Industrial byproduct gypsum waste rubber particle wall body material and preparation method thereof

A technology for industrial by-products of gypsum and wall materials, applied in the field of building materials, can solve problems such as poor thermal insulation performance and high apparent density, and achieve the effects of solving processing problems, improving impact resistance, and achieving significant social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

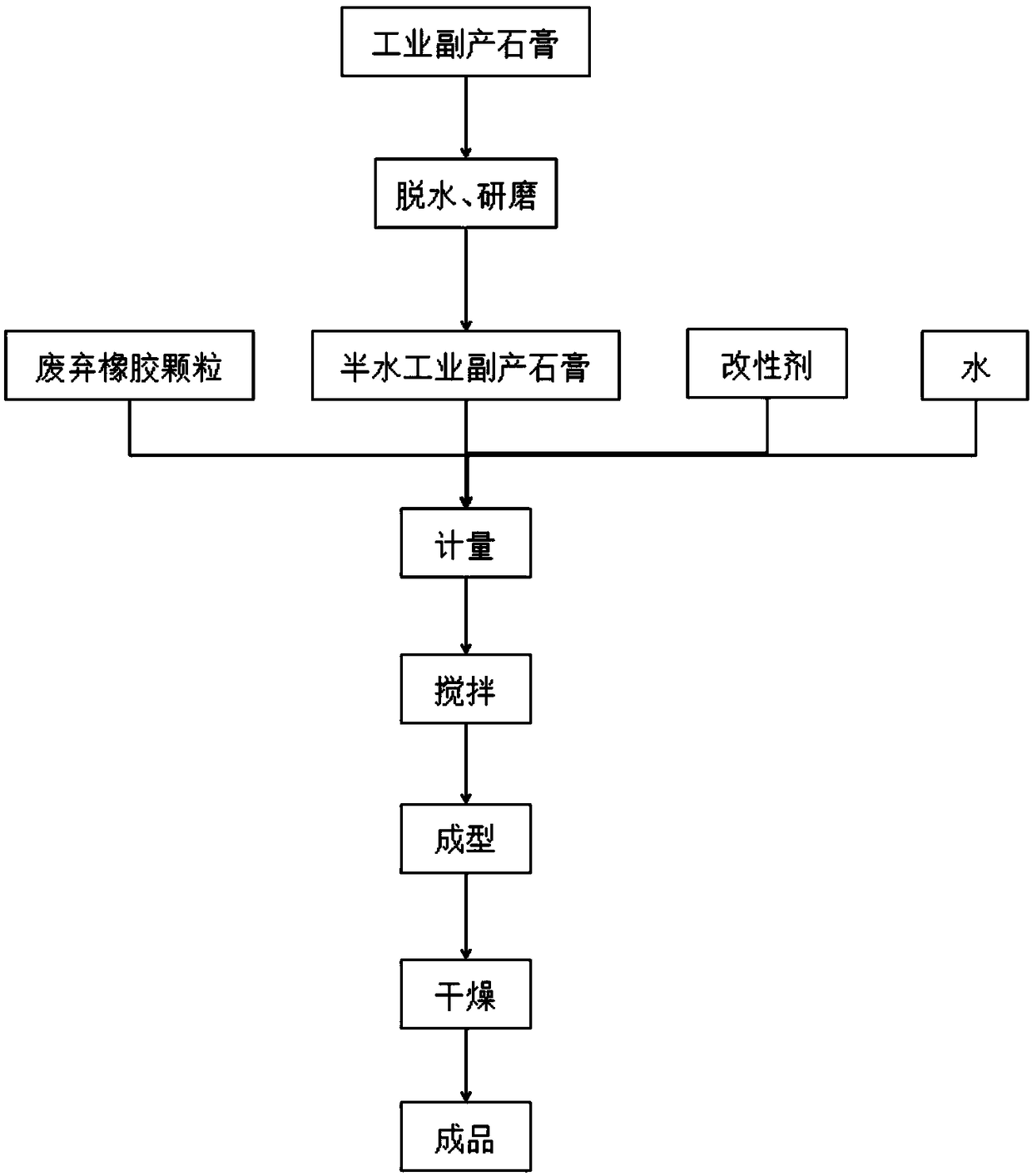

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The industrial by-product gypsum waste rubber particle wall material of this embodiment is made of the following raw materials in weight percentage: 50% of phosphogypsum hemihydrate, 8% of waste rubber particles, 2% of modifier, and 40% of water. Waste rubber particles are particles processed from waste tires, and the maximum particle size is less than 0.18mm. The modifying agent is composed of the following medicaments in weight ratio, a mixture of 0.75% polycarboxylate high-performance water reducer, 1% hydroxypropyl methylcellulose and 0.25% hydroxycarboxylic acid retarder.

[0023] The preparation method of the industrial by-product gypsum waste rubber particle wall material of the present embodiment is:

[0024] (1) First, heat phosphogypsum in a dry environment at 140°C for 8 hours to dehydrate it into hemihydrate phosphogypsum, and grind the hemihydrate phosphogypsum into a powder with a particle size of 0.074-0.1mm; wherein the phosphogypsum is sul...

Embodiment 2

[0027] Embodiment 2: The industrial by-product gypsum waste rubber particle wall material of this embodiment is made of the following raw materials in weight percentage: 52% desulfurized gypsum hemihydrate, 12% waste rubber particles, 3% modifier, and 35% water. Waste rubber particles are particles processed from waste tires, and the maximum particle size is less than 0.18mm. The modifying agent is a mixture of 1.25% polycarboxylate high-performance water reducer, 1.5% hydroxypropyl methylcellulose and 0.25% hydroxycarboxylic acid retarder.

[0028] The preparation method of the industrial by-product gypsum waste rubber particle wall material in this embodiment, the specific steps are as follows:

[0029] (1) Heating the desulfurized gypsum in a dry environment at 142°C for 7 hours to dehydrate it into semi-hydrated desulfurized gypsum, and grind it into a powder with a particle size of 0.074-0.109 mm; the desulfurized gypsum is gypsum produced by power plant exhaust;

[0030...

Embodiment 3

[0032] Embodiment 3: The industrial by-product gypsum waste rubber particle wall material in this embodiment is made of the following raw materials in weight percentage: 55% hemihydrate fluorogypsum, 3% waste rubber particles, 5% modifier, and 37% water. Waste rubber particles are particles processed from waste tires, and the maximum particle size is less than 0.18mm. The modifying agent is composed of the following agents in weight ratio, a mixture of 1.5% polycarboxylate high-performance water reducer, 2.25% hydroxypropyl methylcellulose and 1.25% hydroxycarboxylic acid retarder.

[0033] The preparation method of the industrial by-product gypsum waste rubber particle wall material of the present embodiment is:

[0034] (1) First, heat the fluorogypsum in a dry environment at 145°C for 6 hours to dehydrate it into hemihydrate fluorogypsum, and grind the hemihydrate fluorogypsum into a powder with a particle size of 0.074-0.100mm;

[0035] (2) 55% of the following mass perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com