Large-scale high-temperature test equipment applied to reliability test of solid-state disk

A technology of test equipment and solid-state hard disk, which is applied in the direction of temperature control, static memory, and instruments using electric methods, which can solve the problems of test board charging, test board loss, heat loss, etc., and achieve high precision, accurate temperature control, and prevent The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

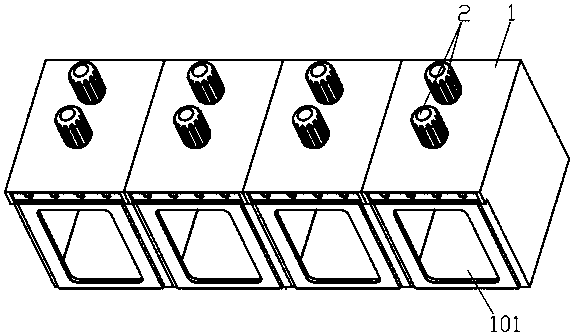

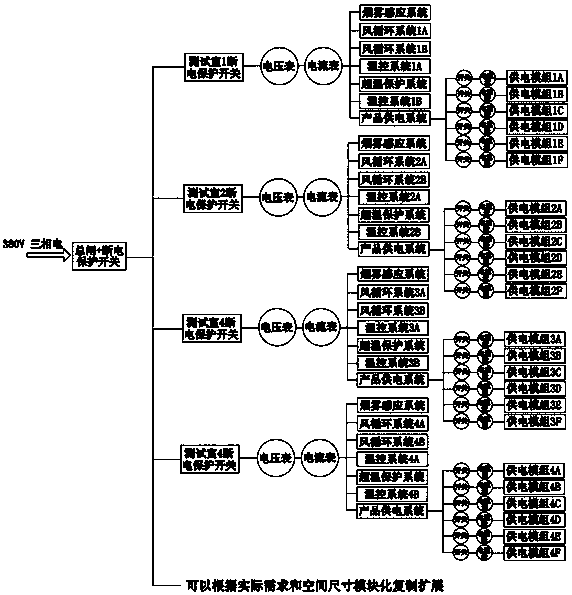

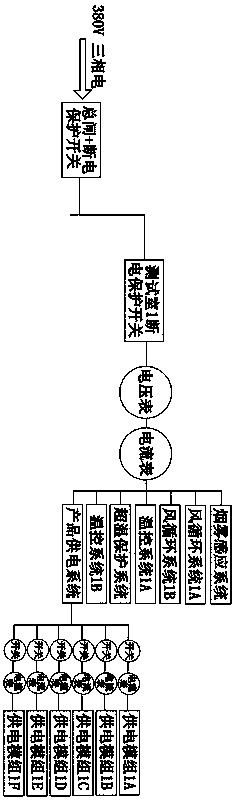

[0053] Please refer to the attached Figure 1-12 , a kind of large-scale high-temperature test equipment applied to the reliability test of solid-state hard disk of the present invention, this large-scale high-temperature test equipment comprises equipment casing 1, and described equipment casing 1 is provided with a plurality of independent burn-in chambers 101, in each equipment casing 1 The shell is equipped with air circulation system, temperature control system, over-temperature protection system and product power supply system;

[0054] A heat insulating layer 113 is arranged in the shell of the device, and an air channel plate 109 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com