Food processor safe to use

A food processing machine and safety technology, which is applied in applications, home appliances, kitchen appliances, etc., can solve the problems of occupying space and inconvenient use, increasing the number of food processing machine products, and increasing the load of the motor, so as to achieve a simple structure and ensure stable operation performance and safety, ease of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

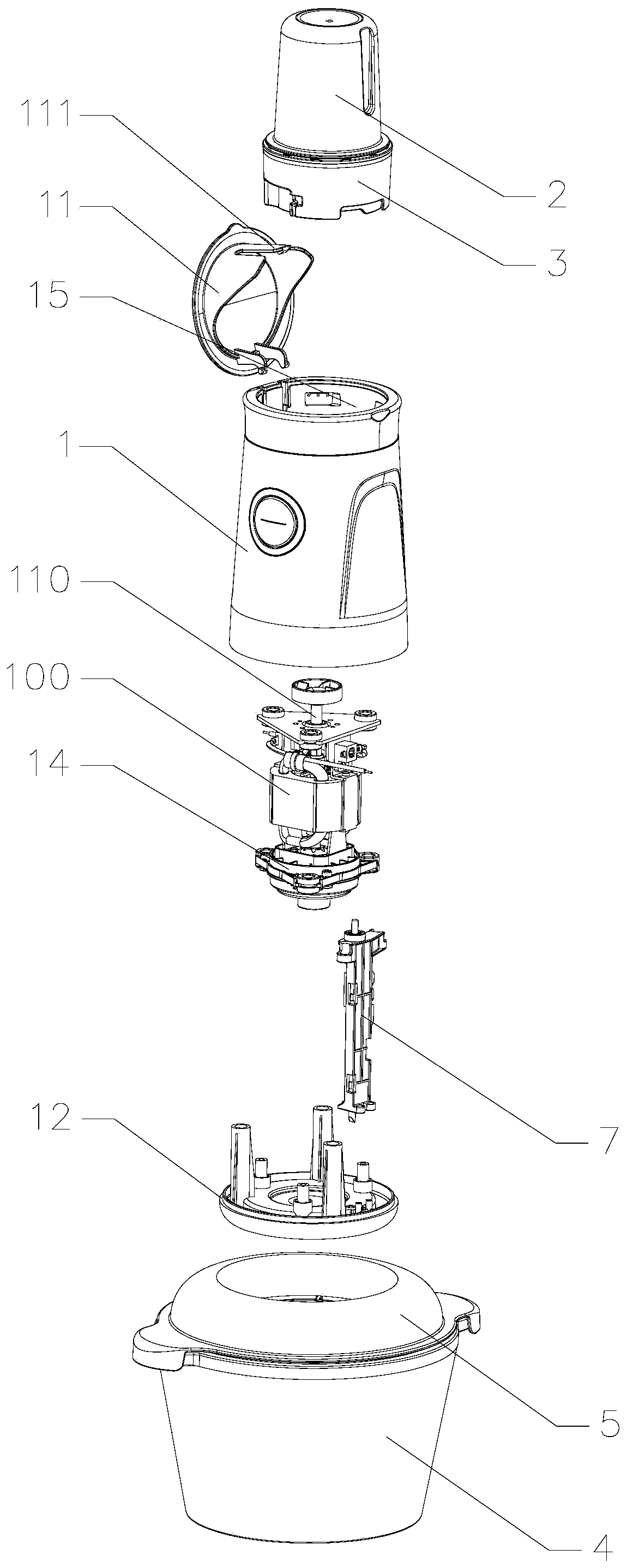

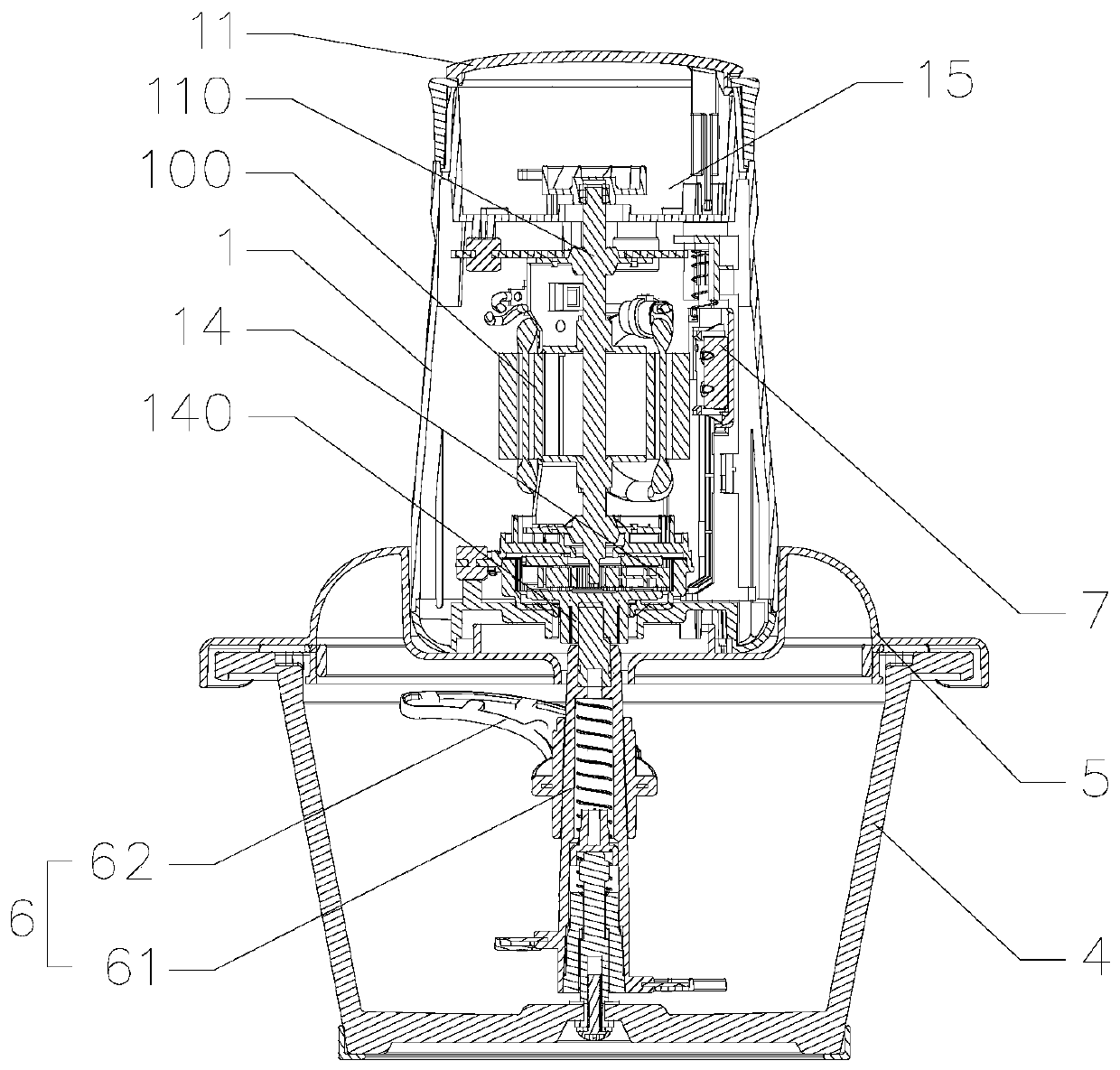

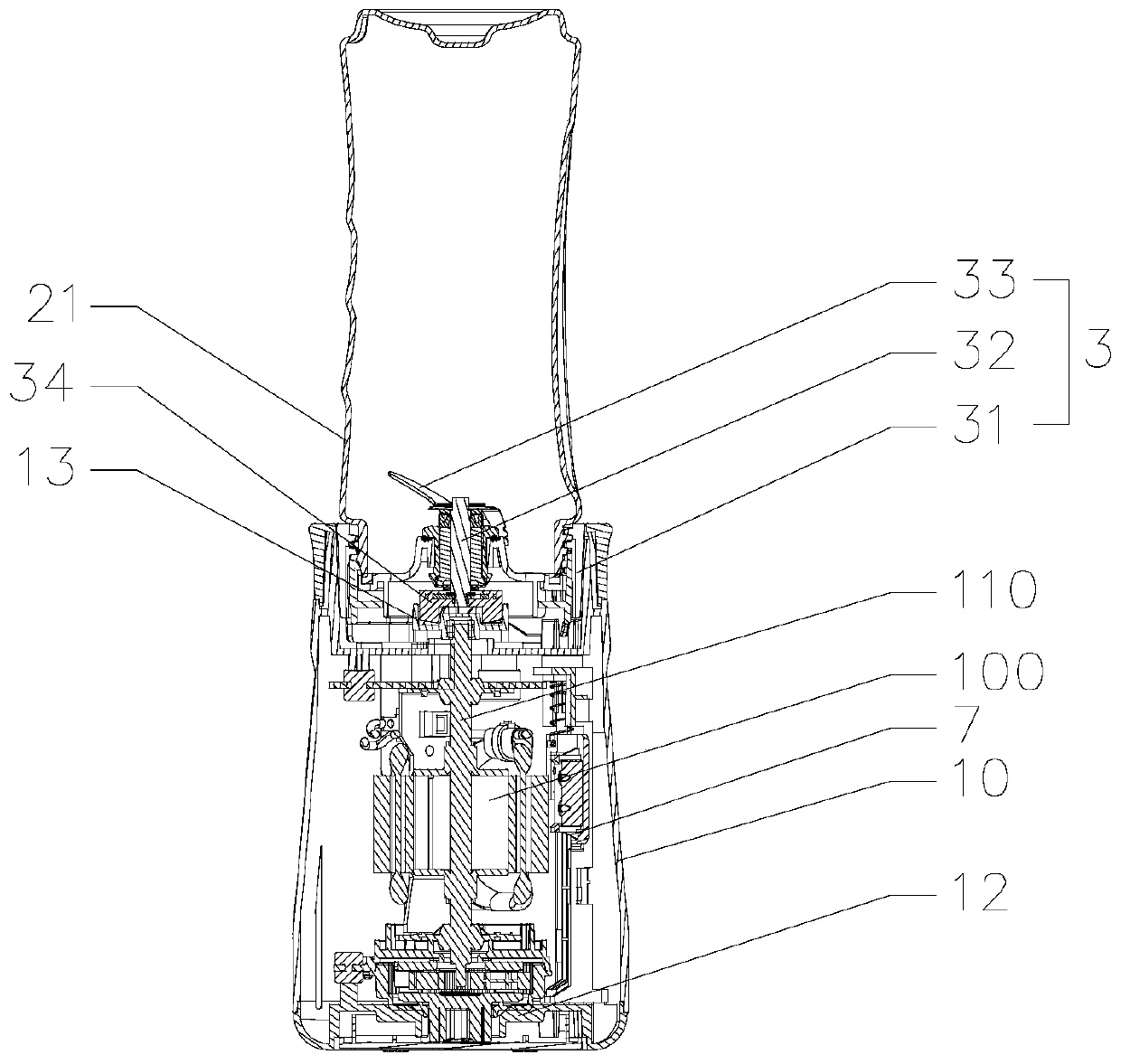

[0047] As a first embodiment of a safe food processing machine of the present application, such as Figures 1 to 10 As shown, it includes machine base 1, the first stirring cup connected to the bottom of the machine base and the second stirring cup connected to the top of the machine