Sesaron combing and sorting method and device

A hemp fiber and combing technology, which is applied to fiber processing safety devices, fiber processing, combing machines, etc., can solve the problems of low fiber utilization rate, poor yarn quality, and high production costs, and achieves improved fiber spinning performance. The effect of improving the splitting degree of hemp fiber and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

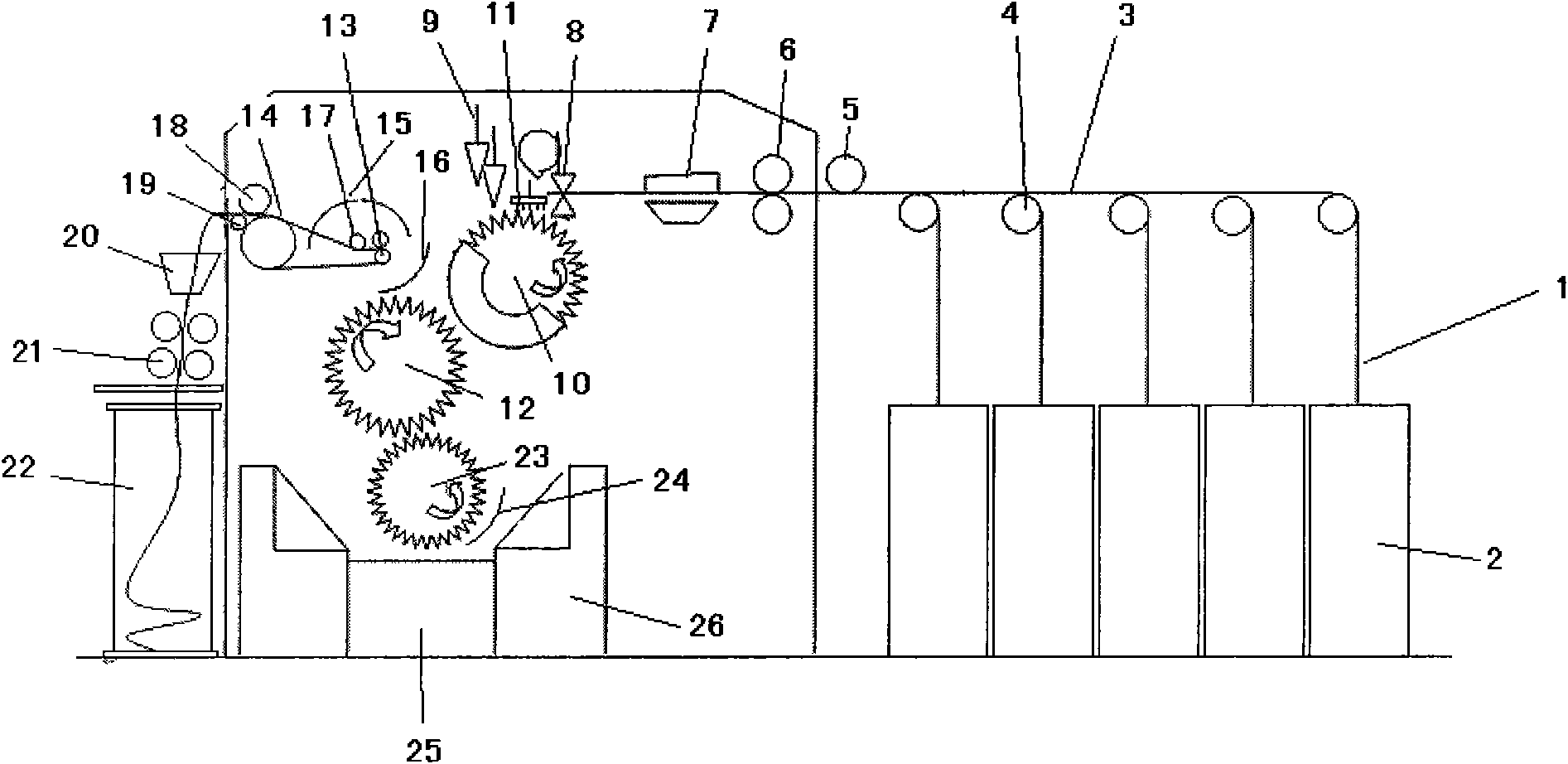

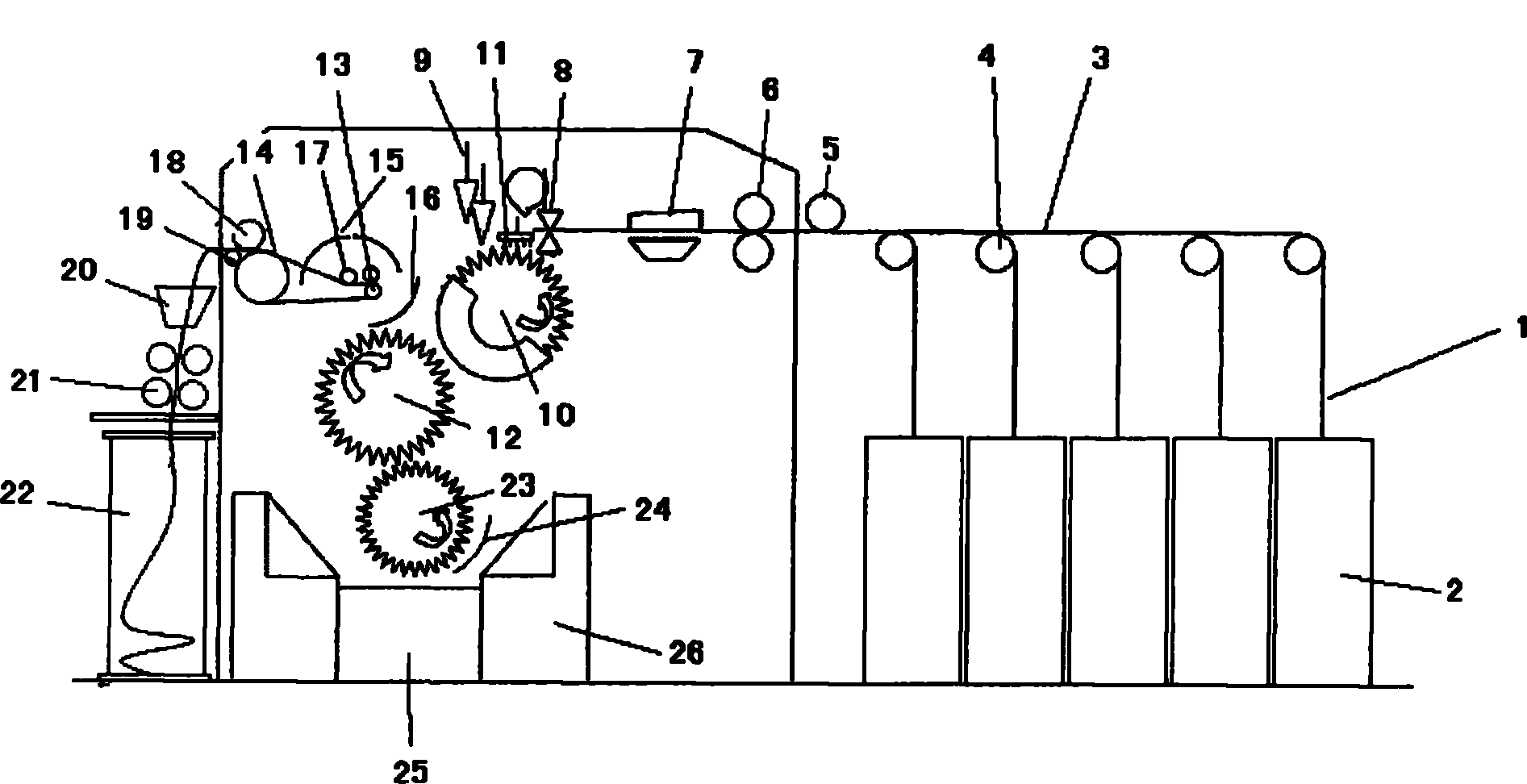

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] Such as figure 1 As shown, the combing and sorting device of the present invention has a similar structure with the existing combing machine, and also includes a feeding mechanism, a nipper mechanism, a carding mechanism, a pulling and separating mechanism, a sliver delivery mechanism, and a cleaning mechanism. At present, the combing machine is a front-swing, intermittent straight-type combing machine. The main working characteristics are: the carding is carried out intermittently and periodically, the position of the nipper mechanism and the carding mechanism does not move, and the pulling car swings back and forth to complete Segmented and directional combing of fibers to remove grains and weeds.

[0026] The feeding mechanism comprises a feeding frame 1, and the lower part of the feeding frame 1 is provided with a plurality of hemp sliver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com