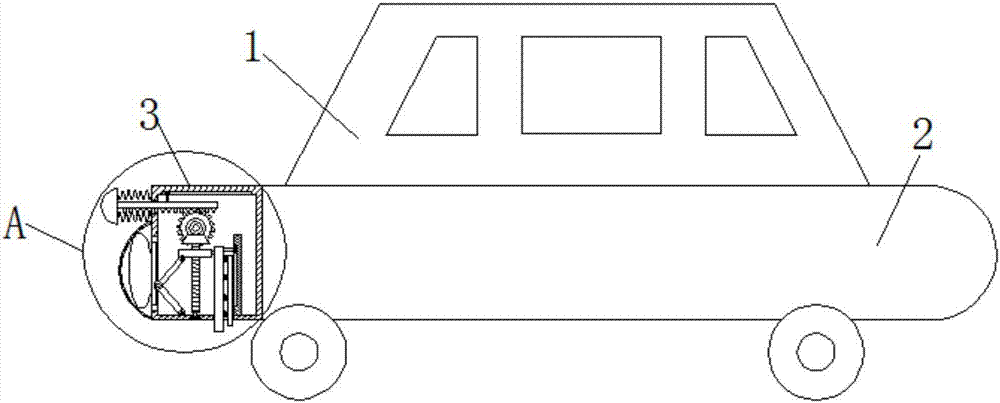

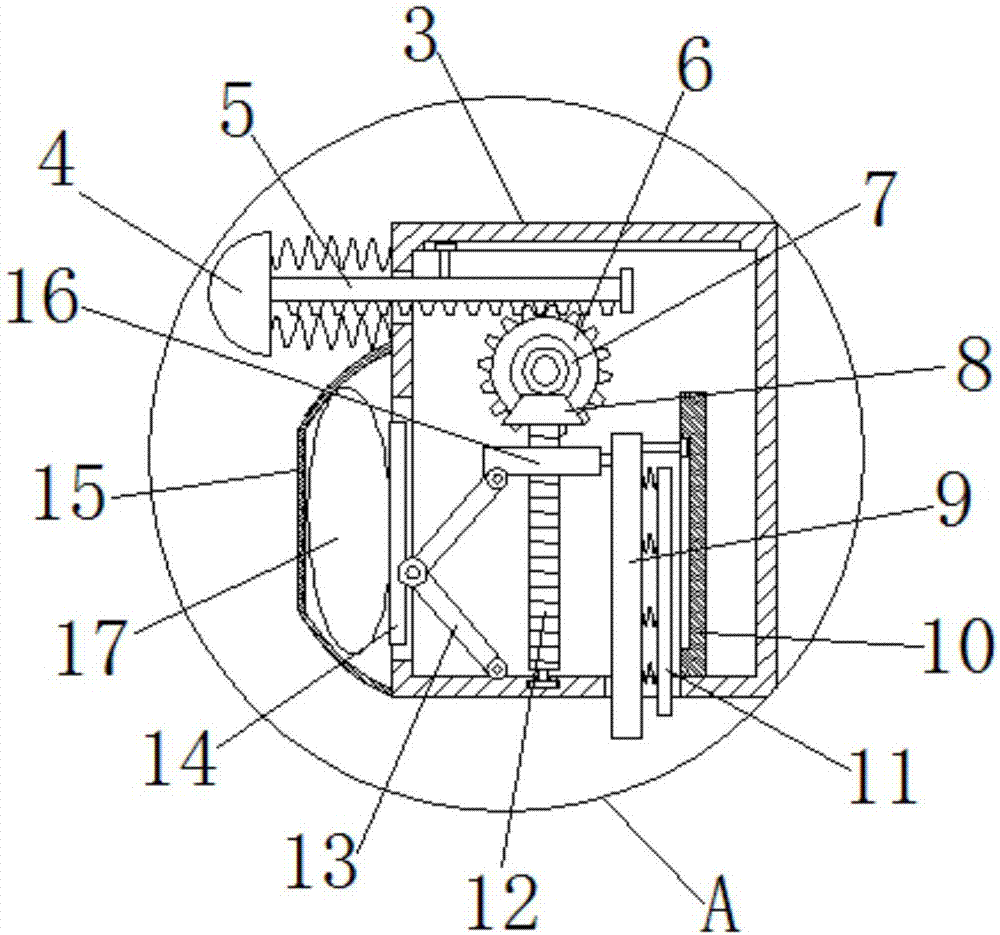

Toy car with buffer device

The invention discloses a toy car with a buffer device. The toy car comprises a car body, a base and a device box. The base is fixedly connected with the bottom end of the car body. The bottom end ofthe base is rotationally connected with four wheels. The side wall of the base is fixedly connected with the device box. Through the combination of an ejecting block, a screw rod and an air bag, a sponge and the air bag are pushed out when the car body hits an object, the head part of the car is buffered and protected when the wheels are prevented from continuing advancing, the screw rod can be made to rotate when the car head hits the object, a screw sleeve is driven to move down, the sponge gets rid of the squeezing of a fixing plate and makes contact with the wheels and prevents the wheelsfrom continuing rolling, meanwhile, a first connecting rod and a second connecting rod rotate, a connecting plate and the air bag can be pushed out, through the deformation of the air bag, the hittingenergy of the toy car is counteracted, the damage of the toy car is avoided, and the air bag can be protected to a certain extent and prevented from colliding with a sharp object by means of an elastic film.

Owner:郭姗姗

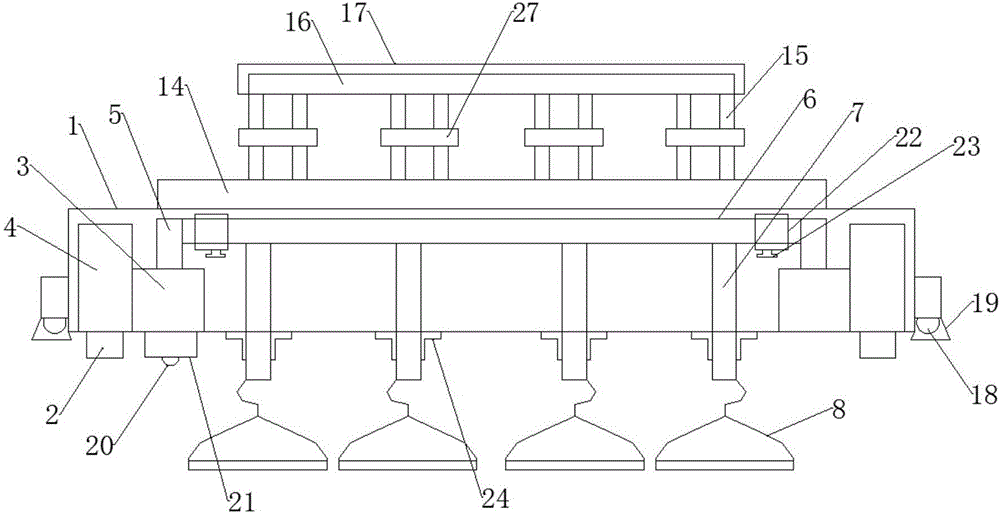

Method for automatically producing shoe-shaped gold ingot-like wontons

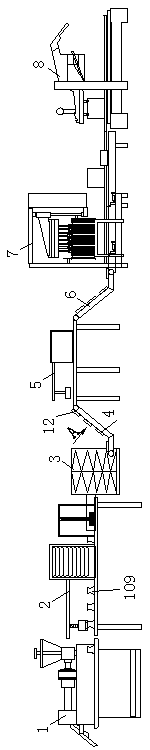

ActiveCN107927040AImprove production efficiencySuitable for large-scale mass productionFood preservationWrapper twisting/gatheringProduction lineIngot

The invention relates to the technical field of food machinery, and in particular relates to a method for automatically producing shoe-shaped gold ingot-like wontons. The method includes molding, quick freezing, tidying, coating, boxing, sealing and other steps. Shoe-shaped gold ingot-like wontons are formed by a molding die, the formed shoe-shaped gold ingot-like wontons are in order conveyed toa loading machine, a quick freezing chamber, a first material tidying device, a coating machine, a second material tidying device, a boxing machine and a sealing machine which are connected. The process from manufacturing, freezing to packaging of the shoe-shaped gold ingot-like wontons is completely automatic. The entire production line is integrated, no manual operation is required, the production efficiency of the shoe-shaped gold ingot-like wontons is greatly improved, the method is applicable to the mass production of the shoe-shaped gold ingot-like wontons, and the shoe-shaped gold ingot-like wontons which are industrially prepared in a large scale are very consistent in size and shape.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

