Wool carding equipment for wool fabric production

A technology for wool and fabrics, applied in the field of wool carding equipment for wool fabric production, which can solve the problems of slow carding speed and unclean impurities in wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

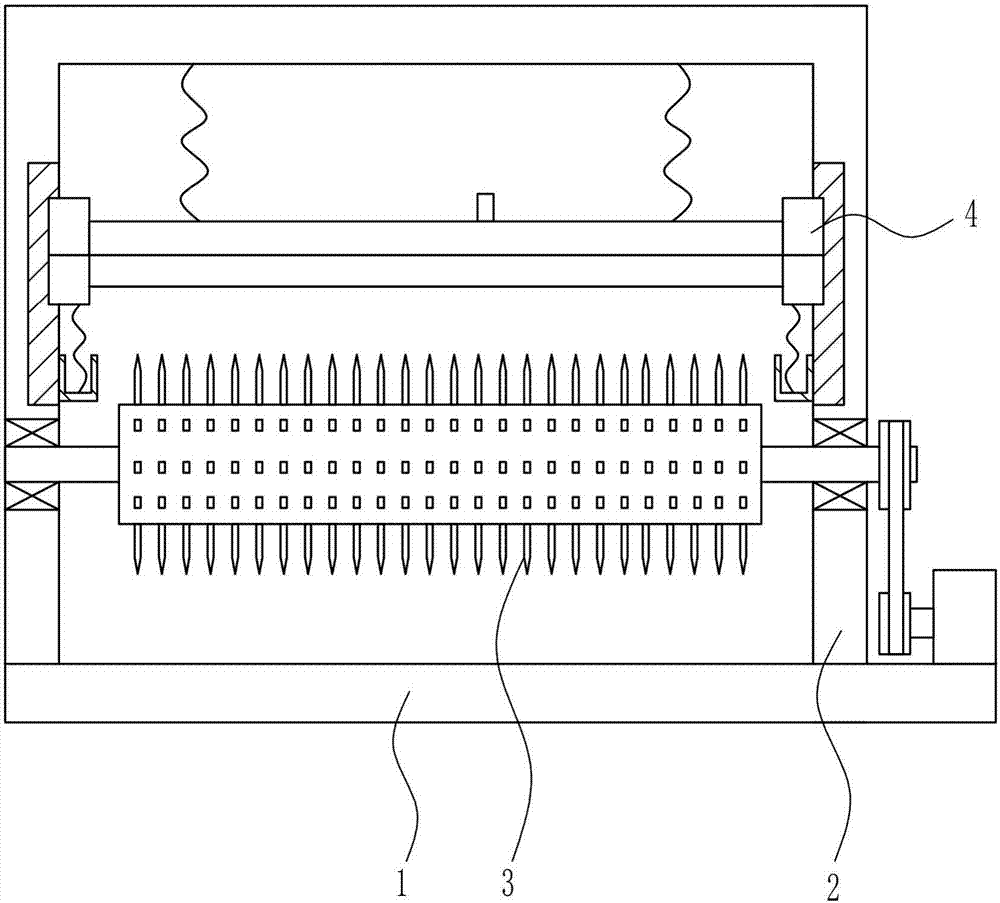

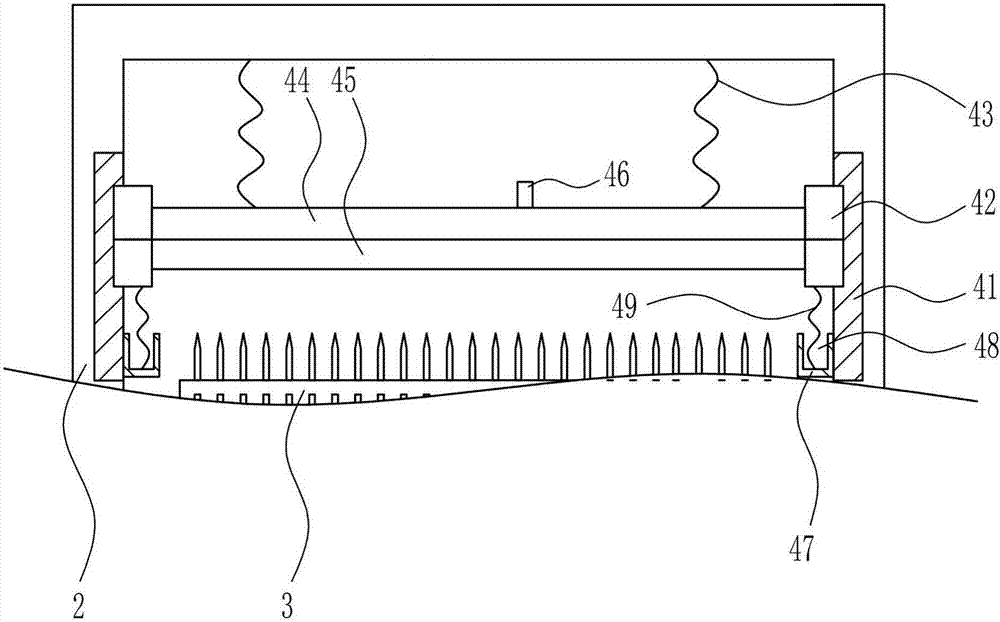

[0029] A kind of wool carding equipment for wool fabric production, such as Figure 1-5 As shown, it includes a base plate 1, a mounting frame 2, a carding device 3 and a fixing device 4, the top of the base plate 1 is provided with a mounting frame 2, the lower part of the mounting frame 2 is provided with a carding device 3, and the upper part of the mounting frame 2 is provided with a fixing device 4 .

Embodiment 2

[0031] A kind of wool carding equipment for wool fabric production, such as Figure 1-5 As shown, it includes a base plate 1, a mounting frame 2, a carding device 3 and a fixing device 4, the top of the base plate 1 is provided with a mounting frame 2, the lower part of the mounting frame 2 is provided with a carding device 3, and the upper part of the mounting frame 2 is provided with a fixing device 4 .

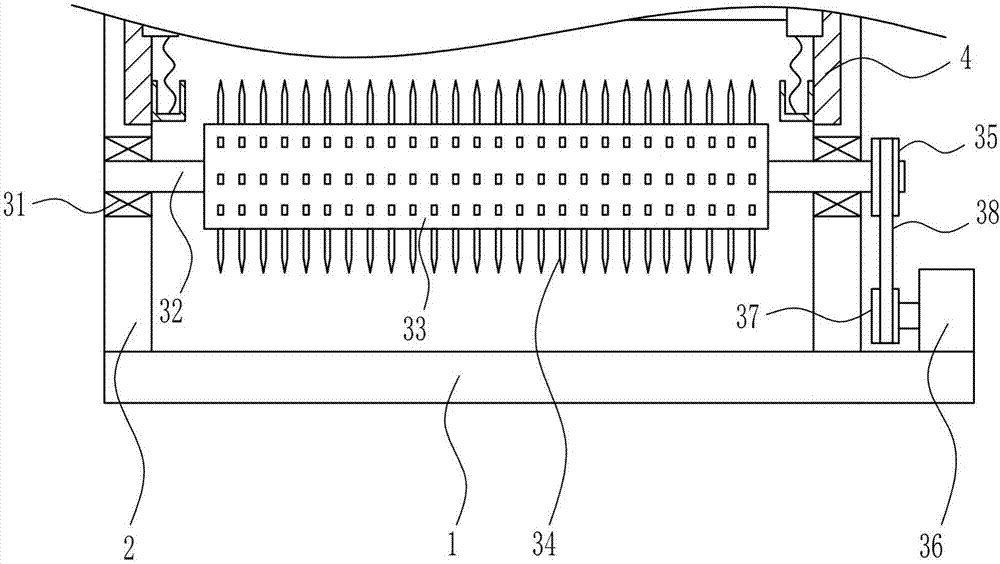

