Triangular cross section drop optical cable and manufacturing method thereof

A technology for introducing optical cables and triangles, which is applied in the field of introducing optical cables with triangular cross-sections and its manufacturing, can solve problems such as affecting the appearance of the interior and complicated construction processes, and achieve the effects of reducing the trouble of later maintenance, improving the aesthetics, and reducing the unit weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

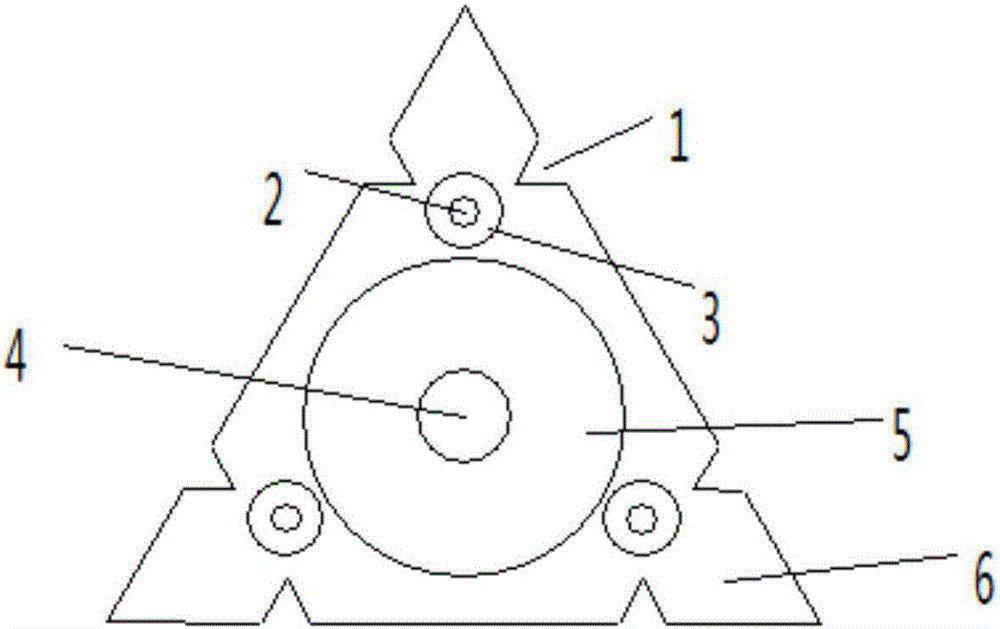

[0038] This embodiment is a kind of triangular section lead-in optical cable, such as figure 1 As shown in the schematic diagram of the triangular cross-section lead-in optical cable, the optical fiber 2 is covered with a tight sheath 3 to form an optical fiber unit. The circular cross-section central reinforcement 4 concentrically wraps the circular cross-section central reinforcement cushion 5 to form a reinforcement assembly. The outer sheath 6 with an equilateral triangle in section covers 3 optical fiber units and 1 strengthening component, wherein the central strengthening member 4 of the strengthening component is placed at the midpoint of the equilateral triangle, and the 3 optical fiber units are placed on the central strengthening member pad Layer 5 is respectively placed on the three midlines of the equilateral triangle, and on the midline s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com