Long-fiber enhanced thermoplastic composite material vane used for wind energy generator

A technology of reinforced thermoplastic and composite materials, applied in wind power generation, wind turbine components, wind engines, etc., can solve the problems of fiber-reinforced nylon blades with large specific gravity, reduced blade processing cost, low specific gravity and impact resistance, and achieve dimensional stability , low cost, corrosion resistance to chemical solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

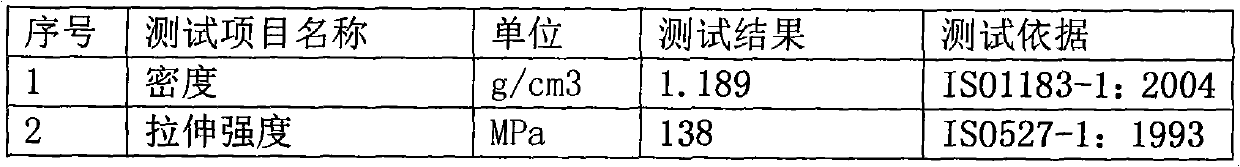

[0019] A long glass fiber reinforced polypropylene composite material blade for a small wind energy generator, consisting of 37wt% glass fiber, 55wt% polypropylene, 3wt% maleic anhydride branched polypropylene, 2wt% ethylene-propylene copolymer (POE), and 0.5wt% of grinding lubricant, 1wt% of antioxidant, 0.5wt% of ultraviolet absorber and 1wt% of toner or color masterbatch are uniformly mixed in proportion to form a long glass fiber reinforced polypropylene composite material, which is heated and injected into the mold by an injection molding machine Rapid cooling and detachment are formed, and the experimental test results of the blade material are as follows:

[0020] Table 1. Experimental test results

[0021]

[0022]

Embodiment 2

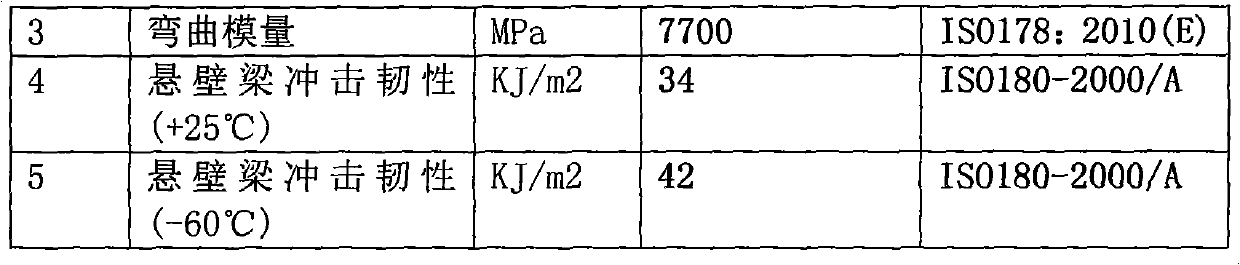

[0024] A long glass fiber reinforced polypropylene composite material blade for a small wind energy generator, consisting of 40wt% glass fiber, 54wt% polyurethane elastomer, 3wt% ethylene-propylene copolymer (POE), 0.5wt% wear-resistant lubricant, anti-oxidant 1wt% UV absorber, 0.5wt% UV absorber and 1wt% toner (color masterbatch) are uniformly mixed in proportion to form a long glass fiber reinforced polypropylene composite material, which is heated and injected into the mold by an injection molding machine, and then quickly cooled and detached. The experimental test results of the blade material are as follows:

[0025] Table 2 Experimental test results

[0026]

Embodiment 3

[0028] A long glass fiber reinforced polypropylene composite material blade of a small wind energy generator, consisting of 40wt% of glass fiber, 52wt% of ASA (copolymer), 3wt% of maleic anhydride branched polypropylene, and 2wt% of ethylene-propylene copolymer (POE) %, 0.5wt% of wear-resistant lubricant, 1wt% of antioxidant, 0.5wt% of anti-ultraviolet absorber and 1wt% of toner or color masterbatch are evenly mixed in proportion to form a long glass fiber reinforced polypropylene composite material, which is passed through an injection molding machine After heating and pouring into the mold, it is quickly cooled and separated to form it. The experimental test results of the blade material are as follows:

[0029] Table 3 Experimental test results

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com