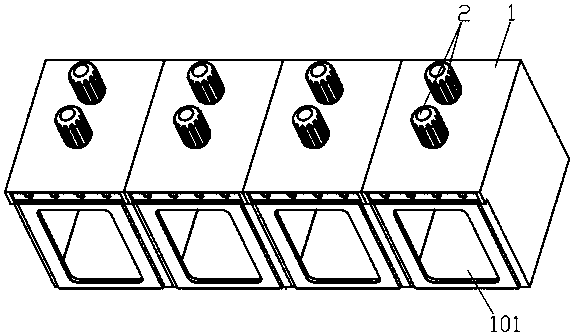

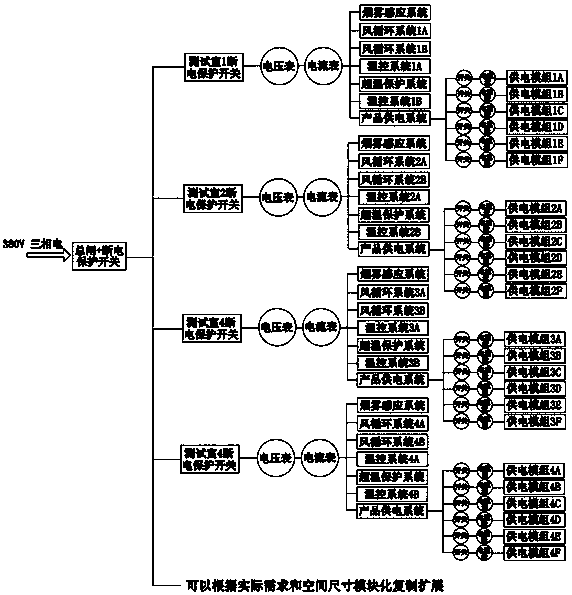

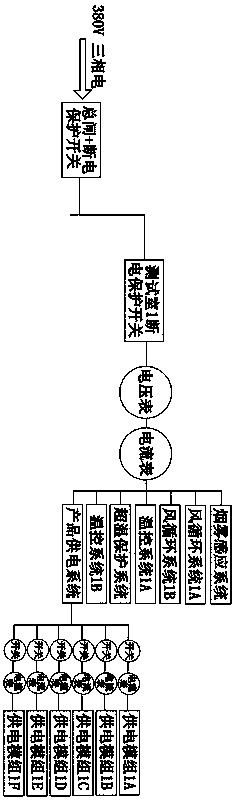

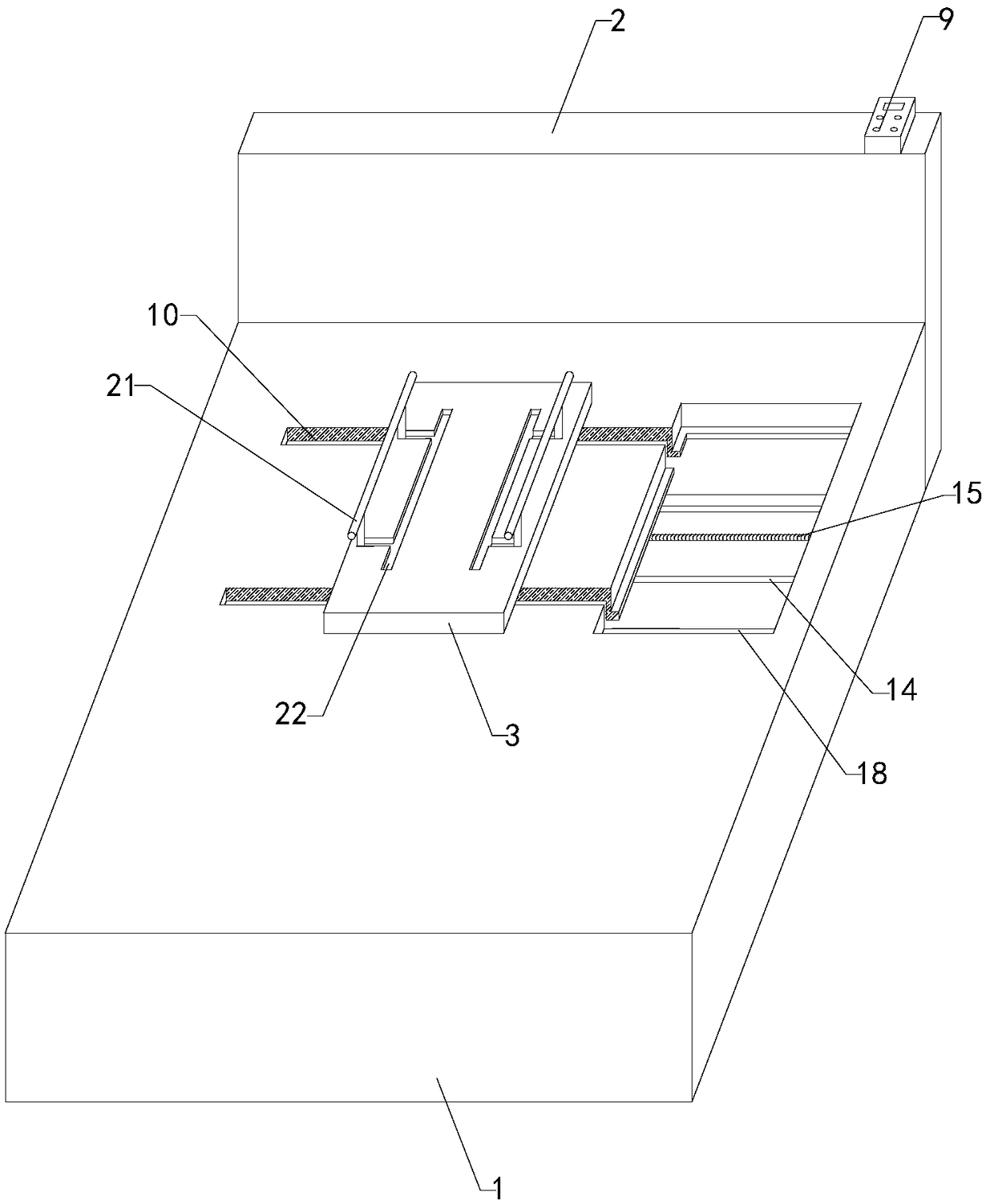

Large-scale high-temperature test equipment applied to reliability test of solid-state disk

PendingCN107680635AReduce frequent shutdown and start-up heating and coolingLess power consumptionTemperature control using electric meansStatic storageRational usePush pull

The invention discloses large-scale high-temperature test equipment applied to the reliability test of a solid-state disk. The large-scale high-temperature test equipment includes a housing of the equipment. The housing is provided with a plurality of independent aging chambers, and the shell of each housing is provided with a wind circulation system, a temperature control system, an over-temperature protection system and a product power supply system. The large-scale high-temperature test equipment is energy-saving and environmentally-friendly, the power source of each high-temperature chamber can be controlled independently, and the reasonable use of each aging chamber can be individually controlled. Frequent shutdown, starting-up, heating, cooling and other operation of the equipment can be minimized. Compared with other equipment with same production capacity, at least 40% of power consumption is saved. A product test rack adopts a cart-type aging rack, and a cart type design is used. Universal wheels are installed at the bottom of the rack body, and the product test rack is easy to push and pull when in use.

Owner:SHENZHEN SHICHUANGYI ELECTRONICS

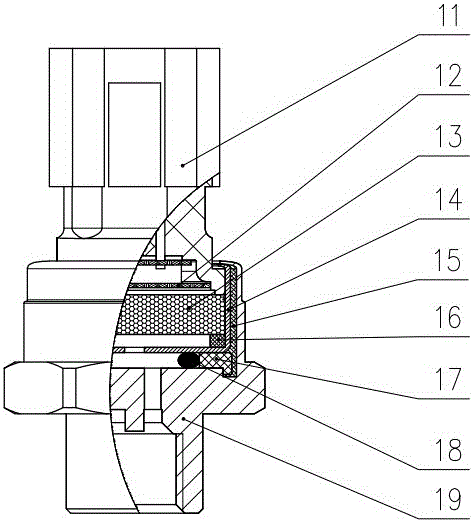

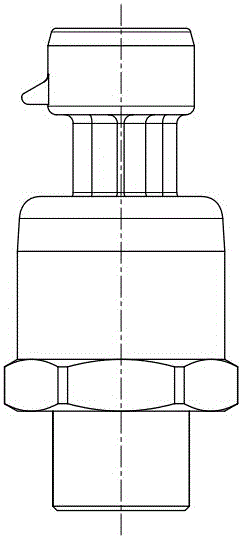

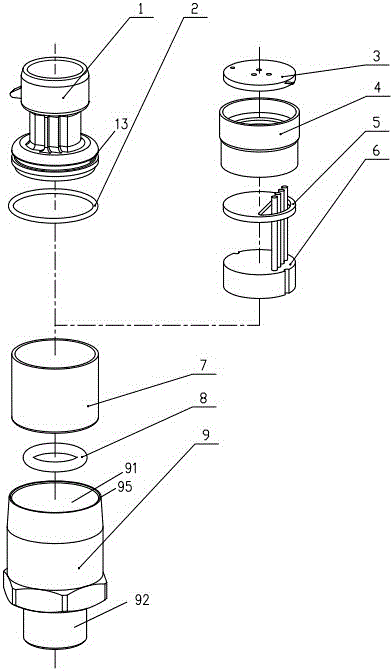

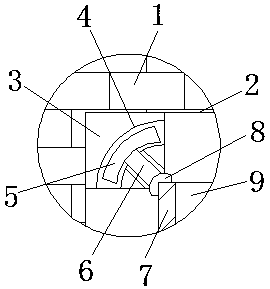

Pressure sensor used in air conditioner

InactiveCN105043658AGood electromagnetic protectionPrevent bumping intoFluid pressure measurementEngineeringForce sensor

A pressure sensor used in an air conditioner comprises a connector, a connector sealing ring, a circuit board assembly, a shielding case, a separation plate, a pressure core body, an insulation sleeve and a shell. The shell is divided into upper and lower portions. The upper portion is a cavity and the lower portion is connected to a joint of a using place. The upper portion and the lower portion are separated by an insulation sleeve placing plane. A through hole connected to an external using place is arranged on the insulation sleeve placing plane. The shielding case is provided with an inner cavity. A step is arranged in the inner cavity. The separation plate is placed below the step of the inner cavity of the shielding case and is limited by the step. The pressure core body is placed in the inner cavity of the shielding case below the separation plate. A bottom of the insulation sleeve is provided with a plane used for placing the shielding case. The plane is provided with the through hole. The through hole is connected to an internal channel of the joint of the shell. The insulation sleeve sleeves the shielding case. An upper portion of the insulation sleeve is connected to a lower portion of the connector and then the whole insulation sleeve is put into the cavity of the upper portion of the shell. An outer edge of the upper portion of the shell fastens a lower portion of the connector. The circuit board assembly is fixed to a bottom plane of the connector and enters into the inner cavity of the shielding case.