base. The first stirring cup and the second stirring cup can be set as different stirring components according to the functional requirements. Wherein the first mixing cup is provided with a first crushing knife, and the second stirring cup is provided with a second crushing knife, which may have different names according to different functions, for example, the first stirring cup in this embodiment includes a meat grinder cup 4. The meat grinder cup cover 5 and the meat grinder assembly 6. The second mixing cup 2 includes a second cup body 21 and a crushing knife assembly 3 . Frame 1 comprises shell 10, bottom cover 12 and motor 100, shell 10 bottom opening, motor 100 is installed in the shell 1...

Embodiment 2

[0065] As a second embodiment of a safe food processing machine of the present application, such as Figure 11-17 As shown, the main difference from the first embodiment is that the safety bottom cover is horizontally rotatable and arranged under the first transmission joint.

[0066] Such as Figure 11-17 As shown, the food processor includes a machine base, a first stirring cup connected to the bottom of the machine base, and a second stirring cup connected to the top of the machine base. The bottom of the machine base is movable with a safety bottom cover 8 that can cover the first transmission joint. The safety bottom cover 8 is movably arranged on the bottom of the machine base 1 for opening and closing the first transmission joint and triggering the safety. switch assembly7. The first stirring cup includes a meat grinder cup 4 , a meat grinder cup cover 5 and a meat grinder assembly 6 . The second mixing cup 2 includes a second cup body 21 and a pulverizer assembly 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com