Ion beam deposition equipment for infrared metal film and film deposition method

An ion beam deposition, metal film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of difficult control, difficult to prepare large-area thin films, long time to establish vacuum, etc., to improve adhesion. Focus, good deposition uniformity, improve the effect of deposition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

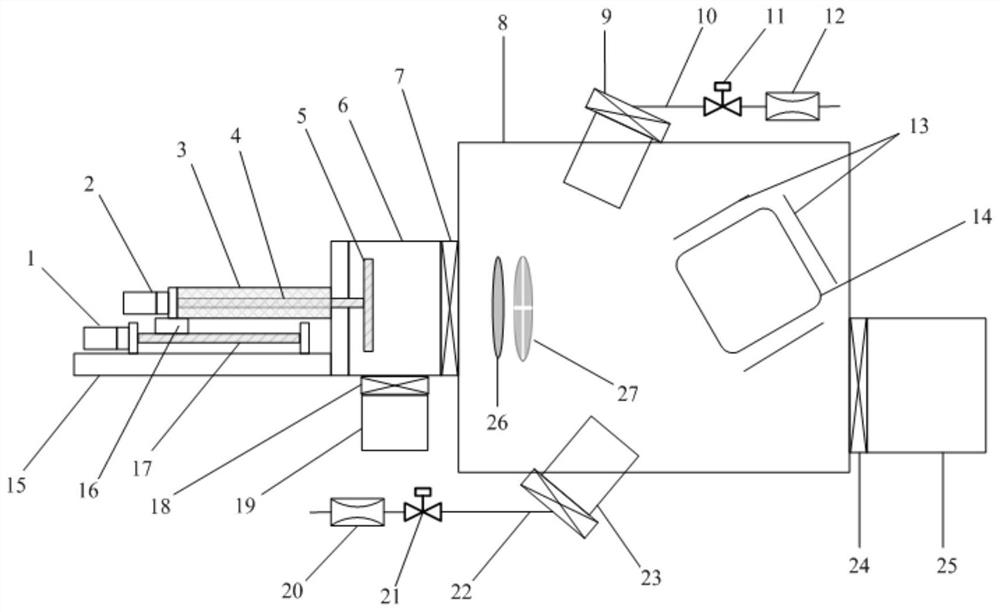

[0044] Such as figure 1 As shown, the ion beam deposition equipment for infrared metal film in this embodiment includes a loading and unloading chamber 6 and a sputtering chamber 8, and a first high vacuum is provided between the loading and unloading chamber 6 and the sputtering chamber 8 Isolation valve 7; Loading and unloading sheet chamber 6 is provided with vacuum sealing door 15, is penetrated with push rod 4 in the vacuum seal door 15, and one end of push rod 4 is provided with workpiece table 5 at the inner side of vacuum seal door 15; There is a propulsion mechanism for pushing the propulsion rod 4; the loading and unloading chamber 6 is connected with a first vacuum device 19. In the present invention, a loading and unloading film chamber 6 is provided on the door side of the sputtering chamber 8. During the film loading process, the first high vacuum isolation valve 7 is closed first to keep the vacuum environment of the sputtering chamber 8 unchanged. , then open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com