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

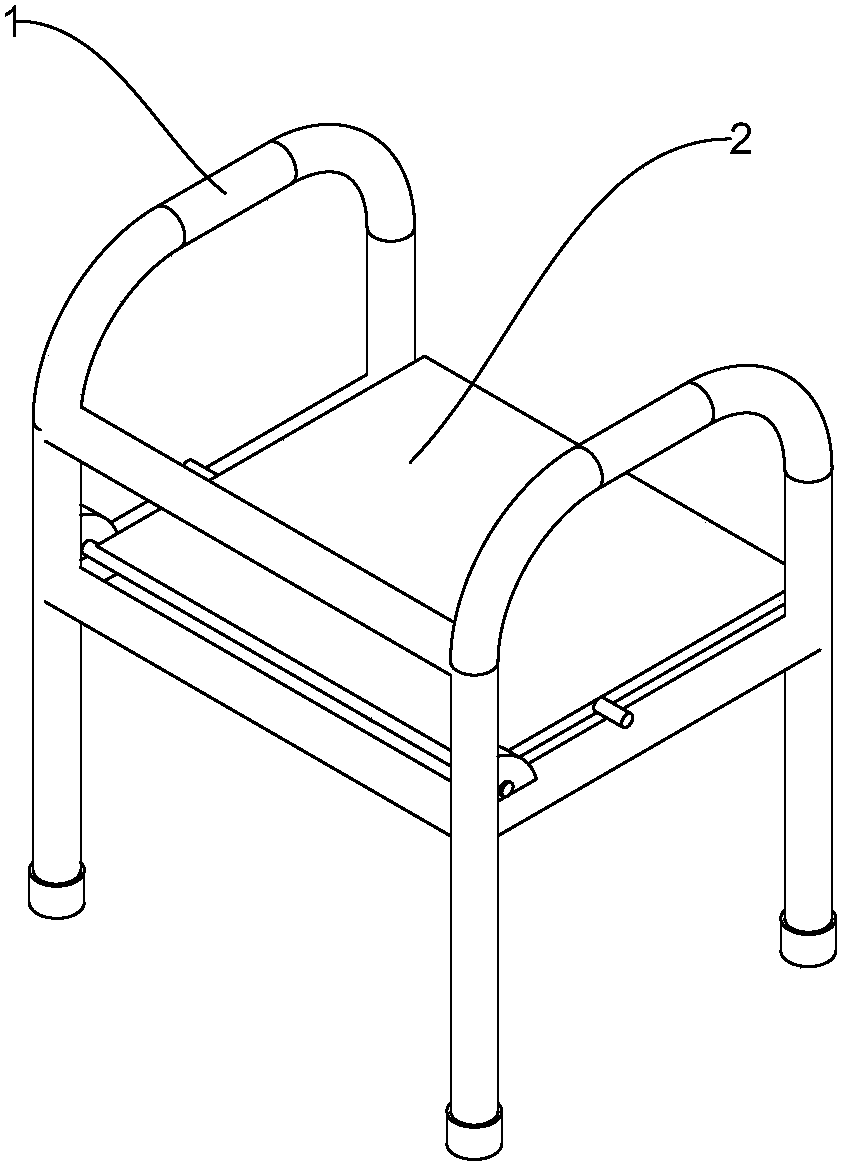

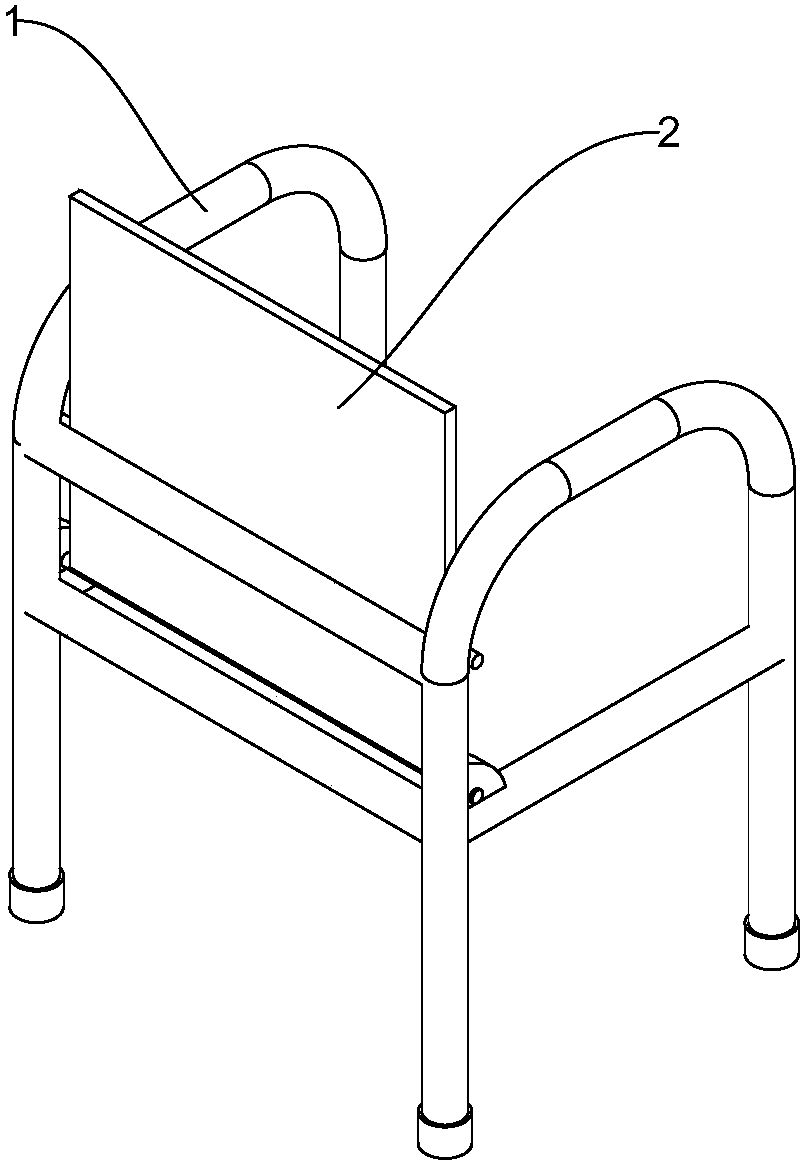

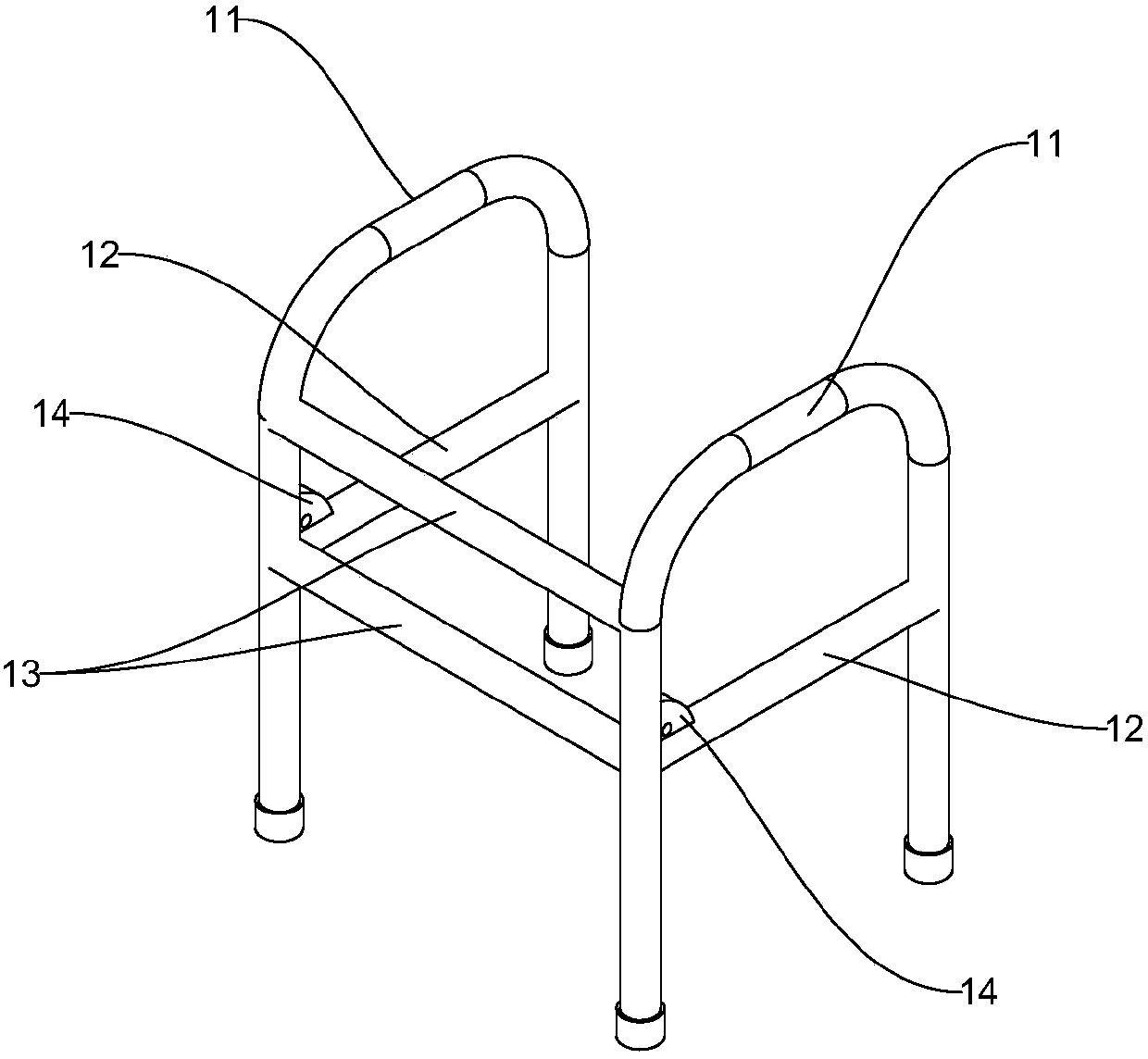

Safe walking aid

The invention discloses a safe walking aid. The safe walking aid comprises a support and a baseboard, wherein the support comprises two n-shaped supporting rods, two reinforcing rods, two distance determining rods and two reinforcing rib boards, the two n-shaped supporting rods are parallel to each other and vertically arranged, the reinforcing rods are horizontally arranged, the two ends of eachreinforcing rod is connected with the corresponding n-shaped supporting rod, the two ends of each distance determining rod are connected with the front sides of the two n-shaped supporting rods respectively, and the reinforcing rib boards are arranged on the joints between the n-shaped supporting rod and the reinforcing rods and located above the reinforcing rods. The safe walking aid has the advantages that the baseboard with the adjustable angle is provided, so that the baseboard can not only be horizontally placed for an old man to sit for resting, but also can be set up to prevent the oldman from being hit when the safe walking aid is used by the old man; the surface of the baseboard is coated with fluorescent material, so that the old man is likely to be noticed by passing vehicles and passengers.