[0032] Carding device 3 includes bearing 31, rotating shaft 32, cylinder 33, comb tooth 34, large belt pulley 35, motor 36, small belt pulley 37 and flat belt 38, and mounting frame 2 left and right two wall bottoms are all provided with bearing 31, between bearing 31 Connected with rotating shaft 32, rotating shaft 32 middle part is provided with cylinder 33, and cylinder 33 is provided with comb tooth 34, and rotating shaft 32 right part is provided with big belt pulley 35, and large belt pulley 35 is on the right side of mounting frame 2, and the right side of mounting f...

Embodiment 3

[0034] A kind of wool carding equipment for wool fabric production, such as Figure 1-5 As shown, it includes a bottom plate 1, a mounting frame 2, a carding device 3 and a fixing device 4. The top of the bottom plate 1 is provided with a mounting frame 2, the lower part of the mounting frame 2 is provided with a carding device 3, and the upper part of the mounting frame 2 is provided with a fixing device 4. .

[0035]Carding device 3 includes bearing 31, rotating shaft 32, cylinder 33, comb tooth 34, large belt pulley 35, motor 36, small belt pulley 37 and flat belt 38, and mounting frame 2 left and right two wall bottoms are all provided with bearing 31, between bearing 31 Connected with rotating shaft 32, rotating shaft 32 middle part is provided with cylinder 33, and cylinder 33 is provided with comb tooth 34, and rotating shaft 32 right part is provided with big belt pulley 35, and large belt pulley 35 is on the right side of mounting frame 2, and the right side of mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com