Owner:王玲芳

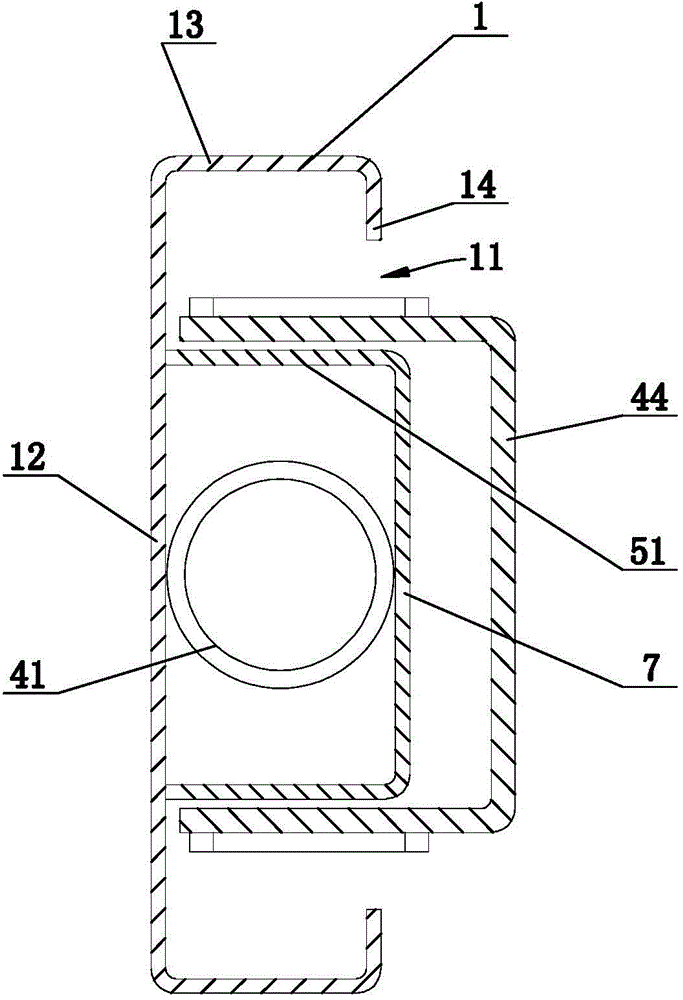

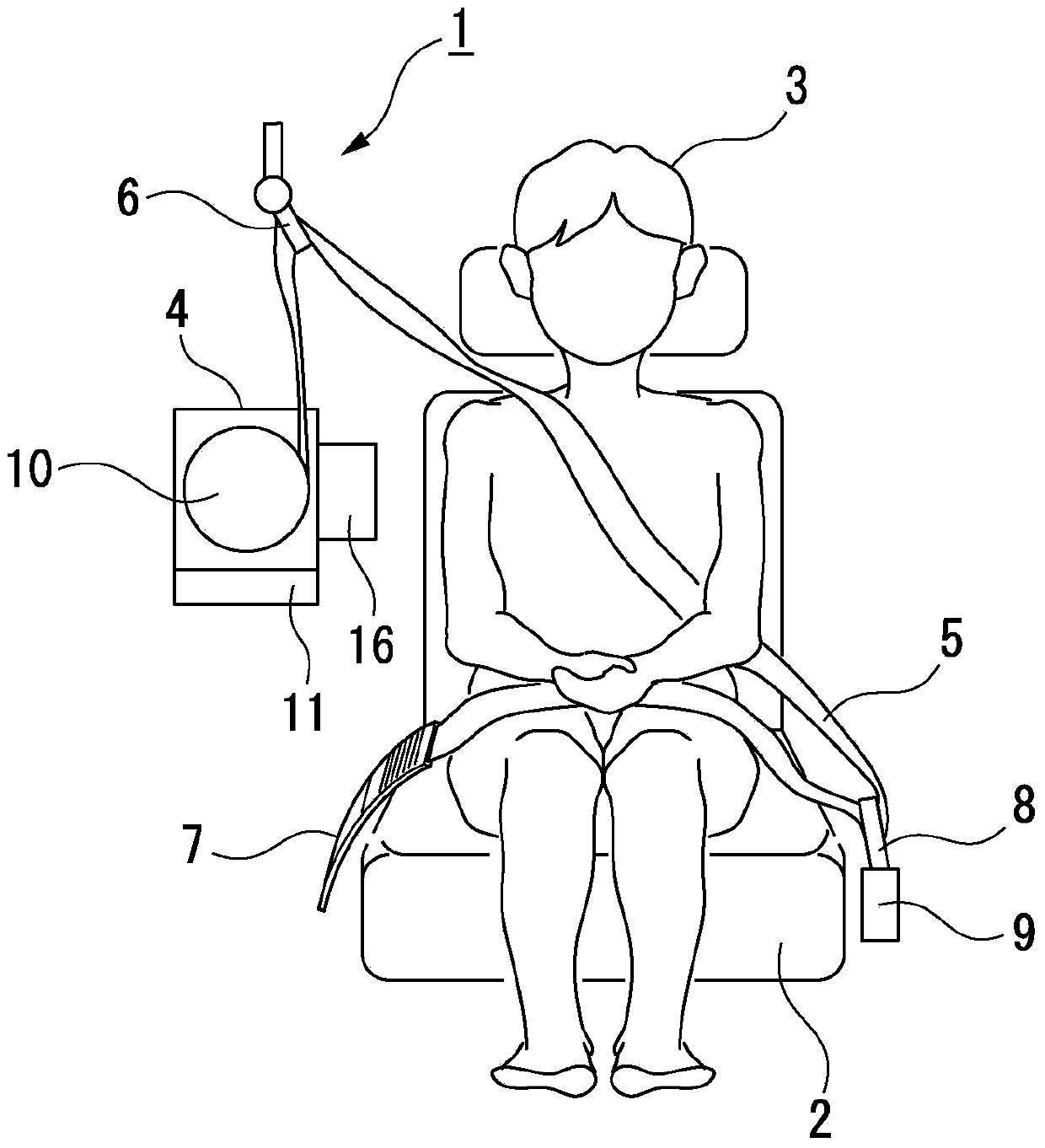

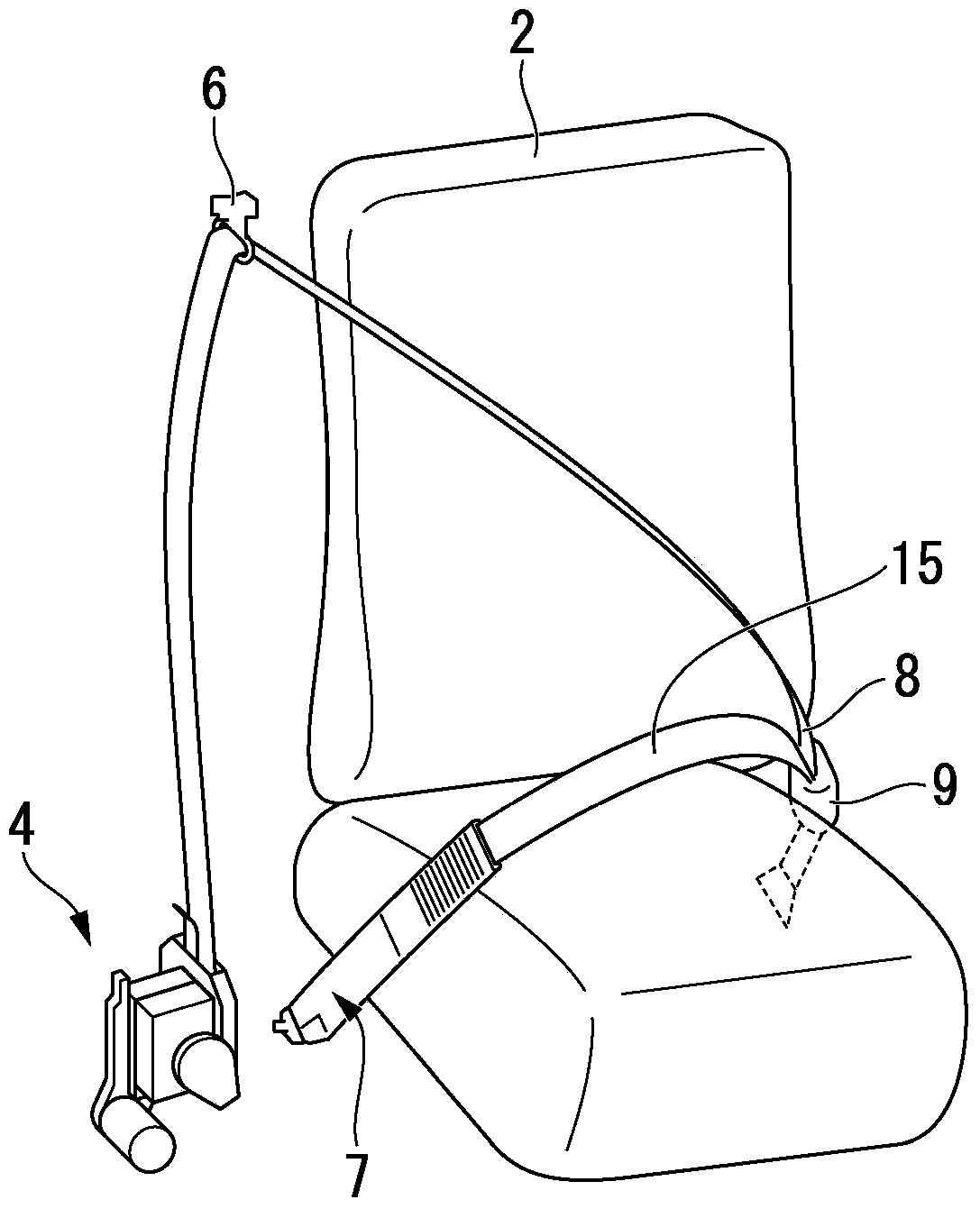

Seat belt apparatus

InactiveCN103723110AReduce processing loadLow costBelt retractorsBelt control systemsSeat beltEngineering

The invention provides a seat belt apparatus. A control device (43) controls driving of a motor (11) such that a clutch (12) of a power transmission mechanism (14) is moved to a disconnecting position and thereby a belt reacher device (7) is moved around in a forward direction of a vehicle by a return spring (7d) of the belt reacher device, if a change from an open state to a closed state of a door is detected by a door switch (55). The control device (43) controls driving of the motor (11) such that a webbing (5) is winded and thereby the belt reacher device is moved around to a retracted position in a backward direction of the vehicle, if a determination is made that no occupant seated in a passenger seat is detected by an output of an OFF signal from a buckle switch (51) of the passenger seat and a determination is made that start-up of the vehicle is detected by an output of an ON signal from an ignition switch (56).

Owner:HONDA MOTOR CO LTD

Mobile phone shell polishing workstation based on industrial robot

ActiveCN106670965AEasy to fixPrevent bumping intoGrinding machinesGrinding work supportsEngineeringWorkstation

The invention discloses a mobile phone shell polishing workstation based on an industrial robot. The mobile phone shell polishing workstation comprises two clamp bases. The upper end of each clamp base is connected with a mobile phone shell imitation clamp. A negative pressure region is arranged at the corresponding position of a battery compartment on the front face of each mobile phone shell imitation clamp. Each negative pressure region is provided with multiple negative pressure grooves arranged at intervals. Even though mobile phones are in various shapes, the shapes of battery compartments are similar, and the area is also large. Accordingly, mobile phone shells are fixed through the region. Air can be pumped out through a negative pressure connector, and the mobile phone shells can be stably fixed to the mobile phone shell imitation clamps through negative pressure. The negative pressure connector is arranged between two forks so as to be protected, and the negative pressure connector is prevented from being collided when the mobile phone shells are loaded and unloaded. Air between the mobile phone shells and the mobile phone shell imitation clamps can be pumped to the maximum due to the arrangement of the negative pressure grooves, and the mobile phone shells are firmly fixed. The mobile phone shell polishing workstation is used for polishing the mobile phone shells.

Owner:FOSHAN HUASHU ROBOTICS CO LTD +1

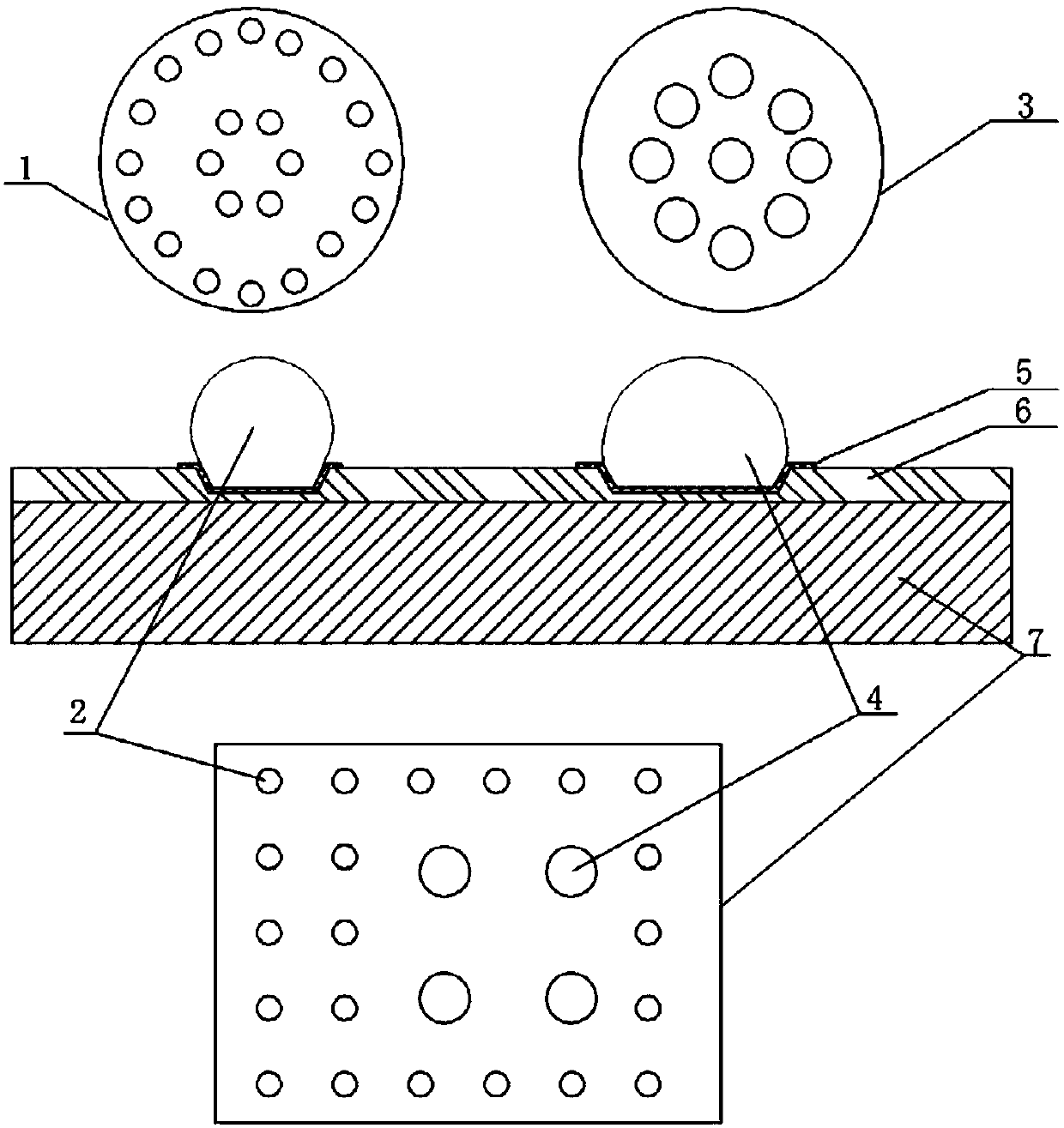

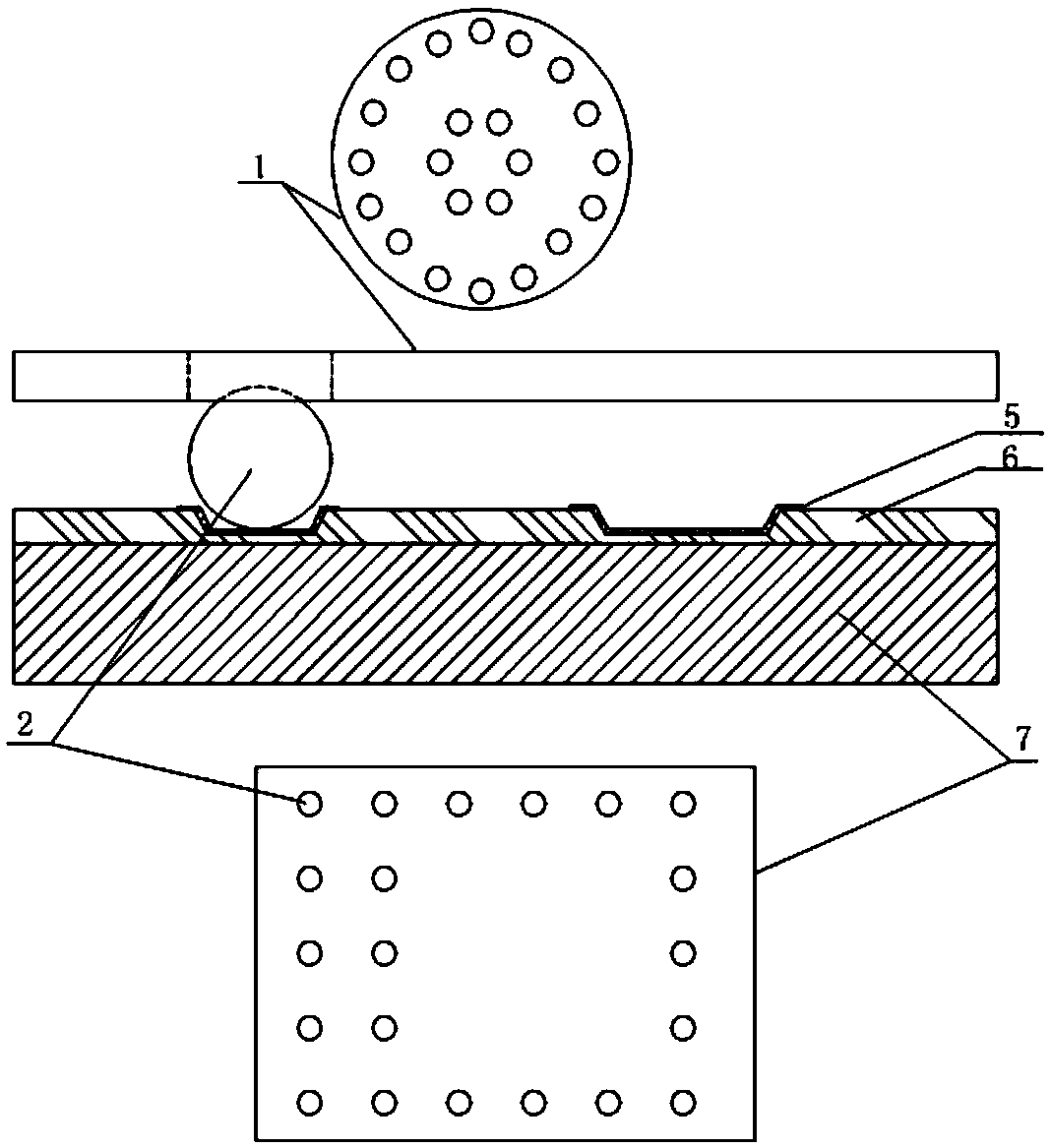

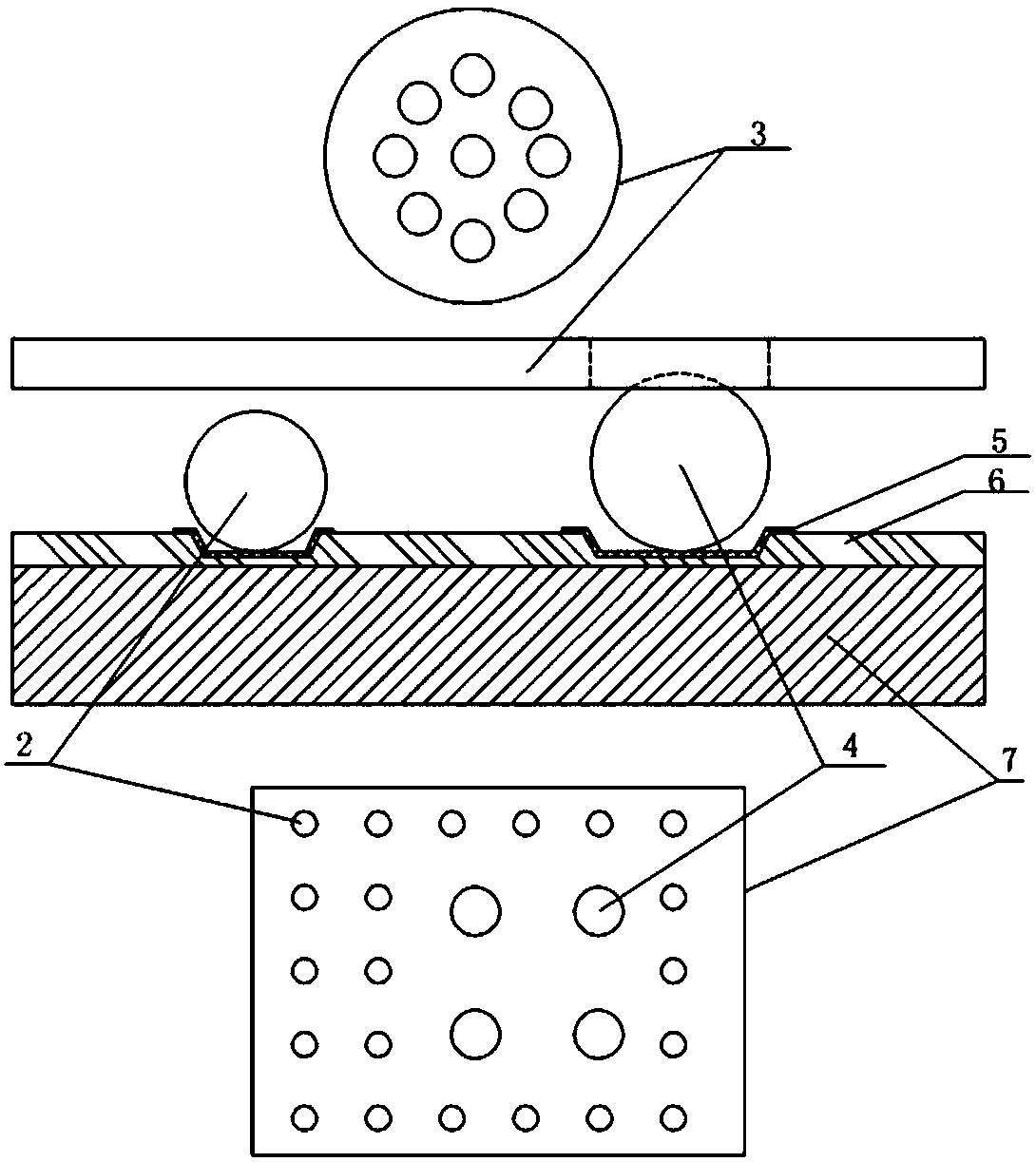

Method for preparing wafers having bumps with different diameters

ActiveCN109637990ASimple methodImprove yield and reliabilitySemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

The invention discloses a method for preparing wafers having bumps with different diameters. The method includes the following steps: for wafers having the bumps with the same composition and different diameters, adopting a small-opening ball placing net plate to complete the placing of a small-sized solder ball first, and then switching to a large-opening ball placing net plate to complete the placing of a large-sized solder ball, and performing uniform refluxing on the whole wafers; and for the wafers having the bumps with different compositions and different diameters, adopting a small-opening ball placing net plate to complete the placing and refluxing of a small-sized solder ball first, and then switching to a large-opening ball placing net plate to complete the placing and refluxingof a large-sized solder ball. According to the scheme of the invention, the bumps with various diameters and different compositions can be prepared on the same wafer by switching the ball placing netplates, and thus the advantages of simple process, high yield and high reliability can be achieved.

Owner:BEIJING MXTRONICS CORP +1

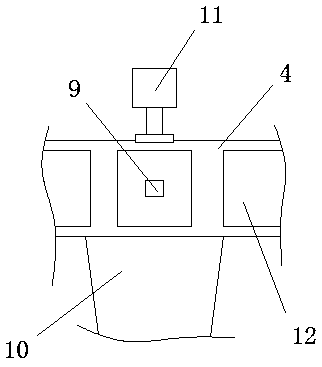

Mother and baby family bed

The invention relates to the technical field of home accessory device, and in particular, relates to a mother and baby family bed; the height of a baby bed can be adjusted to prevent an adult from accidentally touching a baby during sleep; moreover, the baby bed also can move left and right, and the baby bed can move to bedside a bed, so that the baby is convenient to care in normal time. The mother and baby family bed comprises a bed box, a bed head, a baby bed, a support plate, four groups of threaded rods, four groups of threaded tubes, a transmission chain, a first motor, and a controller;the bed head is arranged at the rear end of the bed box, the interior of the bed box is provided with a work cavity, and the top end of the bed box is provided with two groups of strip-shaped throughholes in left and right directions; the left front side, the right front side, the left rear side and the right rear side of the support plate are each provided with a placement groove; the four groups of placement grooves are each internally fixedly provided with a first ball bearing, the output end of the top of the first motor is provided with an active gear; the outer side of each of the fourgroups of threaded tubes is fixedly provided with a driven gear. The bed also comprises two groups of sliding rods, a lead screw, a second motor and second ball bearings.

Owner:林伊婧

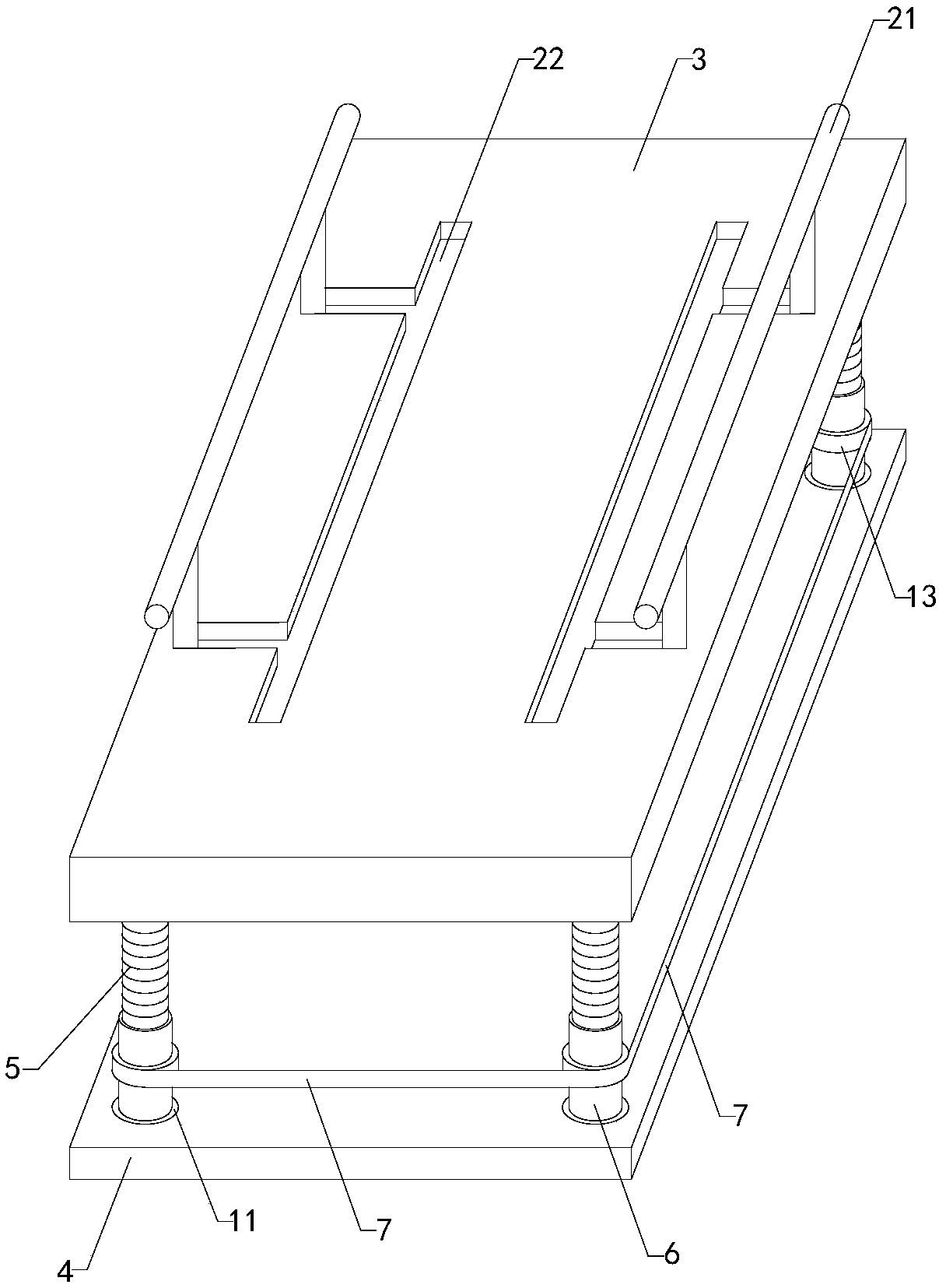

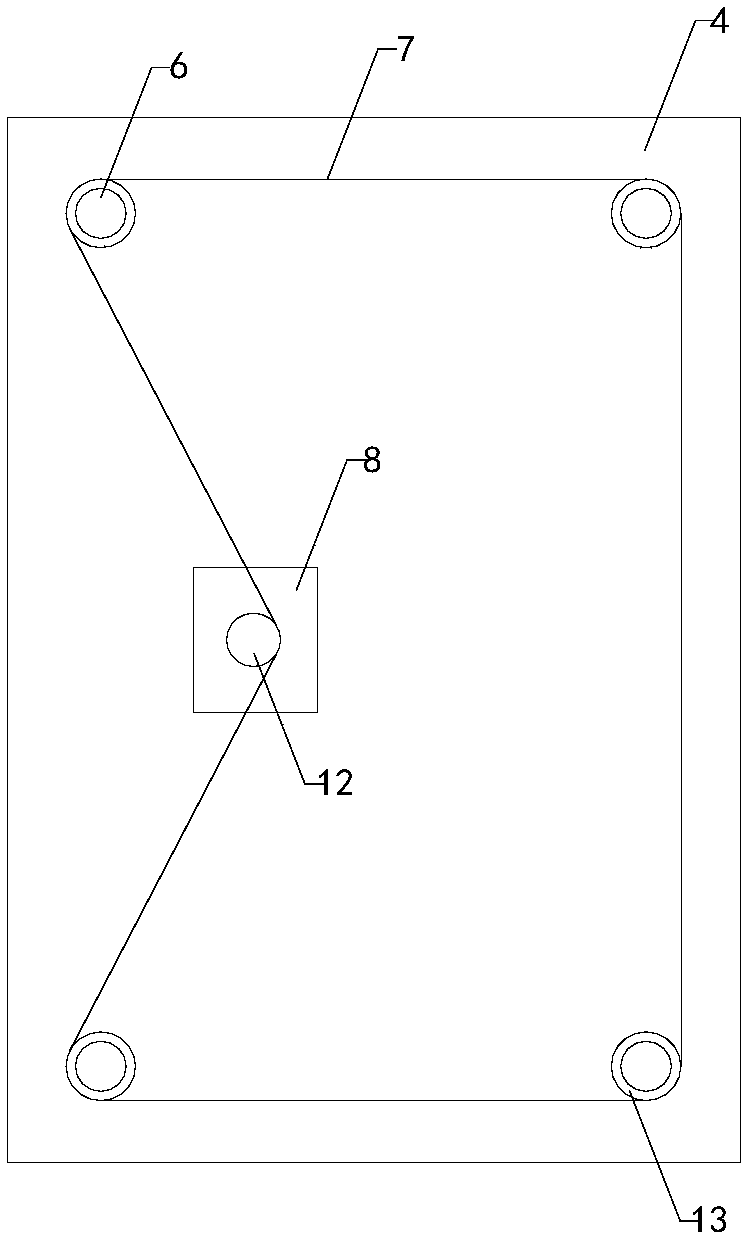

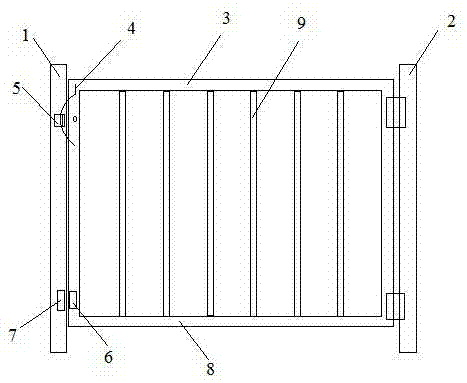

Children safety door fence

InactiveCN106854976AConvenient carePrevent bumping intoShutters/ movable grillesWing fastenersMagnetLocking plate

The child safety gate of the present invention is characterized in that it comprises a left door post, a right door post and a door rail, the right side of the door rail and the right door post are hinged together, and a rotatable crescent lock is provided on the left upper end of the door rail, and the left There is a lock hook corresponding to the crescent lock piece at the upper end of the gatepost, a magnet is provided at the lower end of the left side of the gatepost, and an iron plate corresponding to the magnet is provided at the lower part of the left gatepost, and the edge of the gatepost, the left gatepost and the right gatepost are respectively set. There are anti-collision rubber sheaths; the door rail includes a rectangular frame and several horizontal bars or vertical bars fixed in the frame. The beneficial effect of the present invention is that the structure is simple, the use is convenient, and the children are isolated in a safe area, so that the children can play at home to their heart's content, and it is more convenient for parents to take care of them. It can also isolate pets such as cats and dogs in a certain area, avoiding the cats and dogs' hair flying around and harming children.

Owner:杨欢

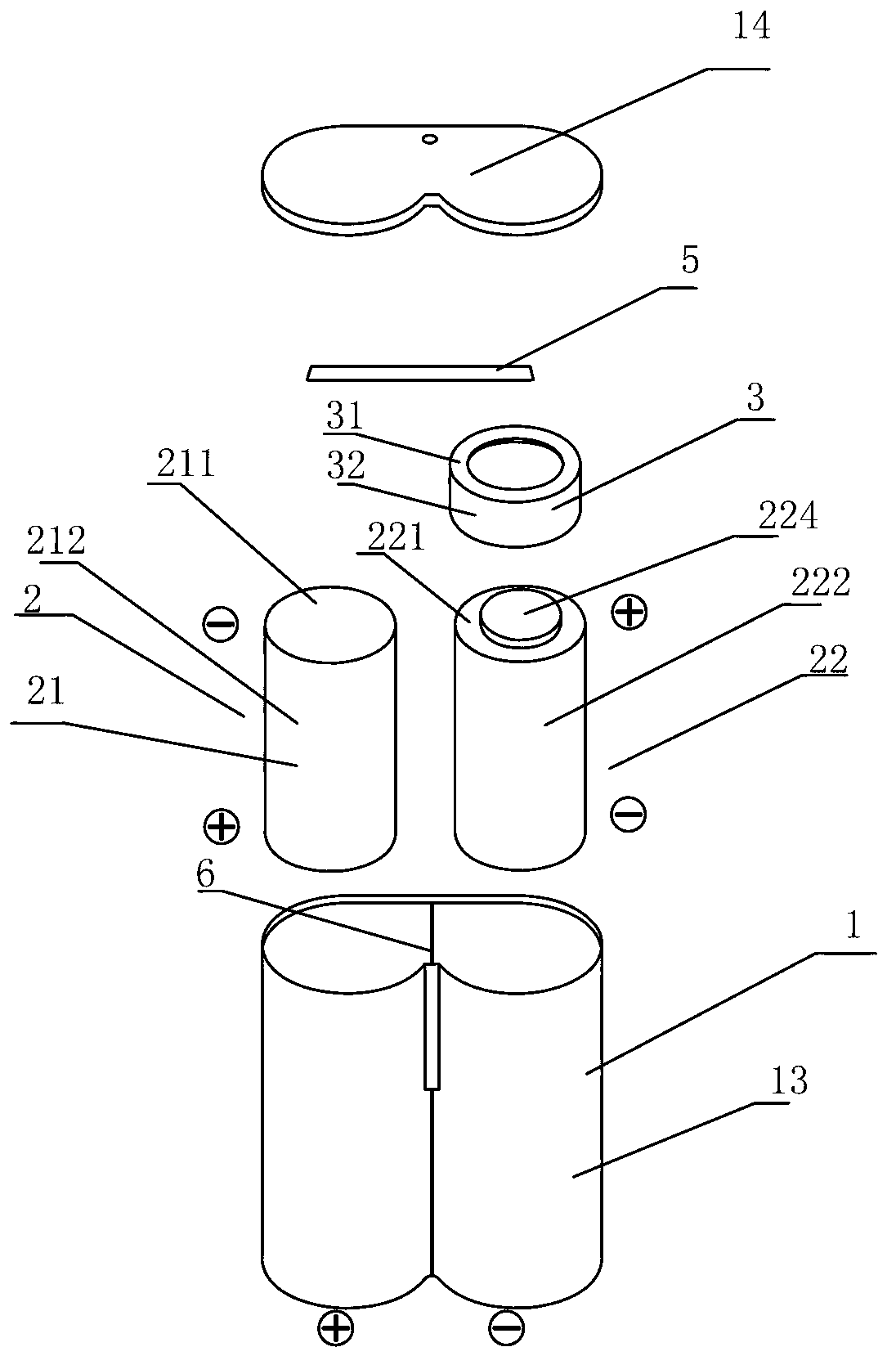

6V lithium battery

ActiveCN103137923AAvoid short circuit problemsSimple manufacturing and processingCell component detailsElectrical batteryNickel

The invention discloses a 6V lithium battery which comprises a plastic casing and two battery cells, wherein the positive pole end of the second battery cell is provided with an insulating sleeve; the insulating sleeve comprises a transverse annular part and a vertical annular part which are arranged integrally; the transverse annular part is covered on the outer annular part on the periphery of the positive pole terminal; the positive pole terminal of the second battery cell is exposed; the vertical annular part is wrapped on the side wall of the negative pole of the second battery cell adjacent to the positive pole terminal; and the negative pole terminal of the first battery cell is connected with the positive pole terminal of the second battery cell through a nickel strap. The invention has the following advantages: the negative pole side wall between the two battery cells is separated; the nickel strap has certain softness, and thus, can be deformed under certain particular conditions, so the addition of the insulating sleeve can prevent the nickel strap from colliding with the outer annular part on the periphery of the positive pole terminal of the second battery cell due to deformation; and the outer annular part on the periphery of the positive pole terminal is the negative pole body of the battery cell, thereby avoiding the problem of short circuit caused by the deformation of the nickel strap.

Owner:NINGBO GP ENERGY CO LTD

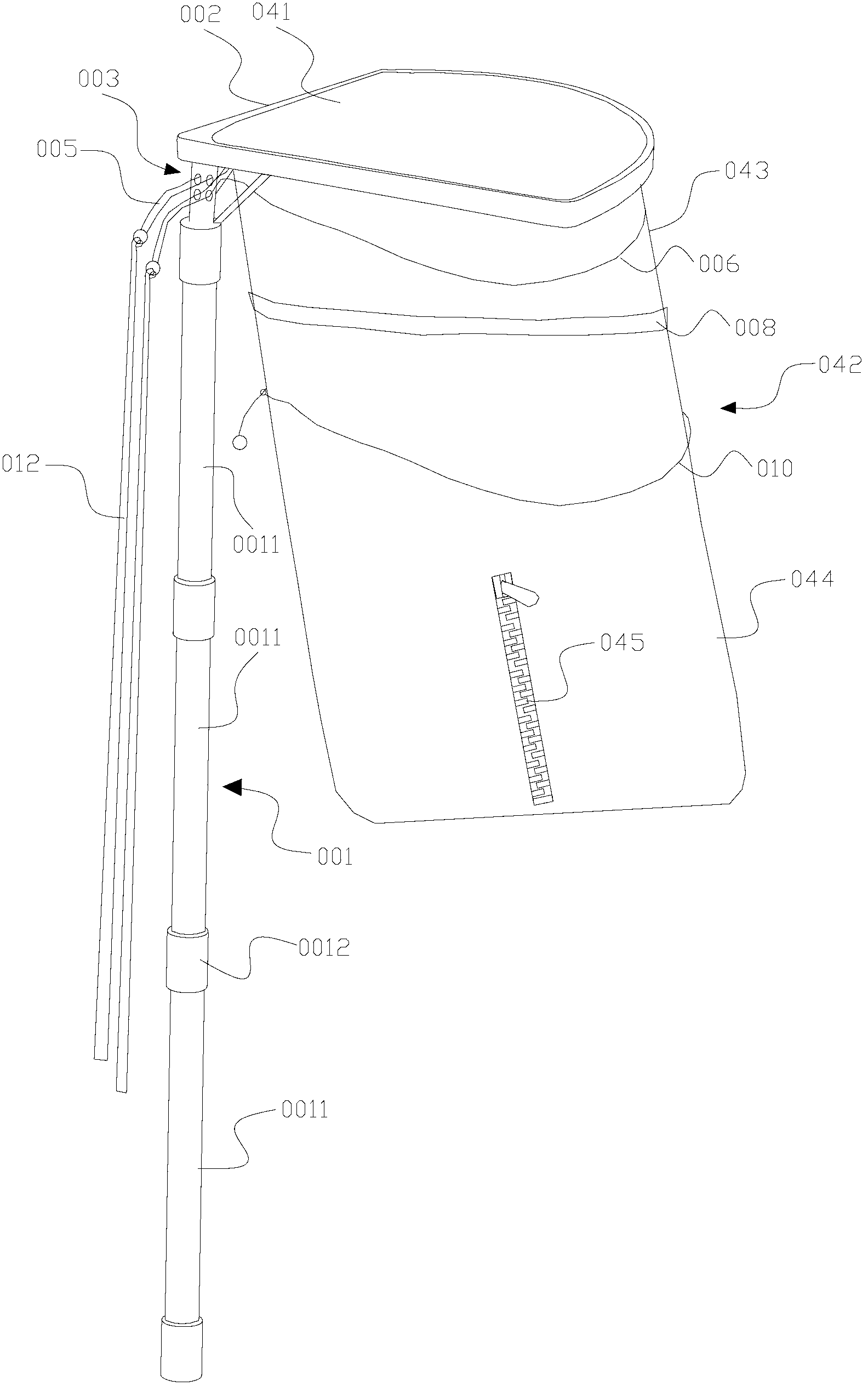

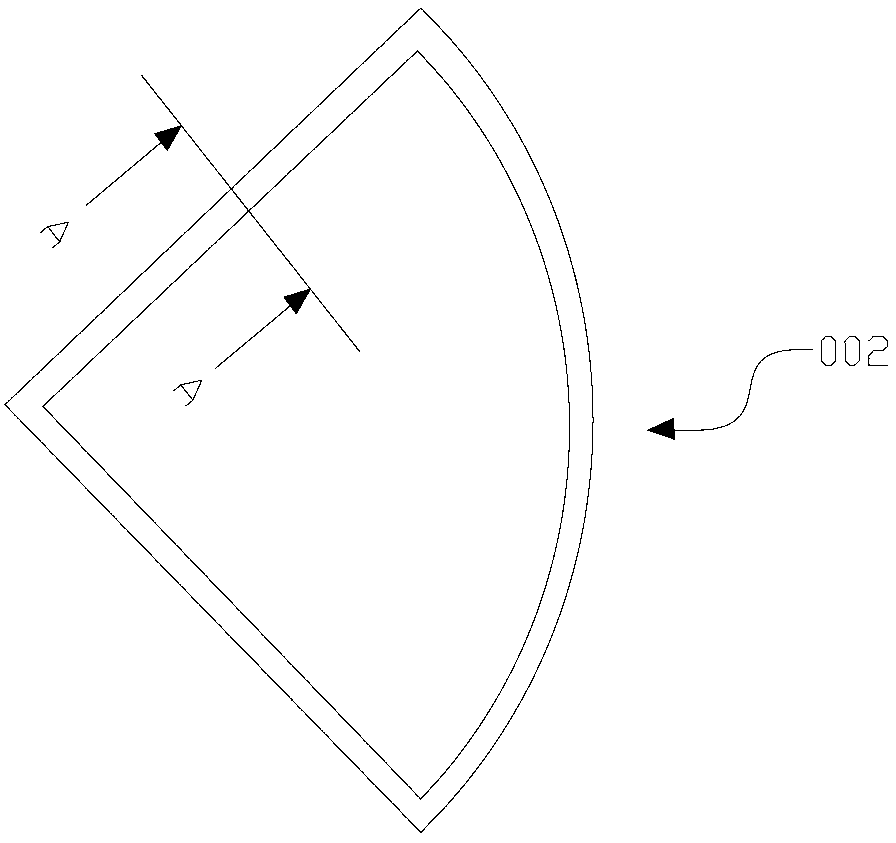

Hornet nest removing device

The invention discloses a hornet nest removing device which comprises a supporting rod, a supporting frame, a collection bag, a cutting rope and an inhaul cable. The supporting rod is connected with the bottom of the supporting frame which is of a cyclic structure, the collection bag comprises a bag mouth and a bag body, the bag mouth is arranged on the side wall of the supporting frame, the cutting rope is arranged on the inner side of the side wall of the supporting frame, two ends of the cutting rope are led out of the connecting position between the supporting rod and the supporting frame, the inhaul cable is sleeved on the outer side of the bag body, and two ends of the inhaul cable are led out of the connecting position between the supporting rod and the supporting frame. The supporting frame is lifted up through the supporting rod, the bag mouth of the collection bag is made to be flush with the top of a hornet nest, the top of the hornet nest can be smoothly cut off through rapid pulling of the cutting rope, the hornet nest falls into the bag body, and a large number of hornets can be prevented from flying out and stinging firemen. The cutting rope can be kept in a horizontal condition due to the fact that the cutting rope is arranged on the inner side of the side wall of the supporting frame, and top connecting position of the hornet nest can be cut conveniently.

Owner:张亚

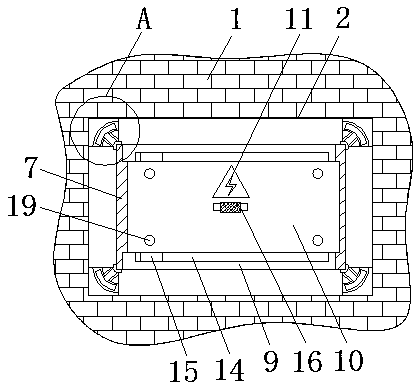

Power distribution box concealed in filler wall

InactiveCN108808500AEasy to installSolve the problem of opening the box door directlyAnti-seismic devicesEngineering

The invention discloses a power distribution box concealed in a filler wall, involving a wall body. A mounting cavity is arranged in the wall body, a mounting block is fixedly connected to each of thefour corners of the inner wall of the mounting cavity, a slide channel is arranged in each mounting block, a slider is slidably connected inside each slide channel, and one side of each slider is fixedly connected with a connection block; a distribution box body is arranged inside the mounting cavity; an anti-impact block is fixedly connected to each of the four corners of the outer surface of the distribution box body and is fixedly connected with the corresponding connection block. With the mounting cavity, the mounting blocks, the slide channels, the sliders, the connection blocks, the distribution box body, the anti-impact blocks, connection plates, a moving door, a cover plate and notches, it is convenient to mount the distribution box body; the mounting cavity can be covered; the problem that a door of a traditional distribution box is opened directly is solved; the distribution box concealed in the filler wall needs less space to open the door and is worthy of popularization.

Owner:许昌商通实业有限公司

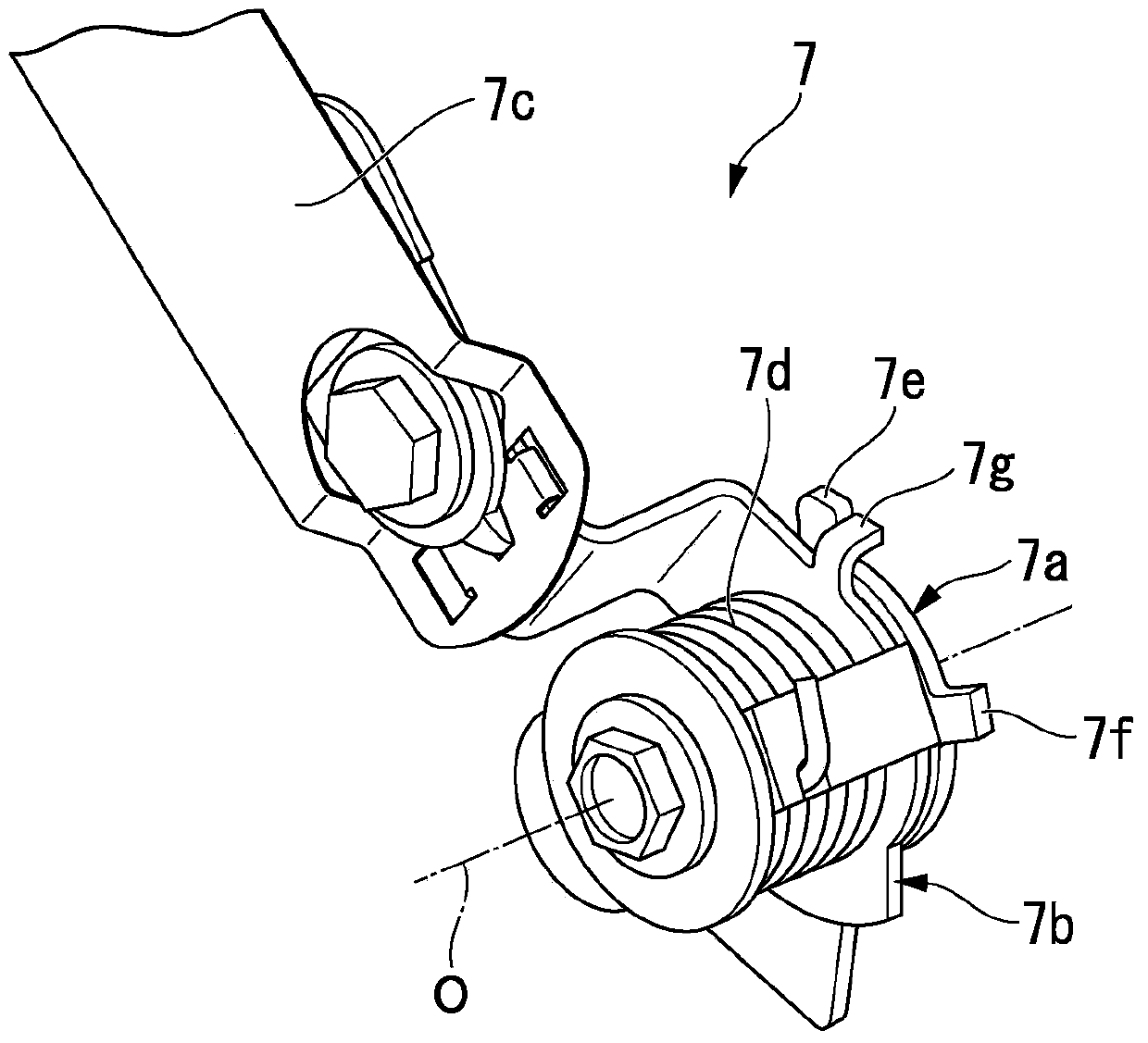

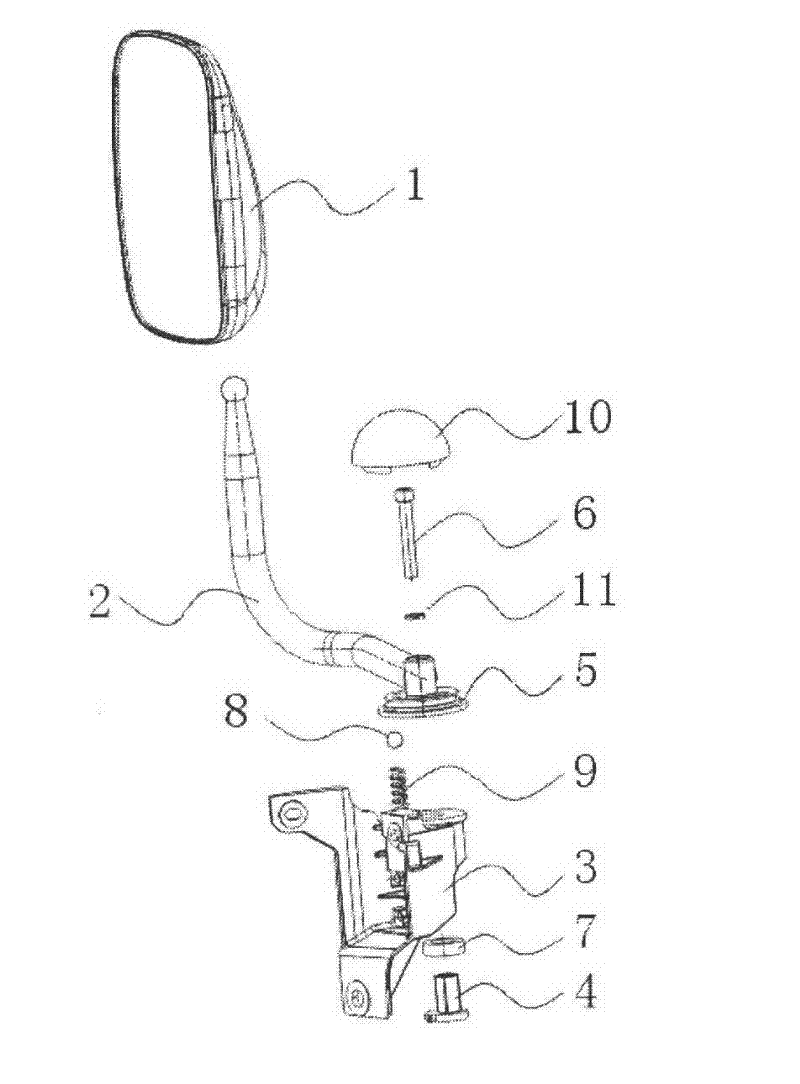

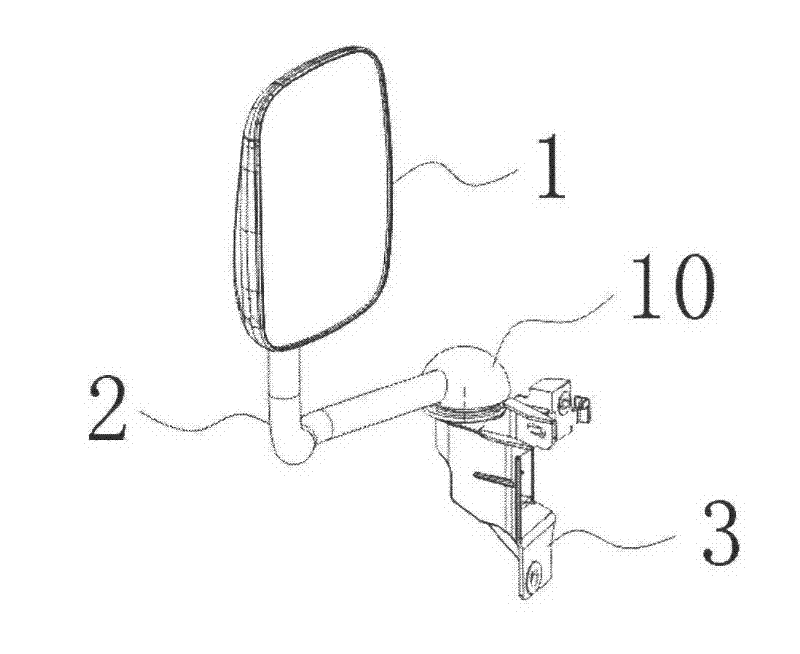

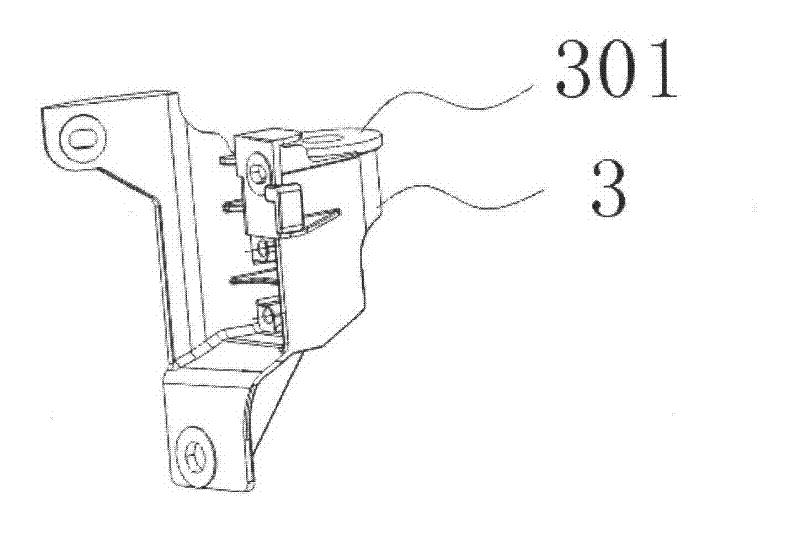

Loosening and rotating preventing device for rearview mirror of automobile

Owner:无锡市锡春汽车部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com